A kind of polyvinylidene fluoride film and preparation method thereof

A polyvinylidene fluoride film technology, applied in the field of polyvinylidene fluoride film and its preparation, can solve the problem of poor weather resistance, gas barrier property and mechanical strength of polyvinylidene fluoride film, failure to meet material performance requirements, and material performance deterioration etc. to achieve excellent UV resistance, excellent weather resistance, transparency and increased mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

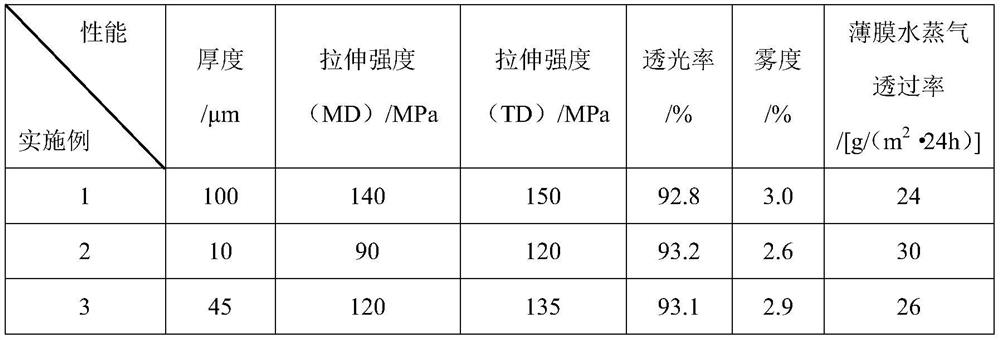

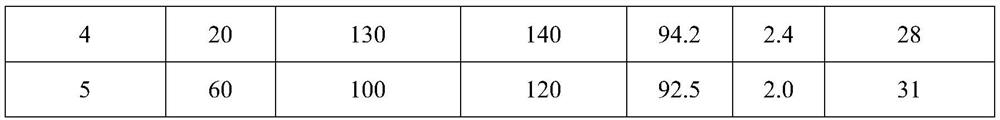

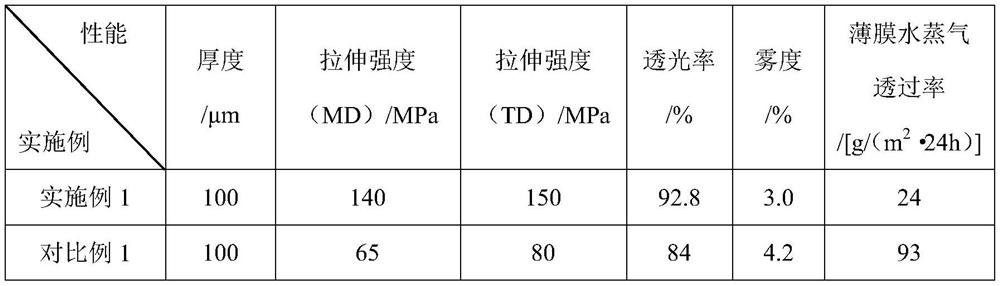

Examples

Embodiment 1

[0014] Raw material and content: 92 parts of polyvinylidene fluoride, 5 parts of polyethylene, 6 parts of calcium carbonate, 3 parts of bis(N,N-dimethylhydrazideamino-4-phenyl)methane, 4 parts of polyisobutylene, methyl 1 part of sodium silicate, 3 parts of microcrystalline paraffin, 6 parts of trichloroethylene, 7 parts of maleic anhydride and 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chloride 8 parts of benzotriazole.

[0015] The preparation method comprises the following steps:

[0016] (1) After mixing polyvinylidene fluoride, polyethylene, calcium carbonate, polyisobutylene, sodium methyl silicate, microcrystalline paraffin, trichloroethylene and maleic anhydride, add bis(N,N-dimethyl Hydrazineamino-4-phenyl)methane and 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, mixed evenly, sent to the mixer and stirred at 900rpm for 20min ;

[0017] (2) Send the above-mentioned uniformly mixed raw materials to the extruder at a speed of 200kg / h for melting, the me...

Embodiment 2

[0021] Raw material and content: 93 parts of polyvinylidene fluoride, 4 parts of polymethyl methacrylate, 6 parts of talcum powder, 2 parts of 1,6-hexamethylene-bis(N,N-dimethylsemicarbazide), 2 parts of polymethylmethacrylate 5 parts of isobutylene, 1 part of sodium methyl silicate, 3 parts of microcrystalline paraffin, 7 parts of trichlorethylene, 6 parts of maleic anhydride and 9 parts of 2-hydroxy-4-n-octyloxybenzophenone.

[0022] The preparation method comprises the following steps:

[0023] (1) Mix polyvinylidene fluoride, polymethyl methacrylate, talcum powder, polyisobutylene, sodium methyl silicate, microcrystalline paraffin, trichloroethylene and maleic anhydride and add 1,6-hexaethylene Methyl-bis(N,N-dimethylsemicarbazide) and 2-hydroxy-4-n-octyloxybenzophenone, mixed evenly, sent to the mixer and stirred at 800rpm for 30min;

[0024] (2) Send the uniformly mixed raw materials to the extruder at a speed of 100kg / h for melting, and the melting temperature is 180°C...

Embodiment 3

[0027] Raw material and content: 93 parts of polyvinylidene fluoride, 6 parts of polypropylene, 7 parts of silicon dioxide, 3 parts of bis(N,N-dimethylhydrazideamino-4-phenyl)methane, 4 parts of polyisobutylene, 2 parts of sodium silicate, 2 parts of microcrystalline paraffin, 6 parts of trichloroethylene, 8 parts of maleic anhydride and 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chloro 7 parts of benzotriazoles.

[0028] The preparation method comprises the following steps:

[0029] (1) Add bis(N,N-dimethyl Hydrazide amino-4-phenyl)methane and 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole, mix well and send to the mixer to stir at 1000rpm 10min;

[0030] (2) Send the uniformly mixed raw materials to the extruder at a speed of 300kg / h for melting, and the melting temperature is 180°C, then filter through 100 mesh, flow out of the die head at a speed of 30r / min after metering feedback, and flow out at a speed of 30m / min speed for casting;

[0031] (3) Preheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com