Patents

Literature

42results about How to "Less prone to yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

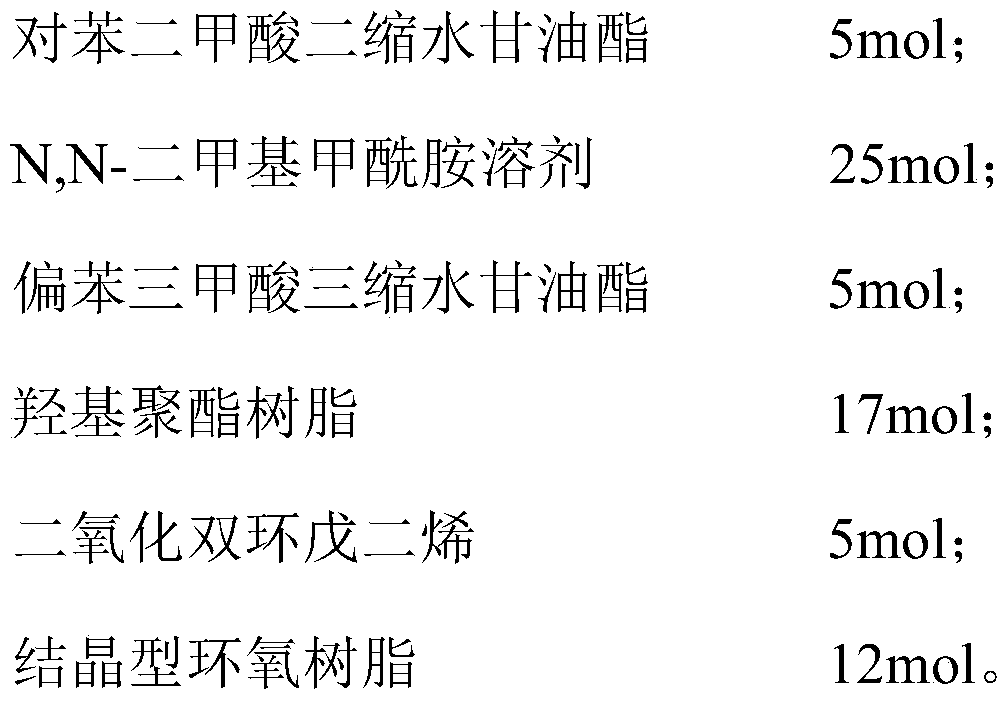

Elastic waterproof sealant, preparation method thereof, and roof waterproof structure formed by eastic waterproof sealant

ActiveCN103555255ANo pollution in the processBonding is versatileNon-macromolecular adhesive additivesBuild-up roofsDioctyl terephthalateUltraviolet

The invention discloses an elastic waterproof sealant comprising 15-25 parts of alpha-dimethoxysilane-terminated polyether resin, 20-30 parts of gamma-trimethoxysilane-terminated polyether resin, 5-10parts of dioctyl terephthalate, 40-55 parts of nano-calcium carbonate, 0.1-5 parts of fumed silica, 0.5-5 parts of titanium dioxide, 0.1-1 part of carbon black, 0.1-0.5 parts of an ultraviolet absorber, 0.1-0.5 parts of a light stabilizer, 0.5-1 parts of a dehydrating agent, 0.5-1 parts of an adhesion promoter. The invention also discloses a preparation method of the elastic waterproof sealant, and a roof waterproof structure formed by the elastic waterproof sealant. The elastic waterproof sealant has the advantages that: the elastic waterproof sealant is harmless to human; a roof waterproofstructure formed by the elastic waterproof sealant can form a completely closed waterproof layer; construction is simple, and waterproof effect is excellent.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

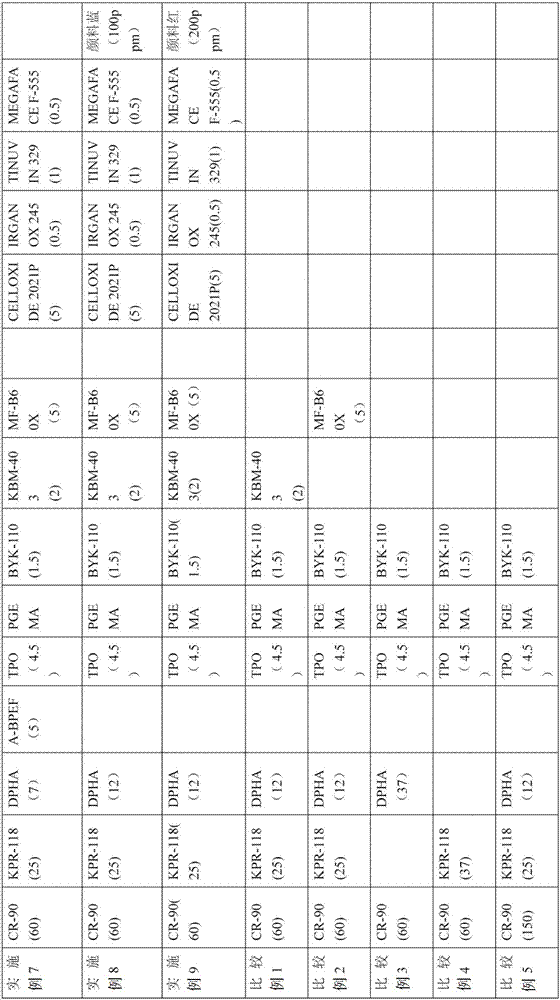

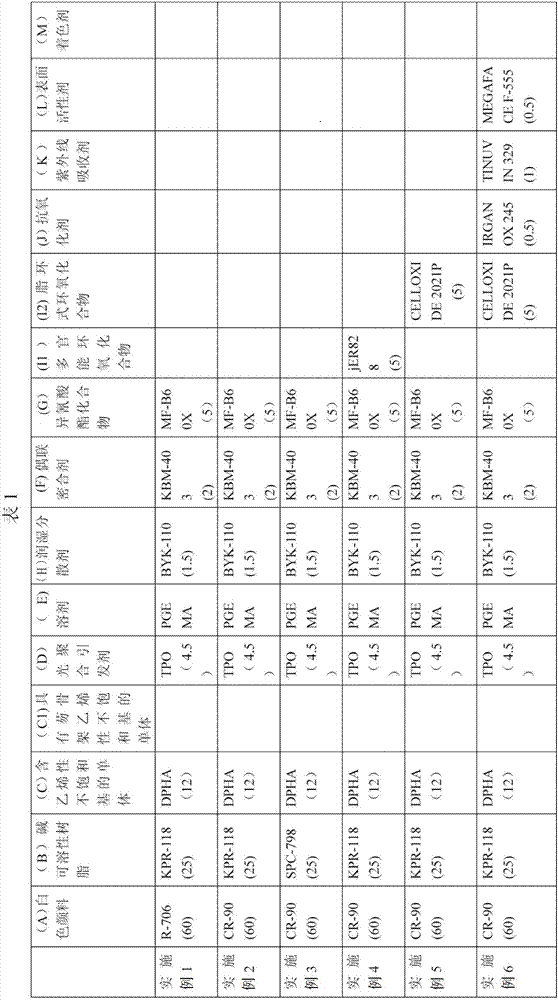

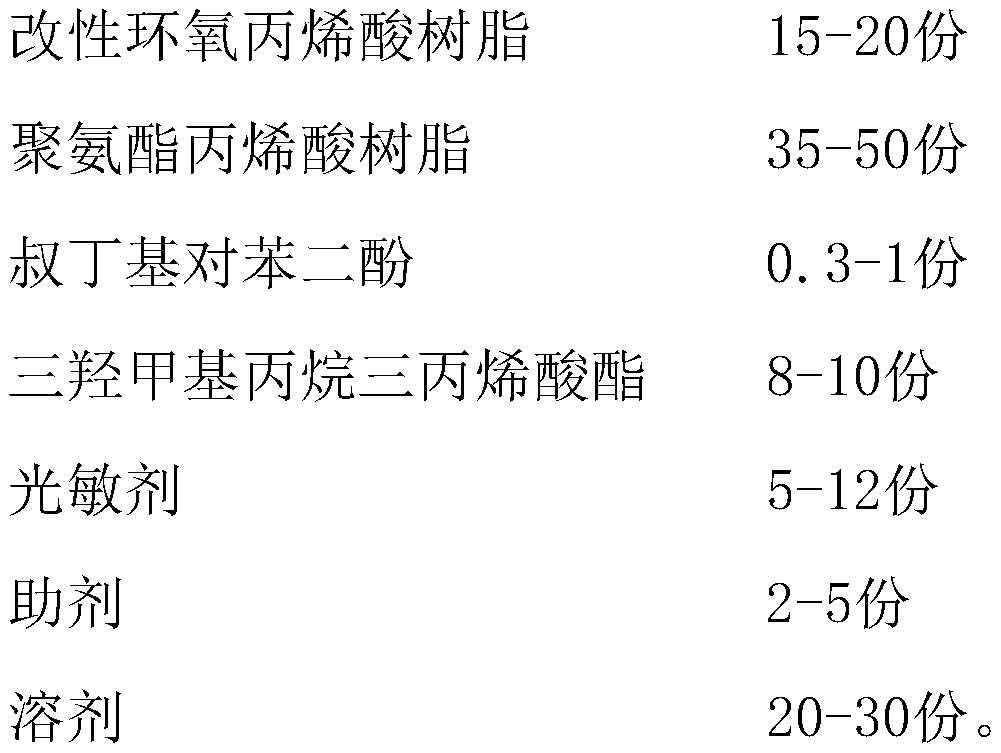

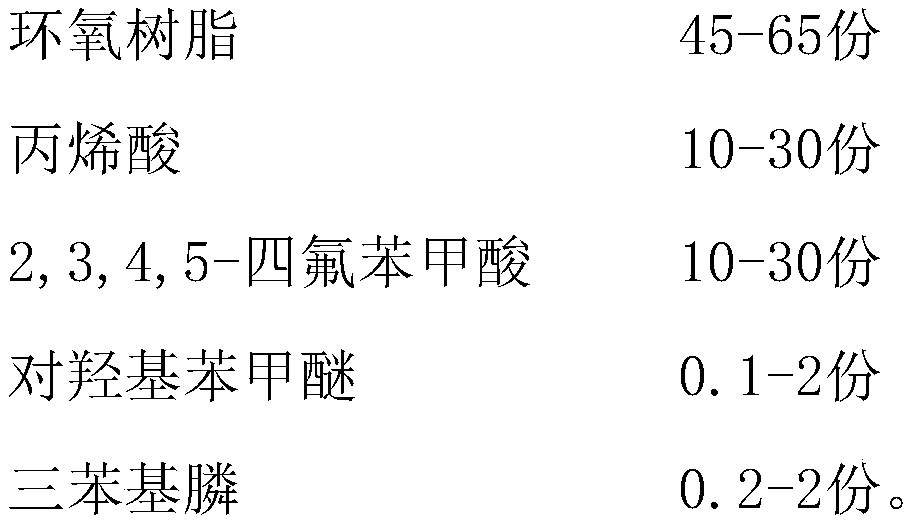

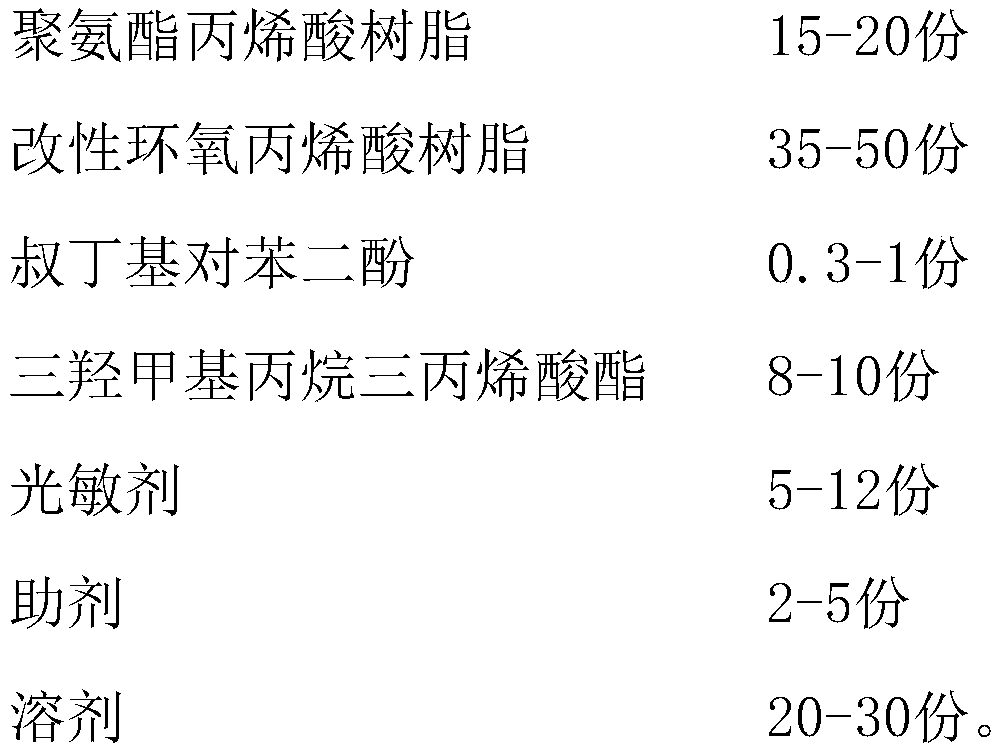

Negative photosensitive white ink for 3D cover plate glass and preparation method and application method thereof

InactiveCN107957655ALess prone to yellowingSimple processInksPhotosensitive materials for photomechanical apparatusCouplingHigh reflectivity

Negative photosensitive white ink for 3D cover plate glass and a preparation method and application method thereof are provided. The negative photosensitive white ink for 3D cover plate glass comprises a white pigment, alkali-solvable resin, a monomer containing ethylene unsaturated groups, a photopolymerization initiator, a solvent, a coupling sealant, and isocyanate compounds. By spraying the ink to 3D cover plate glass and using exposure-development process, a white shade pattern having good film thickness, high resolution, high reflectivity and good shading property can be formed. A pattern formed via the ink is rarely suffered from yellowing, stripping, line breakage or the like.

