Patents

Literature

31results about How to "Not prone to degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

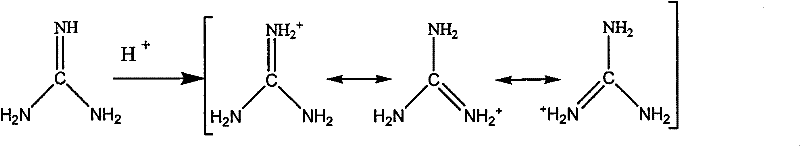

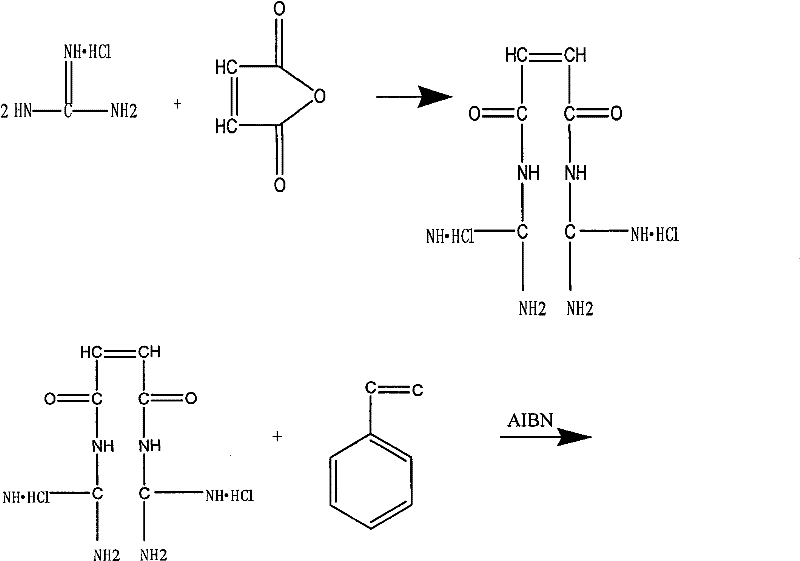

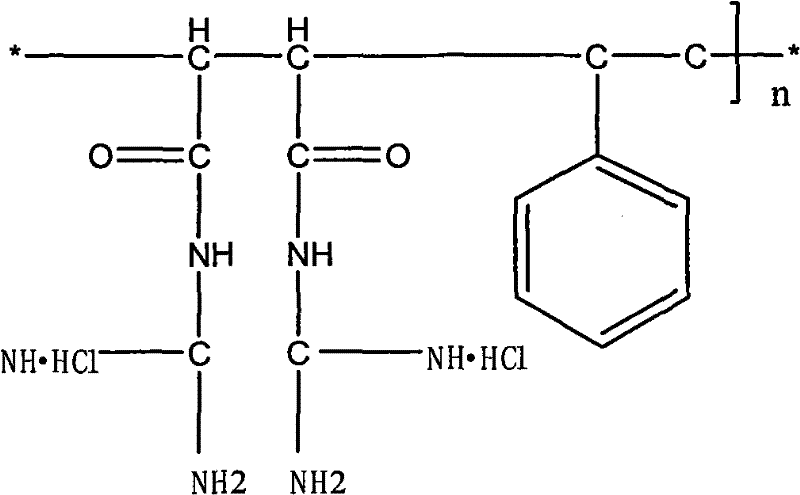

Method for preparing uramine-type macromolecule anti-bacterial agent

ActiveCN101628952ANot easy to migrateImprove antibacterial propertiesBiocideDisinfectantsWater bathsNitrogen gas

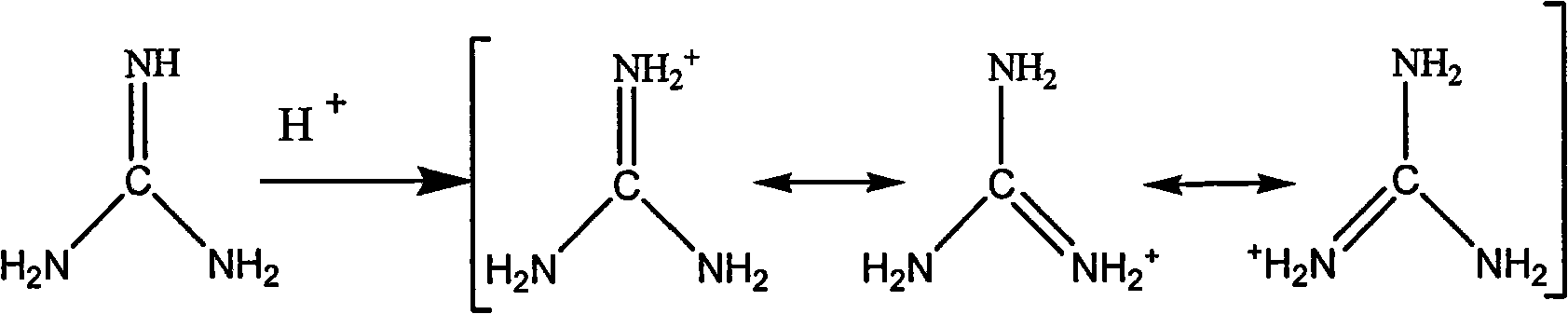

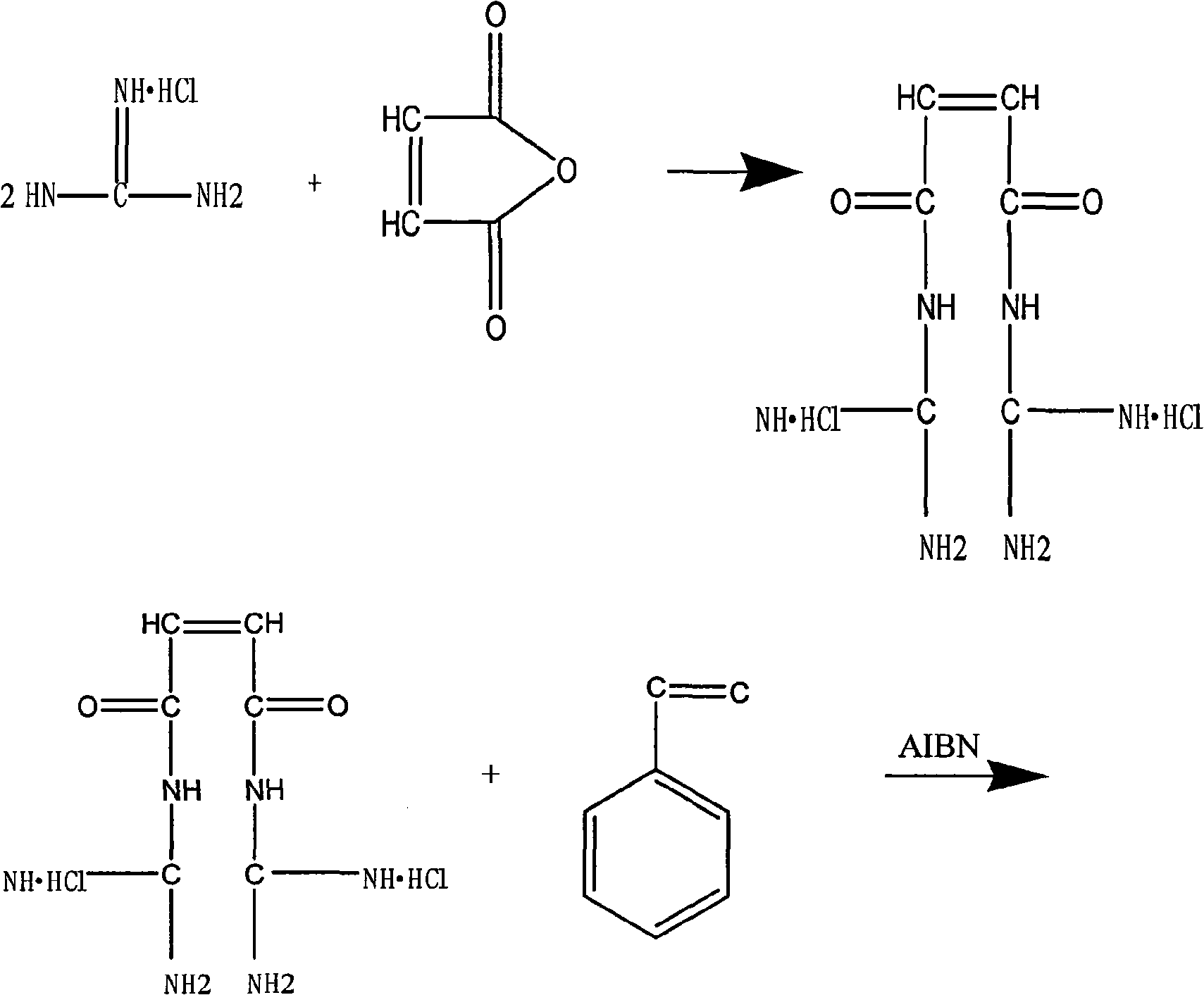

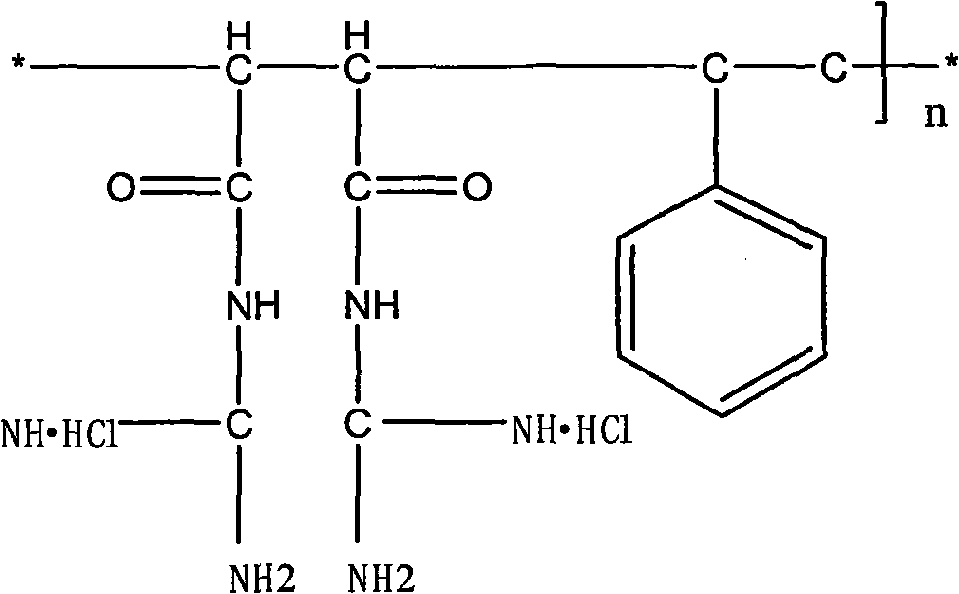

The invention relates to a method for preparing an uramine-type macromolecule anti-bacterial agent, comprising two steps as follows: A, mixing any one solution of guanidine hcl, Polyhexamethyleneguanidine chloride and polyhexamethylene biguanide hydrochloride with maleic anhydride solution; introducing nitrogen for constant-temperature water bath reaction to obtain functional uramine salt; B, mixing functional uramine salt solution with acrylamide and / or styrene for constant-temperature water bath reaction to obtain ivory-white stringy liquid; depositing soft white solid with solvent for vacuum drying to obtain ivory-white bulk uramine-type copolymer, i.e, uramine-type macromolecule anti-bacterial agent. The uramine-type macromolecule anti-bacterial agent has remarkable effect and simple synthesis process, ensures that the anti-bacterial group is hard to move and the processing thermal stability is excellent through copolymerization on macromolecule long chain. The invention can be widely used in fields of plastic, dope, powder dope, rubber, wood plastic, rubber plastic, spinning, water processing, and the like.

