Patents

Literature

94results about How to "No gel phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hyper-concentrated liquid detergent and preparation technique thereof

ActiveCN102643725ANo gel phenomenonEasy to dumpAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsPreservativeSolvent

Hyper-concentrated liquid detergent comprises, in percentage by weight, 8-30% of anionic surfactant, 40-60% of nonionic surfactant, 5-15% of cosolvent, 0-10% of auxiliary, 0.005-1% of deflocculant, 0-0.5% of fluorescent brightener, 0-2% of detergent enzymes, 0-0.1% of preservative, 0.1-1% of essence, and the balance of water. The hyper-concentrated liquid detergent has the advantages of high solid content and high deterging effect.

Owner:CHINA RES INST OF DAILY CHEM IND

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

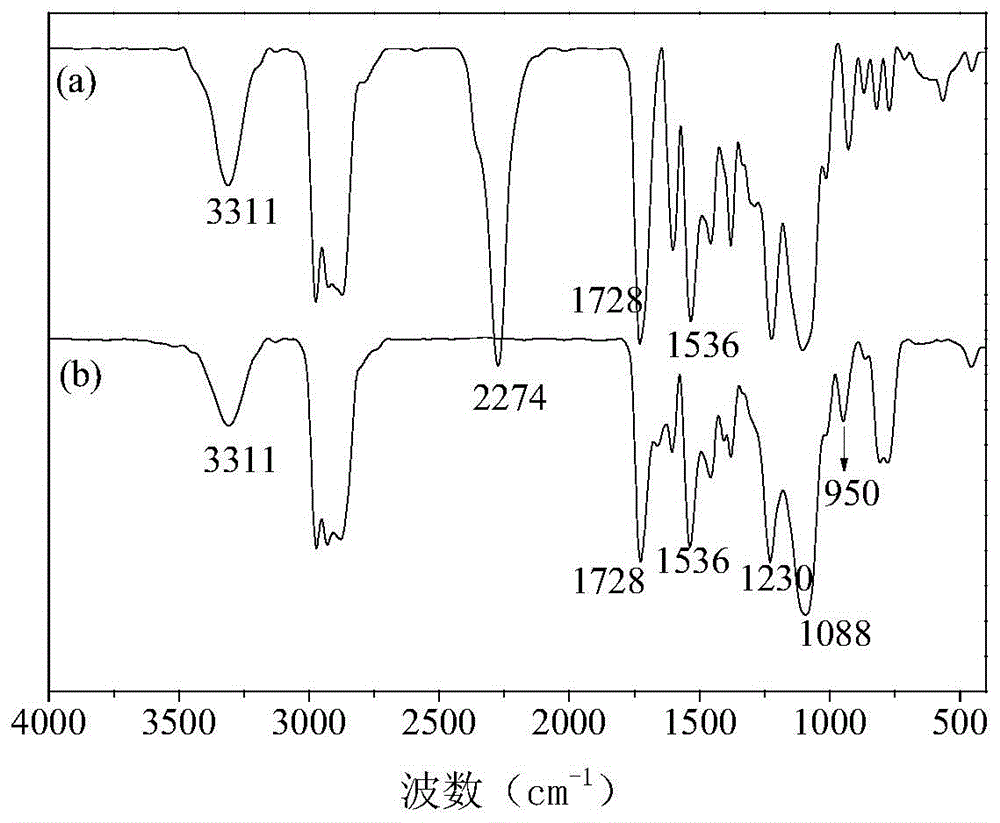

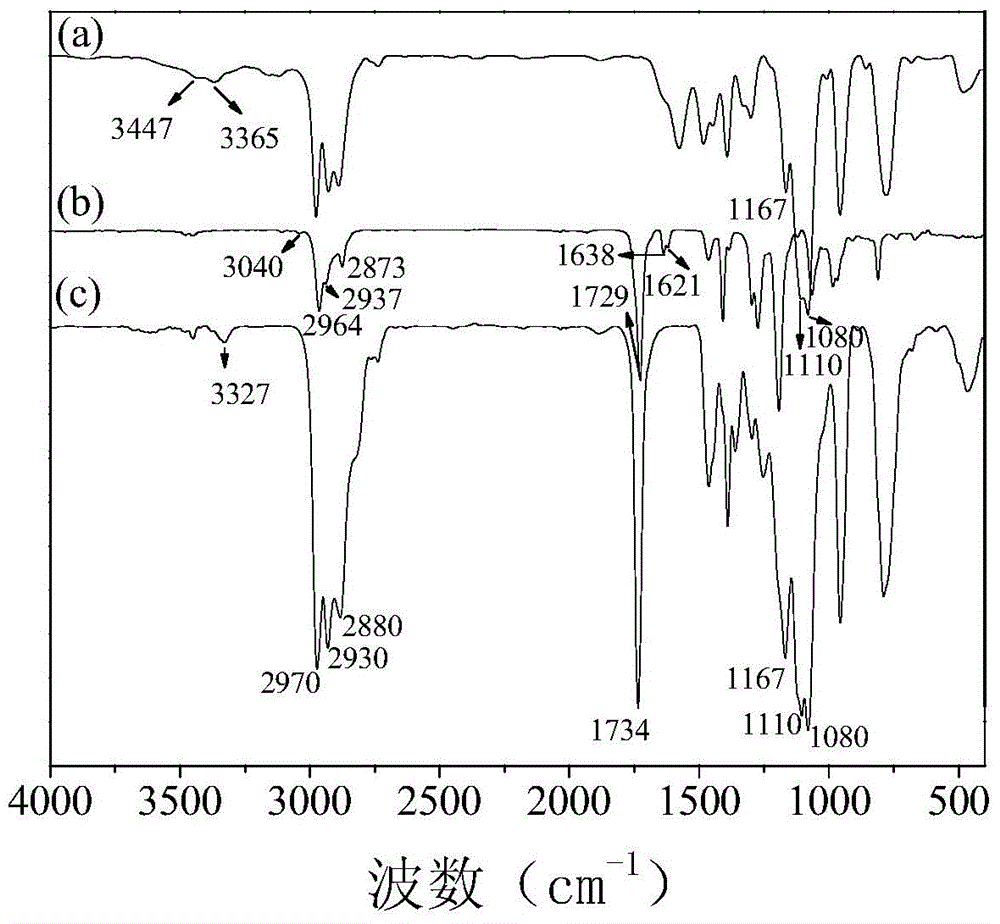

Silane terminated polyurethane oligomer and its preparation method

The invention discloses a silane terminated polyurethane oligomer and its preparation method. The method comprises the following steps: dehydrating polyether polyol under vacuum condition, degassing, and then cooling to the temperature of 50-100 DEG C; adding a micromolecule chain extender through drying treatment, a solvent through drying treatment, diisocyanate and a catalyst in polyether polyol in order, introducing high purity nitrogen as reaction protection gas, uniformly stirring, insulating at the temperature of 50-90 DEG C, and synthesizing the terminated isocyanate polyurethane prepolymer; reacting the terminated isocyanate polyurethane prepolymer and secondary amine silane, stirring at the temperature of 10-90 DEG C under the protection of high purity nitrogen, completing the reaction until no isocyanic acid is exsited in a system through titration, and removing bubbles under vacuum to obtain the silane terminated polyurethane oligomer. The process for terminating and modifying the polyurethane prepolymer by secondary amine silane is easy to controlled, no gelation phenomenon is generated, and the reappearance is good while the product is prepared.