Owner:广州亦盛环保科技有限公司

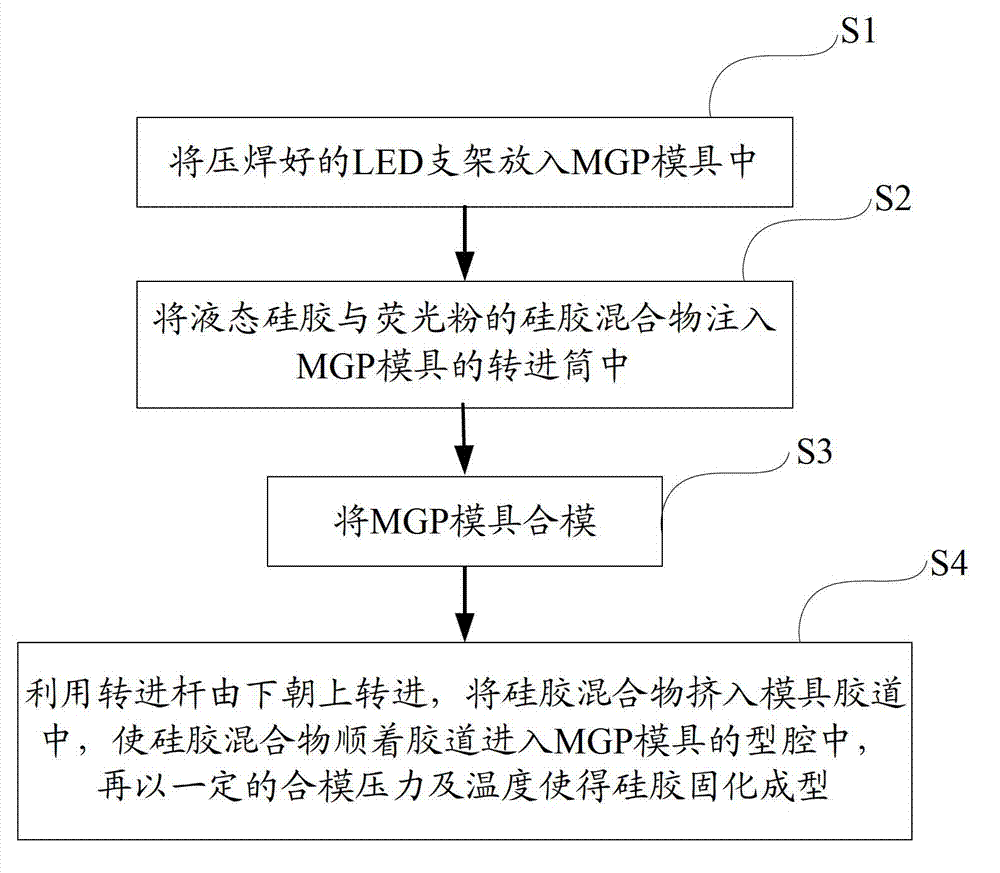

Light-emitting diode (LED) mold pressing packaging process and LED assembly

InactiveCN102922661AGood high and low temperature performanceImprove reliabilitySemiconductor devicesEngineeringSilica gel

The invention provides an LED mold pressing packaging process. The process comprises the steps of placing an LED support which is subjected to press welding in a metal gauze packing (MGP) mold; 2), injecting a silica gel mixture of liquid silica gel and fluorescent powder into a rotating cylinder of the MGP mold; 3), clamping the MGP mold; and 4), performing rotation by using a rotating rod from bottom to top, squeezing the silica gel mixture into a mold gel channel, so that the silica gel mixture enters into a cavity of the MGP mold along the gel channel, and subjecting the silica gel to curing and shaping through certain mold clamping pressure and a certain temperature. The LED mold pressing packaging process is achieved through the MGP mold, the silica gel mixture is cured and shaped, the LED packaging is completed, compared with a process that epoxy glue is used for sealing, the process has the advantages that the silica gel is used for sealing, the reliability of the LED packaging can be improved, and the service life of an LED is prolonged. The invention also provides an LED component, and the component is produced through the LED mold pressing packaging process.

