Varnished wire, manufacturing method of varnished wire, compressor comprising varnished wire and refrigeration device

A technology of refrigeration equipment and enameled wire, which is applied to mechanical equipment, machines/engines, liquid fuel engines, etc., and can solve problems such as inability to meet the working requirements of rotary compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of enameled wire

[0040] Prepare enameled wire according to the method for preparing enameled wire of the present invention, concrete steps are as follows:

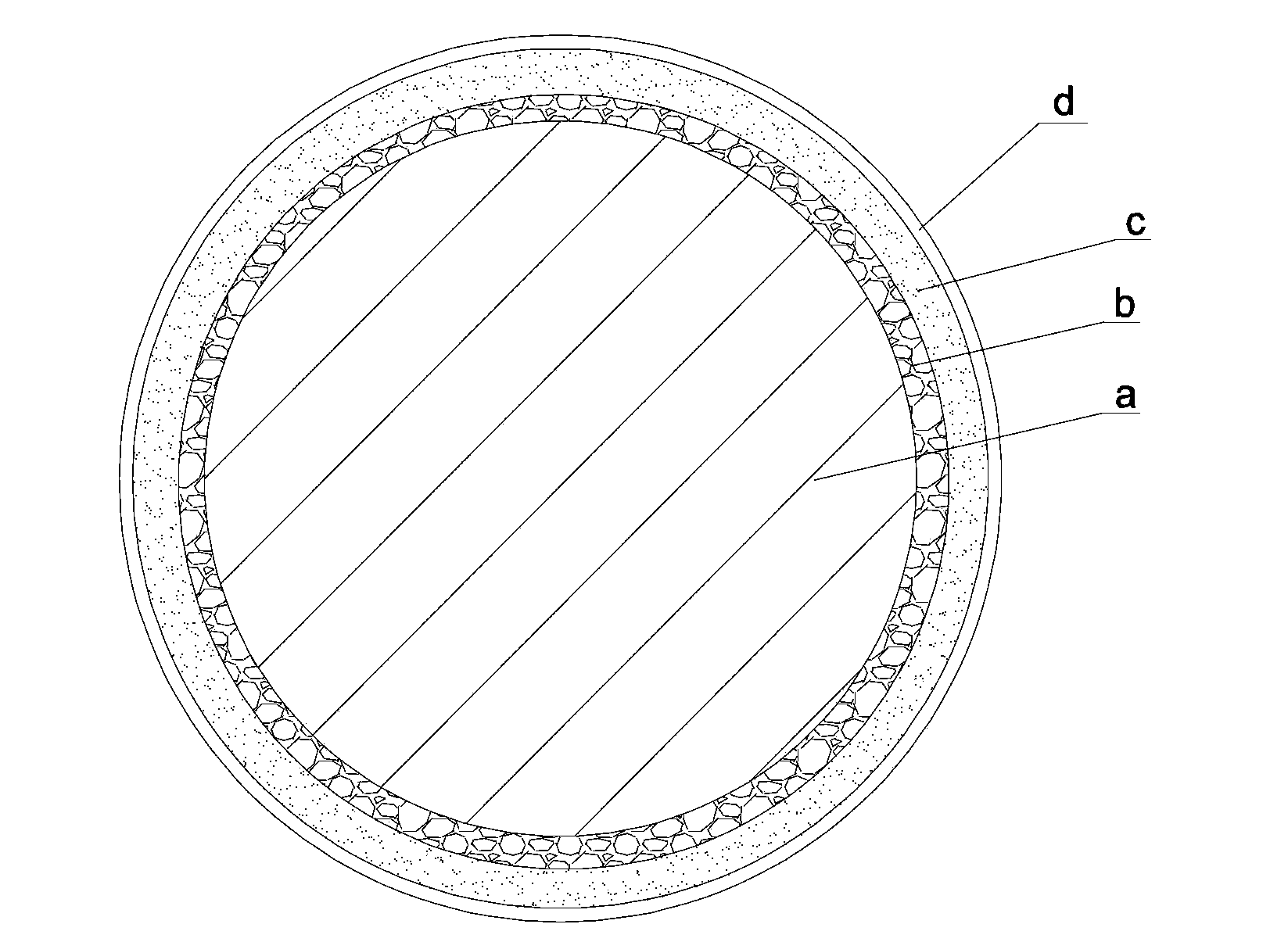

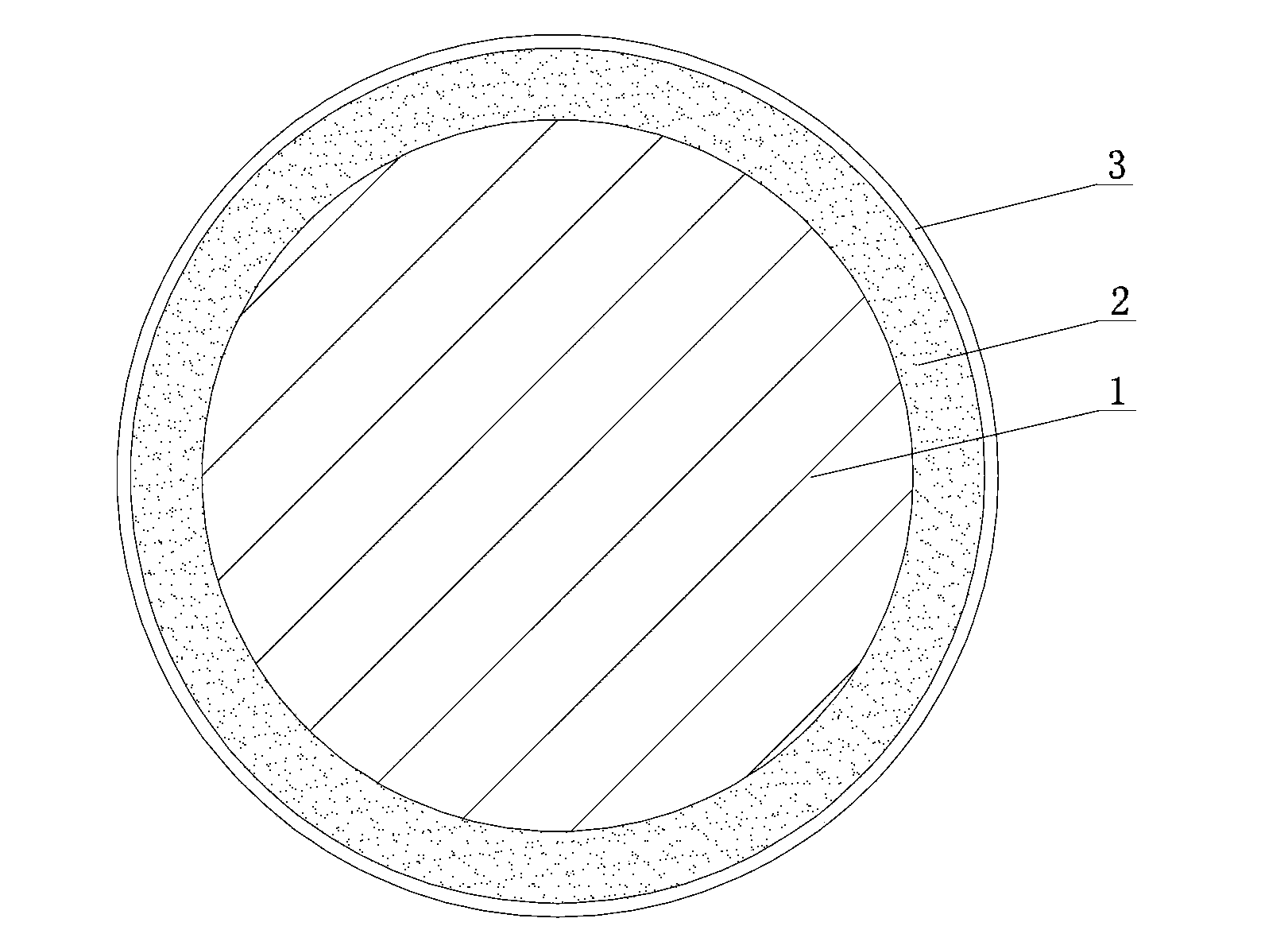

[0041] First, coat 17 layers of polyamide-imide insulating varnish on the outer surface of a copper wire with a diameter of 0.85 mm to form a polyamide-imide insulating varnish layer with a thickness of 0.021 mm to 0.039 mm;

[0042] Then, on the outer surface of the polyamide-imide insulating varnish layer, coat two layers of polyamide-imide insulating varnish added with self-lubricating agent to form self-lubricating insulation on the outer surface of the polyamide-imide insulating varnish layer paint layer.