Owner:SOUTH CHINA UNIV OF TECH

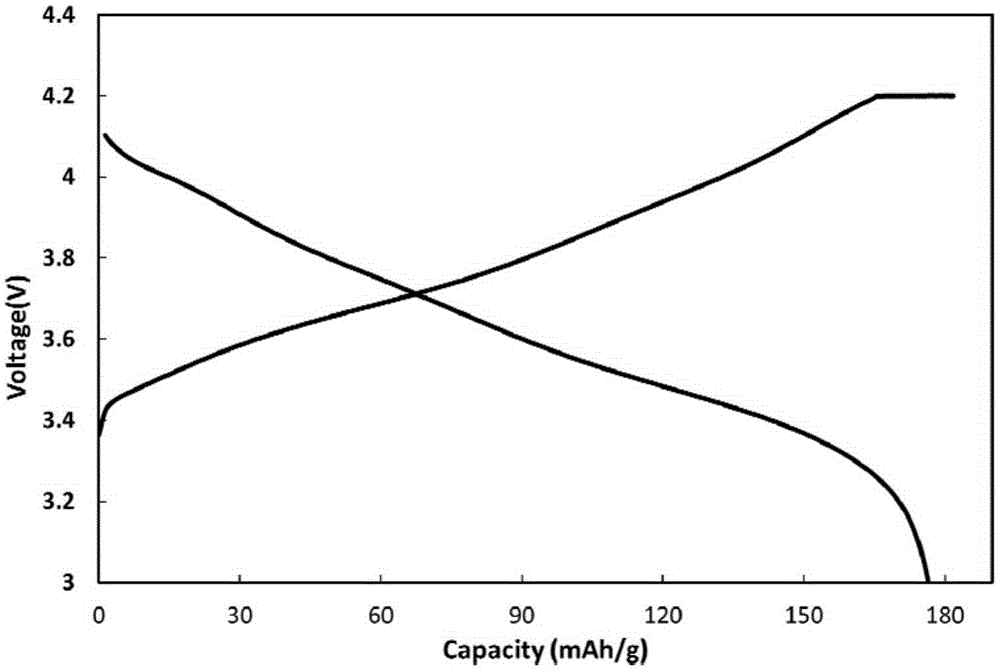

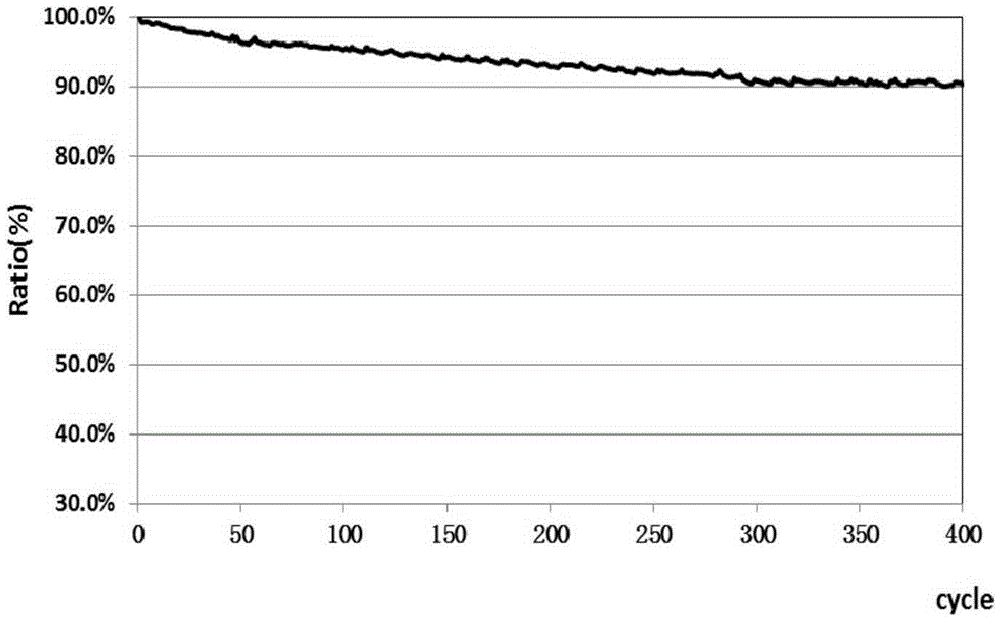

Positive electrode material for lithium ion battery and preparation method of positive electrode material

The invention discloses a positive electrode material for a lithium ion battery as well as a preparation method and application of the positive electrode material. Slurry prepared from the positive electrode material for the lithium ion battery is still stable after being arranged for a period of time and cannot be gelled, and therefore, a positive electrode piece can be prepared easily; meanwhile, the positive electrode material has excellent cycle performance at high temperature and under high voltage. According to the method for preparing the positive electrode material for the lithium ion battery, a microwave absorbent is added so that raw materials can be synthesized and subjected to coating reaction under a relatively high microwave power without secondary high-temperature annealing, and the added microwave absorbent which is taken as the raw material of the coating does not need to be removed, preparation operation is simple and industrial practicability is achieved.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

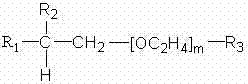

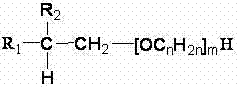

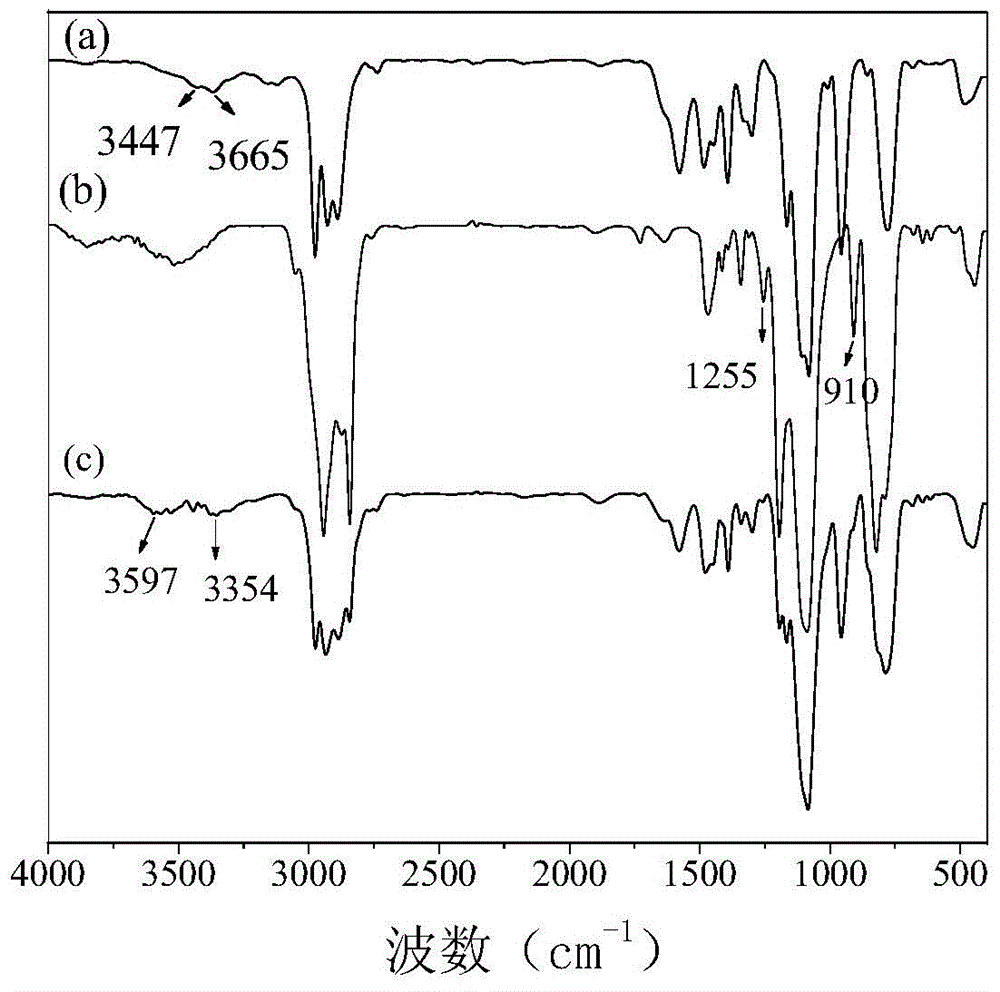

Method for preparing aqueous epoxy resin hardener

The present invention is process of preparing water soluble epoxy resin curing agent. The preparation process includes the following steps: 1. ring-opening reaction of polyethylene glycol and bisphenol A type epoxy resin under the action of catalyst to produce modified epoxy resin with epoxy groups in two ends; 2. dropping the modified epoxy resin into polyethylene polyamine to produce end amino-epoxy addition compound; 3. dropping compound 501 into the addition compound to produce end capping product; and 4. dropping organic acid into the end capping product to form salt and adding certain amount of water to produce the water soluble epoxy resin curing agent. The synthesized curing agent has high water solubility, capacity of well controlling reaction with polybasic amine and high flexibility.