Owner:SUZHOU DONGSHAN PRECISION MANUFACTURING CO LTD

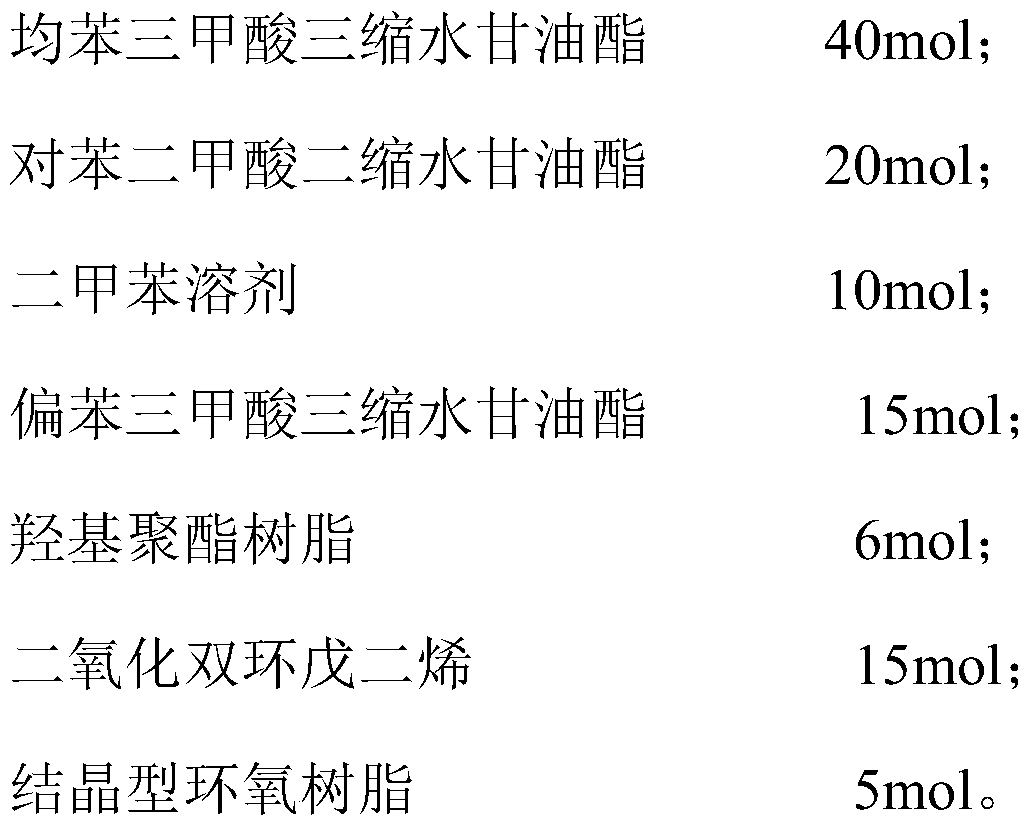

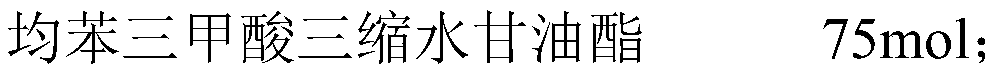

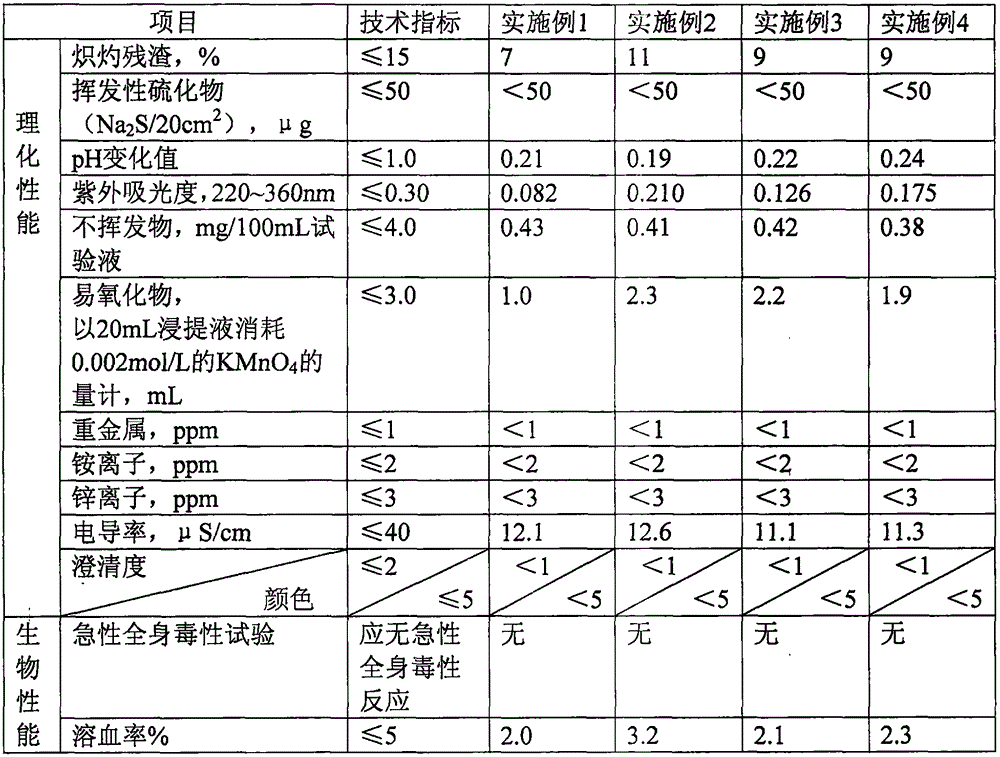

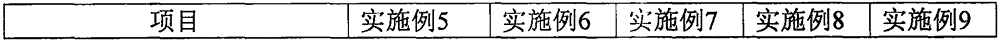

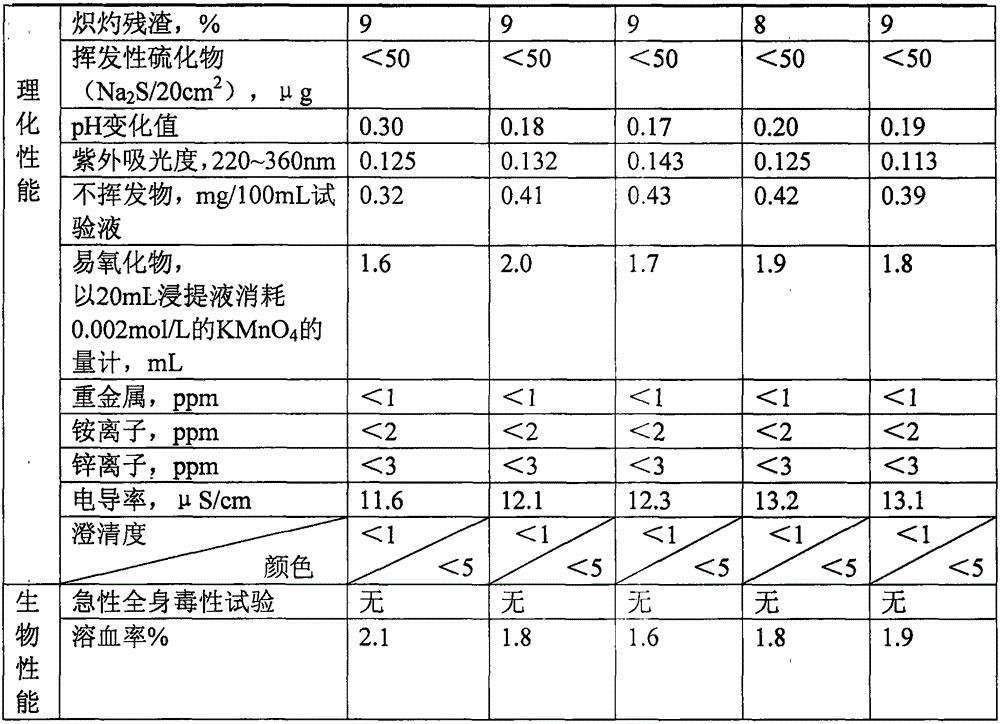

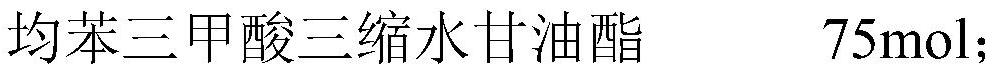

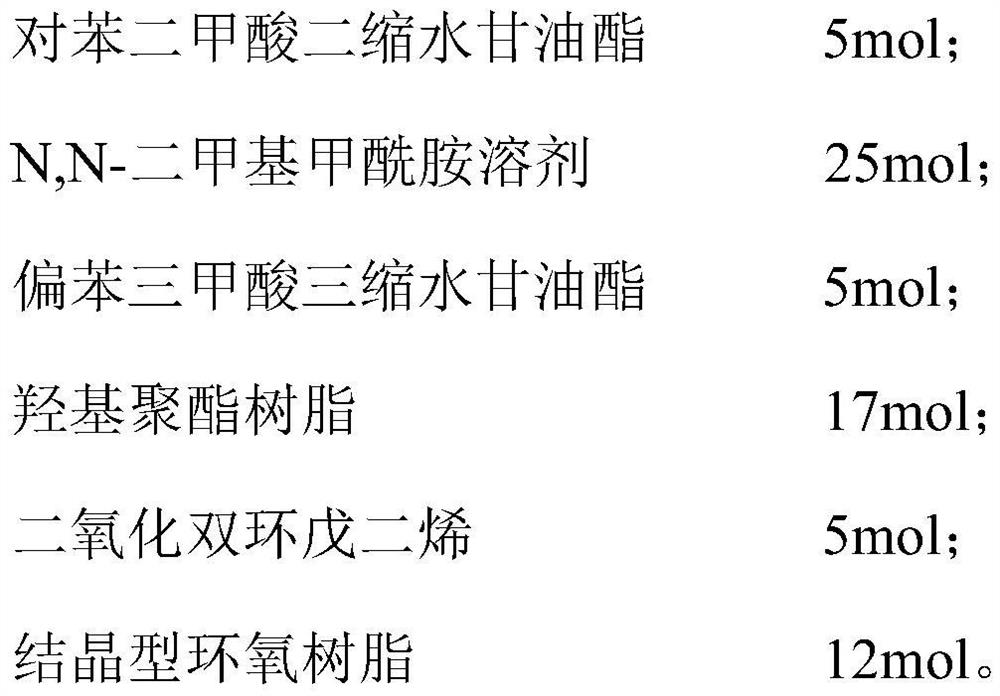

Compound curing agent used for polyester-type powder paint and production method and application thereof

ActiveCN109852127AGood curing effectHigh epoxy equivalentPowdery paintsPolyester coatingsEpoxyTrimellitic acid

The invention belongs to the technical field of powder paint, particularly relates to a compound curing agent used for polyester-type powder paint, and further discloses a production method and application of the compound curing agent used for the polyester-type powder paint. The compound curing agent used for the polyester-type powder paint is mainly produced by using trimesic acid,tris(2,3-epoxypropy)ester and diglycidyl terephthalate as main raw materials and selectively adding 1,2,4-benzenetricarboxylic acid,tris(2,3-epoxypropy)ester, hydroxy polyester resin, bicyclopentadiene dioxide and / or crystalline epoxy resin for mixing reaction. The compound curing agent used for the polyester-type powder paint has a good curing effect, the mechanical performance of a produced coating is stable,and meanwhile, the coating has good boiling-resistant performance; and when the compound curing agent used for the polyester-type powder paint and polyester resin are cured, the performance of a product of the compound curing agent used for the polyester-type powder paint and the polyester resin totally reaches curing effects of current TGIC and HAA curing agents, and the compound curing agent used for the polyester-type powder paint and an existing TGIC or HAA product can be mixed for use, so that the comprehensive performance is more excellent.

Owner:安徽泰达新材料股份有限公司

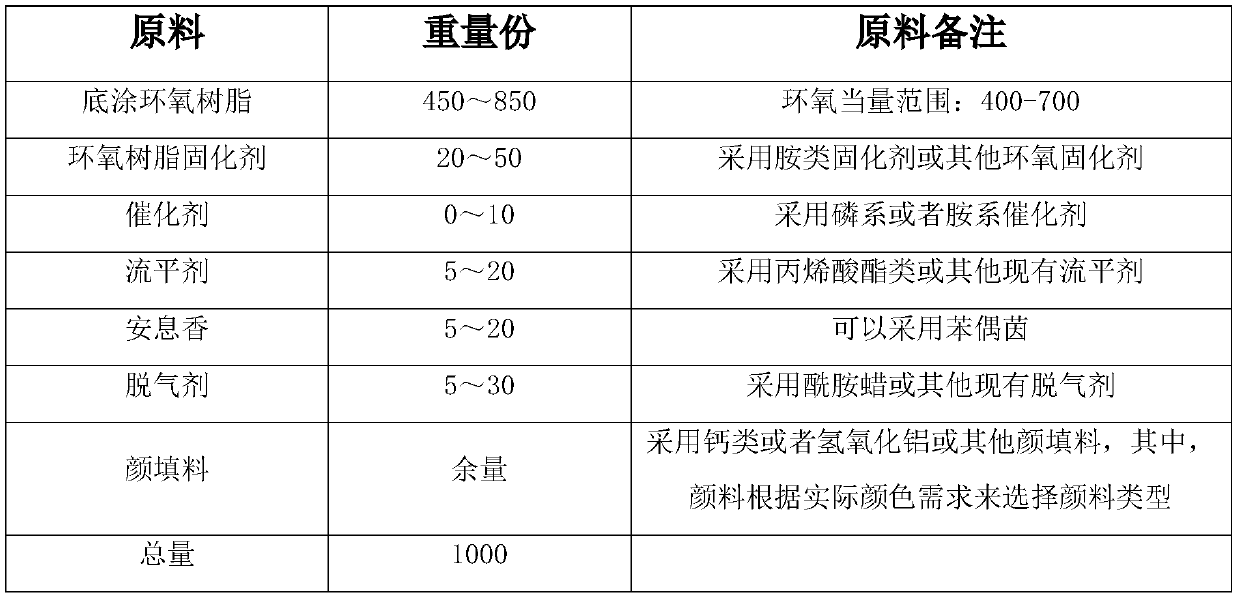

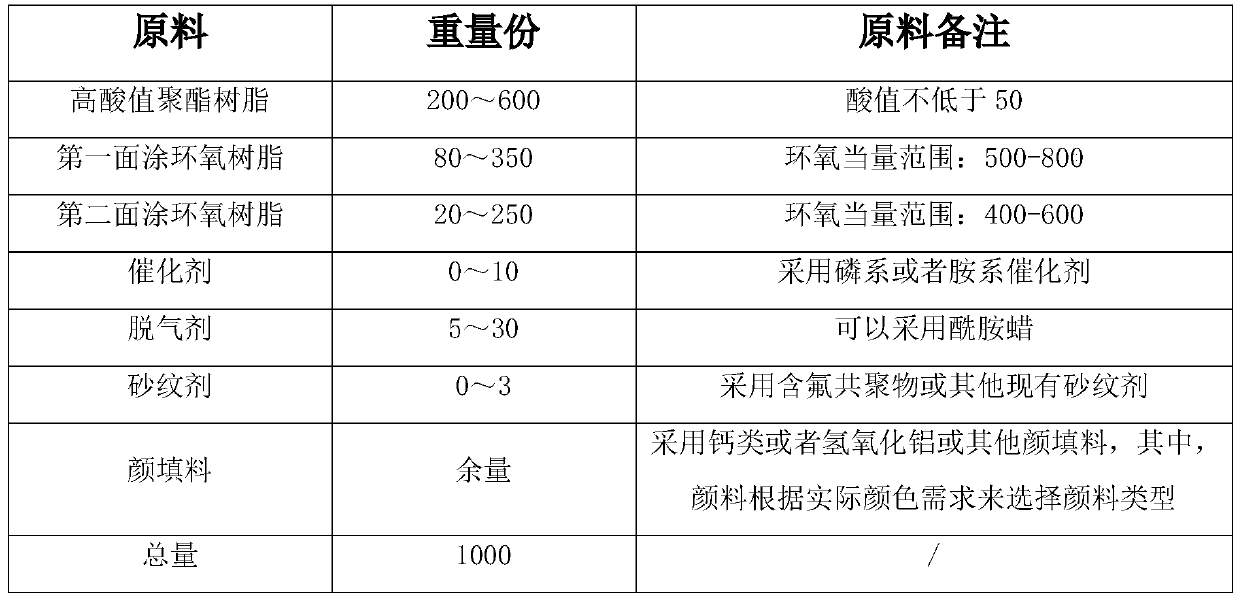

Multi-paint composition system of low temperature rapidly cured powdery paints, coating method thereof, and coating

PendingCN110804377AEnsure Stable Storage PerformanceGood sealingPretreated surfacesPowdery paintsEpoxyPolymer science

The invention discloses a multi-paint composition system of low temperature rapidly cured powdery paints, a coating method thereof, and a coating. The system comprises a prime coating powdery paint for the prime coating of a basic material and a top coating powdery paint for the top coating of the basic material. The prime coating powdery paint comprises prime coating epoxy resin with an epoxy equivalent of 400 to 700. The top coating powdery paint comprises high acid value polyester resin with an acid value not lower than 50 and one or more top coating epoxy resins with an epoxy equivalent of400 to 800. The raw materials are picked, the design of the coating structure is innovative, the stable storage performance of the powdery paint and the excellent protective performance of the coating can be maintained, low temperature rapid curing with a lower curing temperature and shorter curing time can be realized, the system is especially for coating a thermal sensitive basic material suchas MDF, and the coating has an excellent surface resistance performance.

Owner:TIGER DRYLAC TAICANG

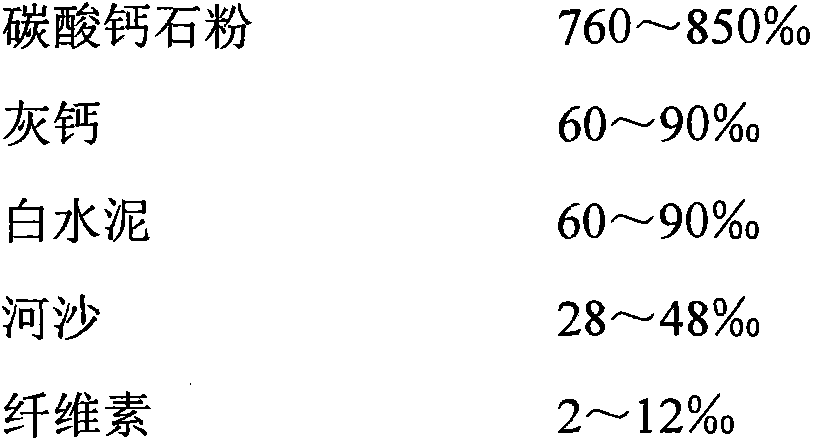

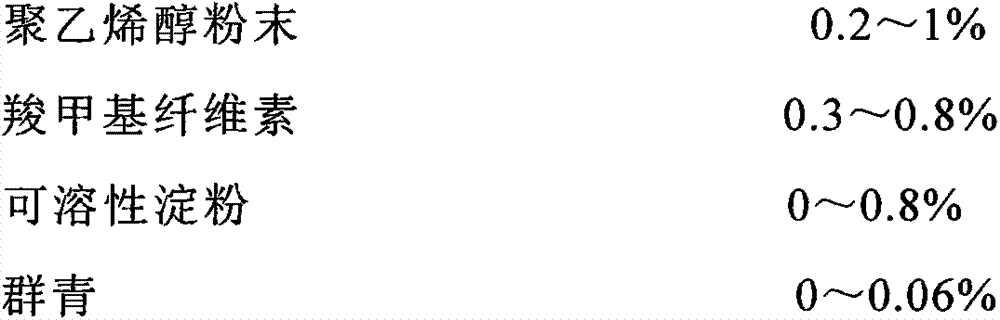

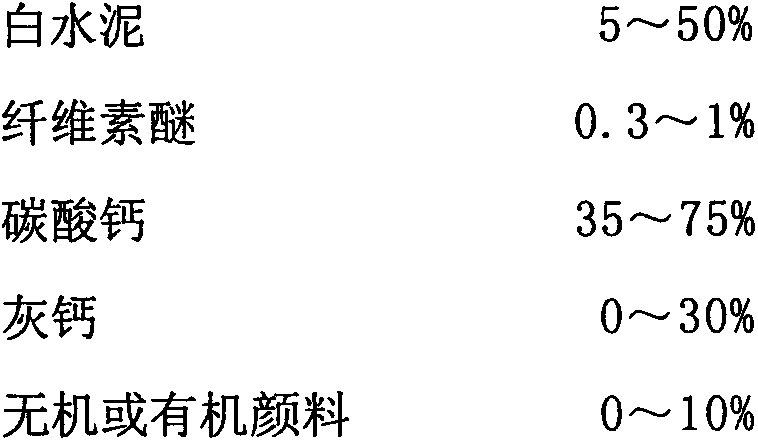

Alkali-free interior wall putty powder

InactiveCN103113776AGuaranteed aestheticsLess prone to yellowingFilling pastesEnvironmental resistanceAlkali free

The invention discloses an alkali-free interior wall putty powder, and relates to the interior wall putty powder of a wall decorative material. The alkali-free interior wall putty powder is prepared from calcium carbonate powder, polyvinyl alcohol powder, carboxymethyl cellulose, soluble starch and ultramarine blue. The alkali-free interior wall putty powder has the characteristics of simple preparation technology, low transportation cost, low cost of raw materials and high bonding strength, has no any volatile and pungent odor and the like. A yellowing phenomenon is difficult to appear by painting the putty powder on a wall surface for too long time; and the yellowing and floating phenomena are difficult to appear by constructing on an old wall surface. Other emulsion paints or wallpapers are added in the putty powder again, and the floating condition of emulsion paints or wallpapers is unlikely to be caused, so that the putty powder belongs to green and environment-friendly wall decoration. The putty powder can be widely used for the wall decoration of new and old interior walls, and particularly suitable for interior wall decoration of places such as an upscale guild hall, a hotel, a restaurant, a conference center and a family.