Owner:安徽合汇金源科技有限公司

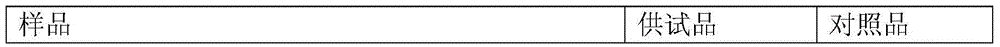

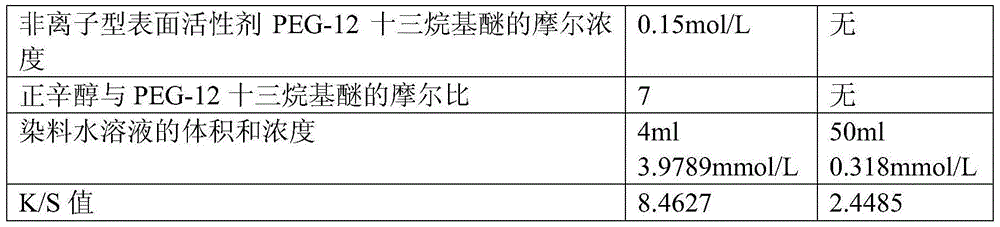

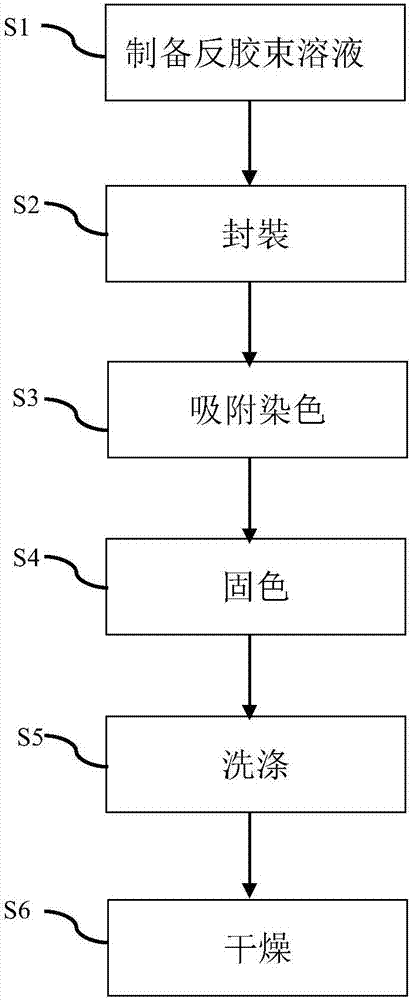

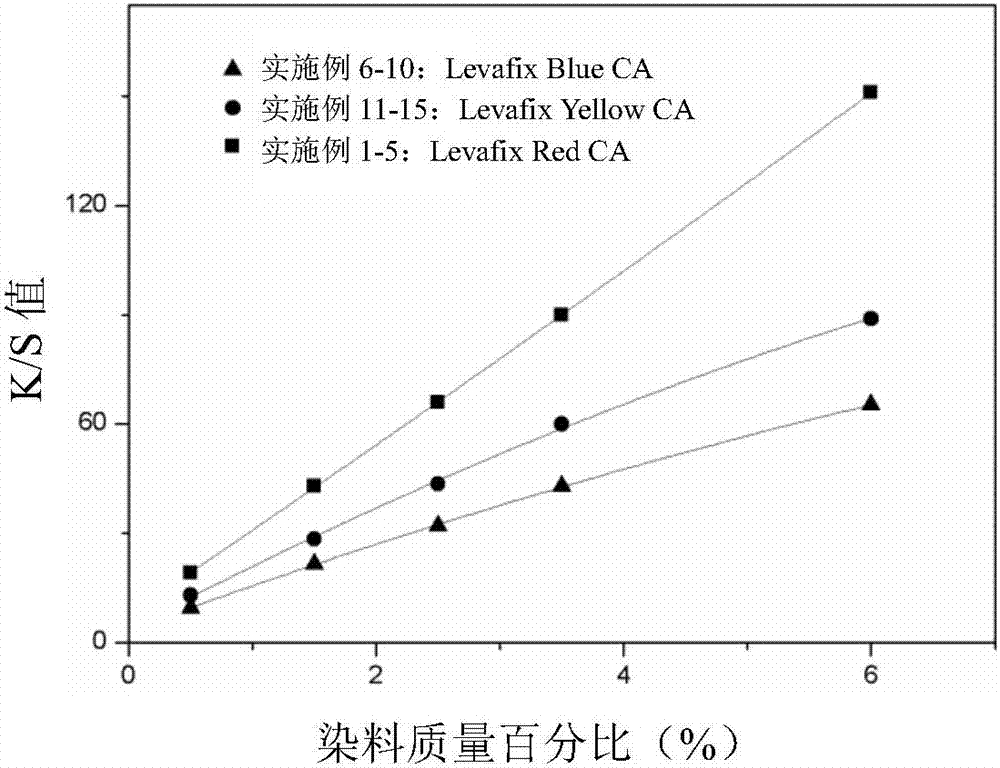

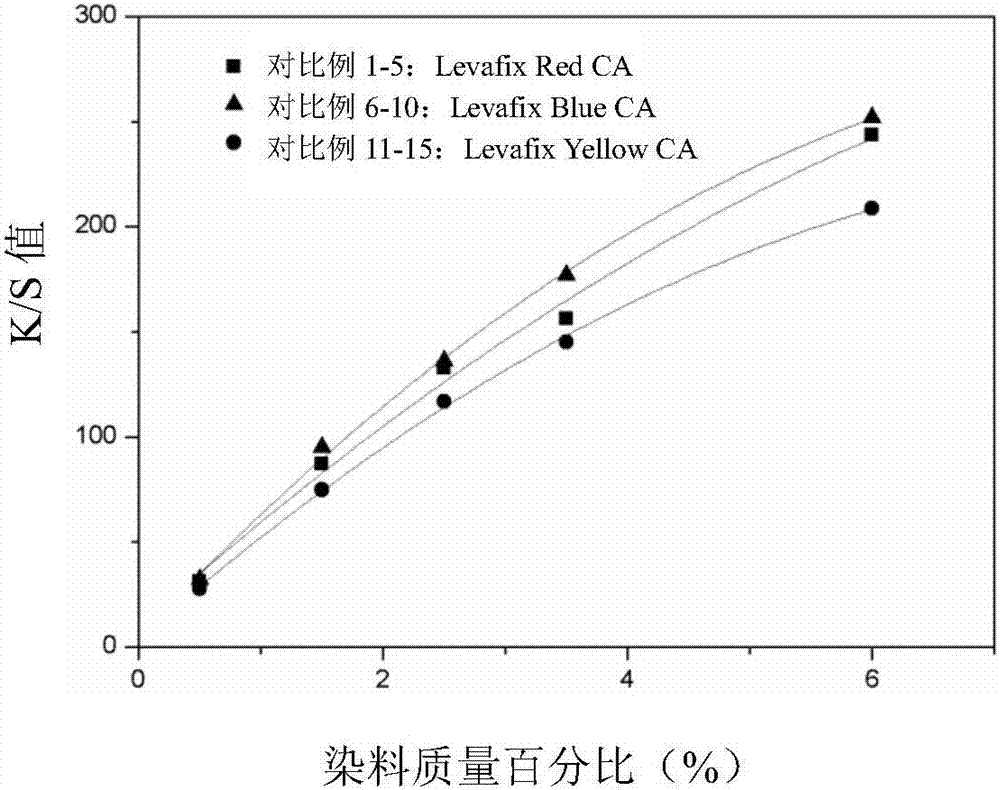

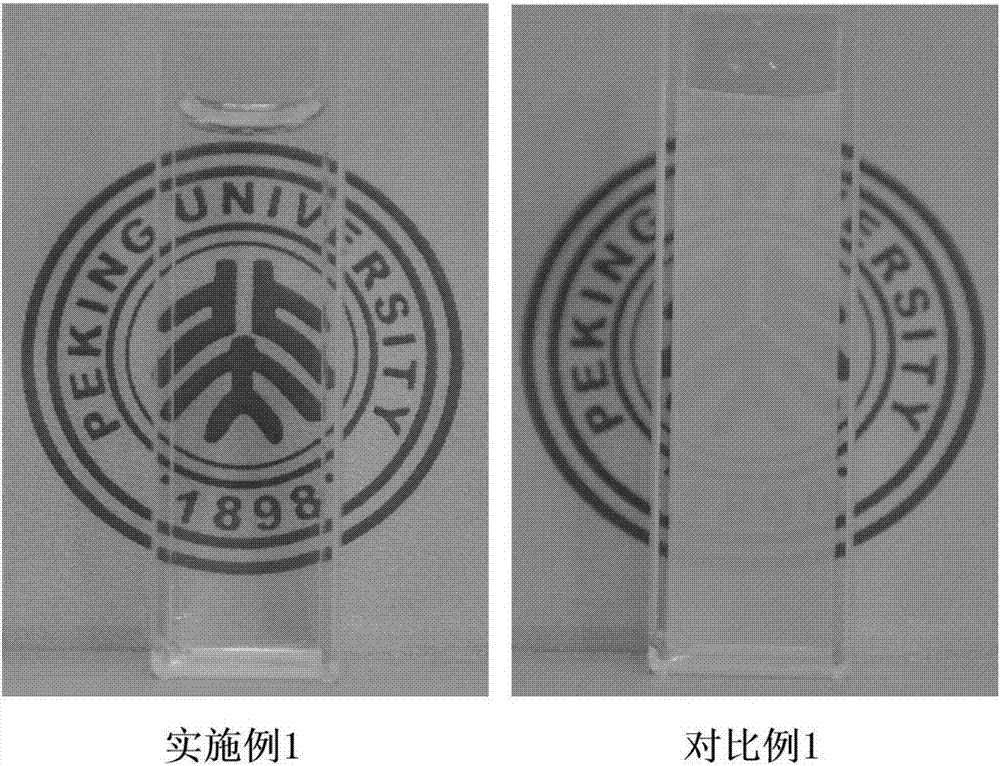

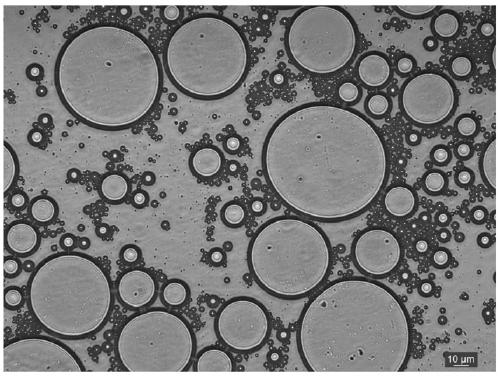

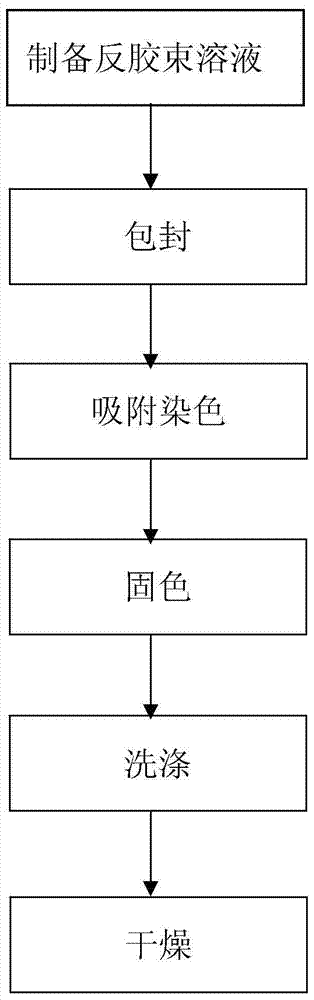

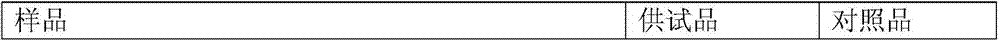

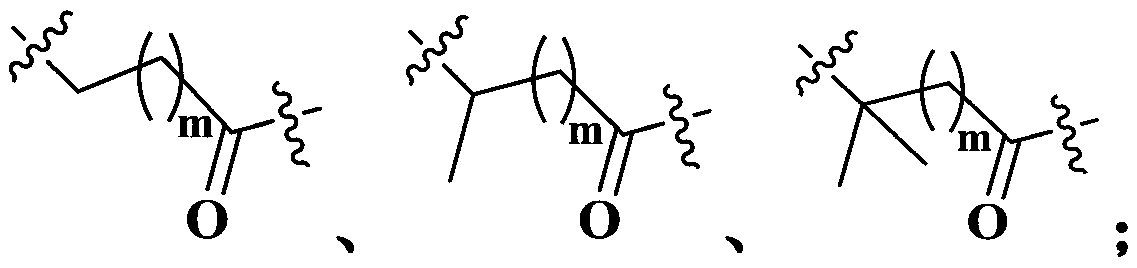

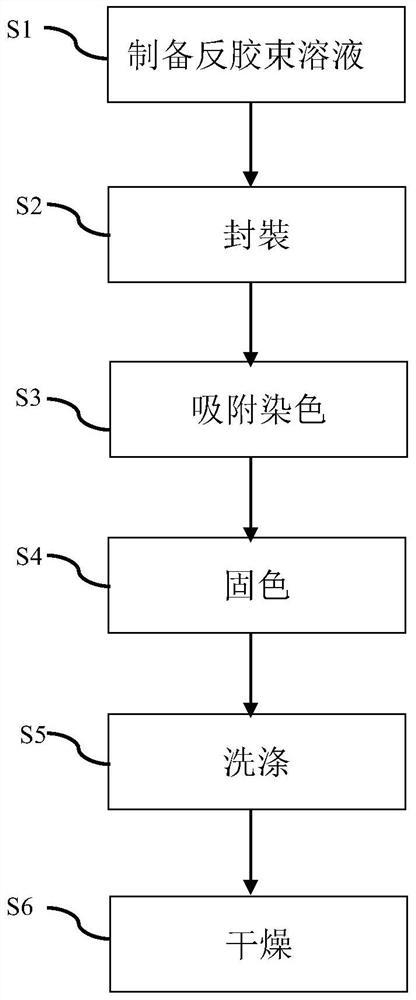

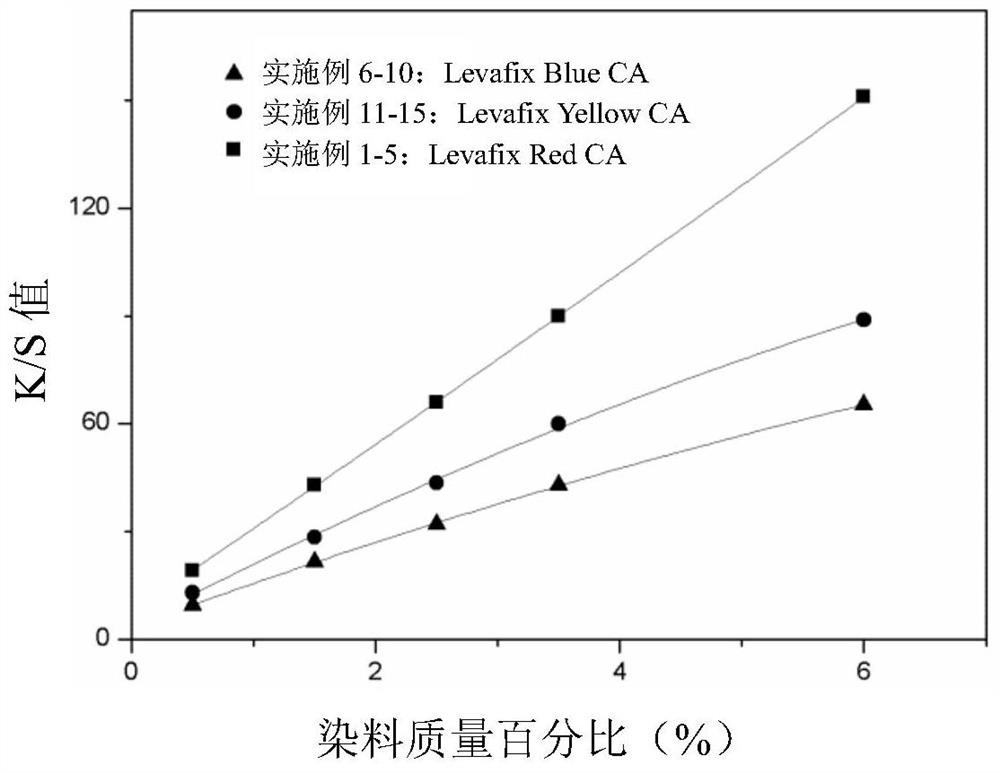

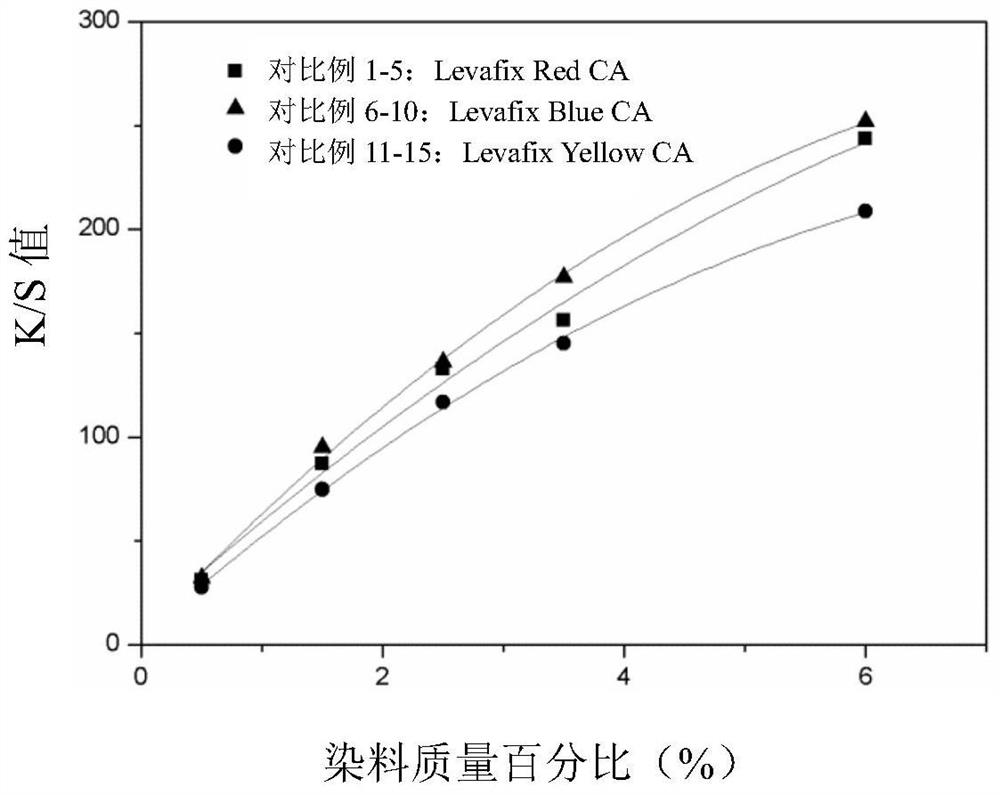

Cotton fabric non-aqueous dyeing process and reverse micelle encapsulated reactive dye liquid

ActiveCN105442359ADyeing is effectiveNot easy to degradeOrganic dyesDyeing processOrganic solventWastewater

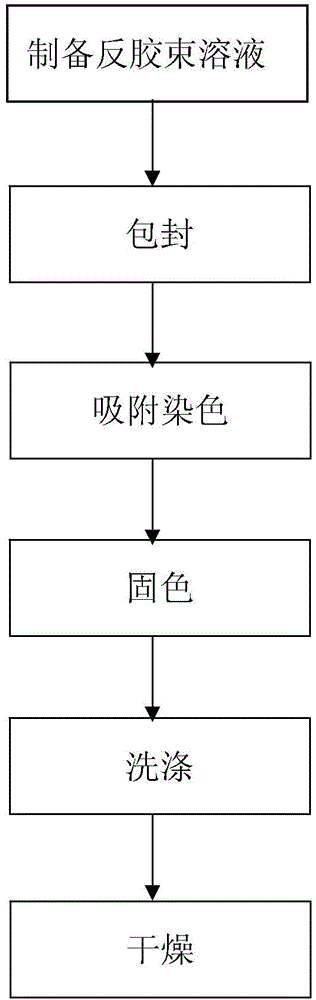

The invention relates to a cotton fabric non-aqueous dyeing process and a reverse micelle encapsulated reactive dye liquid, and concretely relates to a method for carrying out non-aqueous dyeing on a cotton fabric by using the nonionic surfactant reverse micelle encapsulated reactive dye liquid. The dyeing method has the advantages of low cost, good dyeing quality, and simple and safe operation; a good dyeing effect can be reached in the dyeing process without strict process conditions, so the energy consumption is saved; the non-aqueous dyeing process of the cotton fabric by the reactive dye is basically completed at normal temperature to a medium temperature, and the reactive dye is difficult to degrade, so the reactive dye can be recovered, and the color of the dyed cotton fabric obtained after the non-aqueous dyeing process is completed difficultly fades; and use an organic solvent as a medium reduces the water in order to reduce treatment of colored wastewater, and the colored wastewater and the organic solvent can be effectively recovered, so environment pollution is reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

Fabric non-water dyeing method

The invention relates to a fabric non-water dyeing method. The method comprises the following steps: pre-mixing a nonionic surfactant and a co-surfactant, dissolving the mixture into an organic solvent to prepare a reversed micelle solution; slowly adding an active dye solution into the reversed micelle solution, at the same time, stirring the solution until the turbid reversed micelle solution becomes clear to obtain a reversed micelle encapsulated active dye solution; soaking fabrics in the reversed micelle encapsulated active dye solution, vibrating the dye solution continuously to carry out adsorption dyeing at a constant temperature until a balance of adsorption dyeing is reached; adding a color fastening agent solution to obtain reversed micelle encapsulated fastening agent solution; and vibrating the solution continuously so as to fix the color of fabrics at a constant temperature. The fabrics are dyed by a one bath method based on a nonionic surfactant. The cost is reduced, and the dyeing effect is guaranteed. At the same time, an organic solvent is taken as the medium; the using amount of water is reduced, moreover, the organic solvent can be recovered effectively, and the environmental pollution is reduced.