Owner:TIANJIN UNIV

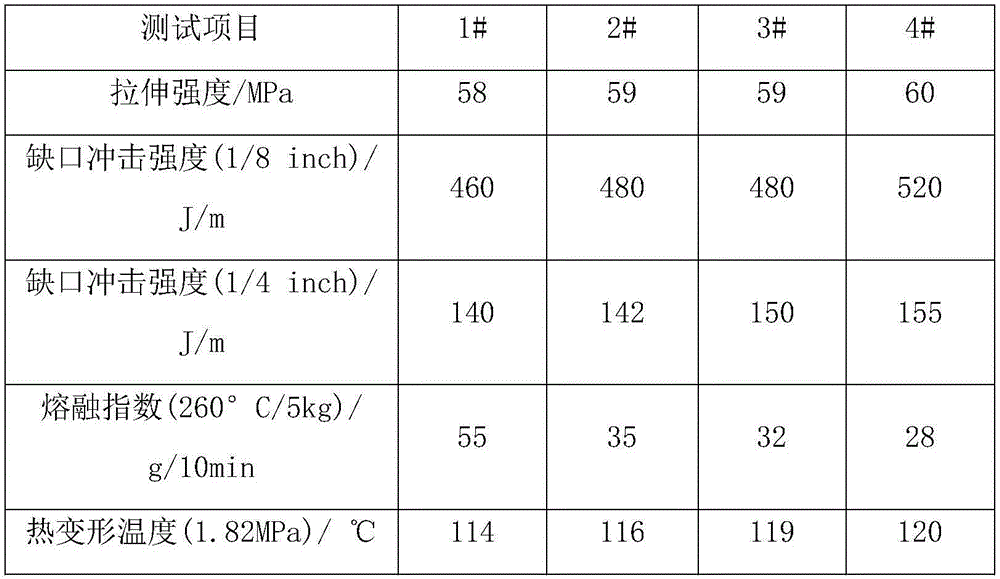

Special compatilizer for improving hydrolysis heat stability of PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) alloy and alloy

InactiveCN104877326AGood extrusion heat stabilityAppropriate GMA contentGlycidyl methacrylateHeat stability

The invention discloses a special compatilizer for improving hydrolysis heat stability of a PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) alloy and an alloy. The compatilizer is a terpolymer formed by copolymerizing aromatic vinyl monomer, acrylonitrile monomer and glycidyl methacrylate. The PC / ABS alloy with high hydrolysis heat stability comprises the following components in percentage by weight: 50-85% of PC, 10-45% of ABS, 0.5-5% of compatilizer, 0.1-1% of antioxidant and 0.1-0.5% of lubricant. Compared with the prior art, the special compatilizer for the PC / ABS alloy can be blended with other raw materials and subjected to extrusion and granulation in the preparation process to obtain the PC / ABS alloy with excellent hydrolysis heat stability on the premise of maintaining excellent mechanical properties in a simple, effective, convenient and cheap way.

Owner:SHANGHAI SUNNY

Preparation method of lithium ion battery high-nickel positive electrode material slurry

The invention discloses a preparation method of a lithium ion battery high-nickel positive electrode material slurry, and relates to lithium ion batteries. The preparation method comprises the steps: 1) adding an adhesive in a solvent, stirring, after dissolving, adding acetone, stirring, then adding an additive after the solution is swelled, stirring, carrying out vacuum deaeration, and thus obtaining a mixed adhesive solution with the additive and the adhesive; 2) adding a positive electrode active material and a conductive agent to the mixed adhesive solution obtained in the step 1), stirring for 0.5-1 h at the speed of 600-900 r / min, after preliminary pre-mixing of the slurry, stirring for 6-7 h at the stirring speed of 2000-3000 r / min to obtain a battery slurry, filtering, and thus obtaining the lithium ion battery high-nickel positive electrode material slurry. The prepared high-nickel positive electrode material slurry has no gel-forming phenomenon and has good slurry liquidity; and the material processability is extremely superior during production of a lithium ion battery positive electrode piece, and the battery has good electrochemical performance after the slurry is made into the battery.

