Softening agent applied to linen fabric and preparation method thereof

A linen fabric and softener technology, which is applied to plant fibers, textiles, papermaking, and fiber processing, can solve problems such as poor elasticity and small elongation, and achieve strong friction resistance, improved wearing effect, and firm adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A softening agent for linen fabrics, comprising the following components, in parts by weight:

[0026] 100 parts of modified polysiloxane, 32 parts of hydroxyl-terminated polymethyl hydrogen siloxane, 21 parts of polydimethylsiloxane, 11 parts of emulsifier, 9 parts of organic acid, 21 parts of chitosan, surfactant 8 copies;

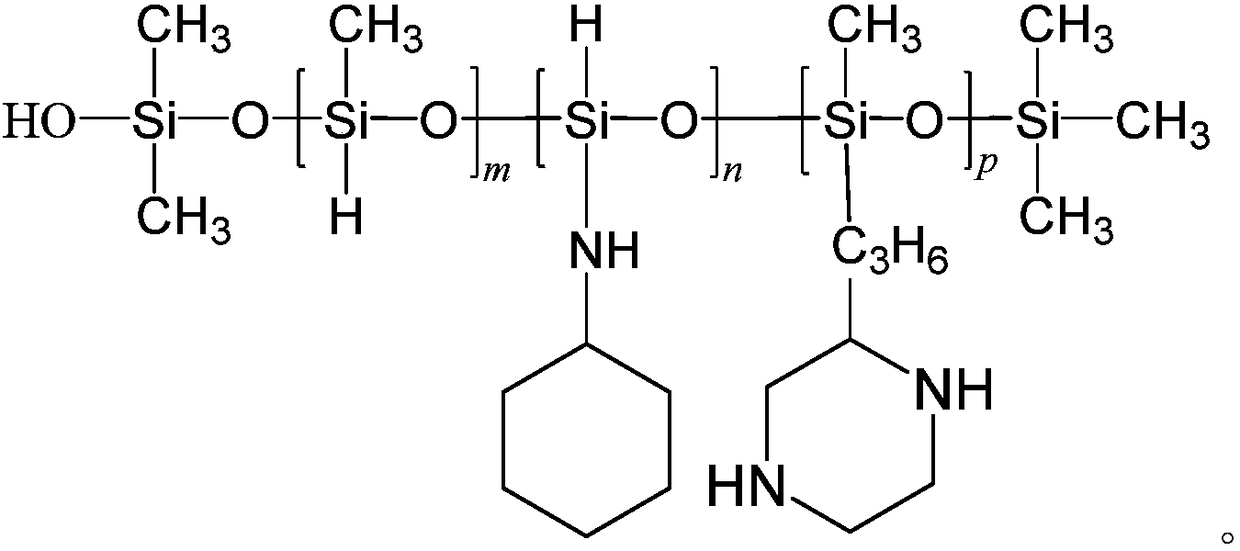

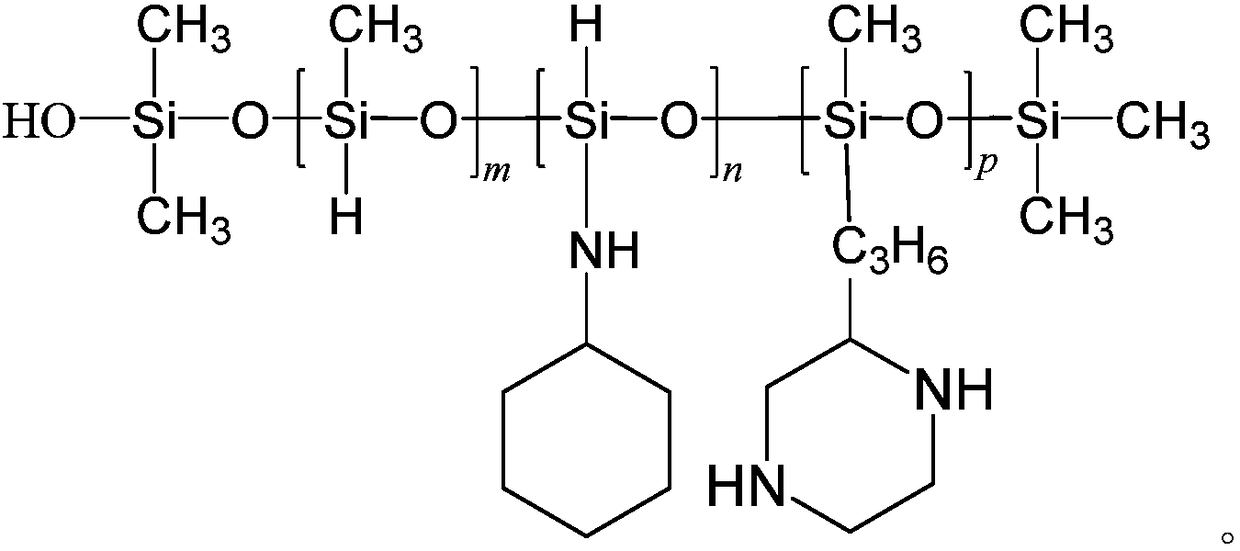

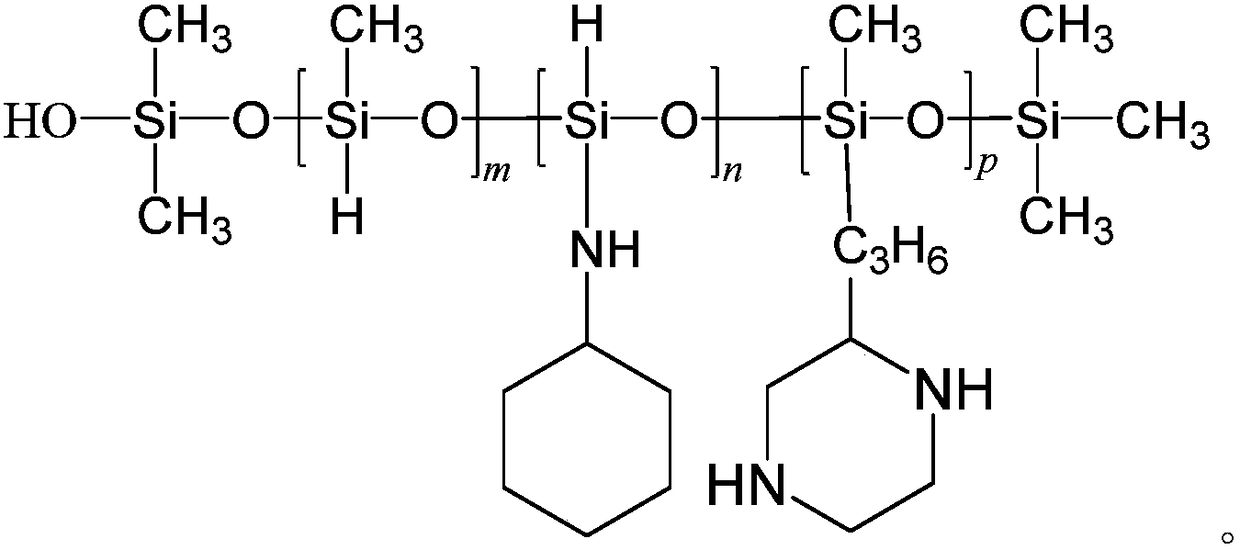

[0027] The modified polysiloxane is mixed and modified by cyclohexyl secondary amine and propyl piperazine, and has a single-end hydroxyl structure polysiloxane, in the modified polysiloxane structure m:n:p=7 :3:1, its structure is shown in the following formula;

[0028]

[0029] Described emulsifying agent is the mixture that the mol ratio of sodium lauryl sulfate and Span-40 is 7:4; The mol ratio that organic acid is citric acid and salicylic acid is the mixture that is 5:1; Surfactant is pentaerythritol A mixture of oleate and castor oil sulfate in a molar ratio of 5:2.

[0030] A preparation method for a softener for linen fabrics, comp...

Embodiment 2

[0035] A softening agent for linen fabrics, comprising the following components, in parts by weight:

[0036] 100 parts of modified polysiloxane, 48 parts of hydroxyl-terminated polymethyl hydrogen siloxane, 33 parts of polydimethylsiloxane, 19 parts of emulsifier, 15 parts of organic acid, 33 parts of chitosan, surfactant 15 copies;