Owner:THE HONG KONG POLYTECHNIC UNIV

Method for preparing insect-proof nets

InactiveCN107151832AGood dark effectImprove stabilityConjugated synthetic polymer artificial filamentsArtifical filament manufactureMagnesium stearateColor changes

The invention discloses a method for preparing insect-proof nets. The method includes mixing polyethylene, polylactic acid, PET (polyethylene terephthalate), coupling agents and compatilizers with one another, melting the polyethylene, the polylactic acid, the PET, the coupling agents and the compatilizers at the temperatures of 170-210 DEG C to obtain mixtures, placing the obtained mixtures in an extruder and heating, extruding and smashing the mixtures to obtain mixture powder; heating the obtained mixture powder, photosensitive color-changing agents, insect repellent agents, nanometer titanium dioxide and magnesium stearate until the temperatures of the mixture powder, the photosensitive color-changing agents, the insect repellent agents, the nanometer titanium dioxide and the magnesium stearate reach 160-180 DEG C, shearing the mixture powder, the photosensitive color-changing agents, the insect repellent agents, the nanometer titanium dioxide and the magnesium stearate at the high speeds of 2000-3000 rpm for 20-30 min to obtain mixtures, cooling the mixtures, then feeding the mixtures into the extruder and heating and extruding the mixtures to obtain master batch; carrying out wire drawing on the master batch to obtain the insect-proof nets. The method has the advantages that the insect repellent rates of the insect-proof nets prepared by the aid of the method can reach 91%, the insect killing rates of the insect-proof nets can reach 83%, the repellent rates can reach 62% after the insect-proof nets are washed by 50 times, and the killing rates can reach 37% after the insect-proof nets are washed by 50 times; the light transmittance of the insect-proof nets is 78%, and the flexibility of the insect-proof nets can reach 80.2 Mpa.

Owner:JIANGSU HUACHANG YARNS & FABRICS CO LTD

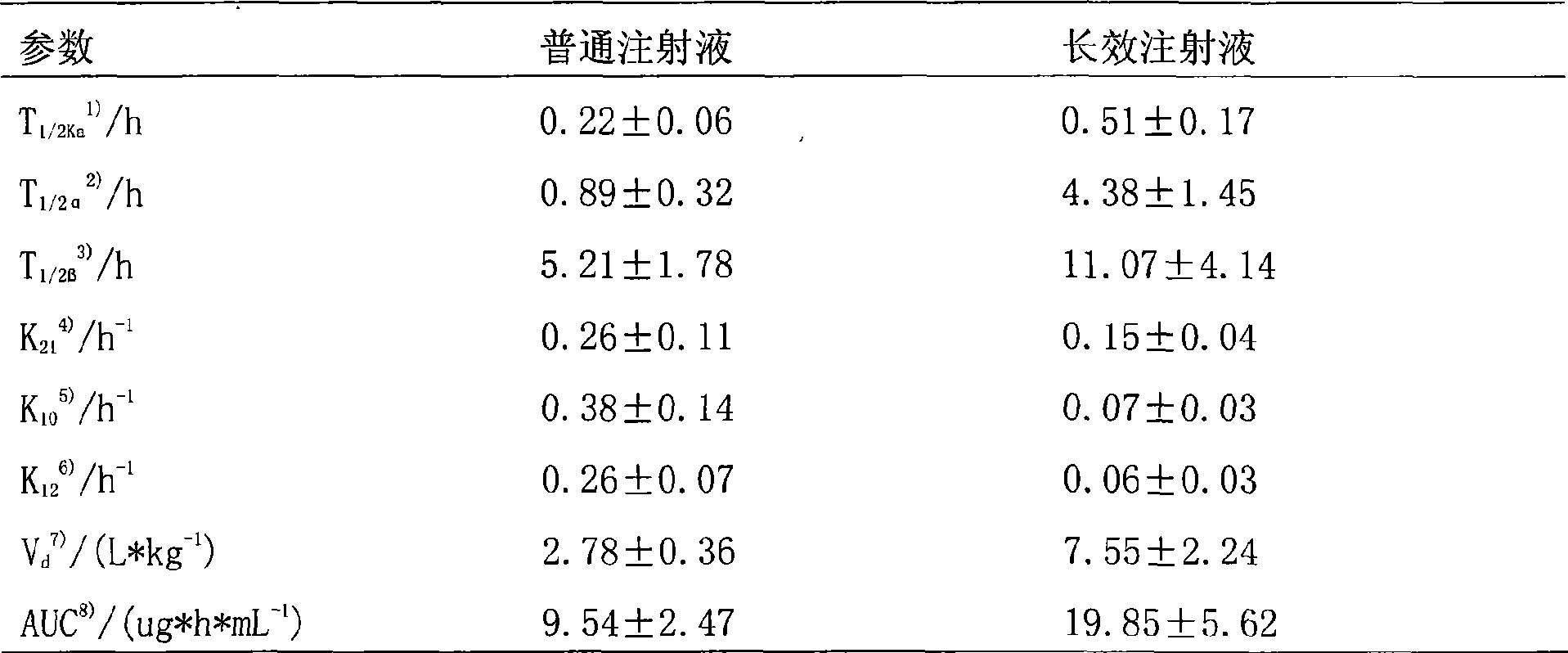

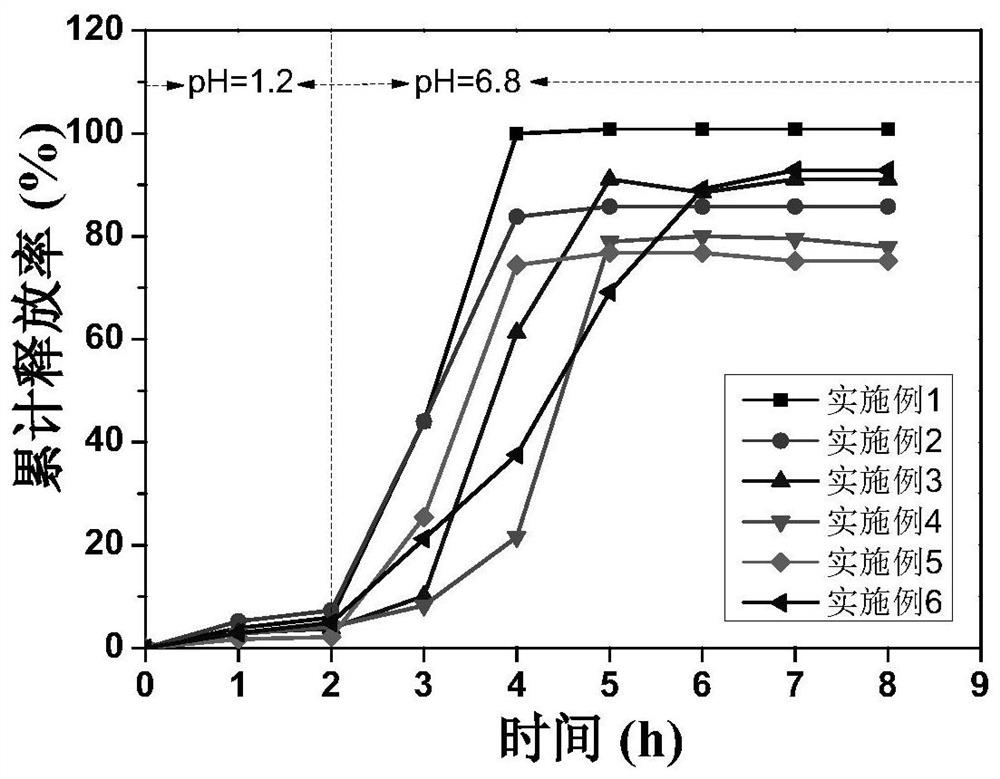

Preparation method of doxycycline long-acting injection

InactiveCN101416974AMeet the determination requirementsSimple methodAntibacterial agentsTetracycline active ingredientsEthylenediamineWater use

The invention discloses a doxycycline long-acting injection which has the formula as follows: 5g to 20g of doxycycline, 10g to 60g of propylene glycol, 2g to 4g of MgCl2, 0.2g to 0.5g of Na2S2O5, and water used for injection. The preparation method comprises the following steps: 1. the doxycycline is added into the propylene glycol to obtain a solution (1); 2. the doxycycline hydrochloride, the MgCl2 and the Na2S2O5 are taken and dissolved in the water used for injection to obtain a solution (2); 3. the solution (2) is slowly added into the solution (1) and stirred while being added, and ethylene diamine is used for regulating the pH value to be 7.5 to 8.5; and 4. the water used for injection is added till the total volume reaches 100ml, and filtering, encapsulation and flowing steam sterilization at the temperature of 100 DEG C for 30min are carried out to obtain the finished product. The doxycycline long-acting injection has the advantages of less dosage, long half-life period, less adverse reaction, and the like.

Owner:PU LIKE BIO ENG

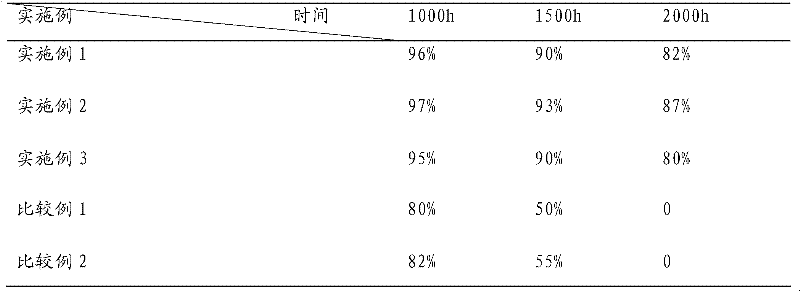

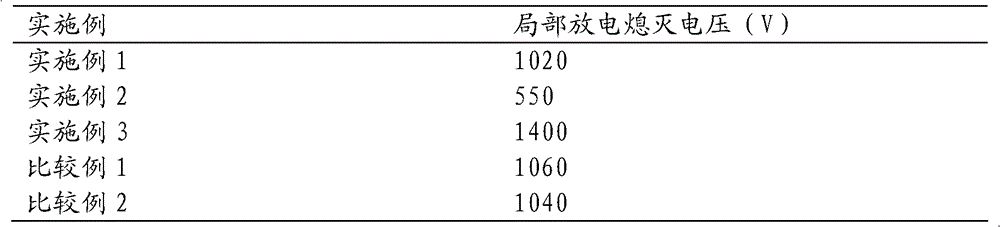

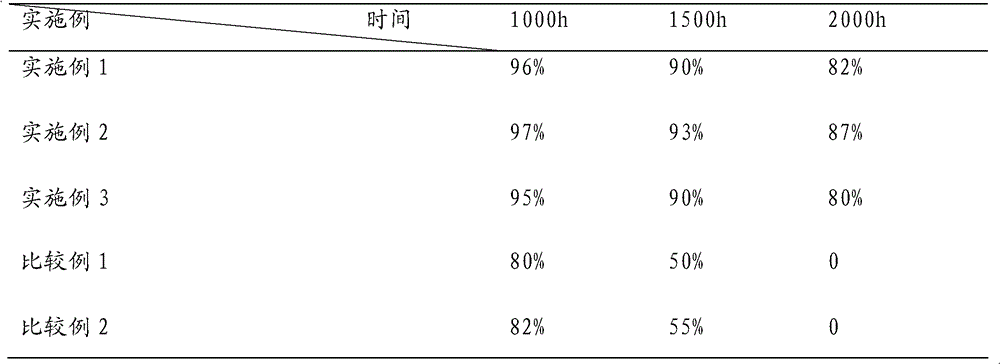

Solar rear panel and production method for same

ActiveCN102642364AImprove insulation performanceGood moisture and heat aging resistanceSynthetic resin layered productsPhotovoltaic energy generationThermal ageingCross-link

The invention provides a solar rear panel, which comprises a base layer, a weather-proof layer and a coating layer, wherein the weather-proof layer is compounded on one side of the base layer, the coating layer is composited on the other side of the base layer, and the base layer is obtained by means of cross-linking and curing polyolefin under the action of curing accelerators. The invention further provides a production method for the solar rear panel, and the polyolefin and the curing accelerators are cured into a film and then cross-linked to obtain the solar rear panel. The solar rear panel has fine aging resistance and chemical stability, and is not easy to hydrolyze or degrade, so that the obtained solar rear panel is not easy to crack, fine insulating property, humidity and heat resistance and aging resistance can be constantly kept, and the risk of component failure is reduced. Performance testing results indicate that the breaking strength retention rate of the solar rear panel is higher than 70% when the solar rear panel produced by the production method is exposed in an ultraviolet condition for 2000 hours, and the breaking strength retention rate of the solar rear panel is higher than 80% when the solar rear panel is exposed in an accelerated aging environment for 2000 hours.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