Owner:XTC NEW ENERGY MATERIALS(XIAMEN) LTD

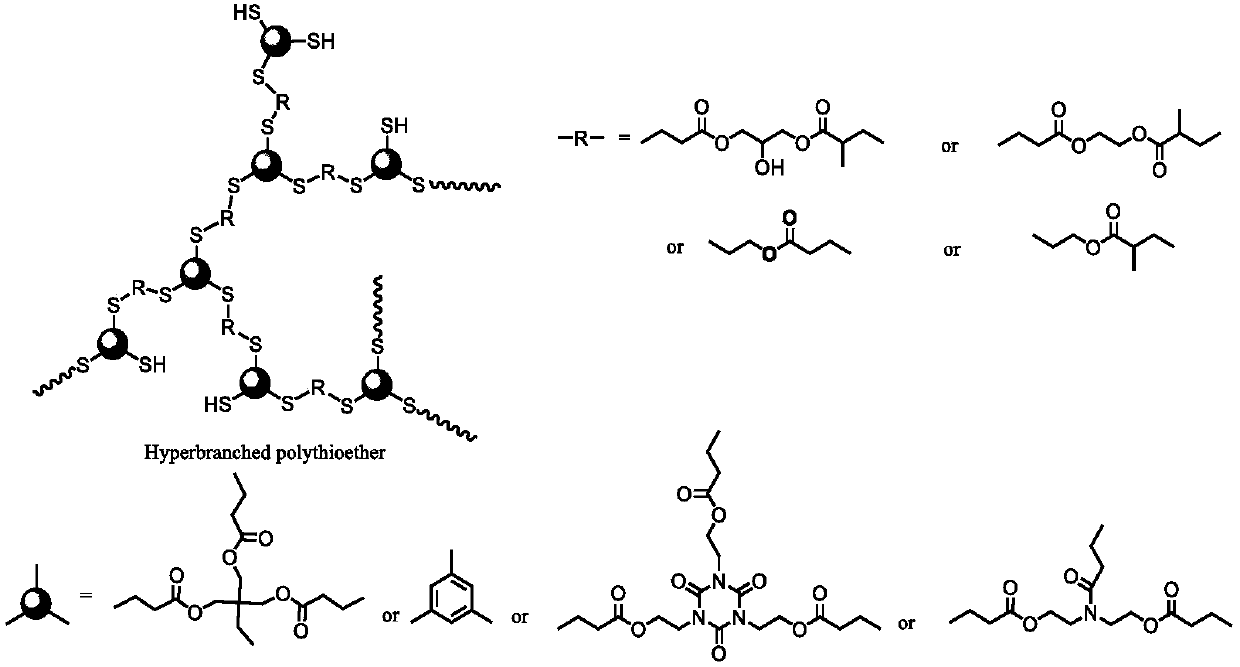

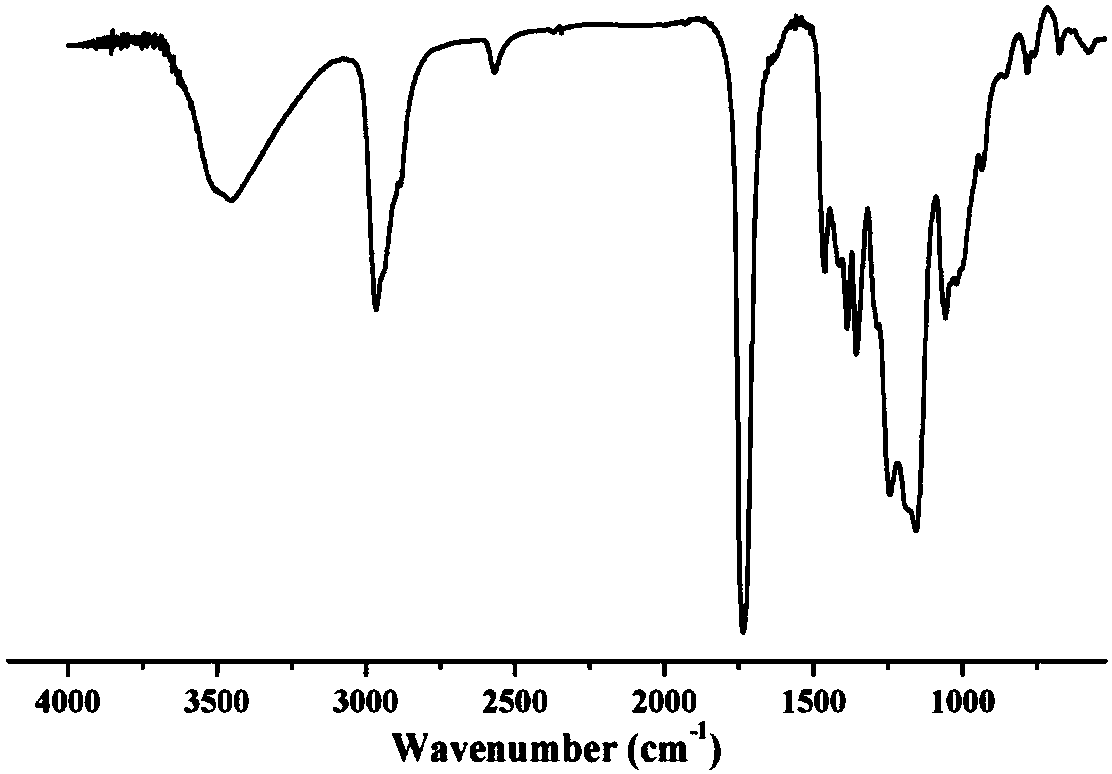

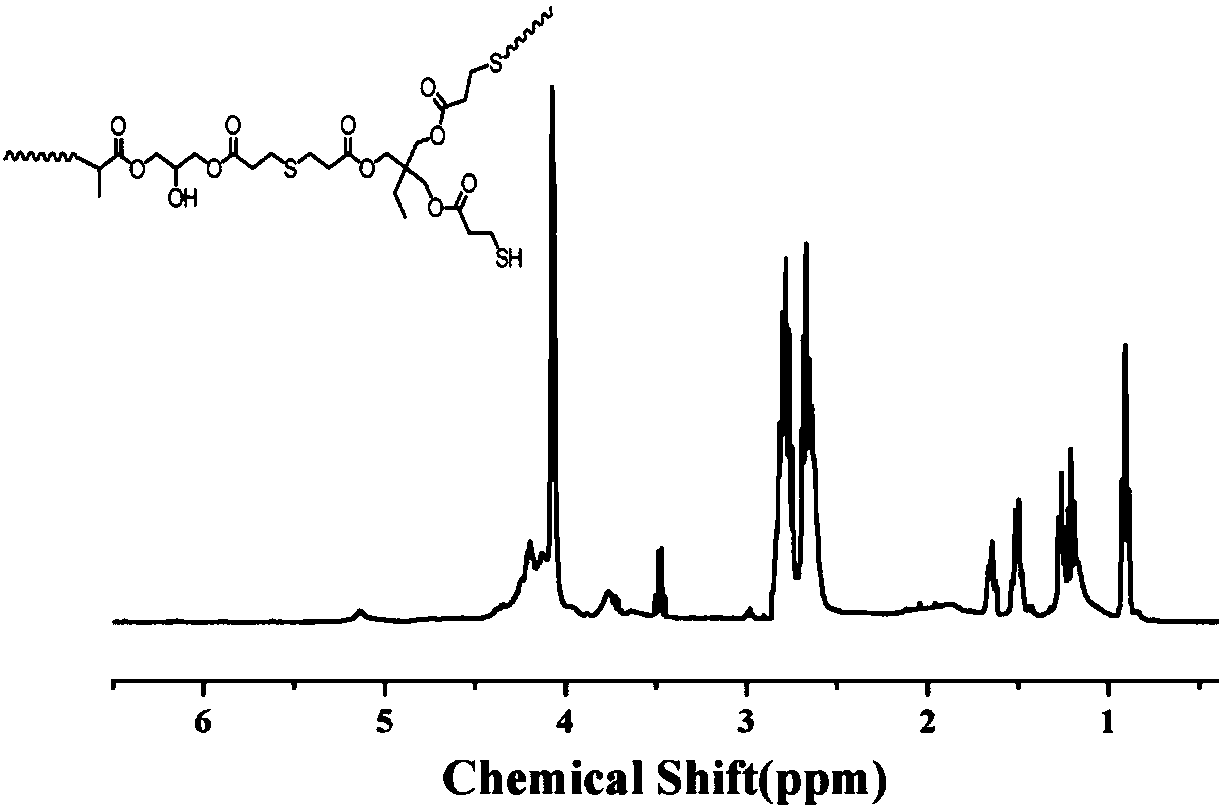

Hyperbranched polythioether preparation method

The invention relates to a hyperbranched polythioether preparation method. According to the preparation method disclosed by the invention, a bi-functionality asymmetric alkene compound and tri-functionality sulfur alcohol are utilized as raw materials, thiol-ene is utilized to perform unequal-reactivity addition reaction, and hyperbranched polythioether is synthesized by a one-pot method. The preparation method disclosed by the invention has the advantages that the raw materials are easy to obtain, and the steps are simple; a terminal group of the prepared hyperbranched polythioether is sulfydryl; functional modification can be further performed; thus, the hyperbranched polythioether with specific performance can be prepared.

Owner:JIANGNAN UNIV

Synthesis of methacrylate allyl propyl ester

InactiveCN1410412ANo gel phenomenonEasy to operateOrganic compound preparationCarboxylic acid esters preparationHydroquinone CompoundP-Toluenesulfonic acid

A process for synthesizing allyl methylacrylate includes such steps as under the existance of catalyst (p-toluenesulfonic acid) and polymerization inhibitor (hydroquinone), reaction between methylacrylic acid and allyl alcohol under the reflux condition while continuously removing the generated water, fractionating to recover the excessive allyl alcohol, and pressure-reduction distilling for purifying the product. Its advantages are high output rate (90-92%), high purity (98-99%), and no pollution.

Owner:湖北武大有机硅新材料股份有限公司

Low-foam green CIP bactericidal concentrated cleaning agent

ActiveCN107937171APromote degradationEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsProduction lineFood industry

The invention discloses a low-foam green CIP bactericidal concentrated cleaning agent, and relates to the field of CIP engineering cleaning agents. The cleaning agent aims to solve the technical problems that the time of a cleaning process is long, industrial wastewater is easy to cause environmental pollution, and green cleaning standards are not met in the existing food industry. The cleaning agent is prepared from an active component, an assistant, a chelating agent, a penetrating agent, an antifoaming agent, a bactericide, a pH regulator and residual deionized water. The cleaning agent isapplicable to the cleaning of food production line CIP, has excellent hard water resistance and dirt-removing power, adopts a nonionic / anionic surfactant with excellent biological degradability, belongs to an efficient CIP green cleaning agent integrating low foam and bactericidal activity, and can effectively remove various food dirt.

Owner:HEILONGJIANG HEIKE TECH CO LTD

Washing composition as well as preparation method and application of washing composition

InactiveCN105779165AReduce surface tensionNo cloud pointCosmetic preparationsOrganic detergent compounding agentsBetaineAllergy

The invention discloses a washing composition as well as a preparation method and application of the washing composition. The washing composition is prepared by taking water, alkyl polyglucoside, propylene glycol, alkyl betaine, sodium lauryl sulfate, flos lonicerae extract, chrysanthemum extract, radix sophorae flavescentis extract, mint extract, table vinegar (edible acetic acid), table salt, edible essence and a thickening agent as raw materials, and has the functions and characteristics of sterilization and disinfection, oil removal and stain removal, itching stopping and skin protection, odor removal and deodorization, low foam, and capability of being cleaned by washing; meanwhile, alcohol, an alkali, a preservative and other disinfection components are not added, so that a functional skin-protection daily chemical washing product, which can be used for naturally killing viruses and sterilizing, removing oil and dirt, stopping itching and dandruff, resisting allergy and protection skins, and has a medicine effect, is obtained.

