Process for preparing printed matter with gravure fission effect

A preparation process and technology of printed matter, applied in the directions of printing, post-processing of printing, printing device, etc., to achieve the effects of good weather resistance and aging resistance, stable quality and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A process for preparing printed matter with gravure fission effect, comprising the following steps:

[0040] Step A: printing the UV fission ink on the carrier through a gravure plate;

[0041] Step B: The carrier printed with the UV fission ink is subjected to UV detonation treatment and UV drying and curing treatment in sequence to obtain a printed matter with gravure fission effect.

[0042] In the step A, the depth of the gravure printing plate is 65 μm, the number of lines is 80, and the section of the cell is tapered.

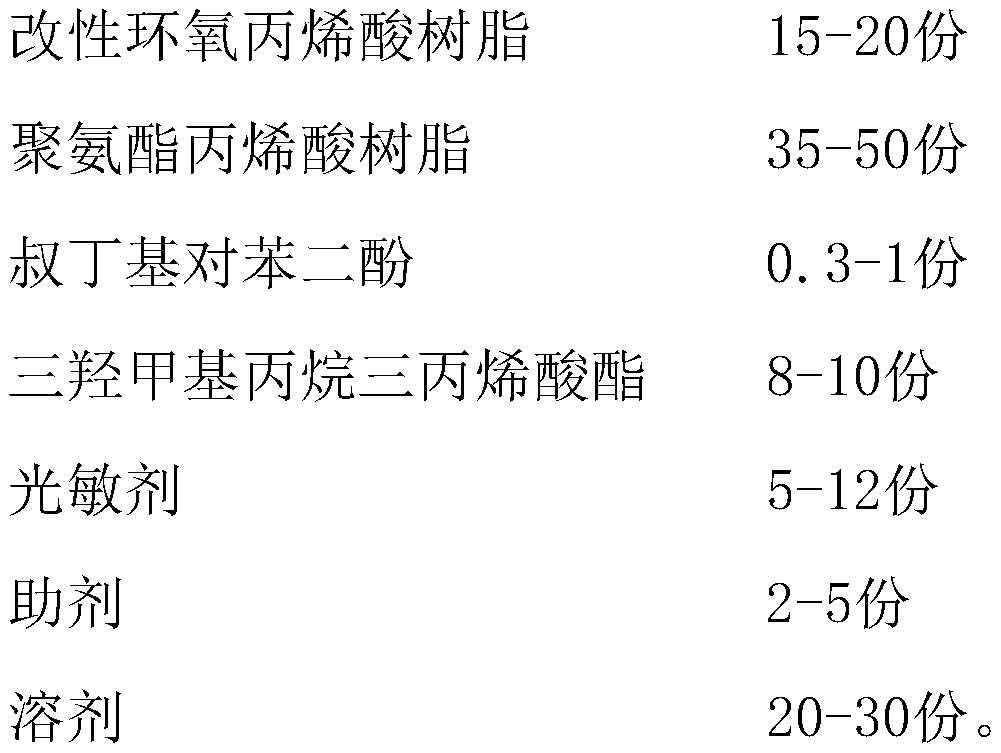

[0043] In the described step A, the UV fission ink comprises the following raw materials by weight:

[0044]

[0045] Each part of the adjuvant includes 3 parts of leveling agent and 6 parts of defoamer; each part of the leveling agent is composed of polydimethylsiloxane, diacetone alcohol and MODAREZ MFP C-type acrylate leveling agent by weight The mixture is composed of a ratio of 2:1.5:2; each part of the defoamer is composed of polyoxyethy...

Embodiment 2

[0060] A process for preparing printed matter with gravure fission effect, comprising the following steps:

[0061] Step A: printing the UV fission ink on the carrier through a gravure plate;

[0062] Step B: The carrier printed with the UV fission ink is subjected to UV detonation treatment and UV drying and curing treatment in sequence to obtain a printed matter with gravure fission effect.

[0063] In the step A, the depth of the gravure printing plate is 66 μm, the number of lines is 82, and the section of the cell is tapered.