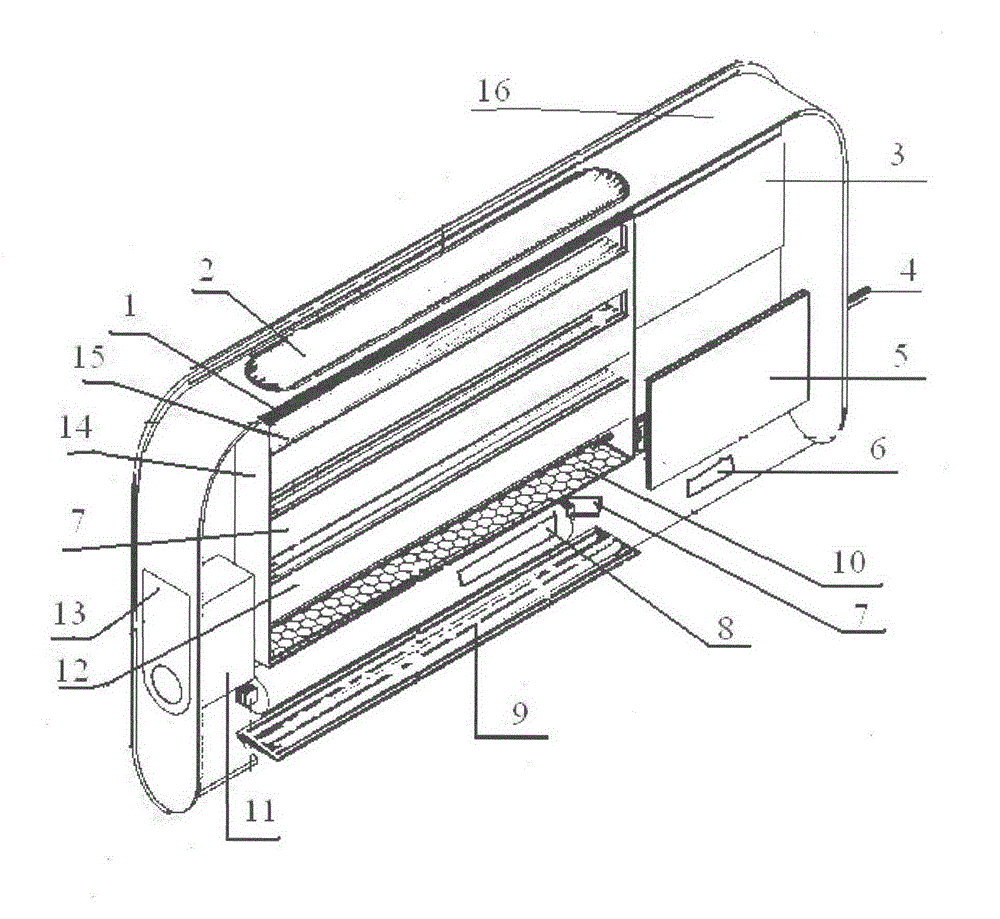

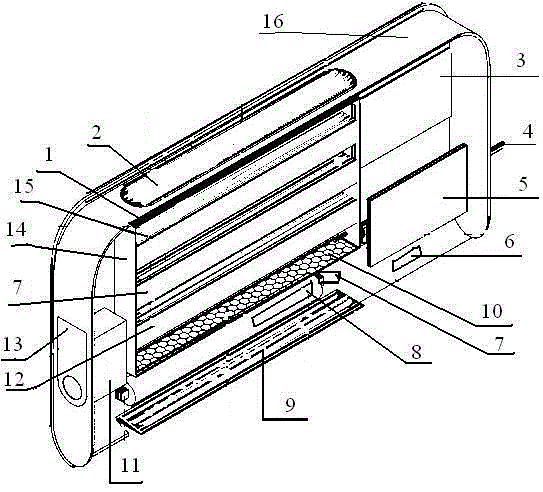

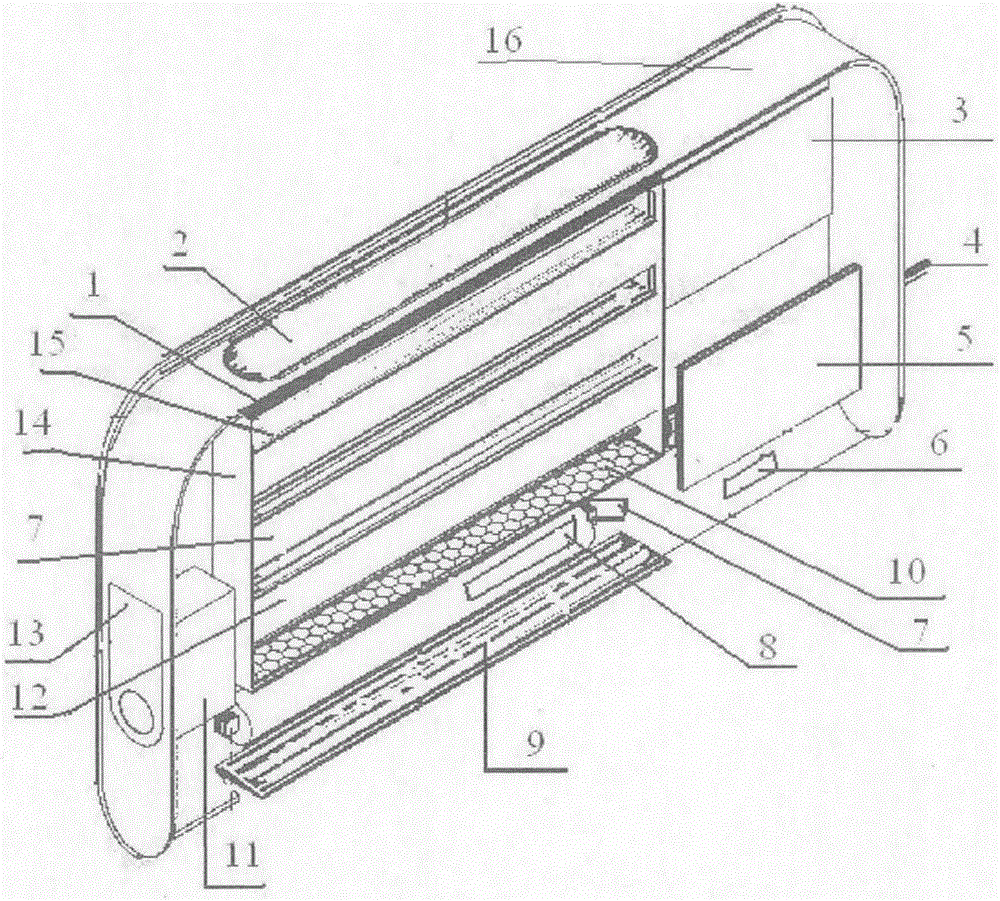

Wall-mounted oxygen distribution instrument

ActiveCN103148541APlay a regulatory roleSimple structureCombination devicesLighting and heating apparatusEvaporationEngineering

The invention relates to a wall-mounted oxygen distribution instrument. The wall-mounted oxygen distribution instrument comprises a frame and an electrostatic negative high-voltage coil, wherein the electrostatic negative high-voltage coil is arranged in the frame; the frame is of a cuboid shape; an air inlet is formed in the top surface of the frame; indoor air enters from the air inlet; a metal filtering net is arranged at one side of the air inlet; an electrostatic dust collector is arranged below the metal filtering net; and a negative ion generator and a trioxide generator are sequentially arranged below the electrostatic dust collector. The oxygen distribution instrument is simple to operate, and green and environment-friendly; through a molecular sieve evaporation technology, calcium and magnesium ions in water are removed; the air is washed by a water curtain, so that germs, dust and particulate matters in the air can be filtered and purified while humidifying; and then a pneumatic device sends the wet and clean air into rooms, so that the environment humidity and cleanness can be improved.

Owner:QINGDAO DAOYIKONGYOU TECH

Vitamin, mineral substance nutrient composition for middle and old people

InactiveCN1422552ABalanced ratioIn line with national conditionsFood preparationBeta-CaroteneVitamin C

The health-care product using vitamins and mineral components as main raw material for middle-aged and old people contains the following components (wt%):vitamin B6: beta-carotene:folic acid: calcium, iron:zinc:selenium=0.05-0.2:25-100:0.00125-0.005: S-12: 0.25-1:0.25-1:0.25-1:0.05-0.6:0.03-0.15:100-400:2-8: 2-8:0.006-0.025. Its preparation method includes the following steps: embedding, mixing, granulating, tabletting, checking and packaging, etc.

Owner:HUANGJIN DADANG BIOLOGICAL SCI & TECH SHANGHAI

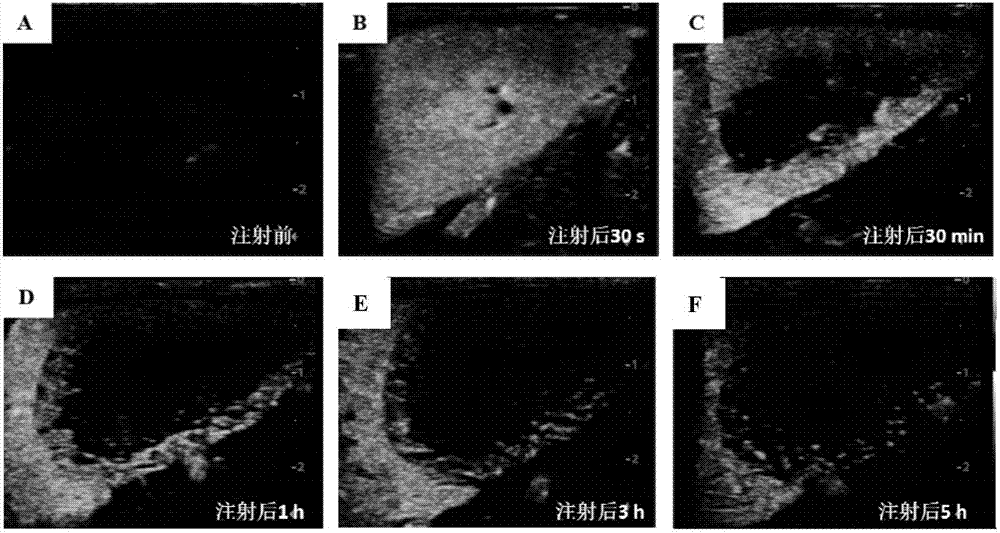

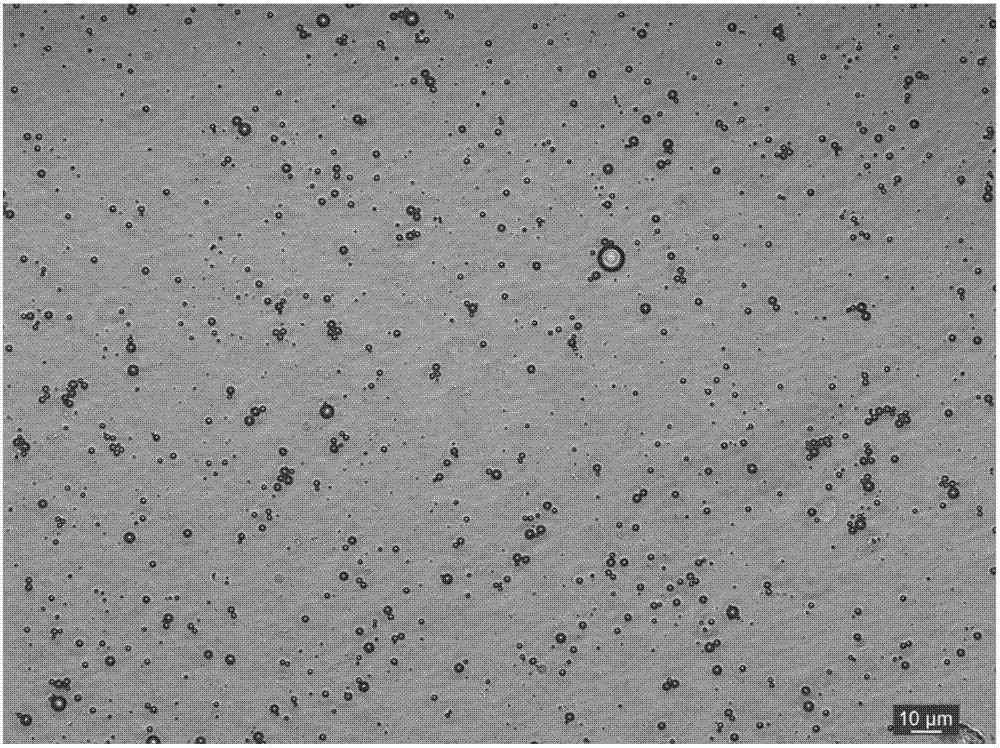

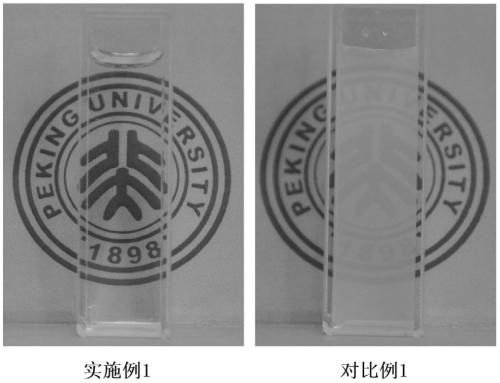

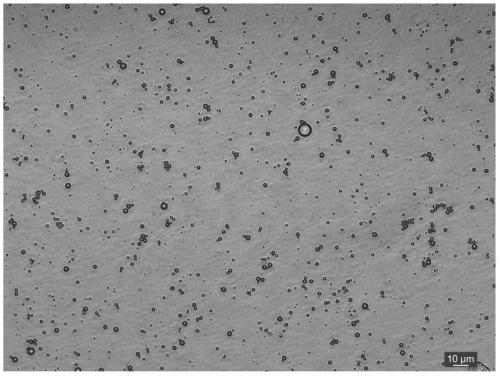

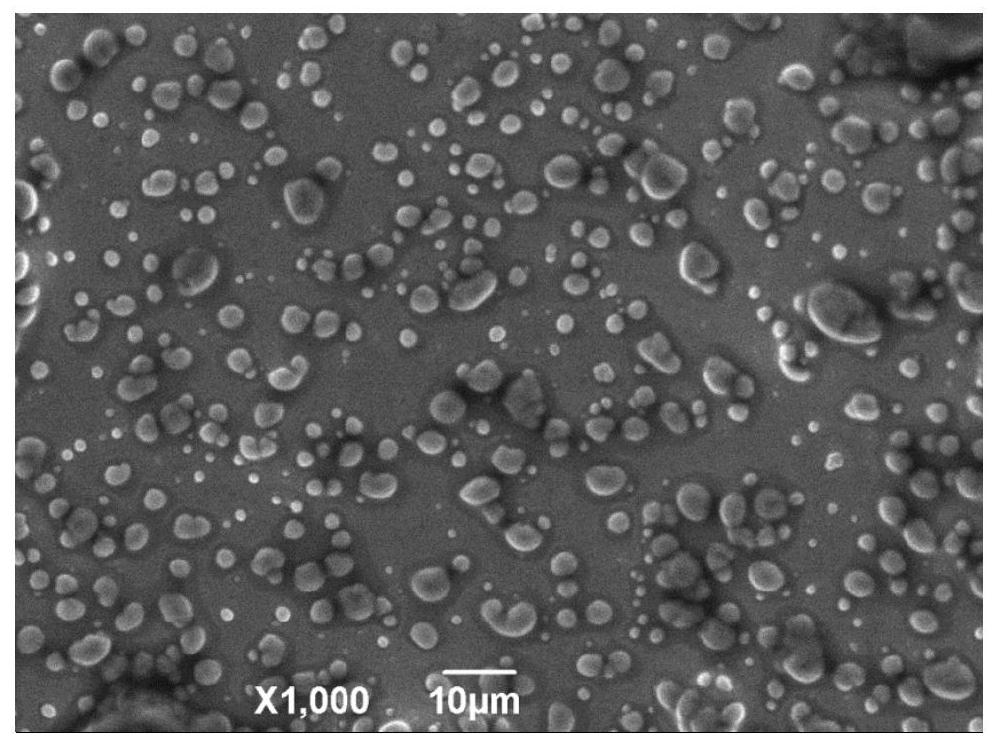

Ultrasonic contrast agent with ultra-long duration time and preparation method of ultrasonic contrast agent

ActiveCN107233583ANot easy to degradeNot prone to degradationEchographic/ultrasound-imaging preparationsSolution deliveryUltrasound contrast mediaRadiology

The invention relates to the field of medicines, and particularly discloses an ultrasonic contrast agent with ultra-long duration time and a preparation method of the ultrasonic contrast agent. The contrast agent has the advantage that the contrast duration time for the organs such as the liver, the kidney and the spleen reaches 2 hours or a longer time, the longest duration time can reach 6 hours or a longer time, and the ultrasonic contrast agent belongs to the contrast agent with the longest ultrasonic contrast duration time in the micro-bubble type ultrasonic contrast agents reported at present. In addition, the preparation process of the contrast agent is simple and controllable, the large-scale production can be easily realized, the production raw materials are injectable medicinal auxiliary materials which are approved at present, and thus the clinical application prospect is broad.