Owner:杨秀庆

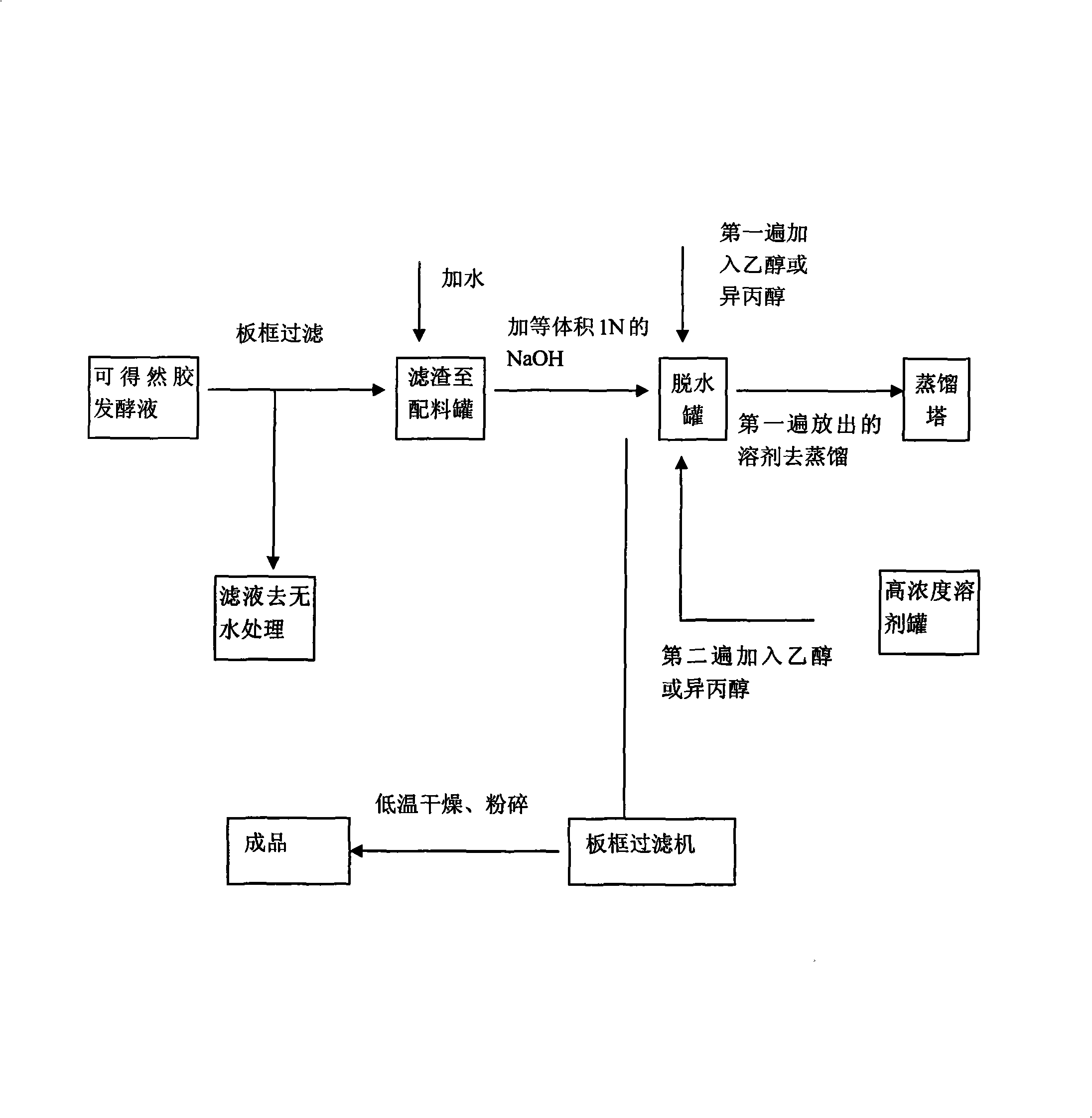

Production method of curdlan by dissolvant method abstraction

The invention provides a solvent method for extracting and making curdlan, relating to the purification and extraction as well as production technique of curdlan products. The technical proposal is as follows: (1) an organic solvent such as alcohol and isopropanol is taken as a dehydrating agent to dehydrate the curdlan aqueous alkali, the gel phenomenon does not exist in the production process, thereby being easy to remove water, salinity and pigment; (2) after the curdlan and the organic solvent are mixed, the solid and liquid are separated by adopting the layered overflow way; (3) the organic solvent is applied for a plurality of times to extract the curdlan with a plurality of times of dehydration. The method adopts the organic solvent method to purify and extract as well as produce the curdlan, and has an extracting yield more than 90 percent; the product has high purity quotient and good quality; the production process can realize the serialization and the automation.

Owner:SHANDONG FOOD & FERMENT IND RES & DESIGN INST

Anti-oxidation paint of fireproof carbon-containing materials

The invention relates to an anti-oxidation paint of fireproof carbon-containing materials which comprises (by weight ratio) filling material 48-72%, yellow dextrin 2-4%, silicon micronized quartz powder 4-10% and balancing water. The invention realizes good storage stability, thus no gelatin phenomenon will happen after long period of storage.

Owner:WUHAN IRON & STEEL (GROUP) CORP

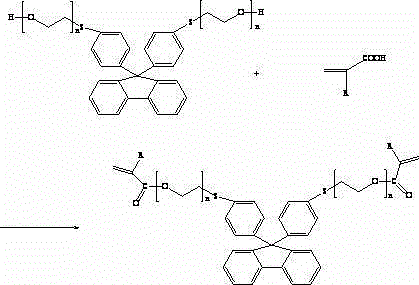

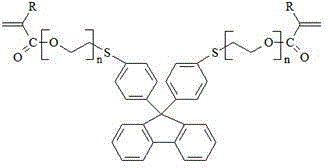

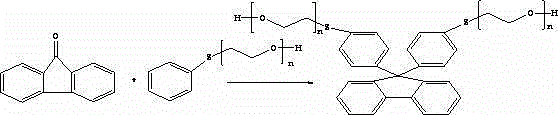

Photocuring resin containing polyethoxy bisthiophenyl fluorene structure and preparation method thereof

The invention relates to the technical field of a resin and a preparation method thereof, particularly a photocuring resin containing polyethoxy bisthiophenyl fluorene structure and a preparation method thereof. The preparation method comprises the following steps: adding 9.9-(4-thiophenyl-hydroxypolyethoxy)bis fluorene and (methyl)acrylic acid into an organic solvent, and carrying out esterification reaction by using an organic acid as a catalyst in the presence of a polymerization inhibitor and a reducer; and after the reaction finishes, carrying out salt washing, neutralization, water washing, drying and reduced pressure distillation to remove the solvent, thereby obtaining the 9.9-(4-thiophenyl-(methyl)acryloyloxypolyethoxy)bis fluorene. The polyethoxy acrylate resin containing bisthiophenyl fluorene structure is a colorless or light yellow transparent photocuring resin, has favorable heat resistance and transparency, and has different refractive index gradients.

Owner:东莞市贝特利新材料有限公司

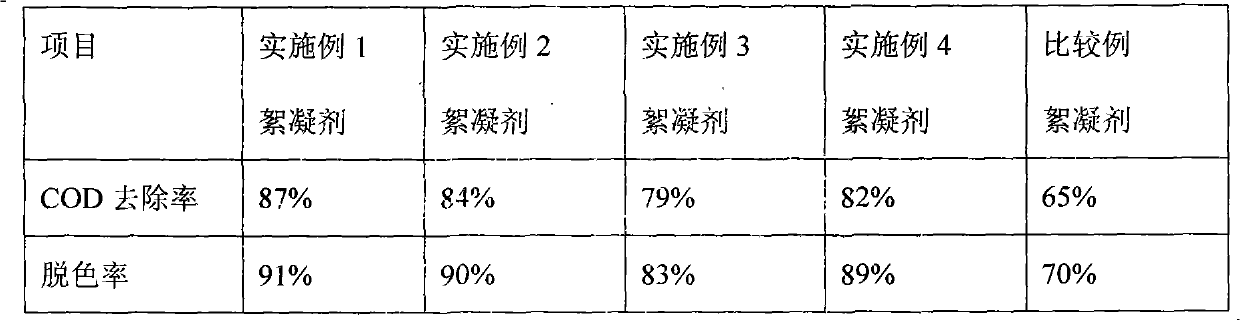

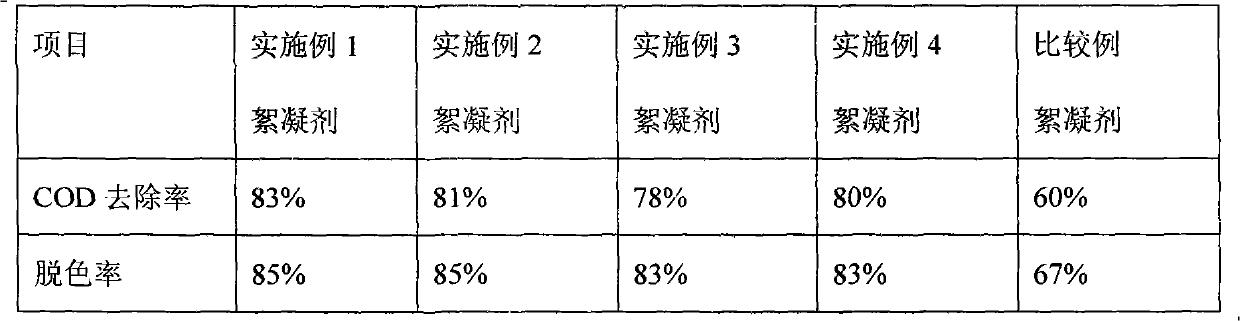

Preparation method of starch-grafted dicyandiamide formaldehyde polycondensate flocculants

InactiveCN102863065AGood storage stabilityNo gel phenomenonWater/sewage treatment by flocculation/precipitationIonDouble bond

The invention discloses a preparation method of starch-grafted dicyandiamide formaldehyde polycondensate flocculants. The preparation method includes the steps: (1) adding formaldehyde and ammonium chloride in a reaction kettle to react for 0.5-1.0h at the temperature of 40-80 DEG C, then adding dicyandiamide to react for 1.0-2.0h, and adding acrylamide and the formaldehyde to react for 0.5-2.0h so that a cationic polymer including C=C double bonds is obtained; and (2) taking, by weight, 5-10 parts of starch, 5-15 parts of the cationic polymer including the C=C double bonds prepared in the step (1), 0.01-1.0 part of initiators and 75-90 parts of deionized water to react for 1-4h in the presence of nitrogen gas at the temperature of 70-85 DEG C. The flocculants prepared by the preparation method are good in decoloring flocculation effect, less in consumption and low in cost and is suitable for flocculating decoloration of industrial sewage such as printing and dyeing and papermaking and urban sewage.

