Foaming agent for NBR sponge rubber

A technology of sponge rubber and foaming agent, applied in the field of foaming agent, can solve the problems of affecting the performance of rubber products, low technical quality level, low foaming ratio, etc., and achieve good temperature adaptability, uniformity of dispersion, low density, The effect of increasing the foaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

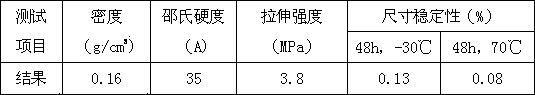

Examples

Embodiment

[0032] A foaming agent for NBR sponge rubber, consisting of the following raw materials in parts by weight:

[0033] Azodicarbonamide 10 parts

[0034] 4,4'-oxobisbenzenesulfonyl hydrazide 6 parts

[0035] 3 parts p-toluenesulfonyl hydrazide

[0036] Dinitrosopentamethylenetetramine 5 parts

[0037] Modified sodium bicarbonate 6 parts

[0038] Polyethylene glycol 25 parts

[0039] 8 parts triethanolamine

[0040] Salicylic acid 3 parts

[0041] Zinc stearate 1.5 parts

[0043] Wherein, the modified sodium bicarbonate is prepared by the following method: take the following raw materials in parts by weight: 15 parts of sodium bicarbonate, 8 parts of urea, 3 parts of fatty acid, 1.5 parts of dibasic lead phosphite, 5 parts of dodecyl Put the sodium alkylbenzene sulfonate into a high-speed kneader, stir at a high speed for 30 minutes, take it out, dry it and pulverize it, and grind it into a 200-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com