A nadh drug-loaded microsphere

A technology of drug-loaded microspheres and weight ratio, which is used in drug combinations, pharmaceutical formulations, allergic diseases, etc., can solve the problems of expensive excipients, acid-intolerant half-life, low absorption and utilization rate, etc., and improve hypoxia tolerance. power, low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

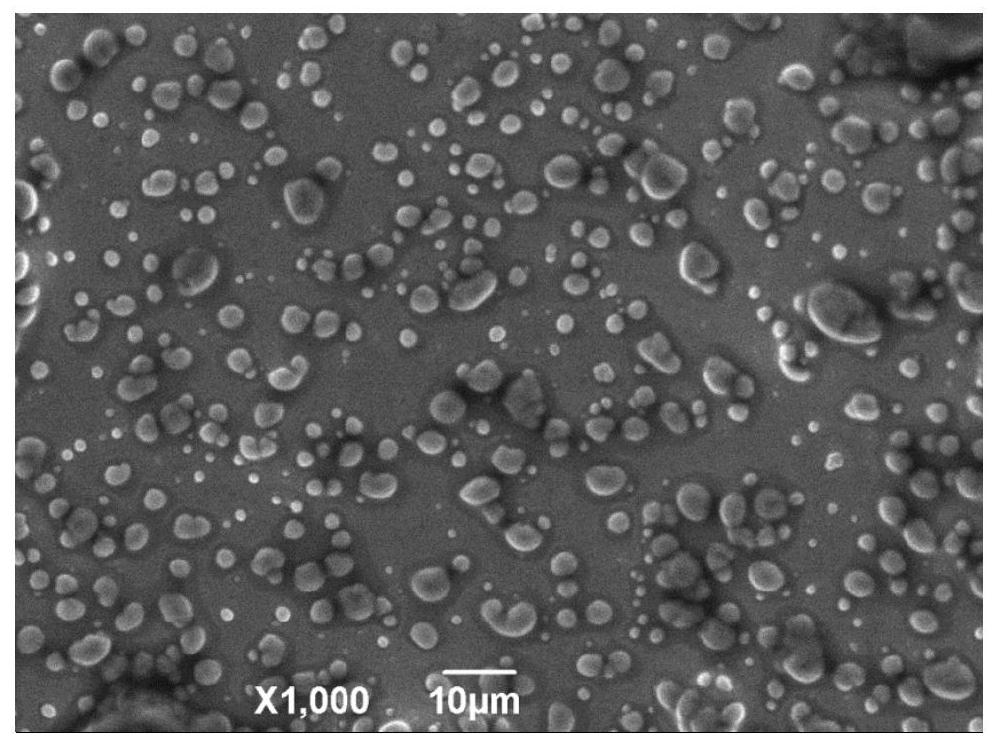

Image

Examples

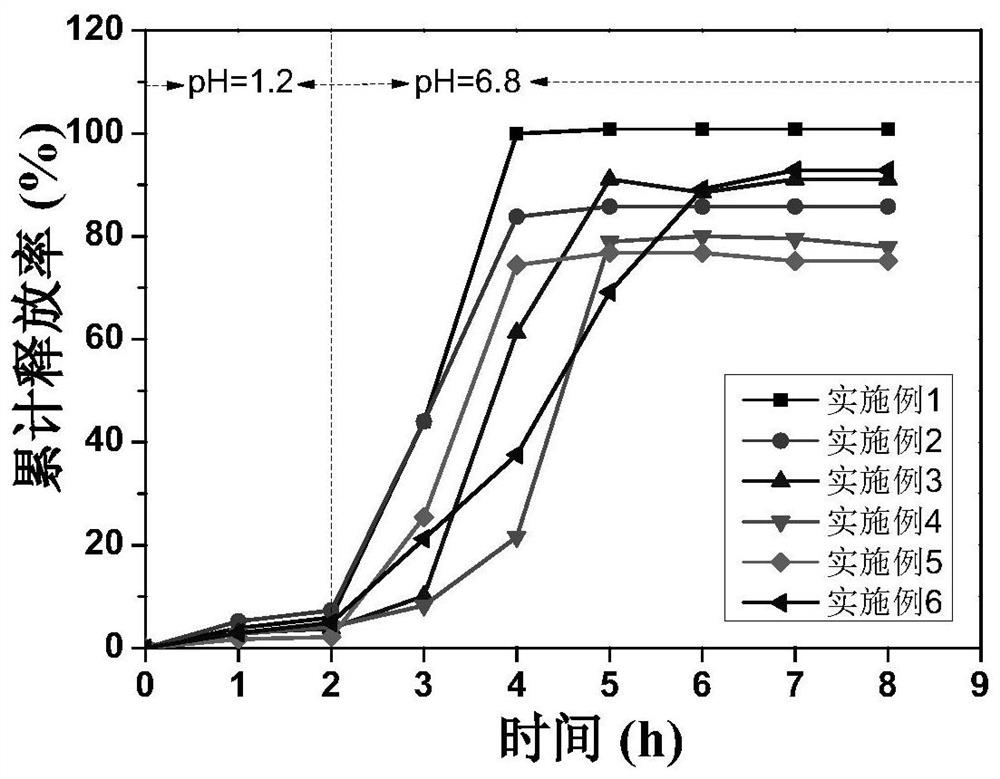

Embodiment 1

[0026]

[0027] The preparation method is as follows: Take 100g of NADH, 500g of palm oil, 150g of lard, 150g of beeswax, and 100g of proanthocyanidins, mix the above materials, stir and heat to 75°C to melt, the heating time is 20min, and the stirring speed is 200r / min (the heating temperature is too high, Too long time is not conducive to the stability of NADH); then the melted material enters the spray drying tower through a peristaltic pump, selects a 1.00mm nozzle, and controls the flow rate of the peristaltic pump to be 800mL / h (feeding speed has a great influence on the appearance and particle size of the particles). Uniformity and fluidity have important influences), the temperature of the nozzle is 110°C (the temperature of the nozzle must be slightly higher than the temperature of the material, otherwise the material is easy to solidify at the nozzle and cause blockage), the atomization pressure is 500Kpa (the atomization pressure is mainly Affect the particle size...

Embodiment 2

[0029]

[0030] The preparation method is as follows: Take 100g of NADH, 600g of soybean oil, 200g of cod liver oil, 50g of beeswax, and 50g of tea polyphenols, mix the above materials, stir and heat to 85°C to melt, the heating time is 15min, and the stirring speed is 100r / min; then the melted The material enters the spray drying tower through the peristaltic pump. The 1.00mm nozzle is selected, the flow rate of the peristaltic pump is controlled to 600mL / h, the temperature of the nozzle is 120°C, and the atomization pressure is 800Kpa, so that the melted material is atomized, and at the same time from the spray drying The bottom of the tower is fed with liquid nitrogen, and the atomized droplets are quickly cooled and solidified by the liquid nitrogen to form drug-loaded microspheres.

Embodiment 3

[0032]

[0033] The preparation method is as follows: Take 100g of NADH, 300g of olive oil, 200g of lard, 300g of laurel wax, and 100g of vitamin C, mix the above materials, stir and heat to 60°C to melt, the heating time is 60min, and the stirring speed is 150r / min; The final material enters the spray drying tower through a peristaltic pump. A 1.00mm nozzle is selected, and the flow rate of the peristaltic pump is controlled to 1000mL / h. The bottom of the drying tower is fed with liquid nitrogen, and the atomized droplets are quickly cooled and solidified by the liquid nitrogen to form drug-loaded microspheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com