A kind of secondary aminosilane modified polyether polymer and preparation method thereof

A technology of secondary aminosilane and polyether polymer, which is applied in the field of secondary aminosilane modified polyether polymer and its preparation, can solve the problems of high price, complicated preparation, gel, etc., and achieve low environmental pollution, convenient construction, Produce reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

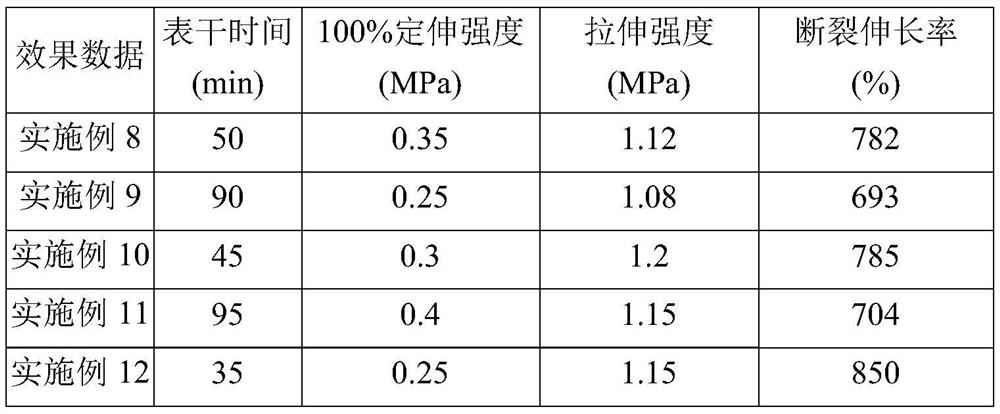

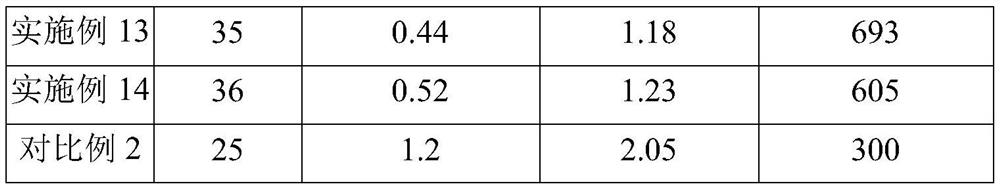

Examples

preparation example Construction

[0040]In a specific embodiment, the present invention provides a method for preparing a secondary amino silicone modified polyether polymer, comprising the steps of:

[0041](1) Dehydrating the polyether polyol under vacuum conditions of 90 to 130 ° C, degassing from 1 to 4 h, then cooling to 50 to 80 ° C, adding diisocyanate and catalyst to polyether polyol, control diisocyanate The molar ratio of the hydroxyl group of the cyananate and the polyether polyol is from 1.1 to 2: 1; high purity nitrogen gas is introduced, stirred well, and then at 50 to 90 ° C for 1 to 6 h, and the terminal isocyanate-based polyether prepolymer is obtained.

[0042](2) Mix the end isocyanate-based polyether prepolymer and secondary amino silisily mixed with secondary amino group and isocyanate molar ratio of 0.9 to 1.2: 1, at 30 to 90 ° C, high purity nitrogen protection reaction 1 ~ 6h until the system ends the reaction when there is no sanocyanate, then the bubbles were removed in the reaction temperature, ...

Embodiment 1

[0059](1) In the four-mouth flask equipped with a stirrer, a constant voltage drip funnel, and a gas tube, an endone-eatel polyether (S1010, Shanghai Dongda Chemical Co., Ltd.) is sequentially added. Getting nitrogen and stirring, add γ-aminopropyltrimethoxysilane, olelene polyether and gamma-aminopropyltrimethoxysilane in 1: 1, 30 minutes by weight at 40 ° C. After completion, then warmed to 90 ° C, reaction for 4 h, resulting in a secondary aminoisilyl coupling agent.

[0060](2) Polyether polyol (C2160, Shanghai Dongda Chemical Co., Ltd.) dehydrated under vacuum conditions at 110 ° C, degassing to 60 ° C, then cool down to 60 ° C, then cool down to 60 ° C, then add TDI (diisocyanate) The molar ratio of the hydroxyl group of isocyanate and the polyether polyol is 2: 1), dibutyltin (0.1% of the polyether polyol mass) in Dihuo (0.1% of the polyether polyol), and the mixing is uniform, The reaction was reacted at 90 ° C for 1 h to obtain an end isocyanate-based polyether prepolymer, and...

Embodiment 2

[0063](1) In the four-mouth flask equipped with a stirrer, a constant voltage drop, the gas tube, a 10-parts having average molecular weight of 1000 is sequentially added, and nitrogen gas is introduced into nitrogen and the stirring, 40 ° C The γ-aminopropyltriethoxysilane, the olelene polyether and the γ-aminopropyltriethoxysilane were added to 1: 1, 30 minutes, and then heated to 90 ° C , The reaction is 4 h to obtain a secondary aminoisilyl coupling agent.

[0064](2) Polyether polyol (C2060, Shanghai Dongda Chemical Co., Ltd.) will be dehydrated under vacuum conditions at 110 ° C under vacuum conditions at 110 ° C, then cool down to 60 ° C, then add TDI (diisocyanate) The molar ratio of the hydroxyl isocyanate and the polyether polyol of 1.3: 1), dibutyltin (0.1% of the mass polyol mass), and passed into high purity nitrogen as reaction protective gas, stir well. The reaction was at 50 ° C for 6 h, and the terminal isocyanate-based polyether prepolymer was obtained, and the NCO co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com