Owner:北京飞锐达医疗科技有限公司

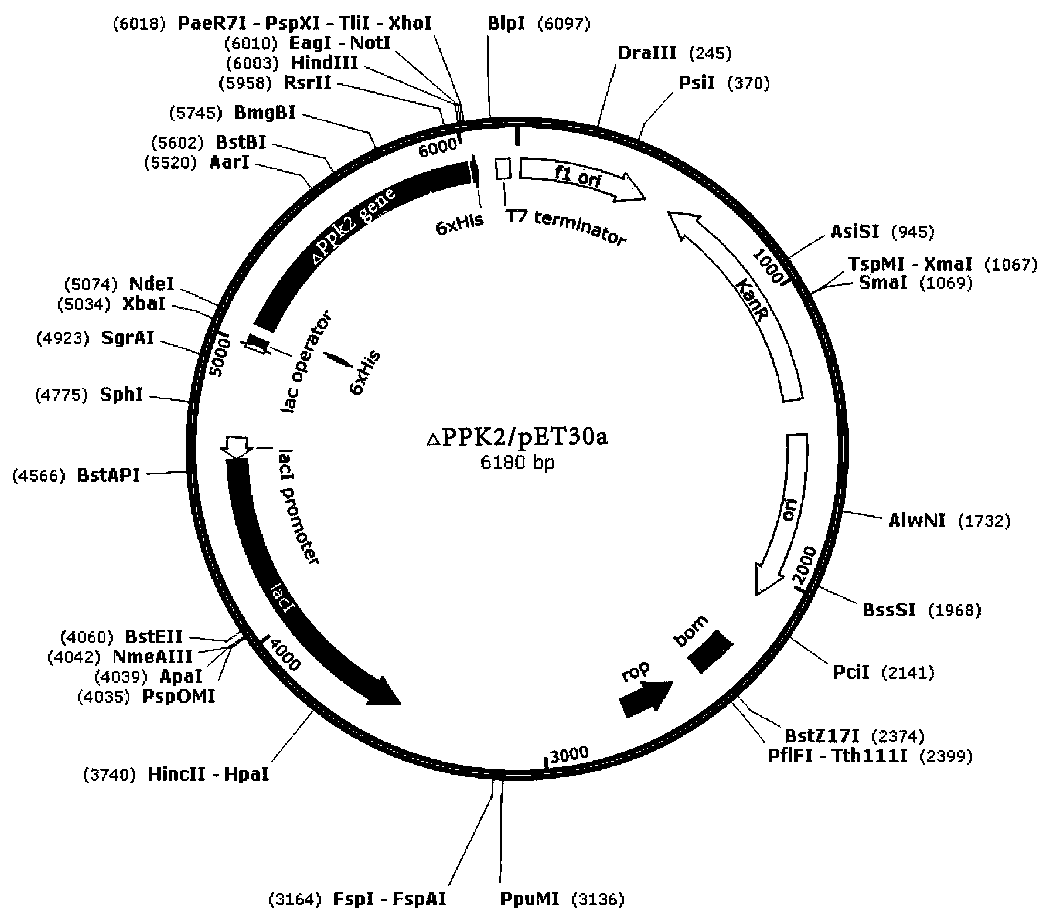

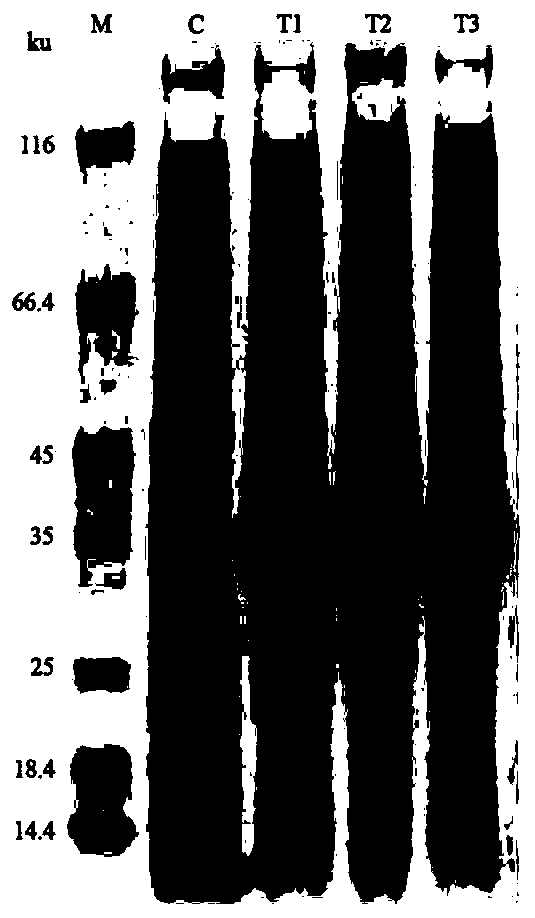

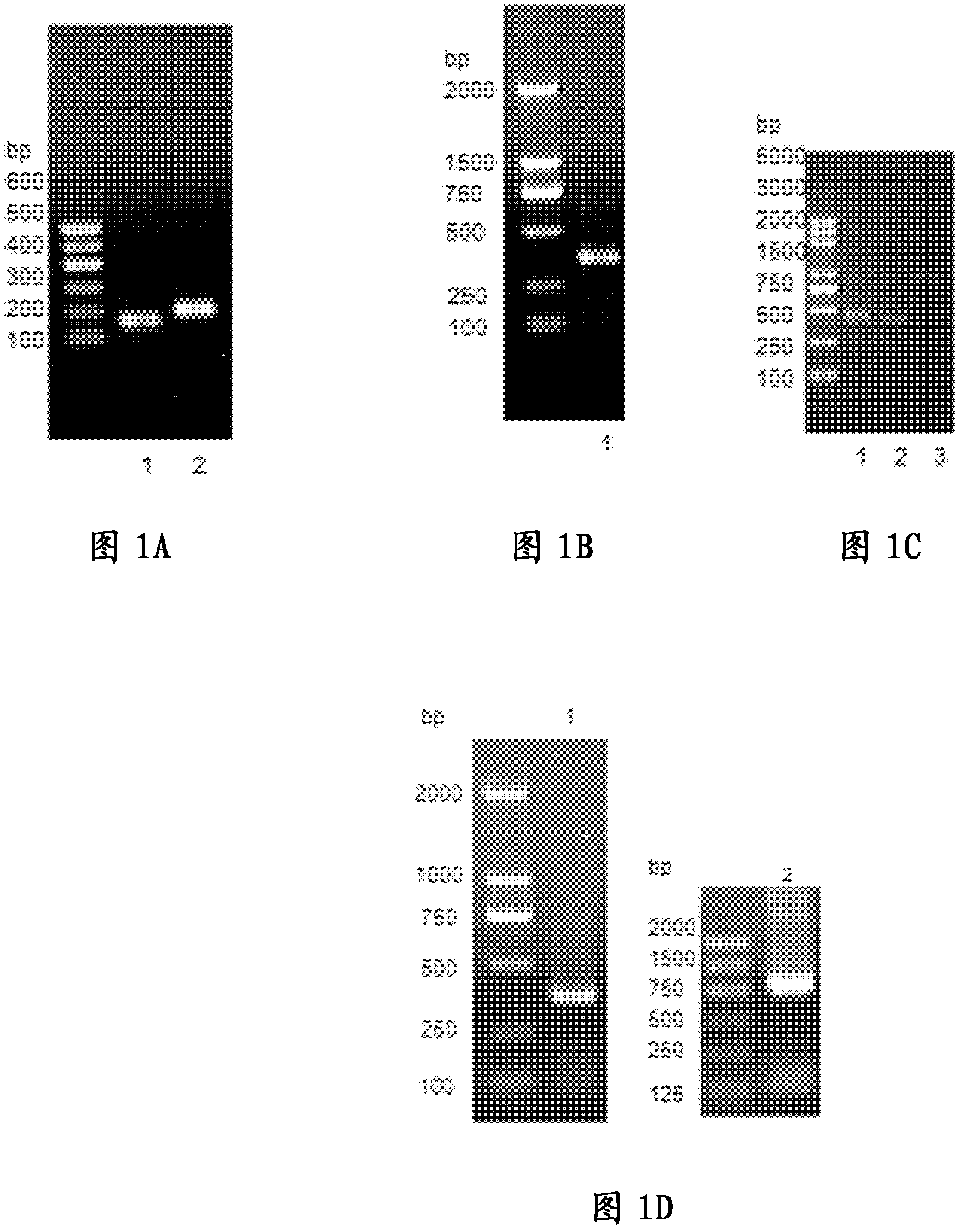

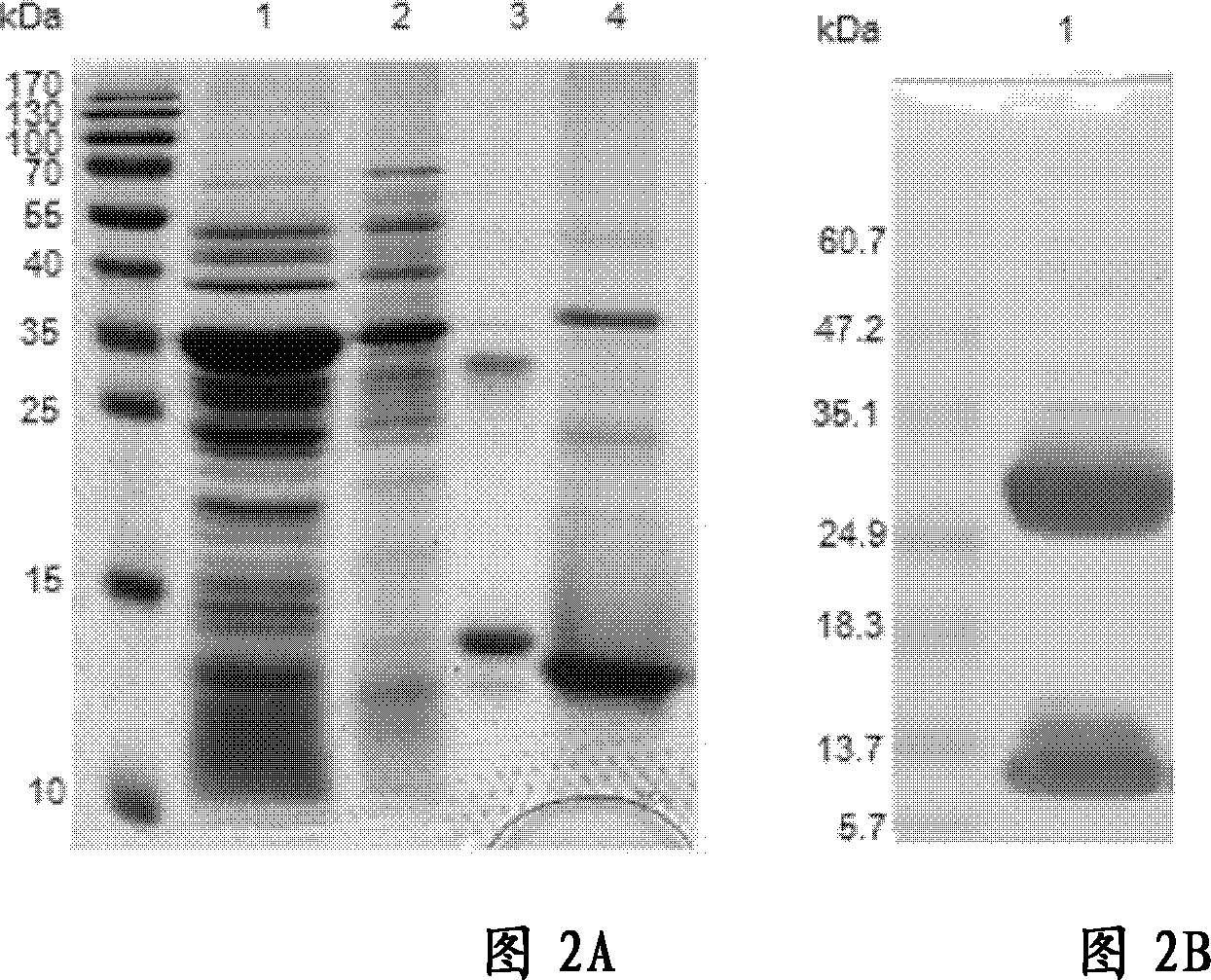

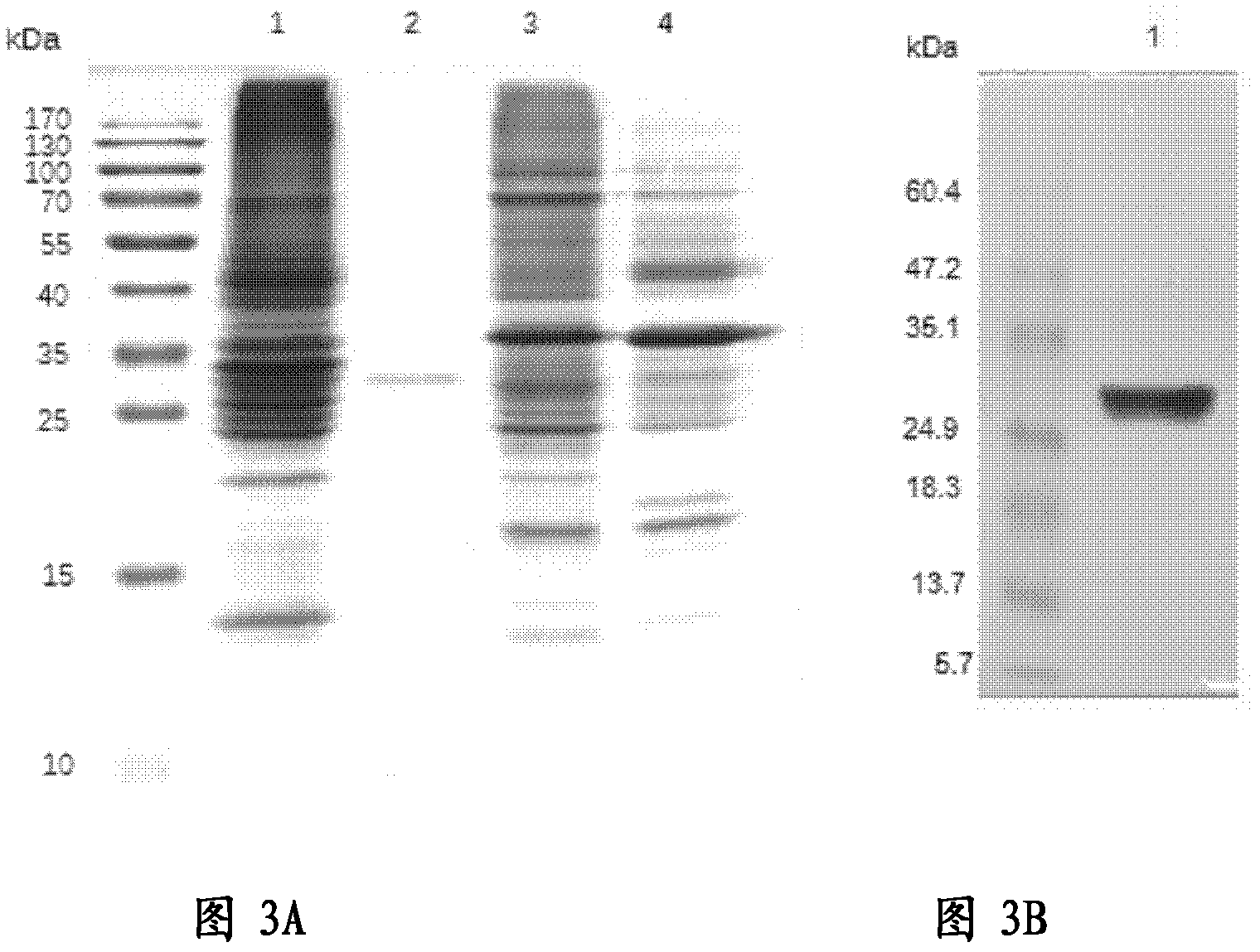

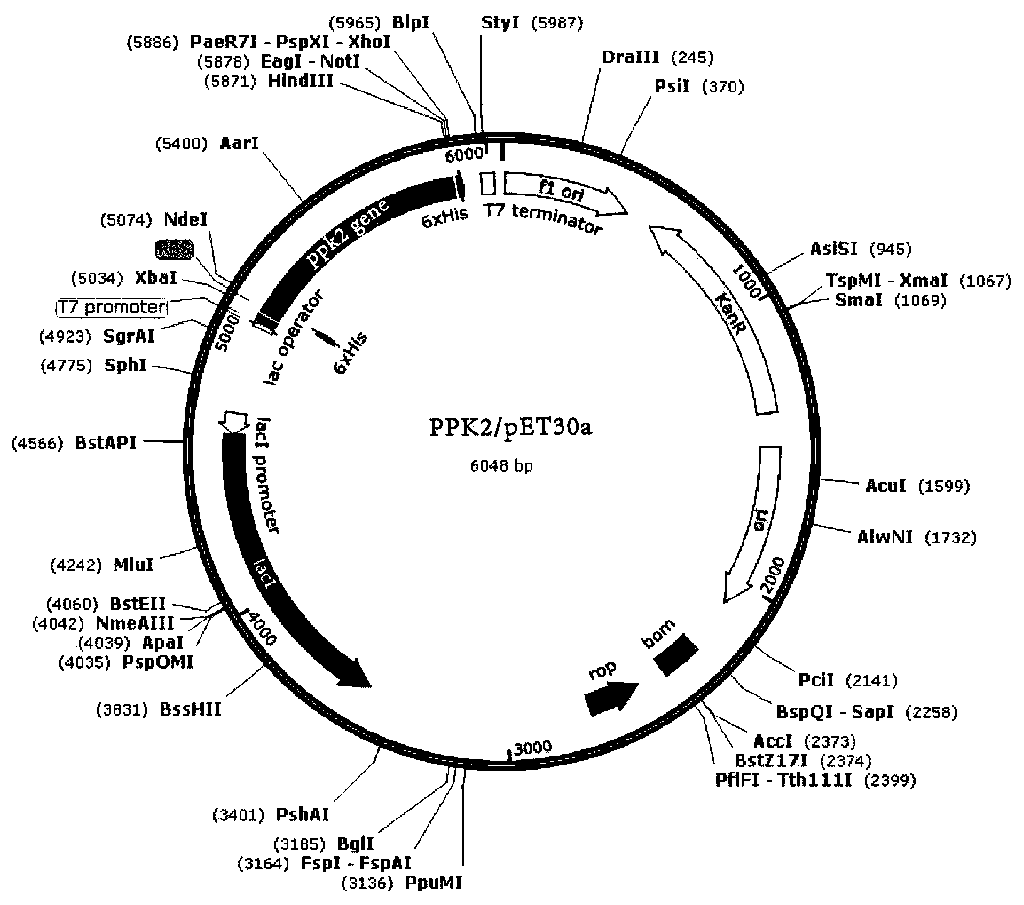

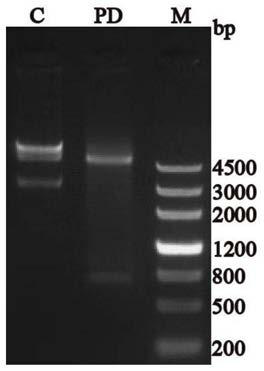

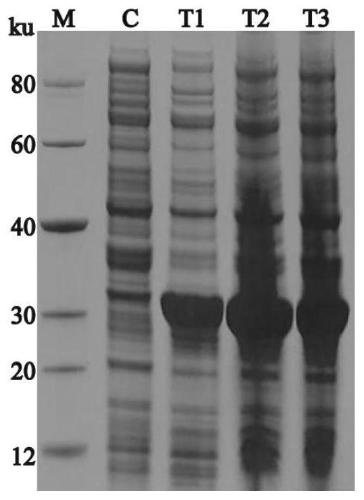

PPK2 protein, and application of PPK2 protein as polyacrylamide gel electrophoresis 35kd standard substance

