Solar rear panel and production method for same

A technology of solar cells and production methods, applied in the field of solar cells, can solve problems such as accelerated degradation behavior, reduced backplane insulation, water vapor barrier and mechanical properties, and water vapor barrier performance decline, achieving good insulation performance and damp heat aging resistance, Good anti-aging performance and chemical stability, the effect of reducing the risk of component failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 100 parts by mass of linear low density polyethylene resin, 1 part by mass of triallyl isocyanurate, 0.2 parts by mass of antioxidant 1010, and 0.2 parts by mass of hindered amine 622 are mixed uniformly in a high-speed kneader, and then Extruded and stretched into a film of 250 μm through a twin-screw extruder. Then carry out cross-linking by electron beam irradiation at a speed of 20 m / min, and the irradiation dose is 10 Mrad to form a cross-linked polyethylene film.

[0050] A 25 μm Tedlar film was laminated on both sides of the cross-linked polyethylene film through a dry lamination process. The adhesive used was a two-component polyurethane glue, and the thickness of the adhesive layer was about 10 μm per layer to obtain a solar cell backsheet.

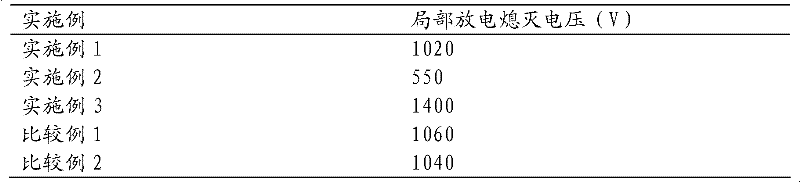

[0051] The partial discharge test was carried out on the prepared solar cell backsheet, and the results are shown in Table 1.

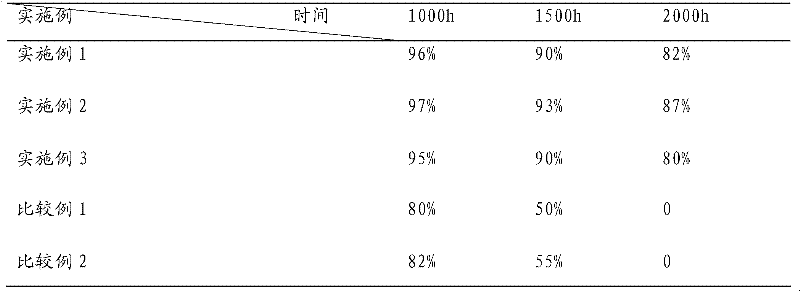

[0052] The prepared solar cell backboard is exposed to ultraviolet radiation for 2000 hours, ...

Embodiment 2

[0055] 100 parts by mass of EPDM rubber, 0.1 parts by mass of triallyl isocyanurate, 0.1 parts by mass of antioxidant 1076, and 0.4 parts by mass of hindered amine 123 were mixed uniformly in a high-speed kneader, and then double A screw extruder extruded and stretched into a 100 μm film. Then electron beam irradiation cross-linking is carried out at a speed of 20 m / min, and the irradiation dose is 20 Mrad to form a cross-linked EPDM film.

[0056] On both sides of the cross-linked EPDM rubber film, a 25 μm PVDF film is laminated by a dry composite process. The adhesive used is a two-component polyurethane glue, and the thickness of the adhesive layer is about 10 μm per layer to obtain a solar battery backplane. .

[0057] The partial discharge test was carried out on the prepared solar cell backsheet, and the results are shown in Table 1.

[0058] The prepared solar cell backboard is exposed to ultraviolet radiation for 2000 hours, the breaking strength retention rate of th...

Embodiment 3

[0061] 100 parts by mass of EPDM rubber and 0.5 parts by mass of hindered amine 123 were uniformly mixed in a high-speed kneader, and then extruded through a twin-screw extruder to form a film of 400 μm. Then electron beam irradiation cross-linking is carried out at a speed of 20 m / min, and the irradiation dose is 30 Mrad to form a cross-linked EPDM film.

[0062]On both sides of the cross-linked EPDM rubber film, a 25 μm PVDF film is laminated by a dry composite process. The adhesive used is a two-component polyurethane glue, and the thickness of the adhesive layer is about 10 μm per layer to obtain a solar battery backplane. .

[0063] The partial discharge test was carried out on the prepared solar cell backsheet, and the results are shown in Table 1.

[0064] The prepared solar cell backboard is exposed to ultraviolet radiation for 2000 hours, the breaking strength retention rate of the backboard is greater than 70%, and the materials of each layer of the backboard are no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com