Owner:CHONGQING UNIV

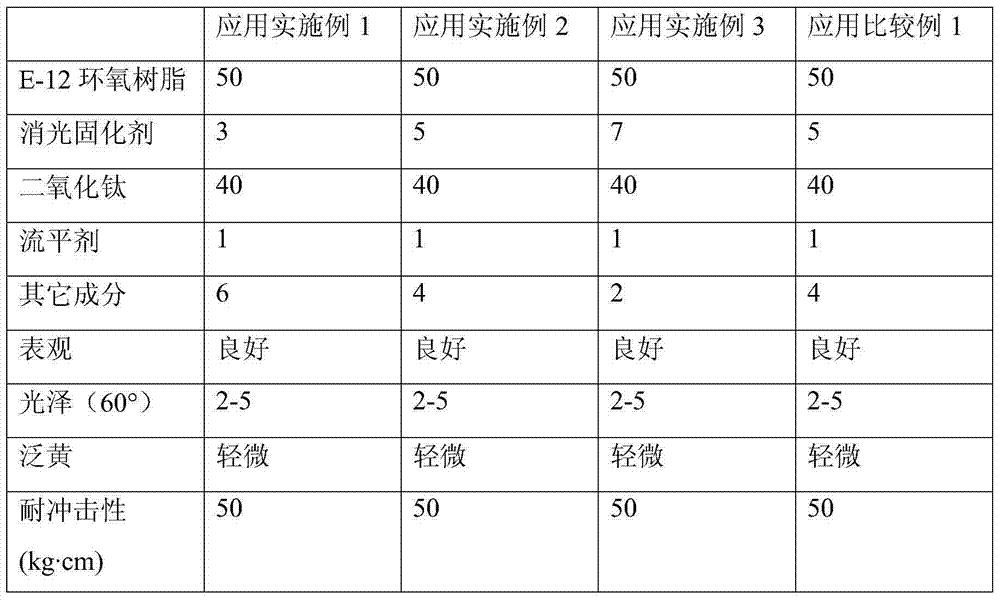

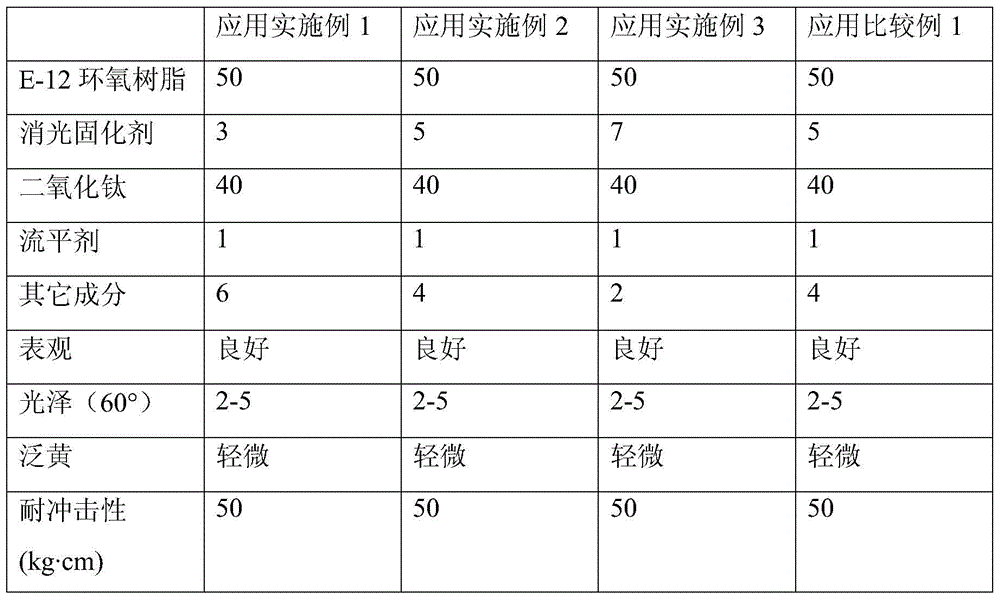

Extinction curing agent for epoxy resin powder coating, preparation method of extinction curing agent and powder coating composition

ActiveCN104744989AGood mattingStable mechanical propertiesPowdery paintsEpoxy resin coatingsEthylenediamineEpoxy

The invention discloses an extinction curing agent for an epoxy resin powder coating. The extinction curing agent is prepared by reaction between polybasic acid and polyamine, wherein the polybasic acid consists of the following components: 60-80mol% of a copolymer containing fumaric acid and methylfumaric acid in a mole ratio of 1:1 and Mn of 800-1200, 10-25mol% of tartaric acid, 5-10mol% of citric acid, and 1-5mol% of 1,2-diamino-cyclohexane tetracetic acid; and the polyamine consists of the following components: 5-30mol% of ethidene diamine, 45-75mol% of diethylenetriamine and 10-55mol% of o-phenylenediamine. Besides, the invention also discloses a method for preparing the extinction curing agent and a powder coating composition containing the extinction curing agent. The extinction curing agent disclosed by the invention is good in extinction effect and stable in mechanical property, is good in baking resistance, cannot become yellow easily, and can basically achieve the extinction effect of a B68 extinction curing agent, and the use cost is significantly reduced.

Owner:HUANGSHAN ZHONGZE NEW MATERIAL CO LTD +1

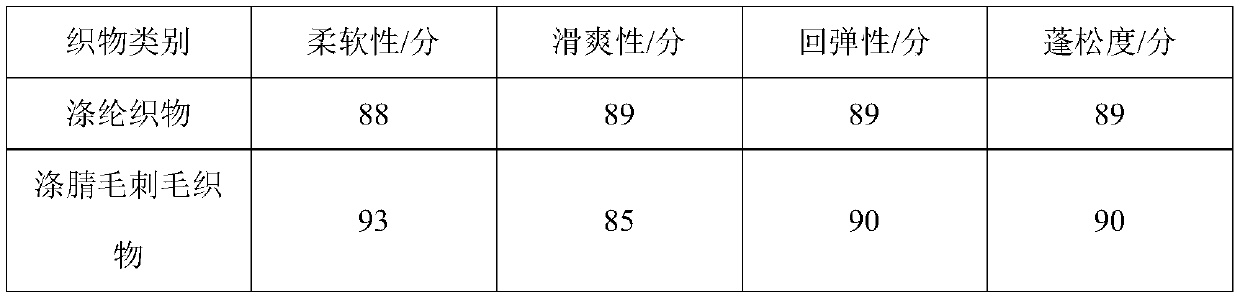

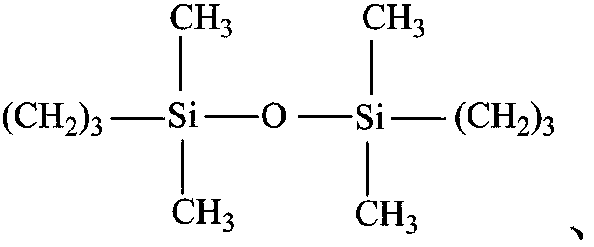

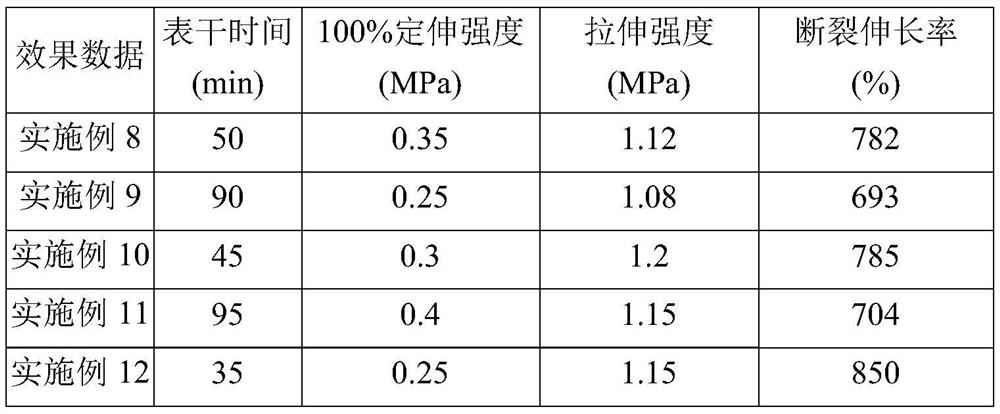

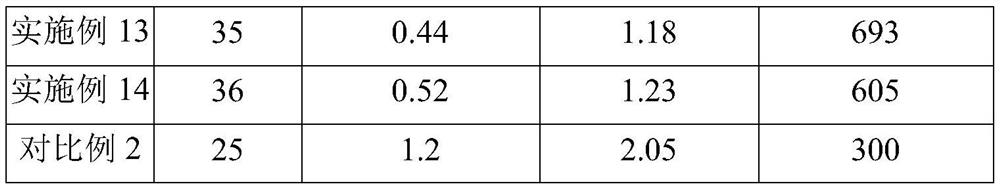

High-safety non-yellowing viscoelastic softening finishing agent and preparation method thereof

ActiveCN110820352AImprove stabilityFeel smoothBiochemical fibre treatmentGrip property fibresCelluloseOrganic acid

The invention relates to the technical field of softening finishing agents, in particular to a high-safety non-yellowing viscoelastic softening finishing agent and a preparation method thereof. The softening finishing agent comprises the following components in parts by weight: 15-25 parts of silicone oil, 8-12 parts of polyvinyl alcohol, 1-2 parts of hydroxymethyl cellulose, 1-3 parts of an antibacterial agent, 5-10 parts of an emulsifier, 1-2 parts of organic acid, 1-2 parts of an aloe extract, 3-8 parts of a solvent and 10-15 parts of water. The high-safety non-yellowing viscoelastic softening finishing agent has the advantages of good hand feeling, good hydrophilicity, high stability and no influence on the whiteness of a fabric.

Owner:多恩生物科技有限公司

Non-alkali interior wall 2-in-1 dry powder paint

InactiveCN103159430AGuaranteed flatness and beautyNot easy to yellowHydroxypropylmethyl celluloseEmulsion

The invention relates to a non-alkali interior wall 2-in-1 dry powder paint, which relates to an interior wall paint of an interior wall decoration material. The non-alkali interior wall 2-in-1 dry powder paint is prepared by heavy calcium carbonate powder, bentonite, polyvinyl alcohol powder, hydroxypropyl methyl cellulose and inorganic or organic pigment. The non-alkali interior wall 2-in-1 dry powder paint has the characteristics of simple making technology, low transportation cost, low raw material price, high bonding strength, no various chemical auxiliary agents in a traditional emulsion paint, no smell with volatility and irritation. The wall surface shaved by the dry powder paint has no yellowing discolouration phenomenon easily, and the phenomena of yellowing discolouration and floating are not easily generated while constructing on the old wall surface. The dry powder paint is taken as a putty surface, other emulsion paints or wallpapers can be added, thereby the floating condition of the emulsion paint or wallpaper are not generated easily, the dry powder paint belongs to green environmental protection wall surface decoration. The 2-in-1 dry powder paint can be widely used for decorating the new wall surface and old wall surface, and can be widely used in high-grade club houses, hotels, restaurants, conference centers, families and the like.

Owner:CHONGQING UNIV

Polyethersulfone micropowder, preparation method and application thereof

The invention discloses polyethersulfone micropowder, a preparation method and an application thereof, and aims to solve the technical problem of high energy consumption, large particle size distribution and low purity of materials produced in our country. The polyethersulfone micropowder is a micropowder prepared by forming a dispersion liquid system having micro-turbid status from polyethersulfone, a mixed solvent and water, then solidifying, separating and drying the system. The preparation method includes: weighing the polyethersulfone, mixed solvent and water according to weight ratio; dissolving the polyethersulfone in the mixed solvent to form a colloid solution; adding the colloid solution to water, uniformly dispersing the mixture, and filtering the mixture to obtain a filter cake; washing the filter cake with water by 2-3 times by mass of the filter cake, uniformly dispersing the filter cake, and filtering the liquid; repeatedly washing the material for 2-3 times; and dryingthe filtered precipitate to obtain the product. The polyethersulfone micropowder is applied to preparation of coating materials. The preparation method is extensive in raw material source, is simple in preparation method and low in energy consumption, is free of pollution and can be extensively applied to the field of high-molecular polymers.

