A kind of polyolefin resin foam sheet and its manufacturing method

A polyolefin-based resin and foam sheet technology, which is applied in the field of polyolefin-based resin foam sheets, can solve the problem of poor bubble density and compressive strength, poor positive water blocking effect of materials, and foam material cushioning. Performance deterioration and other problems, to achieve the effect of reducing the amount of use, beneficial to positive water blocking, and increasing the foaming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

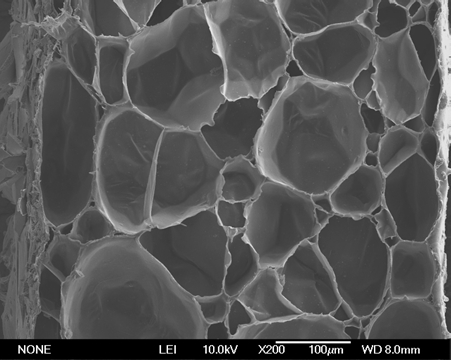

Embodiment 1

[0065] 100 parts by weight of LDPE with MFR of 2g / 10min (trade name: Sinopec 2426H), 5.6 parts by weight of azodicarbonamide, and 0.5 part by weight of antioxidant were mixed in a high-speed mixer, and then kneaded at 130°C, and then Extruded into a strip-shaped sheet, and then irradiated 10Mrad electron beams with an accelerating voltage of 500kV on both sides of the strip-shaped resin sheet to cross-link the resin sheet, and continuously send the cross-linked resin sheet into a heating furnace at 350°C , the heating furnace is heated by an infrared heater to foam the resin sheet, and the foamed resin sheet is blown with room temperature air at the end of the foaming furnace for 5 minutes, so that the surface temperature of the sheet is reduced to below 135 ° C, and then passed through An extrusion roll with a roll surface temperature of 20° C. controls the thickness and simultaneously forms a skin layer. Finally, it was reheated to 120° C., stretched at a draw ratio of 3 tim...

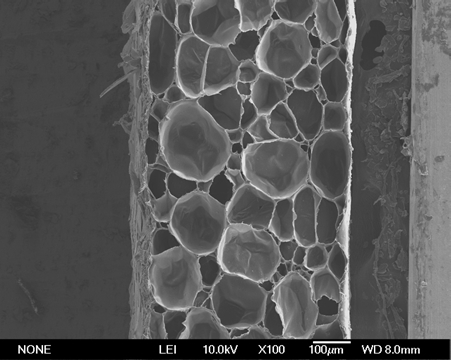

Embodiment 2

[0067] 100 parts by weight of LDPE with MFR of 2g / 10min (trade name: Sinopec 2426H), 3.1 parts by weight of azodicarbonamide, and 0.5 part by weight of antioxidant were mixed in a high-speed mixer, and then kneaded at 130°C, and then Extrude into a strip-shaped sheet, and then irradiate the two sides of the strip-shaped resin sheet with an electron beam of 10 Mrad with an accelerating voltage of 500 kV to cross-link the resin sheet, and continuously send the cross-linked resin sheet into a heating furnace at 215°C , the heating furnace is heated by an infrared heater to foam the resin sheet, and the foamed resin sheet is blown with room temperature air at the end of the foaming furnace for 5 minutes, so that the surface temperature of the sheet is reduced to below 135 ° C, and then passed through An extrusion roll with a roll surface temperature of 20° C. controls the thickness and simultaneously forms a skin layer. Finally, it was reheated to 120° C., stretched at a draw rati...

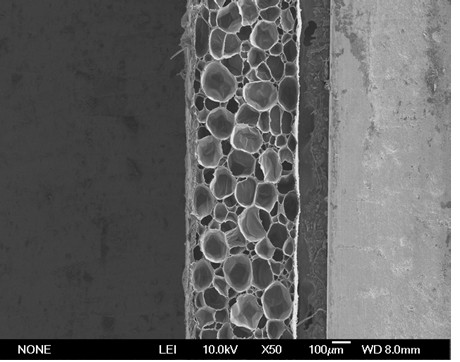

Embodiment 3

[0069]100 parts by weight of LDPE with MFR of 2g / 10min (trade name: Sinopec 2426H), 6.2 parts by weight of azodicarbonamide, and 0.5 part by weight of antioxidant were mixed in a high-speed mixer, then kneaded at 130°C, and then Extrude into a strip-shaped sheet, and then irradiate the two sides of the strip-shaped resin sheet with an electron beam of 10 Mrad with an accelerating voltage of 500 kV to cross-link the resin sheet, and continuously send the cross-linked resin sheet into a heating furnace at 300°C , the heating furnace is heated by an infrared heater to foam the resin sheet, and the foamed resin sheet is blown with room temperature air at the end of the foaming furnace for 5 minutes, so that the surface temperature of the sheet is reduced to below 135 ° C, and then passed through An extrusion roll with a roll surface temperature of 20° C. controls the thickness and simultaneously forms a skin layer. Finally, it was reheated to 120° C., stretched at a stretching rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com