The invention discloses a PPK2 protein, and an application of the PPK2 protein as a polyacrylamide gel electrophoresis 35kd standard substance. A ppk2 gene is inserted into a prokaryotic expression vector pET30a by using NdeI and Hind III, the obtained recombinant expression vector is transferred into an Escherichia coli BL21 (DE3) strain through a physical method, IPTG is used to induce trial expression of the target protein PPK2 at 37 DEG C, 25 DEG C and 16 DEG C, and the obtained expression product is identified and analyzed through SDS-PAGE electrophoresis and Western blotting; and finally, amplification culture is carried out by utilizing 3 L of an expression bacterial liquid, and the expression product is separated and purified through a Ni-IDA affinity chromatographic column, an anion exchange chromatographic column and a gel filtration chromatographic column in sequence. Results show that a large intestine prokaryotic expression system can be stably and efficiently expressed under the induction of the IPTG with the temperature of 16 DEG C and the final concentration of 0.2 mM.L<-1>, and the PPK2 protein has the advantages of specific charged property, existence in a monomerform in a solution, stable properties, non-degradability and long half-life period, and has an application prospect as the polyacrylamide gel electrophoresis 35 kd standard substance.

Owner:TIANJIN VOCATIONAL INST

Method for preparing saikosaponin

InactiveCN101084948BNot prone to degradationIncrease contentPowder deliveryAntipyreticAqueous ethanolRadix bupleuri

The invention discloses a preparation method of Chinese traditional medicine extract, specifically to a preparation method of saikosaponin. The method comprises the following steps in sequence: adding solvent to radix bupleuri or residue of radix bupleuri after extraction of volatile oil, regulating to alkality, extracting to obtain extract, loading on macroporous basic anion-exchange column, eluting with basic solution and pure water, discarding the flushing liquor, eluting with aqueous ethanol, and concentrating the eluant to obtain saikosaponin. The inventive extraction method of saikosaponin has high extraction efficiency and saikosaponin content; can keep high biological activity of saikosaponin; and saikosaponin is not easy to degrade during extraction separation.

Owner:TIANJIN TASLY ZHIJIAO PHARMA

Method for preparing uramine-type macromolecule anti-bacterial agent

ActiveCN101628952BNot easy to migrateImprove antibacterial propertiesBiocideDisinfectantsWater bathsSolvent

The invention relates to a method for preparing an uramine-type macromolecule anti-bacterial agent, comprising two steps as follows: A, mixing any one solution of guanidine hcl, Polyhexamethyleneguanidine chloride and polyhexamethylene biguanide hydrochloride with maleic anhydride solution; introducing nitrogen for constant-temperature water bath reaction to obtain functional uramine salt; B, mixing functional uramine salt solution with acrylamide and / or styrene for constant-temperature water bath reaction to obtain ivory-white stringy liquid; depositing soft white solid with solvent for vacuum drying to obtain ivory-white bulk uramine-type copolymer, i.e, uramine-type macromolecule anti-bacterial agent. The uramine-type macromolecule anti-bacterial agent has remarkable effect and simple synthesis process, ensures that the anti-bacterial group is hard to move and the processing thermal stability is excellent through copolymerization on macromolecule long chain. The invention can be widely used in fields of plastic, dope, powder dope, rubber, wood plastic, rubber plastic, spinning, water processing, and the like.

Owner:安徽合汇金源科技有限公司

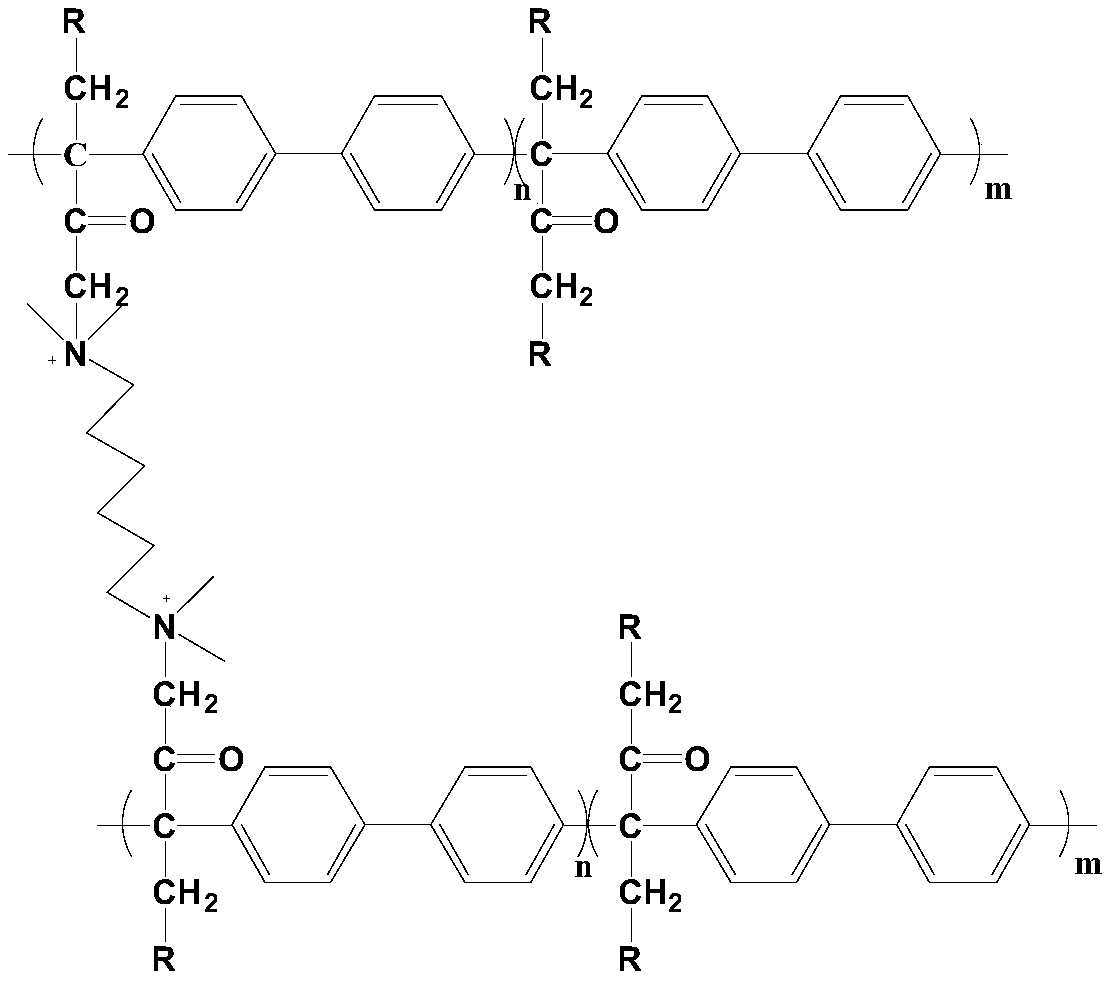

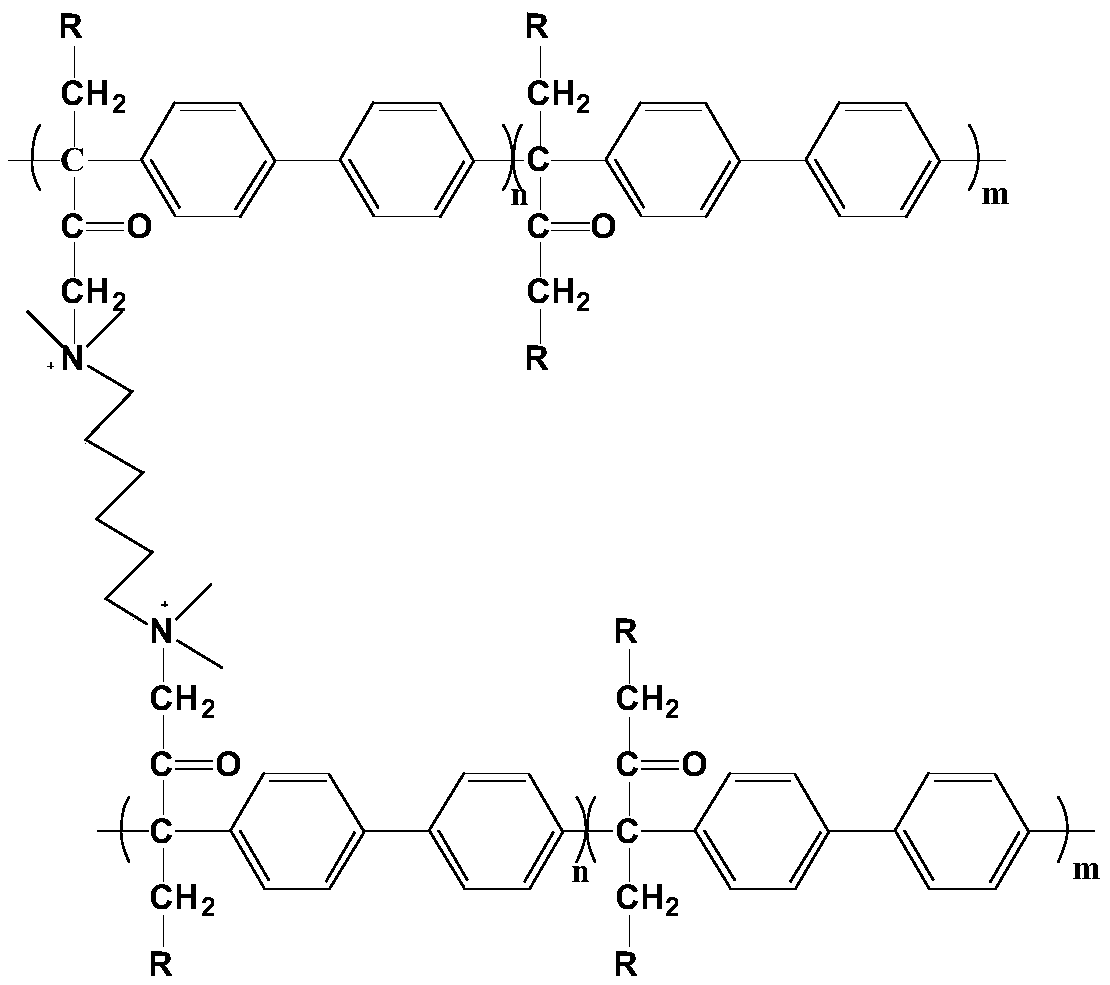

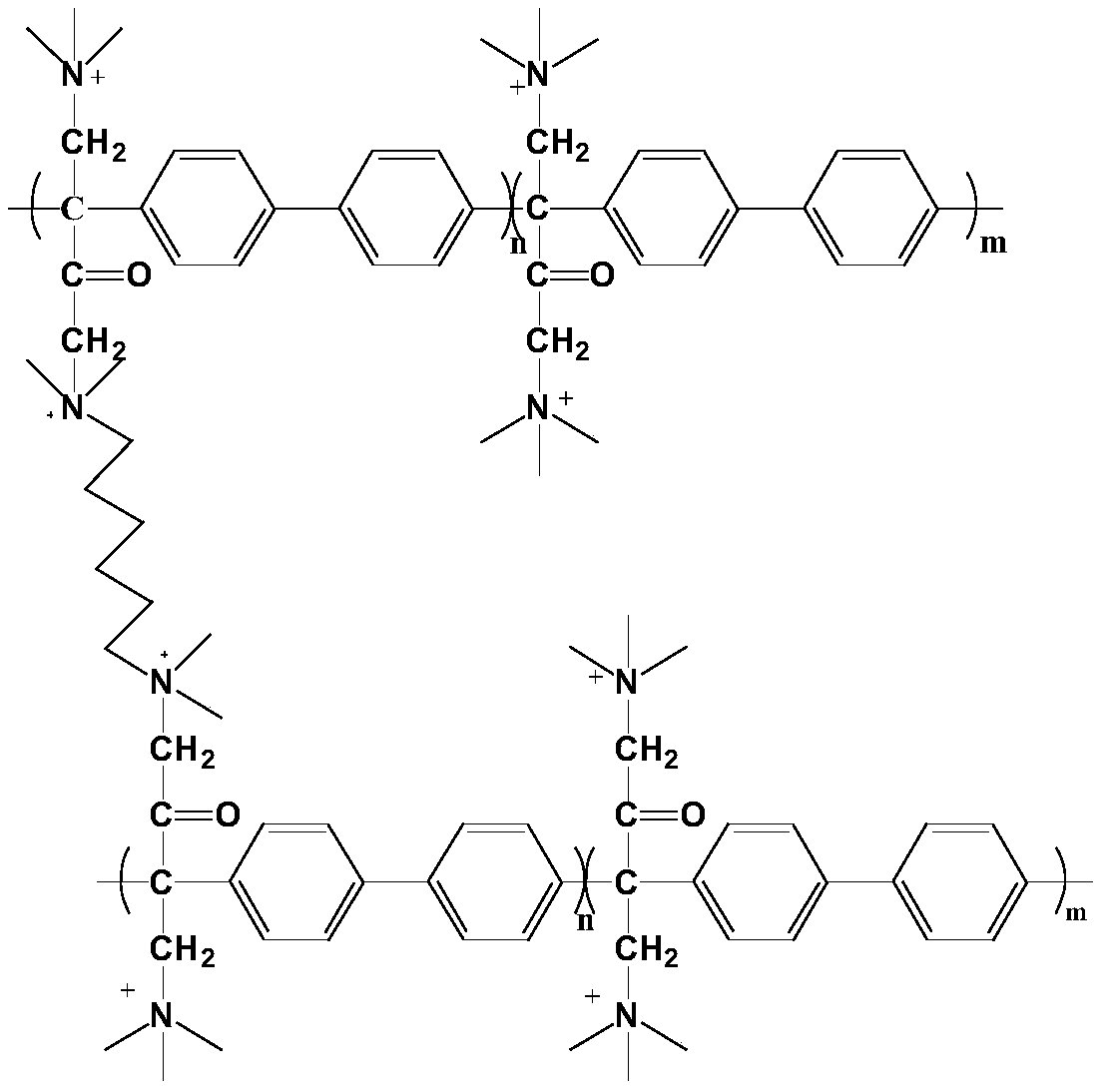

Multifunctional crosslinked polyarylidene butanedione anion exchange membrane and preparation method thereof

The invention discloses a multifunctional crosslinked polyarylidene butanedione anion exchange membrane and a preparation method thereof, and belongs to the technical field of basic anion exchange membranes. The method comprises the steps that firstly, a dibromo-substituted polyarylidene butanedione polymer with good alkali resistance stability is synthesized, then thermal crosslinking is directlyperformed on the polymer by taking bromine of the polymer as a functionalization site, and then remaining sites are subjected to quaternization to obtain a film material. The prepared membrane has better alkali stability and dimensional stability and higher ionic conductivity, and can be applied to an alkaline fuel cell.