[0037] The structure of the modified polysiloxane is the same as that in Example 1.

[0038] Described emulsifying agent is the mixture that the mol ratio of sodium lauryl sulfate and Span-40 is 7:4; The mol ratio that organic acid is citric acid and salicylic acid is the mixture that is 5:1; Surfactant is pentaerythritol A mixture of oleate and castor oil sulfate in a molar ratio of 5:2.

[0039] A preparation method for a softener for linen fabrics, comprising the following steps:

[0040] (1) Mix modified polysiloxane, hydroxyl-terminated polymethylhydrogensiloxane, and polydimethylsiloxane, heat to 80°C, add emulsifier and stir for 2 hour...

Embodiment 3

[0044] A softening agent for linen fabrics, comprising the following components, in parts by weight:

[0045] 100 parts of modified polysiloxane, 32 parts of hydroxyl-terminated polymethyl hydrogen siloxane, 33 parts of polydimethylsiloxane, 11 parts of emulsifier, 15 parts of organic acid, 21 parts of chitosan, surfactant 15 copies;

[0046] The structure of the modified polysiloxane is the same as that in Example 1.

[0047] Described emulsifying agent is the mixture that the mol ratio of sodium lauryl sulfate and Span-40 is 7:4; The mol ratio that organic acid is citric acid and salicylic acid is the mixture that is 5:1; Surfactant is pentaerythritol A mixture of oleate and castor oil sulfate in a molar ratio of 5:2.

[0048] A preparation method for a softener for linen fabrics, comprising the following steps:

[0049] (1) Mix modified polysiloxane, hydroxyl-terminated polymethylhydrogensiloxane, and polydimethylsiloxane, heat to 60°C, add emulsifier and stir for 2 hours,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com