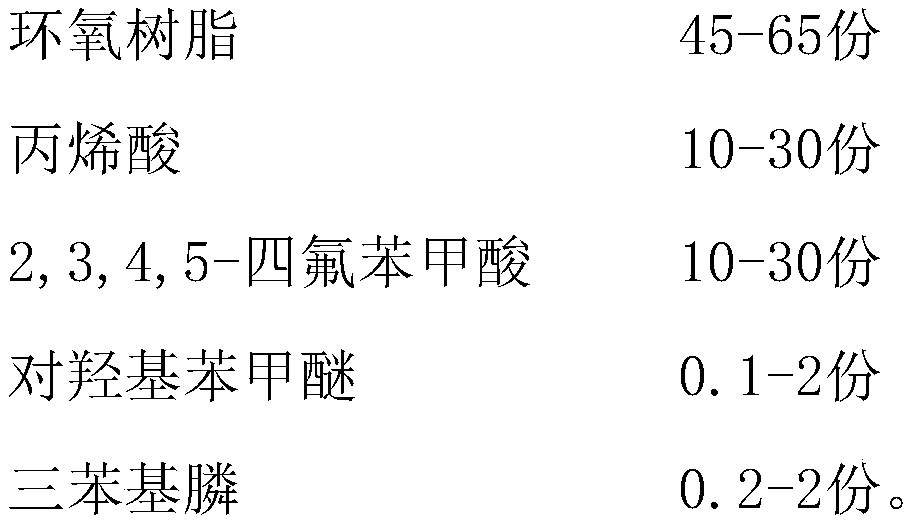

[0064] In the described step A, the UV fission ink comprises the following raw materials by weight:

[0065]

[0066] Each part of the adjuvant includes 4 parts of a leveling agent and 5 parts of a defoamer; each part of the leveling agent is composed of polydimethylsiloxane, diacetone alcohol and MODAREZ MFP C-type acrylate leveling agent by weight The mixture is composed of a ratio of 2.5:1.3:2; each part of the defoamer is composed of polyo...

Embodiment 3

[0081] A process for preparing printed matter with gravure fission effect, comprising the following steps:

[0082] Step A: printing the UV fission ink on the carrier through a gravure plate;

[0083] Step B: The carrier printed with the UV fission ink is subjected to UV detonation treatment and UV drying and curing treatment in sequence to obtain a printed matter with gravure fission effect.

[0084] In the step A, the depth of the gravure printing plate is 68 μm, the number of lines is 85, and the section of the cell is tapered.

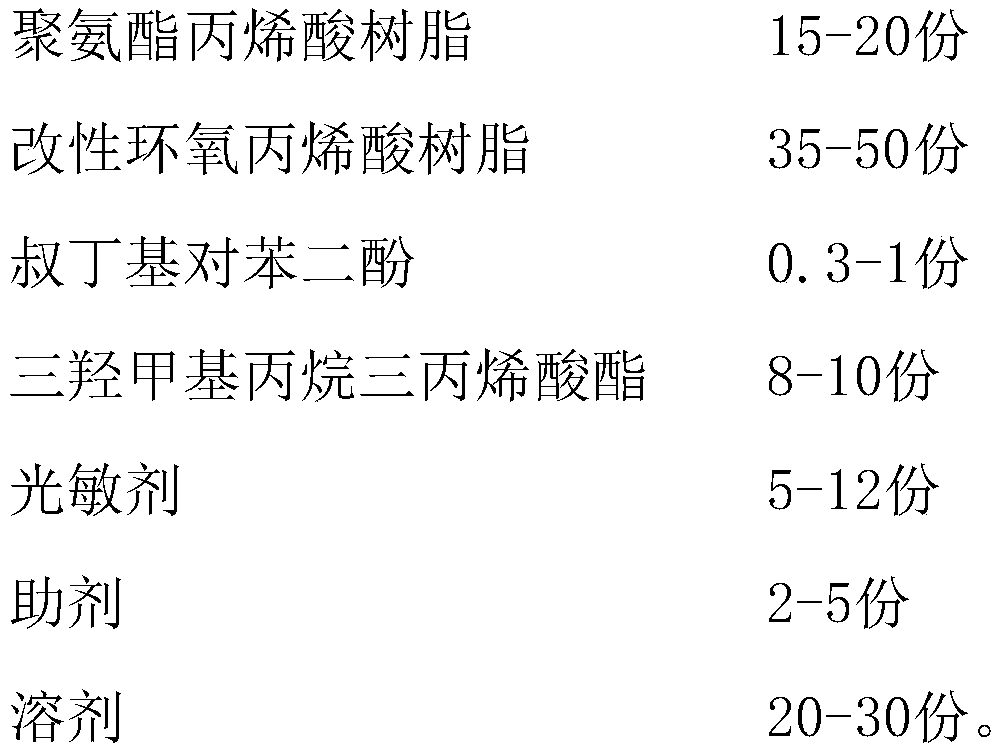

[0085] In the described step A, the UV fission ink comprises the following raw materials by weight:

[0086]

[0087] Each part of the adjuvant includes 5 parts of a leveling agent and 4 parts of a defoamer; each part of the leveling agent is composed of polydimethylsiloxane, diacetone alcohol and MODAREZ MFP C-type acrylate leveling agent by weight The mixture is composed of a ratio of 3:1:2; each part of the defoamer is composed of polyoxyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com