Owner:DALIAN UNIV OF TECH

Humidifying and oxygen-generating device

InactiveCN106765621AEliminate odorEliminate smoke and dustMechanical apparatusSpace heating and ventilation safety systemsOzone generatorMolecular sieve

The invention relates to a humidifying and oxygen-generating device. The humidifying and oxygen-generating device comprises a machine frame and an electrostatic negative-high-voltage line coil installed inside the machine frame. The machine frame is in a cuboid shape. The top face of the machine frame is provided with an air inlet. Indoor air enters the humidifying and oxygen-generating device from the air inlet. A metal filtering net is arranged on one side of the air inlet. An electrostatic dust collector is arranged below the metal filtering net. A negative ion generator and an ozone generator are sequentially arranged below the electrostatic dust collector. The oxygen distributing instrument is easy to operate, environmentally friendly, removes calcium ions and magnesium ions in water through a molecular sieve evaporating technology, washes air through a water curtain and can conduct humidification, filter off germs, dust and particles in the air and purify the air at the same time; and then, wet and clean air is fed into a room through an air drive device, and therefore the environmental humidity and cleanness degree are improved.

Owner:王金鹤

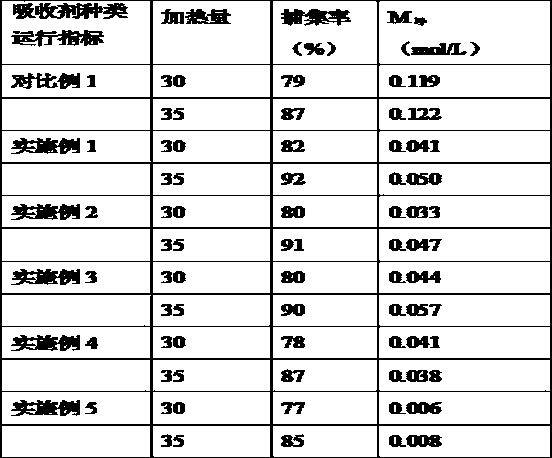

Inorganic salt type carbon dioxide absorbent

InactiveCN108722116AReduce volatile lossLow running costDispersed particle separationAir quality improvementPotassiumMass content

The invention relates to an inorganic salt type carbon dioxide absorbent and belongs to the field of gas separation and purification. The absorbent is prepared from amino acid salt, ionic liquid, ammonia water and a stabilizer, wherein the amino acid salt is potassium salt or sodium salt of amino acid, the melting point of the ionic liquid is greater than 5 DEC below zero, guarant viscosity is (40DEG C) is smaller than 20 centipoise and the mass content is 10 to 45 percent. By utilizing the ultralow vapor pressure of the inorganic salt absorbent, volatile loss in the operation of the inorganic salt absorbent is greatly reduced, and further the operating cost is greatly reduced. In addition, the absorbent has the advantages of environment friendliness, low possibility of degradation and capability of greatly prolonging the service life; the absorbent is suitable for a variety of gas sources, and is equally effective for a carbon dioxide gas source with higher oxygen content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recombinant fusion protein of IL3 and Lidamycin, preparation method and application thereof

InactiveCN103102416AStrong specific killing activityOvercome Killing Side EffectsFungiBacteriaGenetic engineeringAnticancer drug

The invention relates to a strengthened fusion protein of an anticancer drug lidamycin, i.e. mIL3-LDM from mutated I131L and F132L, and a coding gene thereof. The invention also relates to a genetic engineering construction method of the fusion protein and application of the strengthened fusion protein.

Owner:中国医学科学院血液病医院

PPK2 protein and application thereof as 30kd standard substance for polyacrylamide gel electrophoresis

InactiveCN111235129AClear bandFully dyedComponent separationTransferasesEscherichia coliProtein target

The invention discloses a PPK2 protein and application thereof as a 30kd standard substance for polyacrylamide gel electrophoresis. Ppk2 genes are inserted into a prokaryotic expression vector pET30aby virtue of NdeI and HindIII, a recombinant expression vector is transferred into an escherichia coli BL21(DE3) strain by virtue of a physical method, a target protein PPK2 is induced to realize trial expression at 37 DEG C, 25 DEG C and 16 DEG C by virtue of IPTG, and an expression product is authenticated and expressed by virtue of SDS-PAGE electrophoresis and Western Blotting; and finally, amplification culture is carried out by virtue of 3.2L of expression bacteria liquid, and the expression product is sequentially separated and purified by virtue of Ni-IDA affinity chromatography, cation-exchange chromatography and gel filtration chromatography. A result shows that a large intestine prokaryotic expression system can be induced to realize stable and efficient expression by virtue of the IPTG with a final concentration of 0.2mM.L<-1> at 16 DEG C, the PPK2 protein has an exclusive charging property, stable performance and a long half-life period, exists in a solution in a monomer manner, is unlikely to degrade and has an application prospect as the 30kd standard substance for the polyacrylamide gel electrophoresis.

Owner:TIANJIN VOCATIONAL INST

Vitamin and mineral nutrient supplement for middle-aged and elderly people

InactiveCN101828716ANot easily oxidizedFacilitate absorption and utilizationFood preparationNutrientB1 Vitamin

The invention relates to a vitamin and mineral nutrient supplement for middle-aged and elderly people, in particular to a nutrient supplement using various vitamins and minerals as main components, solving the problem that various nutrients can not be mutually promoted to be absorbed and utilized because of unreasonable composition, matching proportion and use dosage of various nutrients in the traditional nutrient supplement. The vitamin and mineral nutrient supplement contains various nutrients and minerals in percentage by mass: 0.075 percent of vitamin A, 30 percent of vitamin C, 0.00125 percent of vitamin D, 5 percent of vitamin E, 0.3 percent of vitamin B1, 0.3 percent of vitamin B2, 0.3 percent of vitamin B6, 0.075 percent of beta-carotene, 0.05 percent of folate, 150 percent of calcium, 2 percent of iron, 2 percent of zinc and 0-0.015 percent of selenium. The nutrient supplement is prepared by the steps of embedding, mixing, pelletizing, tableting, detecting and packaging. The invention is mainly used as the micro nutrient supplement for the middle-aged and elderly people.

Owner:王凯莹

Ultrasonic contrast agent with ultra-long duration and preparation method thereof

ActiveCN107233583BNot easy to degradeNot prone to degradationEchographic/ultrasound-imaging preparationsSolution deliveryUltrasound contrast mediaBiochemistry

The invention relates to the field of medicines, and particularly discloses an ultrasonic contrast agent with ultra-long duration time and a preparation method of the ultrasonic contrast agent. The contrast agent has the advantage that the contrast duration time for the organs such as the liver, the kidney and the spleen reaches 2 hours or a longer time, the longest duration time can reach 6 hours or a longer time, and the ultrasonic contrast agent belongs to the contrast agent with the longest ultrasonic contrast duration time in the micro-bubble type ultrasonic contrast agents reported at present. In addition, the preparation process of the contrast agent is simple and controllable, the large-scale production can be easily realized, the production raw materials are injectable medicinal auxiliary materials which are approved at present, and thus the clinical application prospect is broad.

Owner:北京飞锐达医疗科技有限公司

A kind of cotton fabric non-aqueous dyeing process and reactive dye solution encapsulated by reverse micelles

ActiveCN105442359BDyeing is effectiveNot easy to degradeOrganic dyesDyeing processOrganic solventRoom temperature

The invention relates to a non-aqueous dyeing process for cotton fabrics and a reactive dye solution encapsulated by reverse micelles, in particular to a method for non-aqueous dyeing of cotton fabrics using reactive dyes encapsulated by non-ionic surfactants and reverse micelles , the dyeing process of the present invention has low cost, good dyeing quality, easy and safe operation; good dyeing effect can be achieved without harsh process conditions in the dyeing process, and energy consumption is saved; non-aqueous dyeing of cotton fabrics with reactive dyes During the dyeing process, it is basically completed at room temperature to medium temperature. Reactive dyes are not easy to degrade, so reactive dyes can be recycled and reused, and after the final non-aqueous dyeing process is completed, the dyed cotton fabric is not easy to fade Or the phenomenon of lightening of color intensity; by using organic solvents as media, the amount of water can be reduced, thereby reducing the amount of colored wastewater to be treated, and colored wastewater and organic solvents can be effectively recycled to reduce environmental pollution.

Owner:THE HONG KONG POLYTECHNIC UNIV

A nadh drug-loaded microsphere

ActiveCN110237038BNot prone to degradationReduce the number of dosesOrganic active ingredientsNervous disorderWaxMicrosphere

The invention discloses an NADH drug-loaded microsphere, which is composed of the following ingredients in the weight ratio: NADH 1-20%; oil 50-80%; wax 5-30%; antioxidant 5-30%. The invention solves the technical problem that NADH is unstable in chemical properties and prone to degradation during the preparation process. NADH is melted in oil and wax with relatively stable physical and chemical properties, and antioxidants are added, and then formed by atomization cooling. , it not only effectively prevents the degradation of NADH, but also improves the particle size uniformity, dispersion and fluidity of the drug-loaded microspheres, and also has the advantages of simple and easy process and low production cost.

Owner:HUAZHONG AGRI UNIV

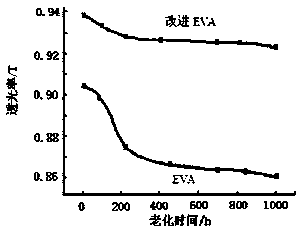

Packaged photovoltaic cell component and preparation method thereof

InactiveCN108123006ANarrow down the wavelength rangeEasy to absorb and utilizePhotovoltaic energy generationSemiconductor devicesChemistryEthyl Ethers

The invention belongs to the technical field of photovoltaic cells and relates to a packaged photovoltaic cell component and a preparation method thereof. The component sequentially comprises a covering layer, a transparent conductive film layer, an adhesive upper layer, a photovoltaic cell, an adhesive lower layer and a substrate layer from top to bottom; and the adhesive upper layer is an improved ethylene-vinyl acetate copolymer thin film layer. The preparation method comprises the following steps: fully and uniformly mixing aluminum oxide and a coupling agent according to the part by weight, drying at a temperature of 80 DEG C, grinding and dispersing and adding in a mixture of a curing agent and EVA pellets; then adding anthriscus sylvestris ethyl ether and uniformly mixing; and pouring the mixture into an extruder for blending extrusion. Compared with the prior art, the packaged photovoltaic cell component provided by the invention has the benefits that through mixing the anthriscus sylvestris ethyl ether into a vinyl-vinyl acetate copolymer, the adhesive upper layer is not easy to degrade when meeting with light with a wavelength of more than 280 nm, so that the degradationwavelength range of the vinyl-vinyl acetate copolymer is shortened; and moreover, the anthriscus sylvestris ethyl ether can also improve the initial adhesive strength of an adhesive.

Owner:中兑志远科技有限公司

A wall-mounted oxygen distribution meter

ActiveCN103148541BPlay a regulatory roleSimple structureCombination devicesLighting and heating apparatusEvaporationEngineering