Owner:开封夸克新材料有限公司

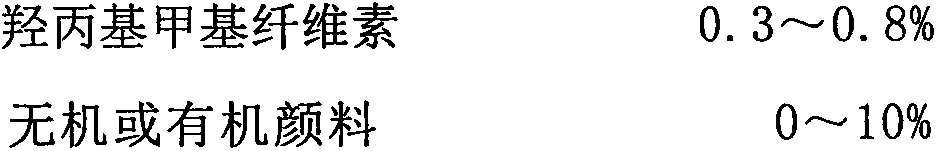

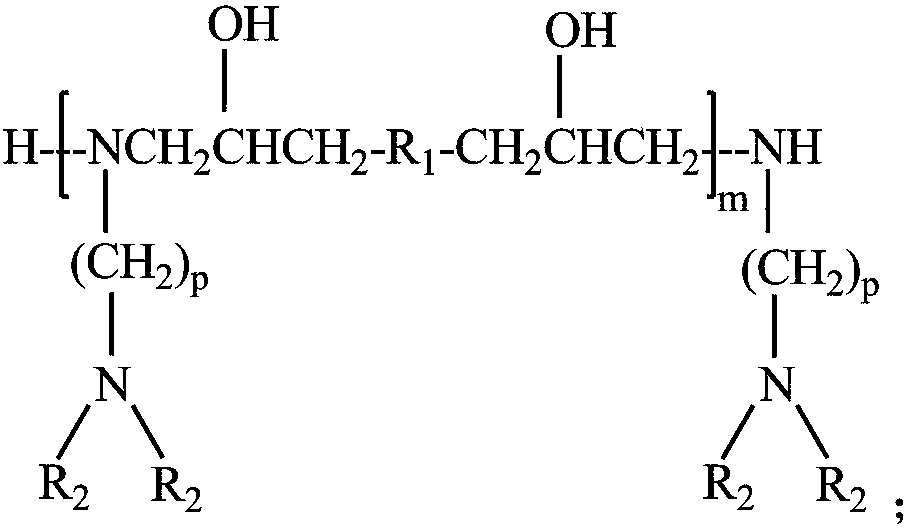

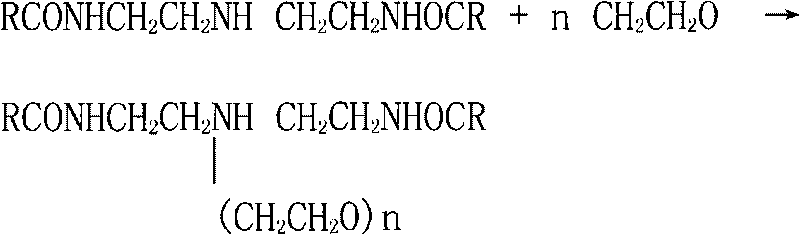

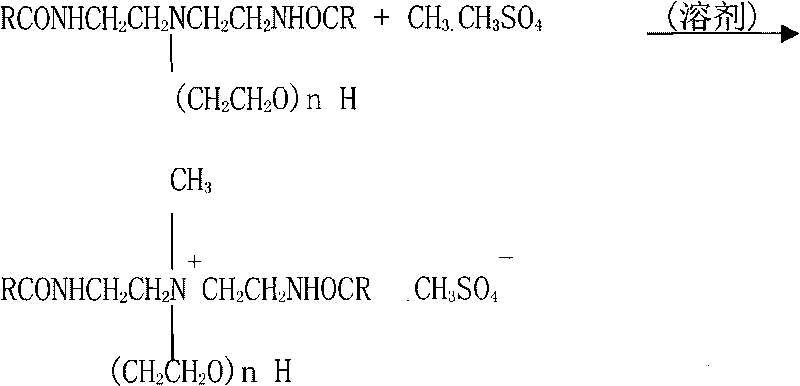

Preparation method and application of main chain embedded terminal amino silicon oil with side chain containing tertiary amino group

ActiveCN107759794AGood directional adsorption effectHigh ammonia valueGrip property fibresVegetal fibresChemistryBackbone chain

The invention discloses a preparation method and application of main chain embedded terminal amino silicon oil with a side chain containing a tertiary amino group. The preparation method comprises thestep: with a side tertiary amino group-containing secondary amine end-capping linear comb-shaped epoxy polyamine compound and end epoxy (polyether) silicone oil as raw materials and an organic solvent as a reaction medium, performing an aminolysis ring-opening reaction of the epoxy group to prepare the main chain embedded terminal amino silicon oil with the side chain containing the tertiary amino group. Then a novel embedded terminal amino silicon oil softening agent for fabric softening and finishing is obtained by adjusting the pH to 5 to 6 with glacial acetic acid, and adding an environment-friendly emulsifier for mechanical emulsification. Compared with the existing main chain embedded terminal amino silicon oil softening agent, the novel embedded terminal amino silicon oil softeningagent has more excellent hand feeling.

Owner:SICHUAN TEXTILE SCI RES INST +1

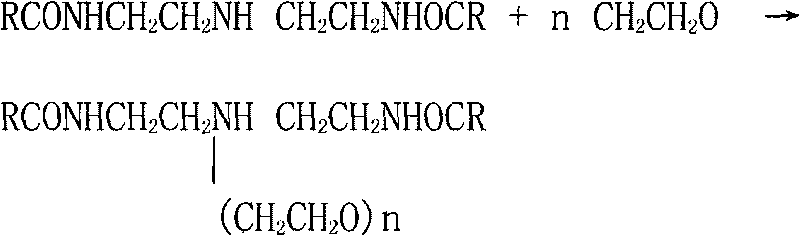

Hydrophilic softening agent and preparing method thereof

InactiveCN101736581AImprove hydrophilicityEasy to degradeNon-fibrous pulp additionFibre treatmentHazardous substancePapermaking

The invention discloses a hydrophilic softening agent and a preparing method thereof. The hydrophilic softening agent contains 70%-90% of quaternary softening agent active matter, and 10%-30% of anhydrous low-carbon solvent with low boiling point or anhydrous water-soluble solvent with high boiling point. The softening agent is free from phosphorus and the harmful substances of alkylphenol ethoxylates, formaldehyde and the like, can be biologically degraded, has the soft, hydrophilic and anti-static functions, and is used for the after treatment of cellulose fiber and the softening arrangement of papermaking, leather and the like.

Owner:苏州联胜化学有限公司

Graphene regenerated EVA (ethylene-vinyl acetate) forming sole colloidal particle and preparation method thereof

The invention discloses a graphene regenerated EVA (ethylene-vinyl acetate) forming sole colloidal particle and a preparation method thereof. The colloidal particle is prepared from, by weight, 22-28parts of ethylene-vinyl acetate copolymers, 45-50 parts of ethylene-vinyl acetate copolymer scrap grinding powder, 13-17 parts of oxidic polyethylene, 4-7 parts of graphene, 1-2 parts of carboxylatedgraphene, 2-4 parts of antioxidants, 1.5-3 parts of light stabilizers and 3-5 parts of zinc stearate. According to the graphene regenerated EVA forming sole colloidal particle, raw materials are carefully selected, a formula is reasonable, the graphene regenerated EVA forming sole colloidal particle serves as an EVA forming sole material, the colloidal particle has the advantages of high tensile strength, tearing strength and rebound rate, good bending resistance and rebound resilience, low size shrinkage rate and the like, the performances of the forming sole colloidal particle is close to even superior to those of marketing EVA sole materials, the EVA is recycled, the utilization rate of the EVA is increased, costs of raw materials are reduced, and the colloidal particle is more environmentally friendly.

Owner:FUJIAN WUCHIHENG TECH DEV CO LTD

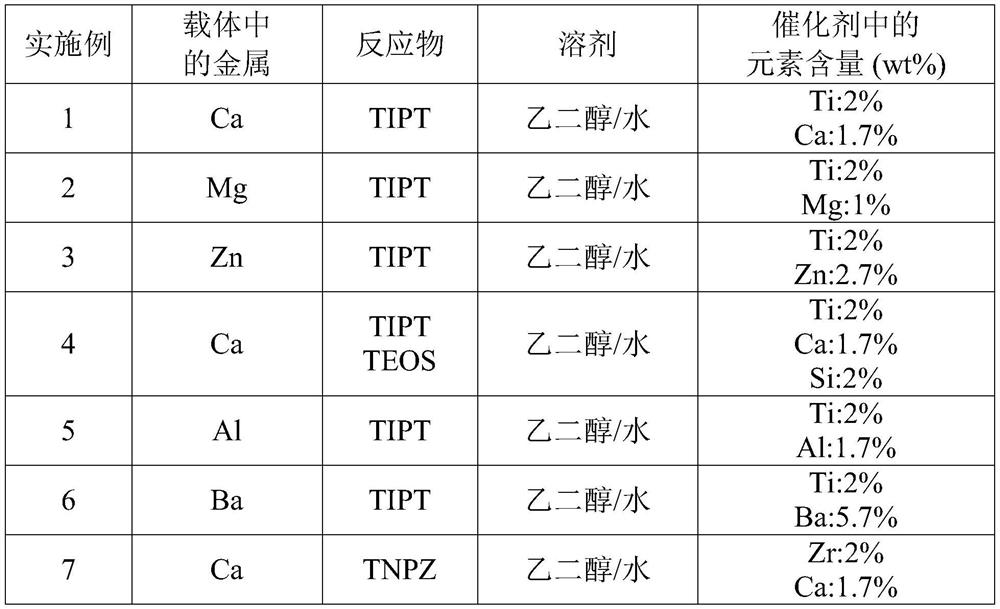

Catalyst for catalyzing esterification reaction and synthesis method thereof

The invention relates to a catalyst for catalyzing esterification reaction and a synthesis method thereof. The catalyst comprises a polar solvent, a plurality of carriers and a plurality of metal coordination polymers. These carriers are dispersed in a polar solvent and include a hydroxide of a metal, an oxide of a metal, a chloride of a metal, a nitride of a metal, a sulfide of a metal, an oxideof silicon, or a combination thereof. These metal coordination polymers include titanate hydrolysates, aluminate hydrolysates, zirconate hydrolysates, or combinations thereof. Some metal coordinationpolymers are attached to the carriers to form a plurality of microparticles having an average particle size in the range of 10 nm to 1 [mu]m. Other metal coordination polymers are dispersed in a polarsolvent. The catalyst is good in dispersity and has a good catalytic effect. Moreover, the polyester obtained by catalyzing the esterification reaction by utilizing the catalyst has good brightness and chroma, and the yellowing problem and the yarn breaking problem are not easy to occur.

Owner:BORICA CO LTD

Polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and preparation method of polyvinyl chloride color masterbatch

InactiveCN109096652AMix evenly and stablyHigh degree of polymerizationPolyvinyl chlorideColoring problem

The invention relates to polyvinyl chloride color masterbatch suitable for high-speed production of automobile wires and cables and a preparation method of the polyvinyl chloride color masterbatch. The active components of the polyvinyl chloride color masterbatch consist of the following raw materials in parts by weight: 45-55 parts of polyvinyl chloride, 5-12 parts of titanium dioxide, 4-8 partsof a brightening agent, 3-6 parts of a calcium zinc stabilizer, 1-3 parts of oxidized polyethlene wax, 1-3 parts of a surface treating agent, 1-3 parts of zinc stearate, 1-3 parts of a coupling agentand 25-35 parts of pigment. The polyvinyl chloride and the oxidized polyethlene wax are pre-stirred, so that substrate materials are stable and uniform when being mixed, the polymerizing degree is higher, when the temperature of masterbatch substrates is lower than that of squeezed materials, diverging and coloring of masterbatch are facilitated, the fusion degree of the masterbatch substrate materials and the squeezed materials is increased, and high-speed squeezing is facilitated; and through measures of added materials and a production technology, the masterbatch materials are more suitablefor high-speed squeezing of automobile wires and cables, the production efficiency is greatly improved, and unnecessary losses caused by color problems are reduced.

Owner:山东寰宇线缆有限公司

UV-LED curable clear ink composition for ink jet printing

ActiveUS10550275B2Improve adhesionExcellent curabilityDuplicating/marking methodsInksPolymer scienceFunctional monomer

An UV-LED curable clear ink composition for ink jet printing including 44 to 80% by mass of a photo-polymerizable mono-functional monomer, 15 to 50% by mass of a photo-polymerizable poly-functional monomer and 5 to 15% by mass of an acylphosphine photo-polymerization initiator, and having a viscosity at 25° C. of 1 to 50 mPa·s, wherein the photo-polymerizable mono-functional monomer and the photo-polymerizable poly-functional monomer include a photo-polymerizable monomer having at least one of functional groups including an amide group and an amino group, and the photo-polymerizable monomer is contained in an amount of 5 to 20% by mass based on a total amount of photo-polymerizable mono-functional monomer and photo-polymerizable poly-functional monomer.

Owner:SAKATA INX

Softening agent applied to linen fabric and preparation method thereof

InactiveCN109056337AHigh whitenessControl contentVegetal fibresAdditive ingredientSurface-active agents

The invention discloses a softening agent applied to a linen fabric and a preparation method thereof. The softening agent is prepared from the following ingredients in parts by weight: 100 parts of modified polysiloxane, 32 to 48 parts of hydroxyl-terminated polymethyl hydrosiloxane, 21 to 33 parts of polydimethylsiloxane, 11 to 19 parts of an emulsifier, 9 to 15 parts of organic acid, 21 to 33 parts of chitosan and 8 to 15 parts of a surface active agent. After being treated by the softening agent disclosed by the invention, the linen fabric has soft hand feeling; furthermore, a wearing effect is obviously improved, the linen fabric can still keep good softness after being used for a long time and washed for many times, and the linen fabric is not prone to yellow.