[0043] Thus, the enameled wire of the present invention was prepared.

Embodiment 2

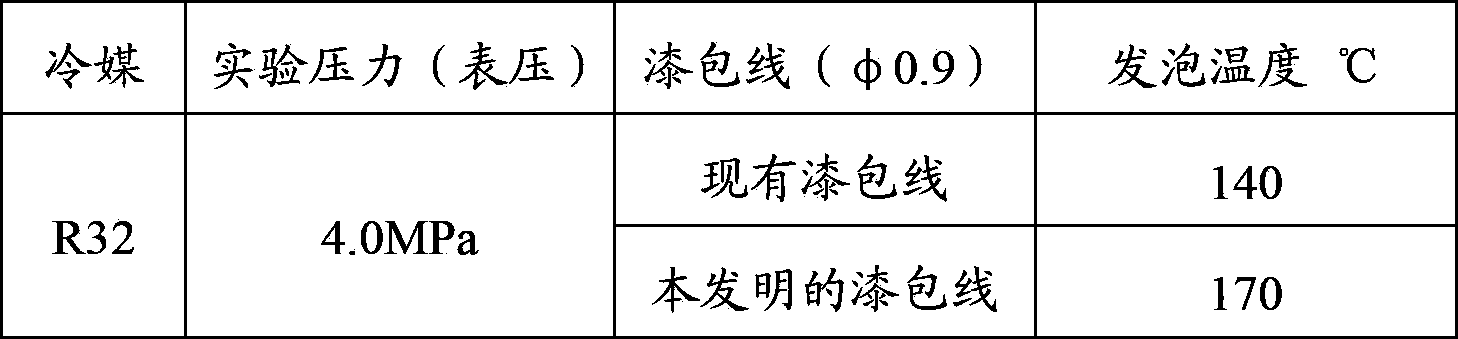

[0045] With existing enameled wire as contrast, according to the following method, the enameled wire of the present invention prepared in embodiment 1 is carried out quality inspection:

[0046] Seal 400ml of refrigerating machine oil and several enameled wire samples with a length of about 20cm in a dried airtight container with a volume of about 2L. After the airtight container is evacuated, R32 refrigerant is added to it until the pressure of the refrigerant in the airtight container reaches 4.0 at 95°C. MP (gauge pressure). Next, place the airtight container containing the enameled wire sample, refrigerant, and refrigerating machine oil at a temperature of 95°C for 48 hours. After cooling, take out the enameled wire sample and divide it into equal parts, and then place them at 130°C, 140°C, 150°C, 160°C, 170°C, and 180°C incubators, take them out after 10 minutes, and use the naked eye to observe the foaming conditions of the enameled wire samples treated in the incubators...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com