Owner:QINGDAO UNIV OF SCI & TECH

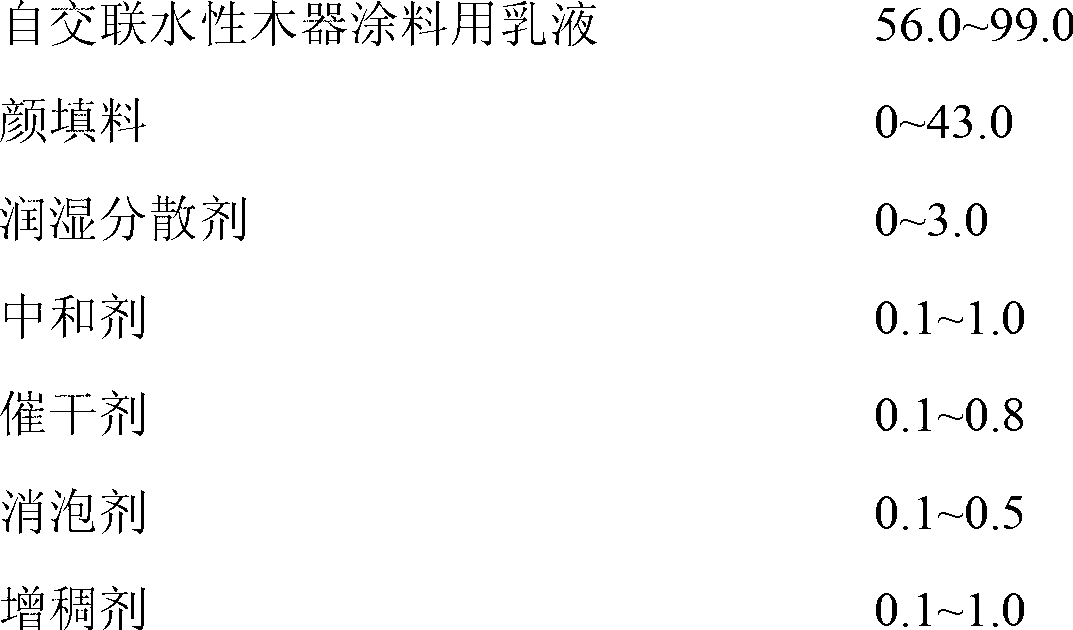

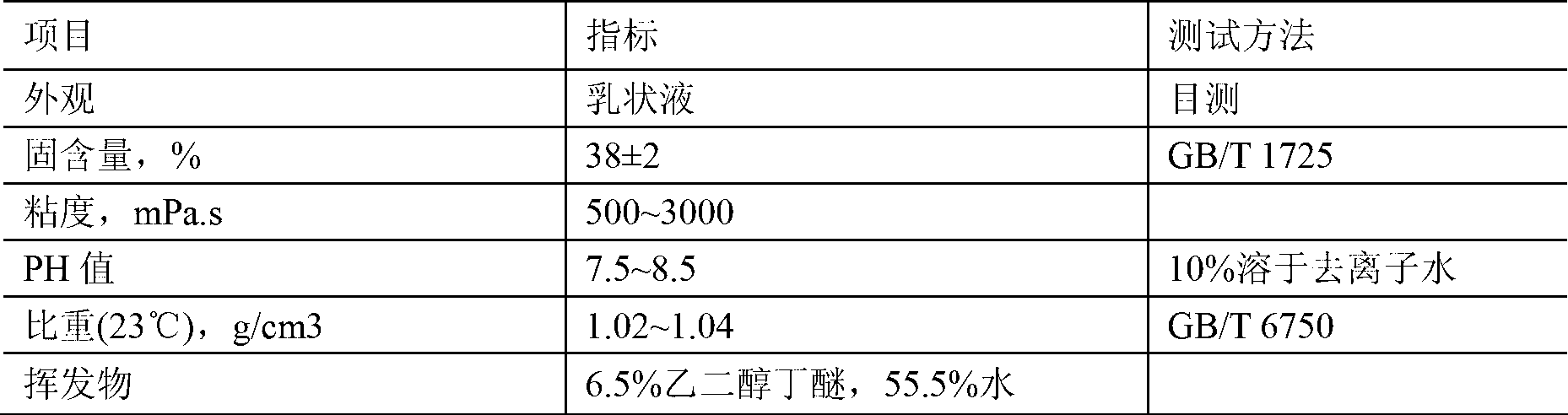

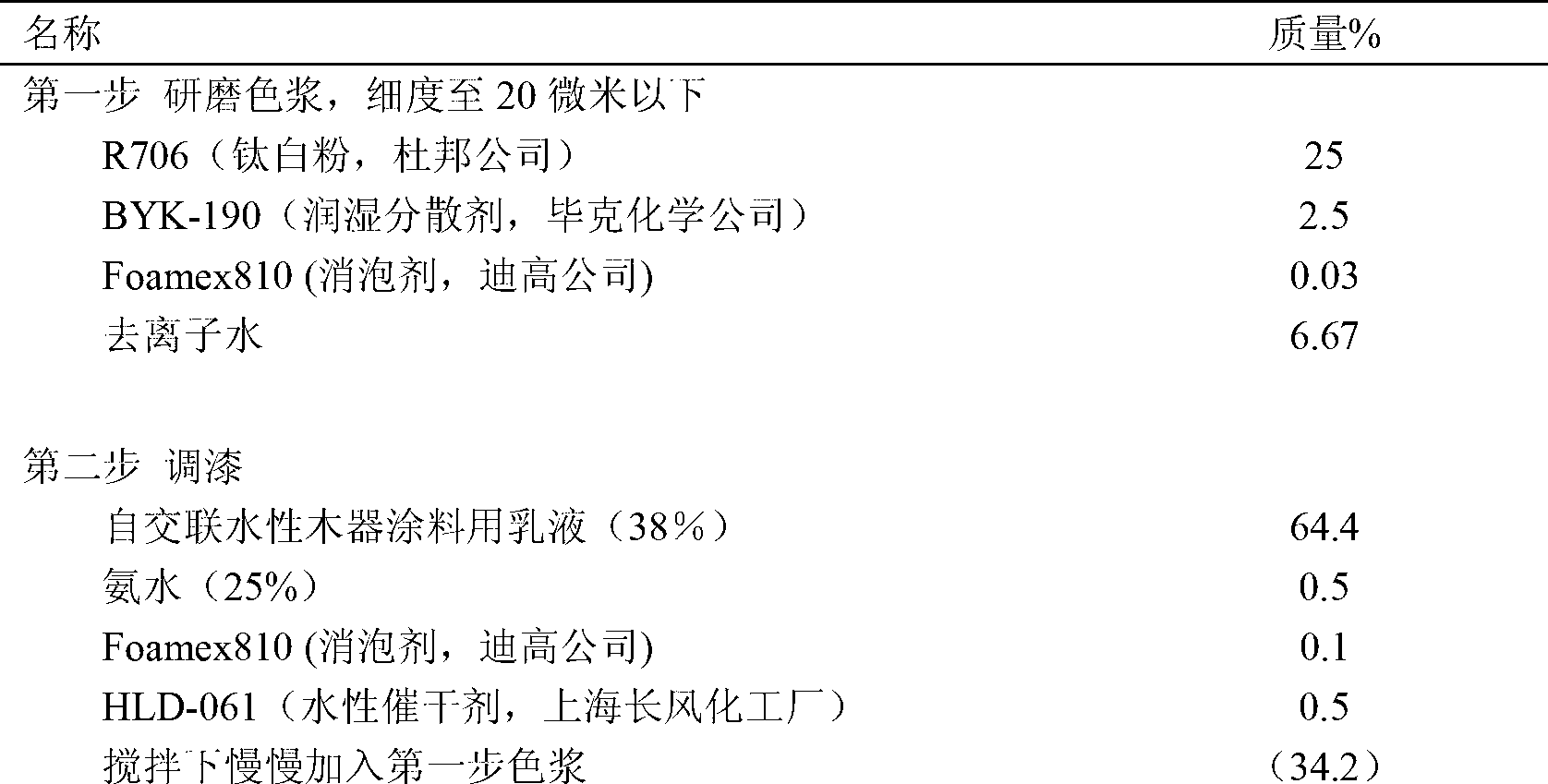

Method for preparing emulsion for self-crosslinked waterborne wood coating

The invention discloses a method for preparing emulsion for a self-crosslinked waterborne wood coating. The emulsion comprises a component A and a component B. The method is characterized in that the preparation process comprises the following steps of a, for the component A, preparing acrylic resin with a high acid value containing air dry vegetable oil fatty acid composition, wherein the acid value is 180-240mgKOH / g; b, for the component B, preparing the acrylic resin with a high hydroxyl value, wherein the hydroxyl value is 120-260mgKOH / g; c, carrying out esterification reaction between the acrylic resin (component A) with the high acid value and the acrylic resin (component B) with the high hydroxyl value, neutralizing with ammonia (or amine) and diluting with water after the acid value is qualified, so as to obtain the emulsion C for the self-crosslinked waterborne wood coating. The emulsion can be used for preparing the self-crosslinked waterborne wood coating. The paint is low in VOC (volatile organic compound) content, accords with the environmental protection requirement, belongs to the environment friendly type, and can be widely applied to furniture coating and house decoration.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Method for rapidly judging stability of neutral high-fiber milk