Owner:SUZHOU INSILK CO LTD

Process for preparing printed matter with gravure fission effect

ActiveCN110588195AImprove adhesionNot easy to appear edgeInksOther printing apparatusDetonationHigh volume manufacturing

The invention relates to the technical field of printing, and in particular to a process for preparing printed matter with a gravure fission effect. The process for preparing the printed matter with the gravure fission effect comprises the following steps that step A, UV fission ink is printed on a carrier material through a gravure plate; and step B, the carrier material printed with the UV fission ink is sequentially subjected to UV detonation treatment and UV drying and curing treatment to obtain the printed matter with the gravure fission effect. The process for preparing the printed matter with the gravure fission effect is simple to operate, easy to control and high in production efficiency, the printed matter is enabled to have the obvious gravure fission effect, and the cured ink has relatively good adhesion on the carrier material, the phenomena of edge rising, warping and the like are not prone to occurring, relatively good weather resistance and aging resistance are achieved, the phenomenon of yellowing or fading is not prone to occurring, the quality is stable, and the process for preparing printed matter with the gravure fission effect can be used for mass production

Owner:东莞智源彩印有限公司

Waterborne wood paint with high weather resistance and production method of waterborne wood paint

InactiveCN108587352AAvoid damageImprove performanceAntifouling/underwater paintsPaints with biocidesPROPYLENE GLYCOL BUTYL ETHERWeather resistance

The invention discloses a waterborne wood paint with high weather resistance and a production method of the waterborne wood paint. The waterborne wood paint with high weather resistance comprises thefollowing raw materials in parts by weight: 30-40 parts of waterborne acrylic resin, 15-25 parts of waterborne polyurethane resin, 0.3-0.7 part of defoaming agent, 0.2-1 part of substrate wetting agent, 2-5 parts of dipropylene glycol monobutyl ether, 2-4 parts of dipropylene glycol methyl ether, 1-3 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 0.5-1 part of kathon mildewcide, 0.3-0.6part of wetting agent, 1-2 parts of water repellent, 1-3 parts of waterproof agent, 1-3 parts of dry film mildewcide, 0.1-0.5 part of polysiloxane, 0.2-0.5 part of flatting agent, 0.3-0.8 part of hindered amine light stabilizer, 0.5-1 part of ultraviolet light absorber, 0.2-0.5 part of polyurethane tackifier, 0.3-0.8 part of acrylic tackifier and 10-20 parts of deionized water.

Owner:东莞市家美环保涂料有限公司

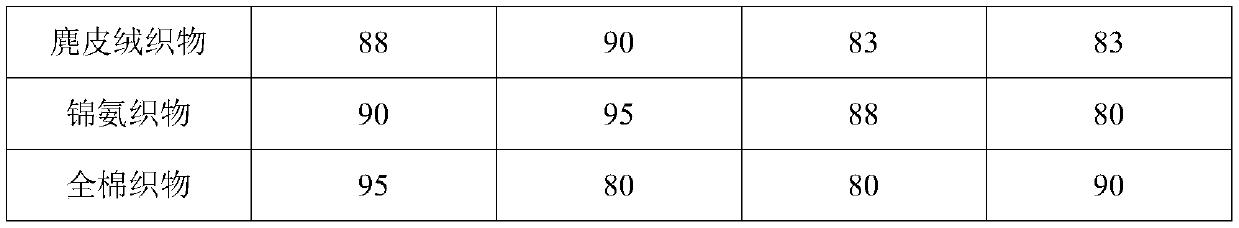

Water washing method for denim fabric and denim fabric

PendingCN114836971AHigh color fastnessLess prone to yellowingOther chemical processesDry-cleaning apparatus for textilesColour fastnessDenim

The invention relates to the field of fabric after-finishing, and discloses a denim fabric washing method and denim fabric, and the denim fabric washing method comprises the following steps: desizing the denim fabric; performing chlorine bleaching treatment on the denim fabric; an adsorbent is added in the chlorine bleaching treatment process; performing cellulase washing treatment on the denim fabric; the denim fabric is subjected to drying treatment; and carrying out padding treatment on the jean fabric. According to the denim fabric washing method provided by the invention, by optimizing the washing process, the denim fabric can be endowed with a vintage style, the color fastness of the denim fabric can be improved, methods for destroying a fiber structure, such as ozone and alkali treatment, do not need to be added after the last washing process, staining of the bottom surface of the fabric can be effectively reduced, and the service life of the denim fabric is prolonged. And the denim fabric is not easy to yellow.

Owner:GUANGDONG FORWARD DENIM

Matting curing agent for epoxy resin powder coating and its preparation method and powder coating composition

ActiveCN104744989BGood mattingStable mechanical propertiesPowdery paintsEpoxy resin coatingsEpoxyExtinction

Owner:HUANGSHAN ZHONGZE NEW MATERIAL CO LTD +1

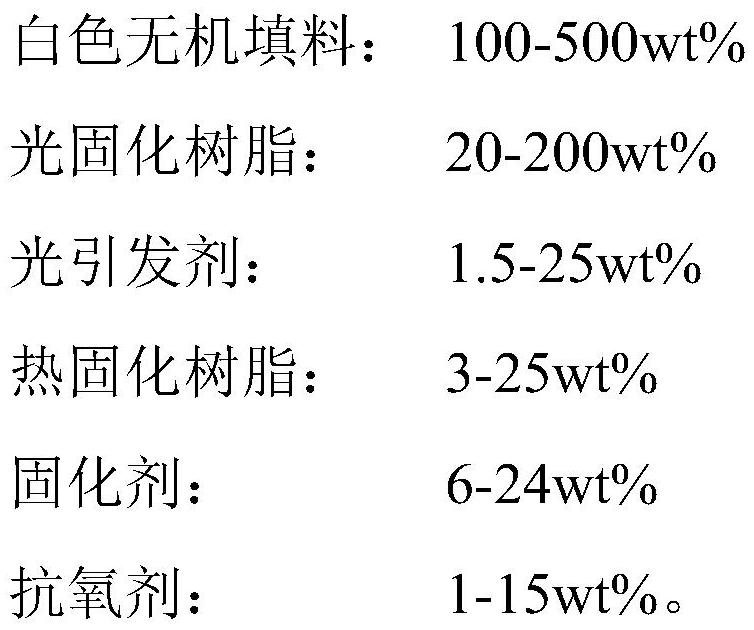

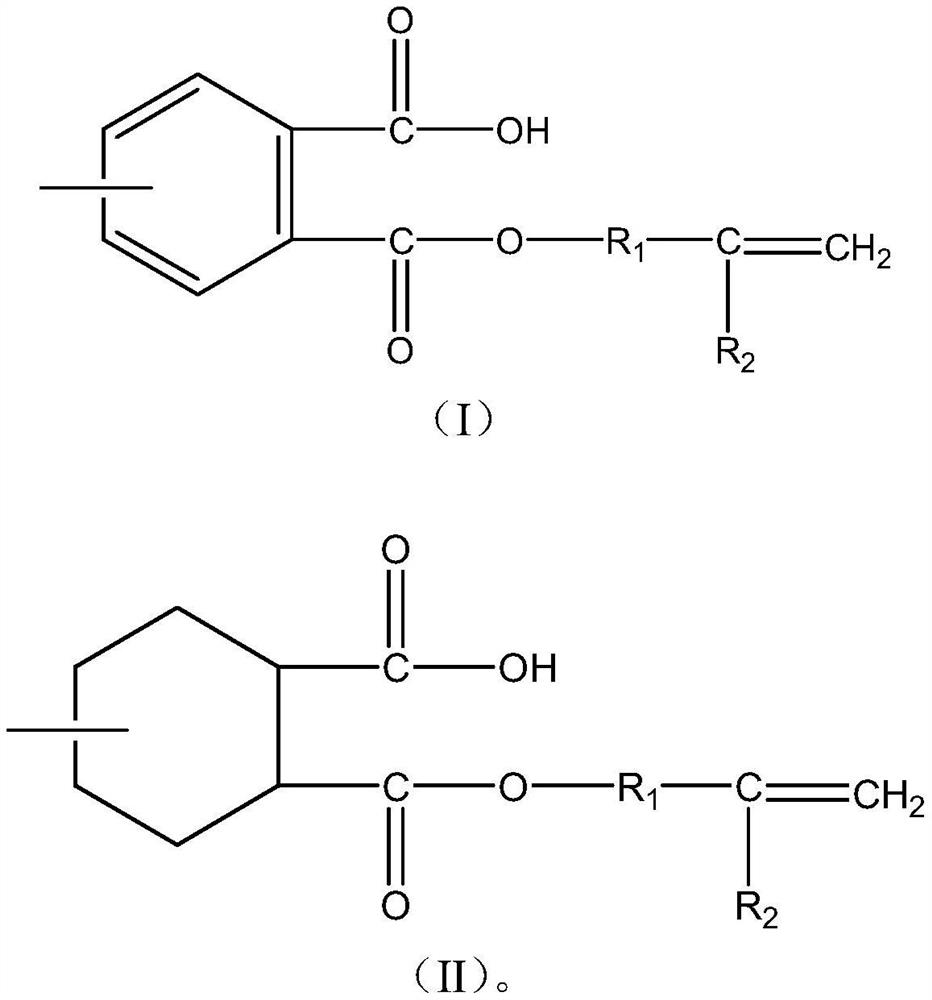

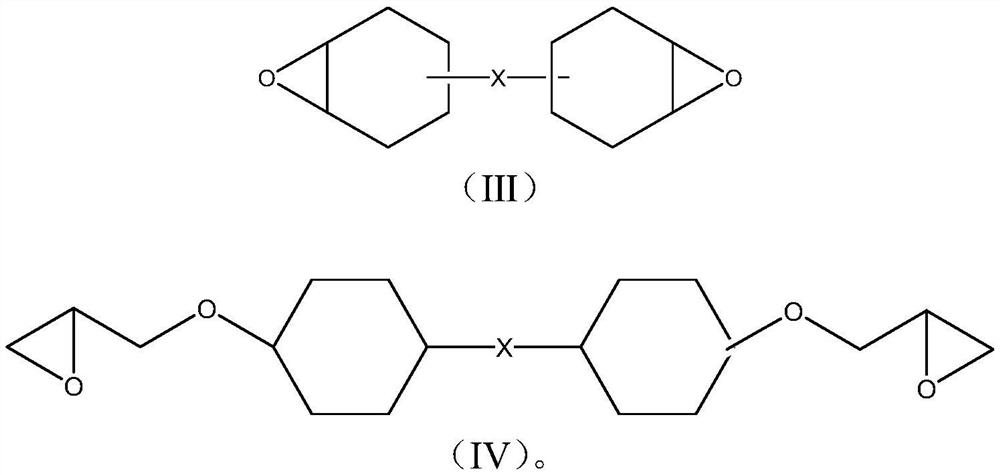

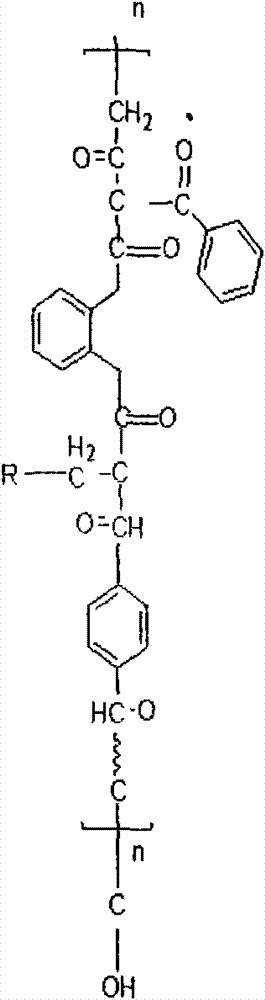

White photosensitive film, and preparation method and application thereof

PendingCN111650811AImprove reflectivityLower b valuePhotosensitive materials for photomechanical apparatusPolymer scienceSide chain

The invention discloses a white photosensitive film, and a preparation method and application thereof. The white photosensitive film comprises a white inorganic filler, alkali-soluble resin, light-cured resin, a photoinitiator, heat-cured resin, a curing agent and an antioxidant; and the curing agent is an anhydride curing agent. A white photosensitive film formula is used to form a coating liquid, a carrier film is coated with the coating liquid, and the carrier film is heated and baked to obtain the white photosensitive film. According to the white photosensitive film, the formula is improved, and by adding the anhydride curing agent and the alkali-soluble resin with the side chain and / or the tail end containing a carboxyl group, the prepared white photosensitive cover film can meet therequirements of an existing product in the aspects of development precision, high temperature resistance and the like; and the cured film is low in b value and high in reflectivity.

Owner:SHANGHAI FUSAITE NEW MATERIAL

Waterborne polyurethane antiseptic paint for yellowing-and-ageing resistant vine artware and preparation method of waterborne polyurethane antiseptic paint

InactiveCN106366888AImprove bindingImprove toughnessAnti-corrosive paintsPolyurea/polyurethane coatingsFiberUltraviolet

The invention discloses waterborne polyurethane antiseptic paint for yellowing-and-ageing resistant vine artware. The waterborne polyurethane antiseptic paint comprises, by weight, 10-15 parts of nano-cellulose suspensions with the solid content of 10-12%, 0.5-1 part of nano zinc oxide, 0.3-0.5 part of guar gum, 0.5-1 part of hydroxyl silicone oil, 40-50 parts of waterborne polyurethane resin, 0.1-0.15 part of nonylphenol polyoxyethylene ether, 0.5-1 part of octenyl succinic anhydride, 4-6 parts of absolute ethyl alcohol, 0.05-0.1 part of benzotriazole, 0.5-1 part of Kathon aseptic and 0.3-0.5 part of sodium salicylate. The waterborne polyurethane antiseptic paint has the advantages of good antiseptic performance, high tenacity, good combination performance with vine fibers, less proneness to cracking and shedding, high ultraviolet and ageing resistance, less proneness to yellowing and high appearance quality.