Owner:QINGDAO DAOYIKONGYOU TECH

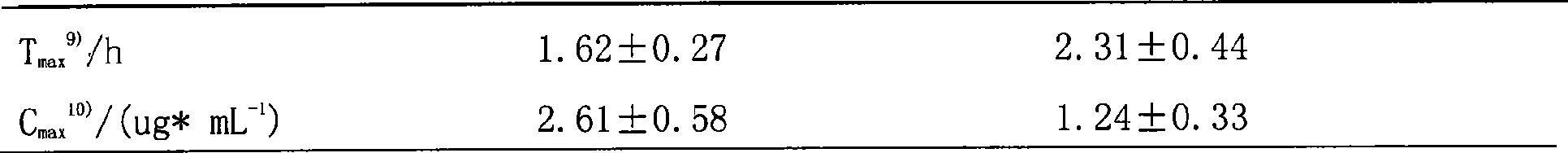

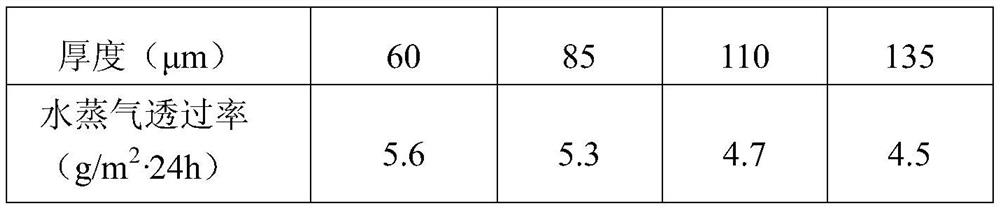

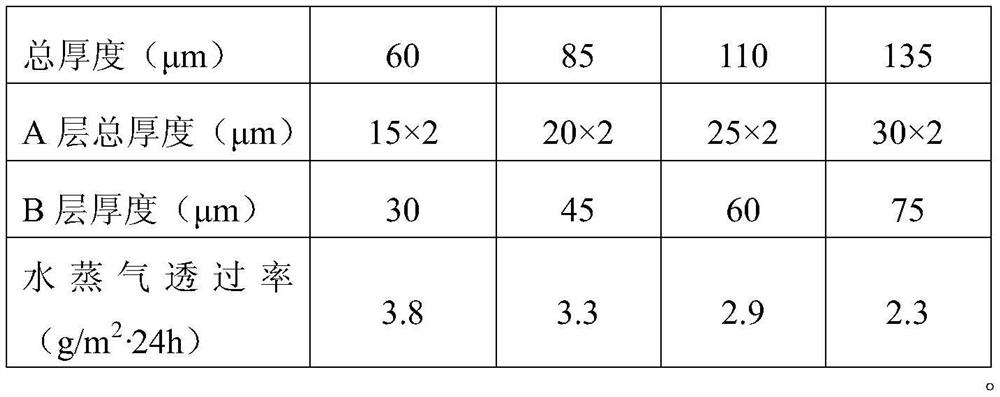

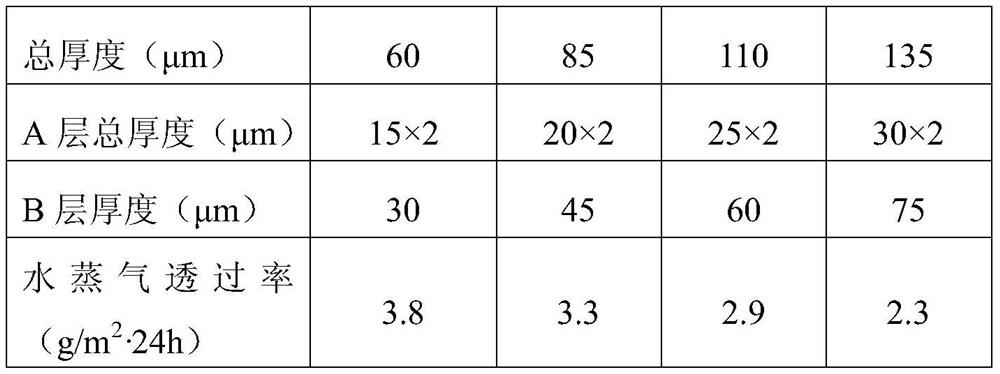

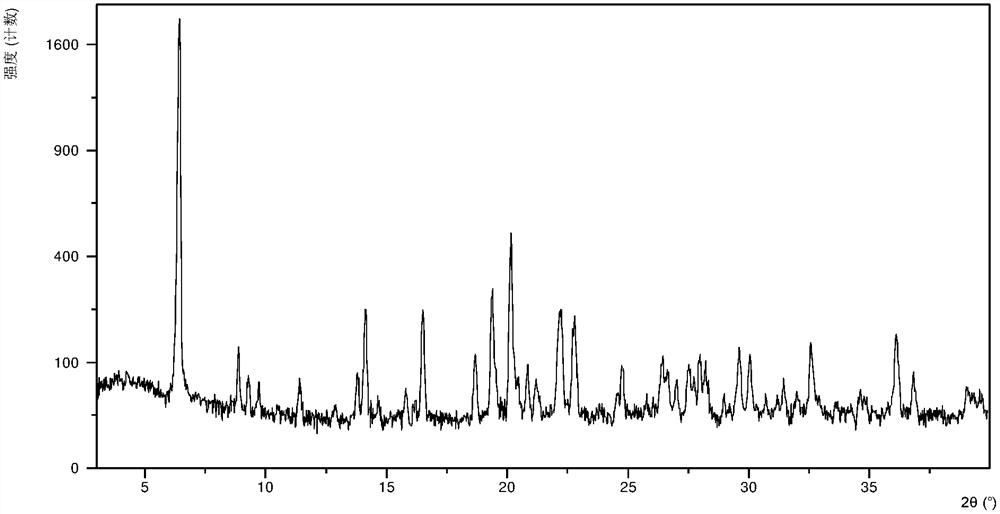

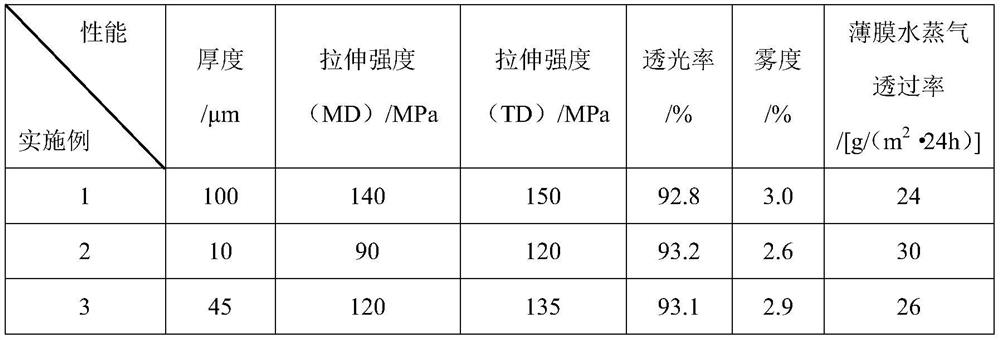

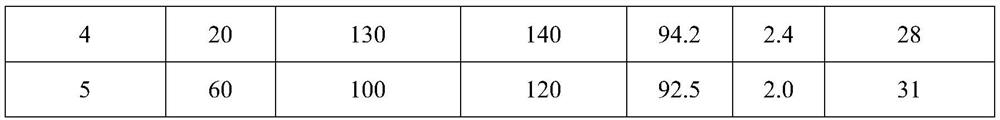

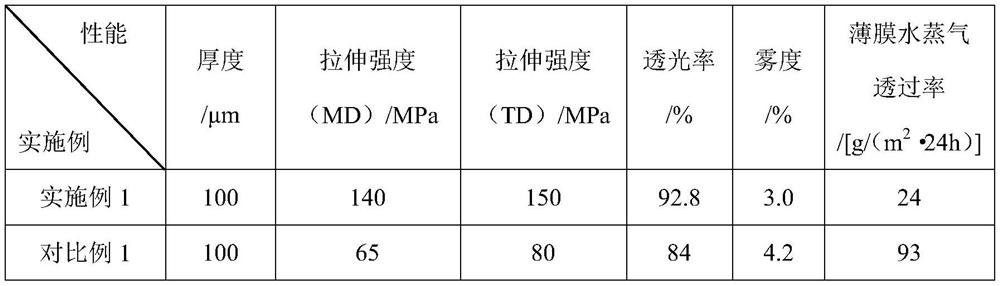

A kind of co-extruded biaxially stretched pet/pps composite film and preparation method thereof

ActiveCN109648976BHigh glass transition temperatureLower glass transition temperatureSynthetic resin layered productsXylylenePolymer science

The invention discloses a co-extruded two-way stretching PET / PPS composite film. The film is characterized in that: the film is an ABA three-layer structure composite film with a total thickness of 60-135microm, wherein the layer A is modified PPS, the layer B is modified PET, the thickness of the layer A is 15-30microm, and the thickness of the layer B is 30-75microm. The preparation method includes: preparation of modified PET resin, preparation of modified PPS resin and preparation of the co-extruded two-way stretching PET / PPS composite film. The co-extruded two-way stretching PET / PPS composite film has a low-molecular weight xylene extraction value of 0.2%-0.42%, a long-term heat resistance temperature of 155DEG C, and a water vapor permeability of 2.3-3.8g / m<2>.24h. The composite filmprovided by the invention has the characteristics of high strength and dimensional stability, high temperature resistance, low water vapor permeability, high transparency and the like, and can be used for preparation of high temperature resistant film adhesive tapes, compressor insulation films, food packaging films, etc.

Owner:四川东方绝缘材料股份有限公司

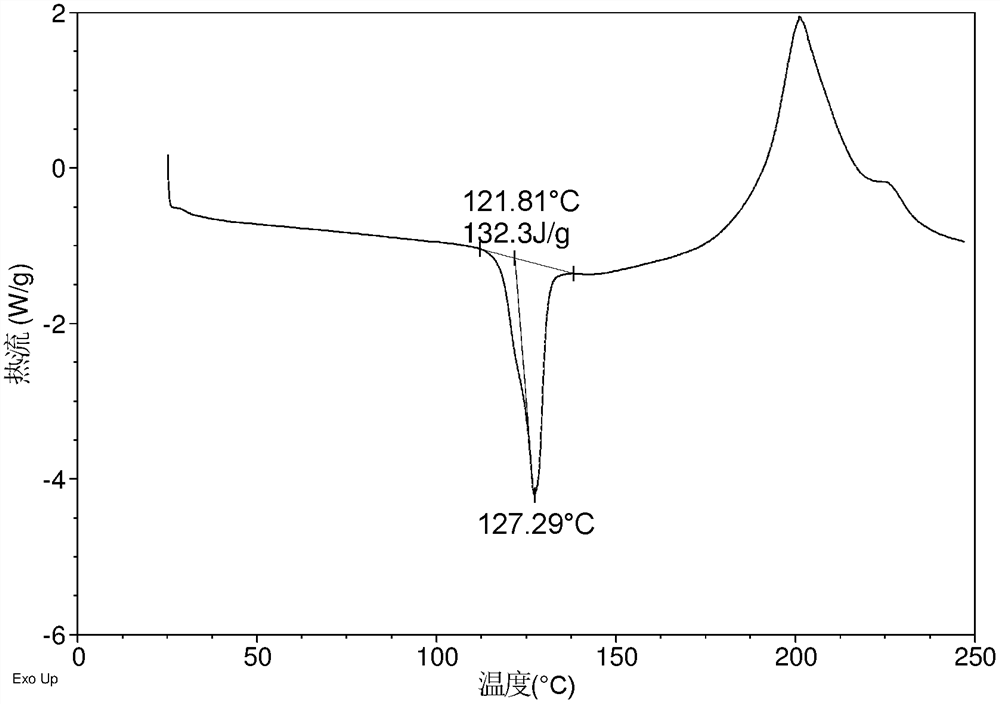

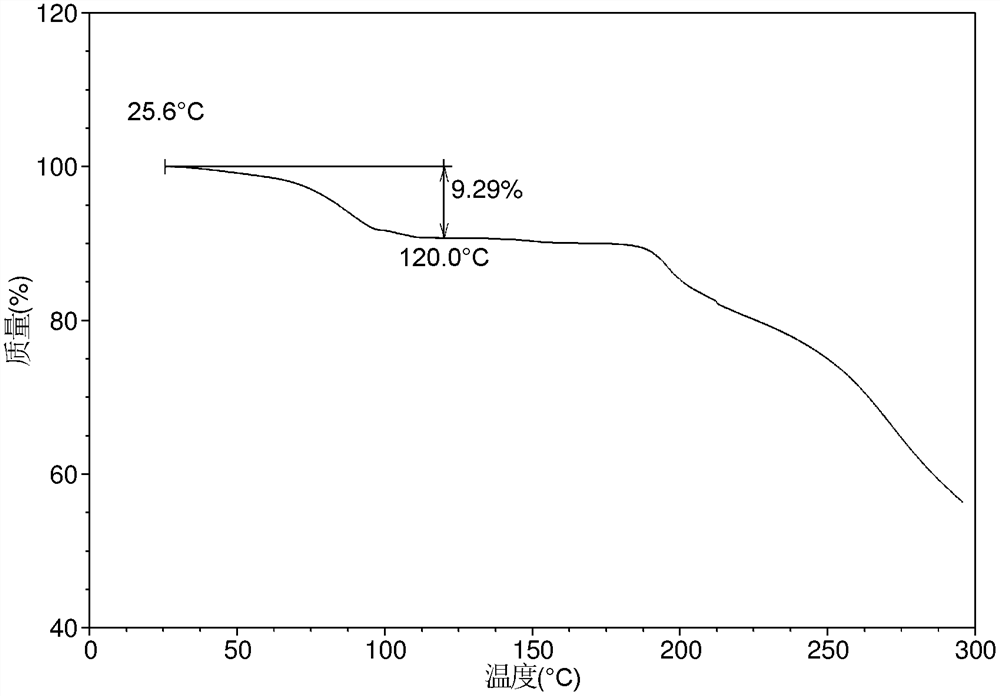

Crystal form of salt of sb-939 and its preparation method and use

ActiveCN110291071BFor long-term storageGood for quantitative accuracyOrganic active ingredientsOrganic chemistryMechanical stabilityCombinatorial chemistry

The present invention relates to the crystal form of the salt of compound (I) and its preparation method and application. The new crystal forms CS7, CS9, CS1 and CS3 provided by the present invention have low hygroscopicity, good stability, high purity, low degradation, high solubility and good mechanical stability. It provides new and better options for the preparation of drugs containing compound (I), and is of great significance for drug development.

Owner:CRYSTAL PHARMA CO LTD

Preparation method of composite fiber felt for water treatment

InactiveCN108842444AImprove adsorption capacityHigh adsorption selectivityBiochemical treatment with enzymes/microorganismsVegetal fibresCellulaseAcetic acid solution

The invention discloses a preparation method of a composite fiber felt for water treatment. The method comprises the following steps: first, hemp fiber is degummed, carded and opened; web formation isperformed by using an air-laid machine; needling and slitting are performed to obtain hemp fiber felt; modification is performed on the hemp fiber felt through a combination of acid soaking treatmentof an acetic acid solution and enzymolysis treatment of a cellulase solution; finally, socking treatment is performed by using a biomimetic mineralization solution, and the composite fiber felt for water treatment is obtained after drying. The composite fiber felt for water treatment prepared according to the invention is not liable to degrade in water, has large adsorption capacity, high adsorption selectivity, a good use effect and running stability, and a long service life.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

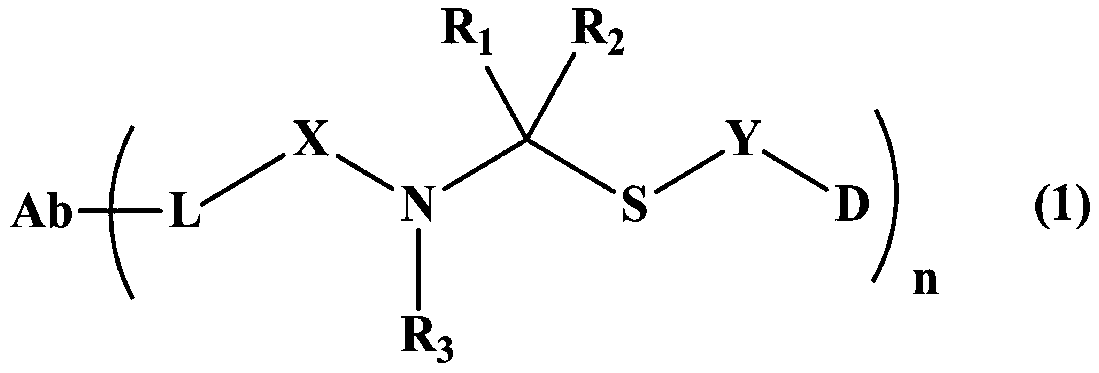

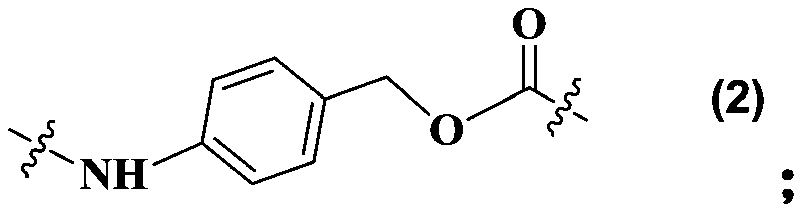

Maytansine antibody drug conjugate and application thereof

ActiveCN111195353ANot prone to degradationGood effectOrganic active ingredientsPharmaceutical non-active ingredientsAnticarcinogenic EffectAntiendomysial antibodies

The invention provides a cleavable maytansine antibody drug conjugate. An innovative structural design is adopted, one end is connected with a maytansine medicine, one end is connected with a connexon, and by using the acetal structure, spontaneous hydrolysis can be achieved in the intracellular acidic environment so as to remove chemical groups introduced on the maytansine and release the free unmodified maytansine, so the cleavable purpose is achieved, thereby the bystander effect is generated, the drug effect is enhanced, and the excellent effect is provided for solid tumor cancers; and themaytansine is more stable in vivo, is not prone to degrading before entering cells, can release maytansine only after entering the cells and being hydrolyzed, and plays an anticancer role, so that non-targeted degradation is difficult, the toxic and side effects of the ADC medicine are reduced, the treatment window of the ADC medicine is truly increased, and the druggability is improved.

Owner:MABPLEX INT LTD

A kind of solar battery backplane and its production method

ActiveCN102642364BImprove insulation performanceGood moisture and heat aging resistanceSynthetic resin layered productsPhotovoltaic energy generationThermal ageingPolyolefin

The invention provides a solar battery back sheet, which comprises a base layer, a weather-resistant layer compounded on one side of the base layer and a coating layer compounded on the other side of the base layer, and the base layer is made of polyolefin crossed under the action of a curing accelerator. Combined curing obtained. The invention provides a production method of a solar battery backboard, which comprises curing polyolefin and a curing accelerator to form a film, and performing cross-linking treatment to obtain a solar battery backplane. The solar cell back sheet of the present invention has good aging resistance and chemical stability, and is not easy to be hydrolyzed and degraded, thereby ensuring that the obtained solar cell back sheet is not easy to crack, and always maintains good insulation performance and moisture-heat aging resistance, reducing risk of component failure. The performance test results show that the solar battery back plate prepared by the invention has a breaking strength retention rate greater than 70% when exposed to ultraviolet light for 2000 hours; and a breaking strength retention rate greater than 80% when exposed to an accelerated aging environment for 2000 hours.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

A kind of fabric non-aqueous dyeing process

The invention relates to a fabric non-aqueous dyeing process, which comprises: premixing a nonionic surfactant and an auxiliary surfactant, and dissolving them in an organic solvent to prepare a reverse micellar solution; mixing the reactive dye solution Slowly inject in the reverse micelle solution and keep stirring until the reverse micelle solution changes from turbidity to clarification to obtain the reactive dye liquid encapsulated by reverse micelles; the fabric is immersed in the reactive dye liquid encapsulated by reverse micelles and Continuously vibrate at a constant temperature for adsorption dyeing until the adsorption dyeing reaches equilibrium; add a fixative solution to obtain a fixative solution encapsulated in reverse micelles, and continuously vibrate at a constant temperature to achieve color fixation on the fabric. The invention adopts the one-bath method based on nonionic surfactant to dye the fabric, which can guarantee the dyeing effect while reducing the cost; at the same time, the organic solvent is used as the medium, which can reduce the water consumption, and the organic solvent can be effectively recycled, reducing environmental pollution.

Owner:THE HONG KONG POLYTECHNIC UNIV

A kind of polyvinylidene fluoride film and preparation method thereof

ActiveCN108299772BGood weather resistanceExcellent gas barrier propertiesMicrocrystalline waxUltraviolet lights

The invention discloses a polyvinylidene fluoride film and a preparation method thereof. The film is prepared from polyvinylidene fluoride, auxiliary materials, inorganic filling materials, anti-yellowing agents, polyisobutene, sodium methyl silicate, microcrystalline wax, trichloro ethylene, maleic anhydride and ultraviolet light absorbers. According to the preparation method, the polyvinylidenefluoride, the auxiliary materials, the inorganic filling materials, the polyisobutene, the sodium methyl silicate, the microcrystalline wax, the trichloro ethylene and the maleic anhydride are mixed;then, the anti-yellowing agents and the ultraviolet light absorbers are added; uniform mixing and sheet casting are performed; next, the cast sheets are preheated; longitudinal stretching is firstly performed; then, transverse stretching is performed. The polyvinylidene fluoride film and the preparation method have the obvious advantages that the polyvinylidene fluoride film obtained through biaxial stretching has excellent weather resistance, gas blocking performance and waterproof performance; in addition, degradation and yellowing cannot easily occur under the sunlight irradiation in a short period; excellent UV-resistance performance, high transparency and high mechanical property are realized.

Owner:南京君弘新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com