ActiveCN103487560AIncrease the sedimentation rateTo promote floatingTesting dairy productsFiberViscosity

The invention discloses a method for rapidly judging stability of neutral high-fiber milk and belongs to the technical field of rapid dairy stability judgment. According to the method for rapidly judging the stability of the neutral high-fiber milk, the stability of the neutral high-fiber milk in shelf life is judged by measuring change conditions of viscosity, particles size and potential index before and after accelerated quality deterioration under constant temperature conditions of 4 DEG C, 25 DEG C, 37 DEG C and 50 DEG C. According to the method, the observation time of the stability of high-fiber milk products is greatly shortened, good or poor stability of the high-fiber milk products are basically judged within 10 days, the product development period is shortened, and the labor productivity is improved; the method has significance on developing products in dairy enterprises, and a gap of rapidly judging the stability of the neutral high-fiber milk is filled.

Owner:HEBEI BROS ILONG FOOD TECH LLC

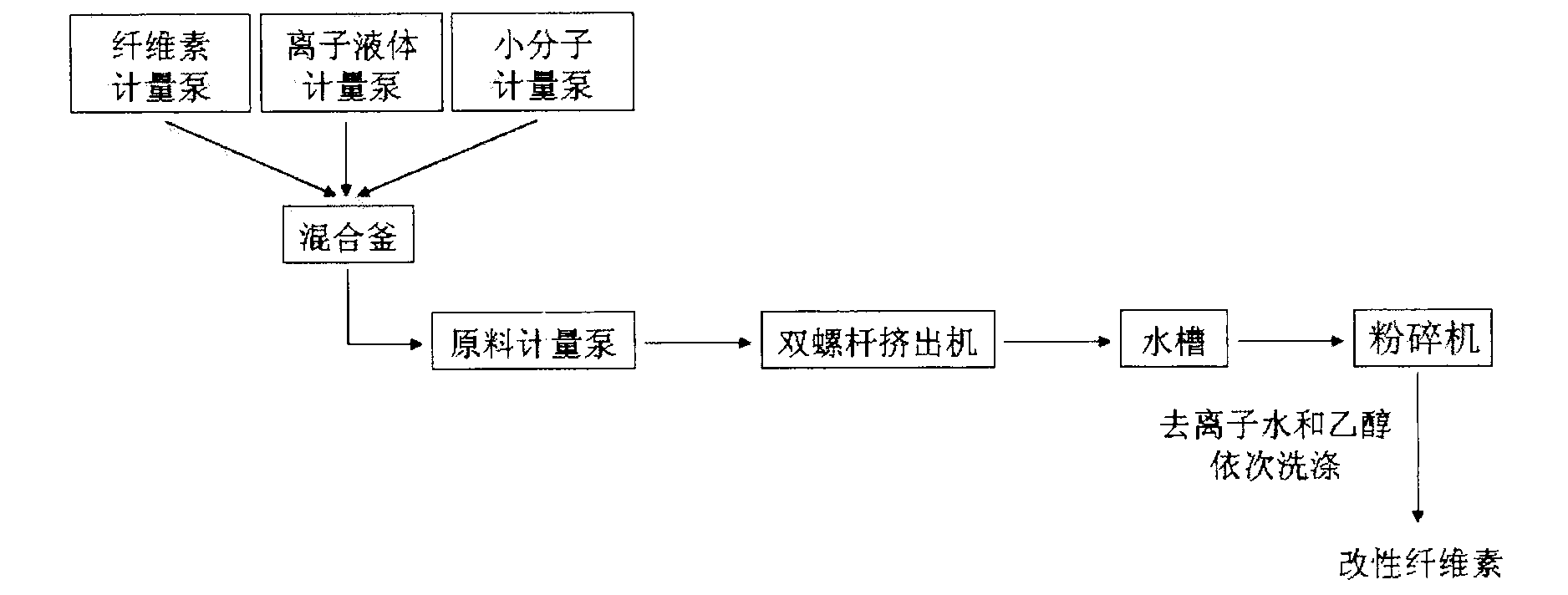

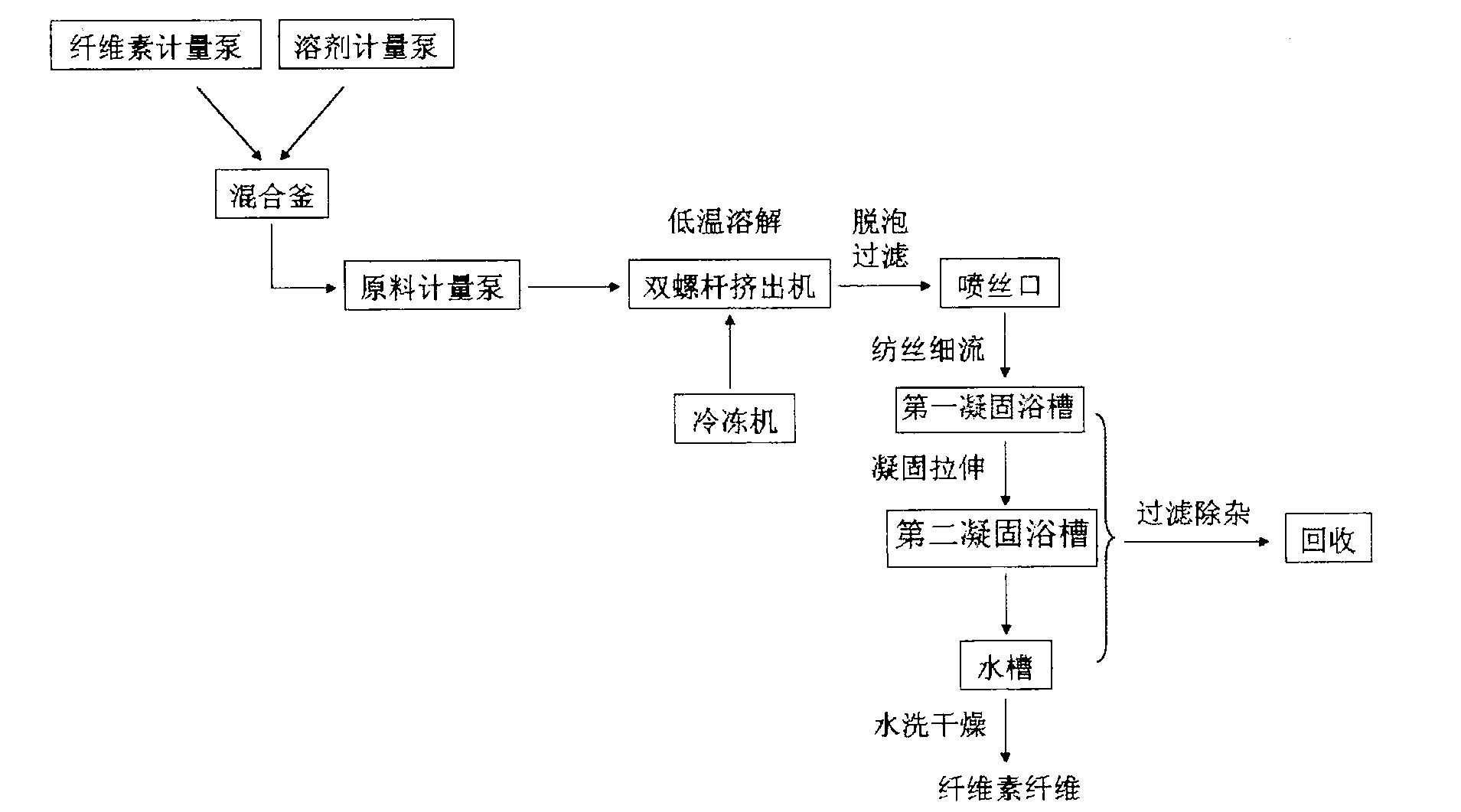

Process and devices for chemical modification of cellulose and for continuous low temperature solution spinning

InactiveCN103290503AEasy to processImprove solubilityArtificial thread manufacturing machinesArtificial filaments from cellulose derivativesFiltrationCellulose fiber

The invention provides a process and devices for chemical modification of cellulose and for continuous low temperature solution spinning. The process for the chemical modification of the cellulose and for the continuous low temperature solution spinning comprises: after vacuum drying the cellulose, uniformly mixing the dried cellulose with an ionic liquid and modified small molecules in a certain proportion to obtain a mixture, extruding the obtained mixture by a double-screw extruder, and washing the extruded product successively by water and ethanol solvent, drying, crushing to obtain a modified cellulose powder; adding the modified cellulose powder and a solvent in a certain proportion to a mixing kettle, after stirring and mixing uniformly at the room temperature, carrying out extrusion, deaeration, and filtration by using the double-screw extruder, then putting into a spinning assembly, spaying out of a spinneret of the spinning assembly to obtain fibers, putting the obtained fibers successively into a first coagulation bath and a second coagulation bath to rapidly solidify and stretch into solids, after water washing in a water tank, and winding into modified cellulose fibers. The process and the devices can substantially enhance the spinning efficiency, and improve the cellulose fiber performance.