Owner:FUNAN COUNTY TIANYI CRAFTS

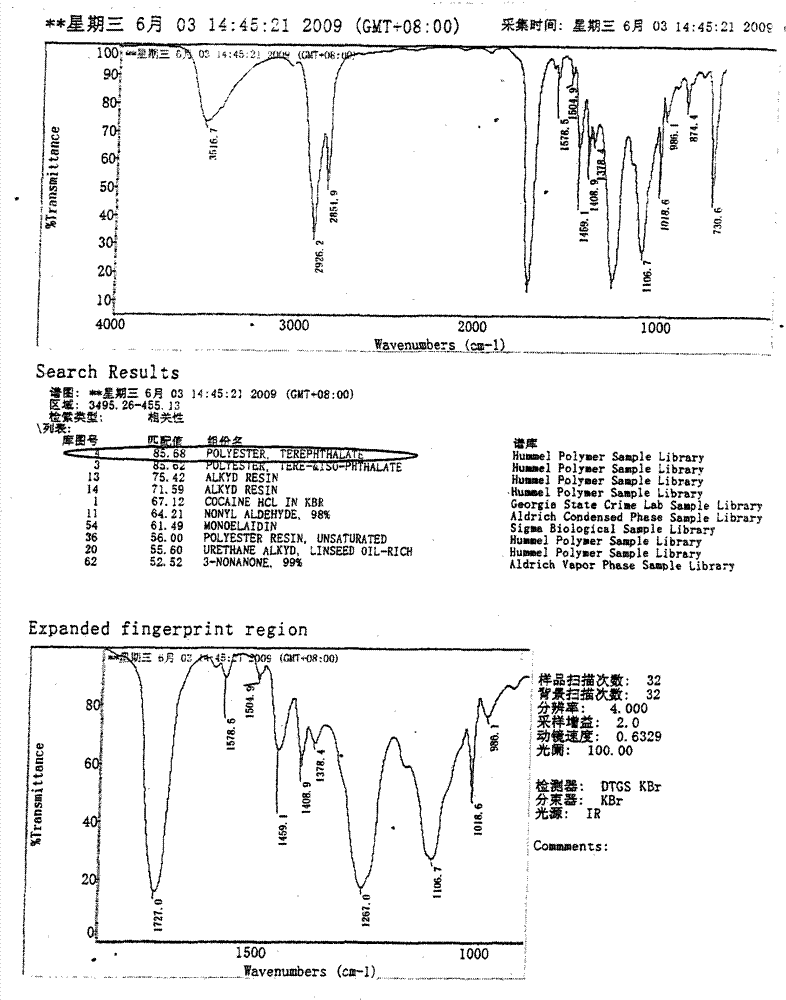

Alkyd resin for metal coiled material back paint

Owner:江苏三木化工股份有限公司 +1

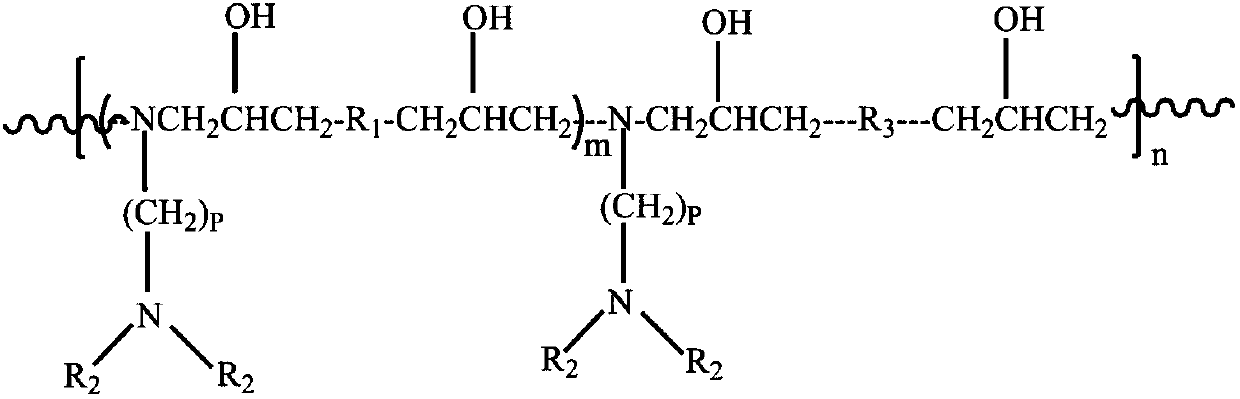

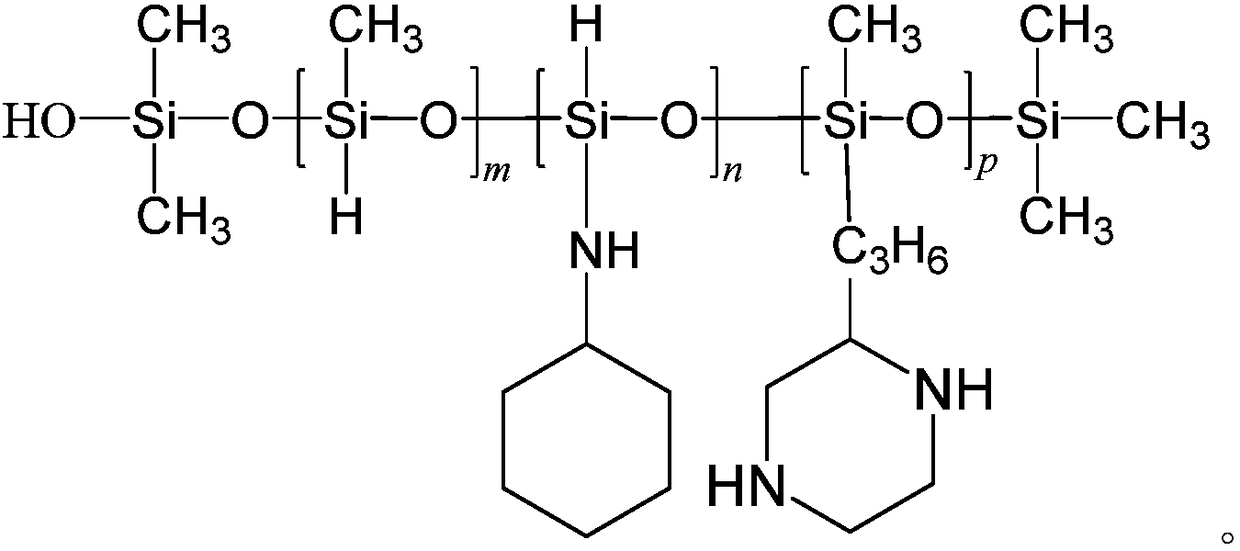

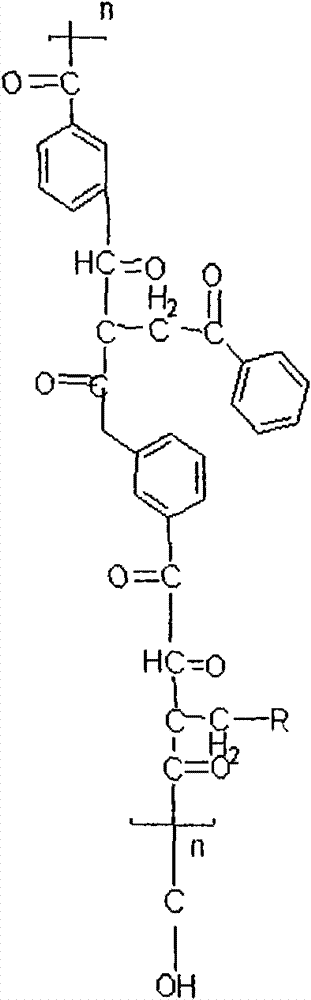

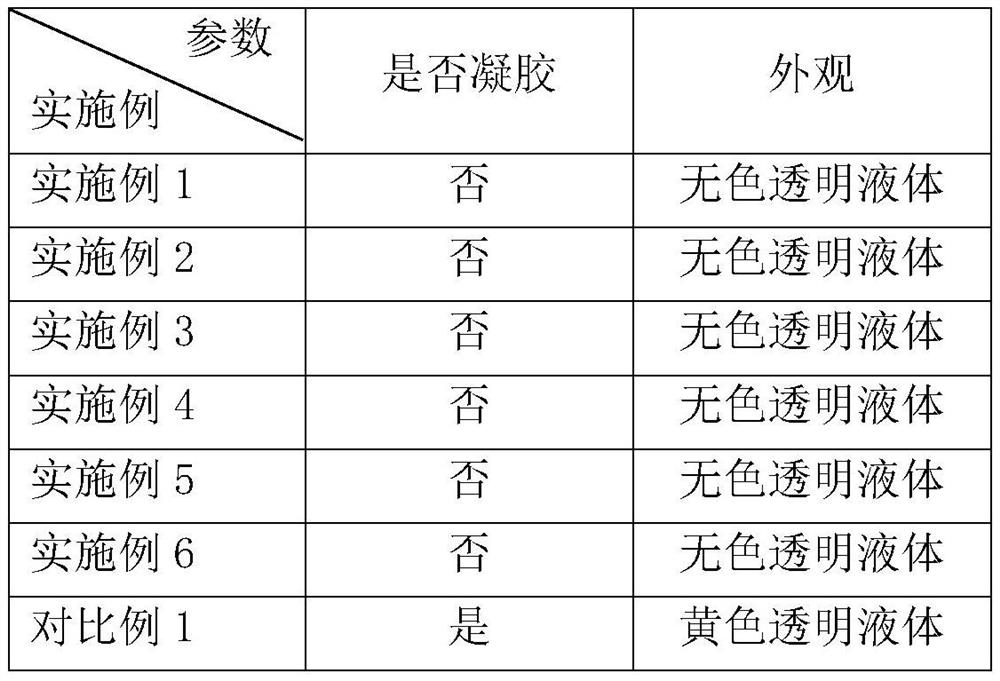

A kind of secondary aminosilane modified polyether polymer and preparation method thereof

ActiveCN109535366BLess prone to yellowingNo gel phenomenonNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

Owner:SHANGHAI DONGDA CHEM

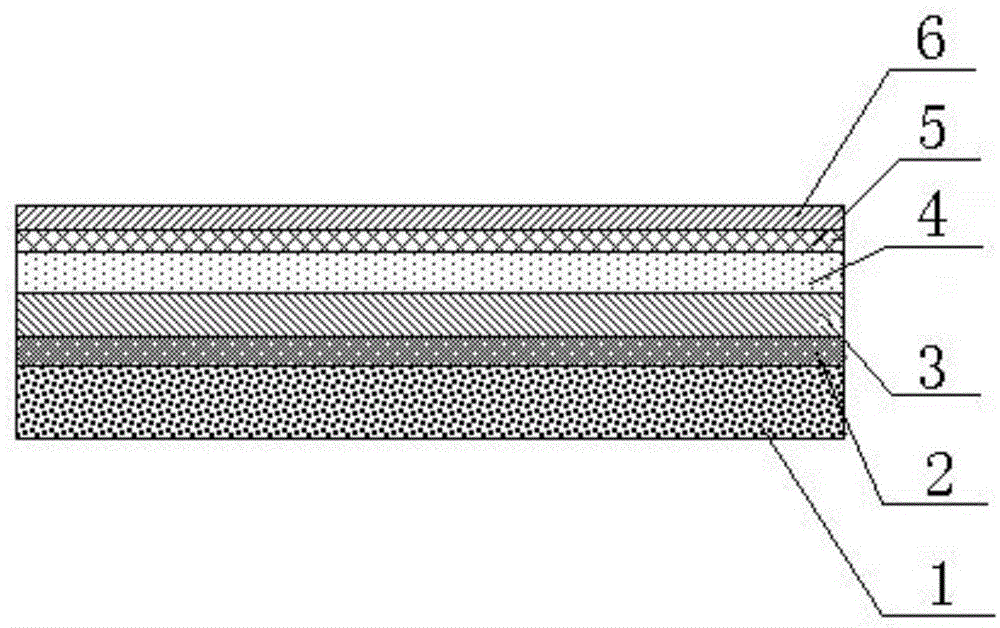

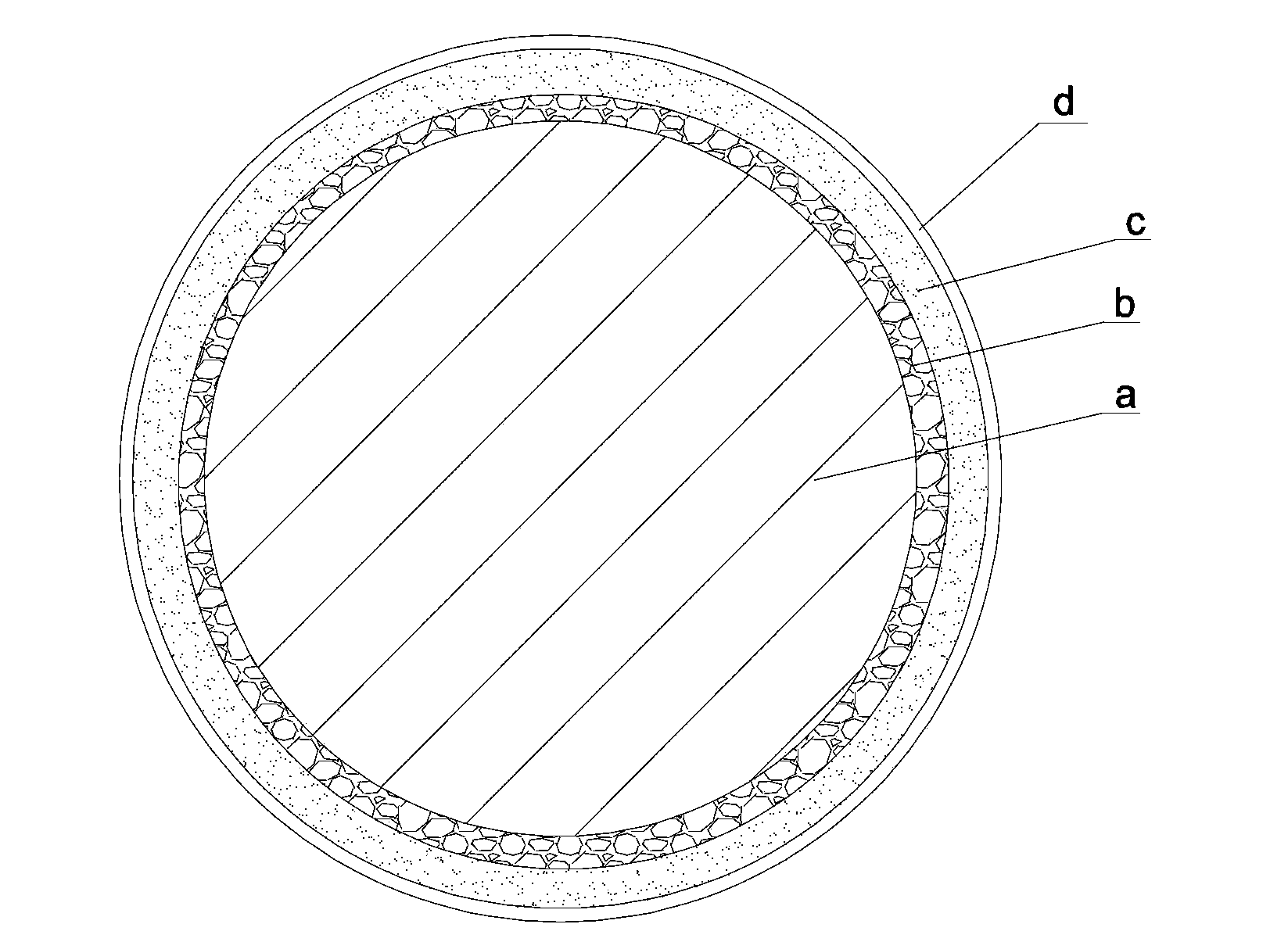

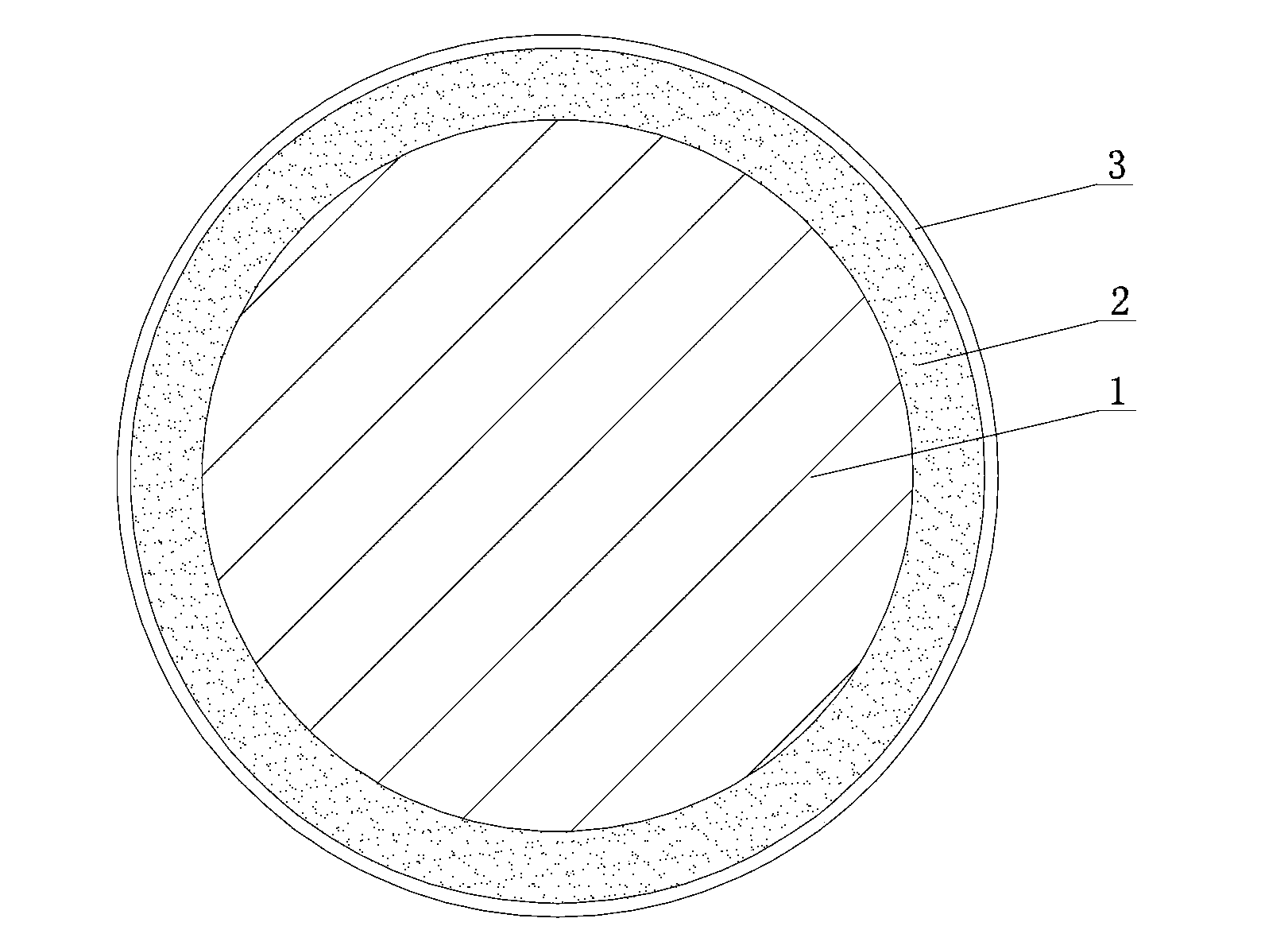

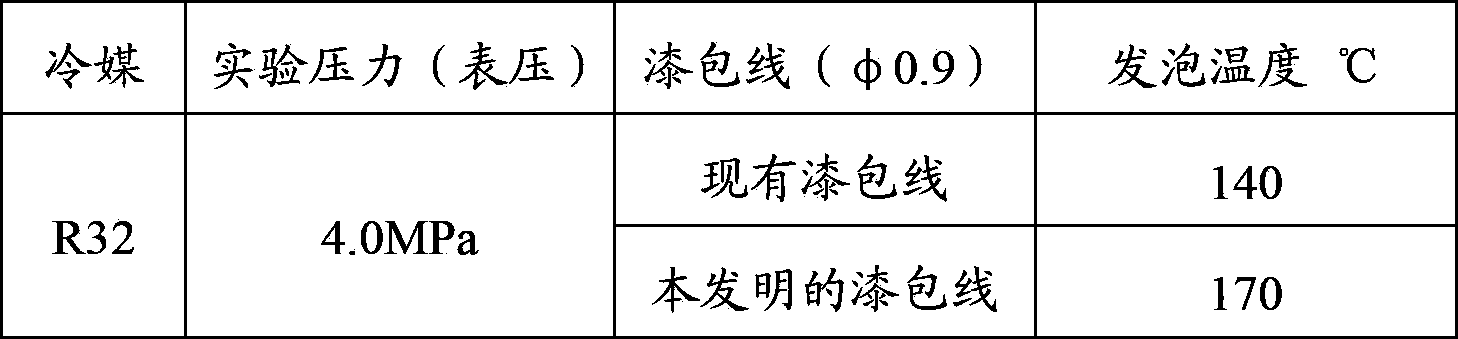

Varnished wire, manufacturing method of varnished wire, compressor comprising varnished wire and refrigeration device

InactiveCN103514992ASignificant oil resistance and refrigerant resistanceRaise the foaming temperatureInsulated cablesRotary/oscillating piston pump componentsInsulation layerPolyamide-imide

The invention discloses a varnished wire, a manufacturing method of the varnished wire, a compressor comprising the varnished wire and a refrigeration device. The varnished wire comprises wire bodies, a polyamide-imide insulation varnish layer and a self-lubricating insulation layer, wherein the polyamide-imide insulation varnish layer is formed on the outer surfaces of the wire bodies, and the self-lubricating insulation layer is formed on the outer surface of the polyamide-imide insulation varnish layer. The varnished wire has the remarkable oil resistance and the remarkable refrigerant resistance, the foaming temperature can be remarkably raised, and the varnished wire is suitable for the compressor, in particular to an R32 refrigerant compressor.

Owner:GUANGDONG MEIZHI COMPRESSOR

A kind of secondary aminosilane coupling agent and preparation method thereof

The present application relates to a preparation method of a secondary aminosilane coupling agent, which comprises, under an inert atmosphere, performing a Michael addition reaction on a pre-treated allyl-terminated polyether and a primary aminosilane coupling agent to obtain the described Secondary aminosilane coupling agent; the pretreatment method of the allyl polyether is: add 0.05-5% antioxidant to the allyl polyether, under the protection of inert gas and at 60-100°C Reaction at a temperature of 0.5-3h, and then under the pressure of -0.085 to -0.095MPa and vacuum dehydration at a temperature of 90-120°C for 0.5-2h, and then lower the temperature to 40-60°C. The present application also relates to the secondary aminosilane coupling agent prepared by the above method, the isocyanate-based polyether polymer modified by it, the polyurethane polymer modified by it and its preparation method. The preparation method of the invention is simple, and the process of capping and modifying the polyurethane prepolymer by the prepared secondary aminosilane is easy to control without gel phenomenon.

Owner:SHANGHAI DONGDA CHEM

A kind of preparation method of amino-modified acrylic resin composite microsphere

ActiveCN105601831BGood spherical regularityLarge refractive indexMicroballoon preparationMicrocapsule preparationAcrylic resinMicrosphere

The invention relates to a preparation method of amino modified acrylic resin composite microspheres. According to the method, the composite microspheres prepared by the method have better haze and photodiffusion effect than the single acrylic acid microspheres, and thus, can be used as a photodiffusant in optical films and photodiffusion plates. The technical scheme is as follows: the preparation method sequentially comprises the following steps: (1) preparing an amino resin prepolymer; (2) preparing a nano amino resin particle dispersion solution; (3) forming micron-sized monomer droplets with uniform particle size; (4) carrying out polymerization reaction, and heating to further react; and (5) after the reaction finishes, filtering the product material, cleaning the filter cake with a cleaning solution, filtering, drying and pulverizing to obtain the amino resin-acrylic resin composite microspheres. Preferably, the amino compound in the step (1) is one or the mixture of several of urea, melamine and benzoguanamine in any ratio.

Owner:浙江精迈高分子材料有限公司

Rubber plug for puncture-type infusion connecting member heparin cap

The invention discloses a rubber plug for a puncture-type infusion connecting member heparin cap and belongs to the technical field of medical instruments. The rubber plug comprises, by weight, 100 parts of isoprene rubber, 3-5 parts of transparent zinc oxide, 1-3 parts of stearic acid, 1-1.3 parts of sulfur, 0.1-0.4 part of promoter TRA, 0.1-0.3 part of promoter TMTM and 5-8 parts of lightweight magnesium carbonate. The rubber plug has the advantages of stable physiochemical and biological performance, excellent compatibility with medicine, resistance to perforation, good closing performance after puncture and capability of meeting clinical using needs.

Owner:林洁

Composite curing agent for polyester powder coating and its preparation method and application

ActiveCN109852127BImprove curing effectHigh epoxy equivalentPowdery paintsPolyester coatingsPolymer scienceFirming agent

The invention belongs to the technical field of powder coatings, in particular to a composite curing agent for polyester powder coatings, and further discloses its preparation method and application. The composite curing agent for polyester resin powder coatings according to the present invention mainly consists of trimellitic acid triglycidyl ester and terephthalic acid diglycidyl ester as main raw materials, and selectively adds trimellitic acid triglycidyl ester It is prepared by mixed reaction of glycidyl ester, hydroxyl polyester resin, dicyclopentadiene dioxide and / or crystalline epoxy resin. The composite curing agent for the polyester resin powder coating has a good curing effect, and the mechanical properties of the obtained coating are stable, and also has good water boiling resistance; when it is cured with the polyester resin, its product performance fully reaches The curing effect of the current TGIC and HAA curing agent can be mixed with the existing TGIC or HAA products, and the comprehensive performance is better.

Owner:安徽泰达新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com