Owner:DONGHUA UNIV

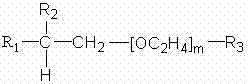

Fluorosilicon modified polyether polymer and preparation method thereof

InactiveCN109535362ANo gel phenomenonGood reproducibilityPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolPrepolymer

The invention relates to a preparation method of a fluorosilicon modified polyether polymer. The method includes: (1) subjecting polyether polyol to dehydration and degassing under a 90-130DEG C vacuum condition for 1-4h, then performing cooling to 50-80DEG C, adding diisocyanate and a catalyst into polyether polyol; introducing inert gas, stirring the substances evenly, and carrying out reactionat 50-90DEG C for 1-6h, thus obtaining an isocyanate group-terminated polyether prepolymer; and (2) mixing the isocyanate group-terminated polyether prepolymer with a fluorine-containing secondary amino silane coupling agent, and carrying out reaction at 30-90DEG C under inert gas protection for 1-6h till no existence of isocyanato in the system through titration, and ending the reaction, thus obtaining the fluorosilicon modified polyether polymer. The invention also relates to the fluorosilicon modified polyether polymer and the fluorine-containing secondary amino silane coupling agent. The process of termination and modification on the isocyanate group polyether prepolymer with the secondary amino silane coupling agent is easily controllable, no gelation phenomenon occurs, and the product has good preparation reproducibility.

Owner:SHANGHAI DONGDA CHEM

Low foam lubricating liquid for food beverage chain conveying belt

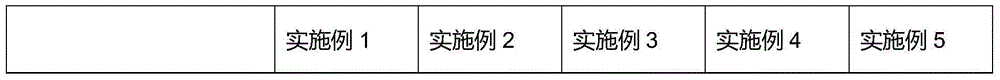

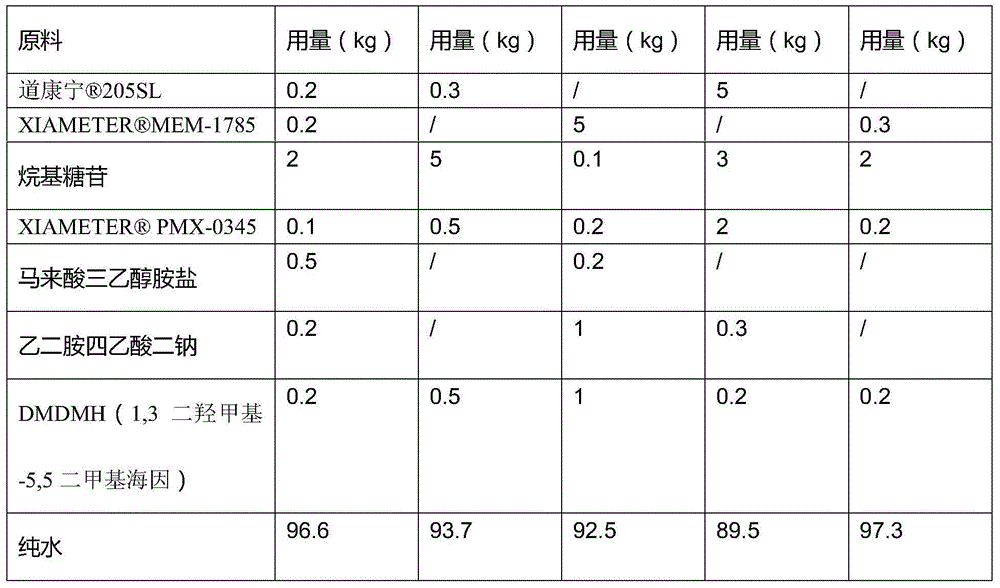

InactiveCN104479841AImprove the lubrication effectGood water solubilityLubricant compositionSolubilityPreservative

The invention discloses a low foam lubricating liquid for a food beverage chain conveying belt, wherein 0.1-5% by weight of water-soluble emulsified silicone oil, 0.1-5% by weight of alkyl glucoside, 0.1-2% by weight of an anti-foaming lubricant, 0-0.5% by weight of an anti-rust agent, 0-1% by weight of a scale inhibitor, 0.2-1.0% by weight of a preservative, and the balance of water are mixed, and a pH value adjusting agent is added to adjust the pH value to 6.0-7.0 so as to obtain the low foam lubricating liquid. The low foam lubricating liquid has characteristics of good lubricity, good cleaning effect, good water solubility, low foam, no toxicity, no corrosion, good environmental compatibility, easy production, and convenient use.

Owner:HANGZHOU WAHAHA TECH

Room temperature vulcanized fluorosilicone rubber and preparation method thereof

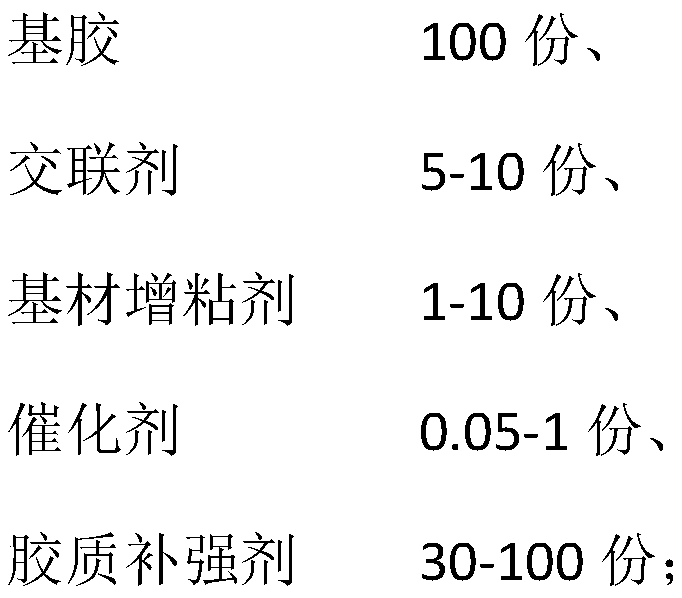

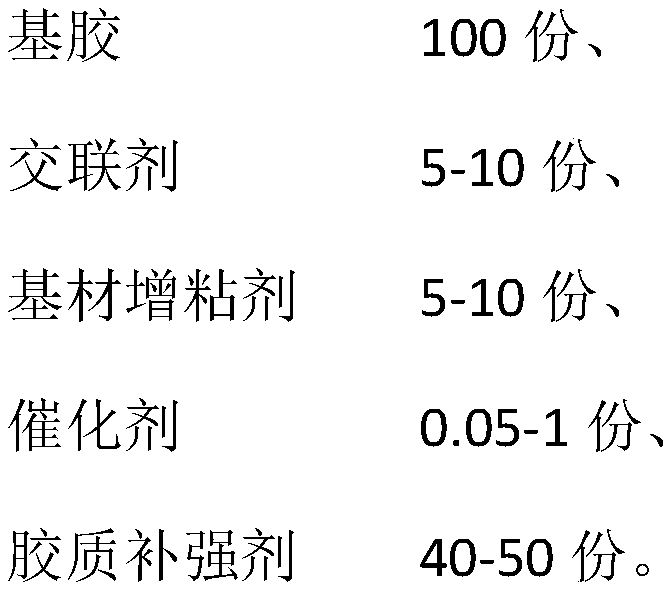

The invention relates to a room -temperature vulcanized fluorosilicone rubber and a preparation method thereof. The room temperature vulcanized fluorosilicone rubber is prepared from, by weight, 100 parts of a base rubber, 5-10 parts of a cross-linking agent, 1-10 parts of a base material tackifier, 0.05-1 part of a catalyst and 30-100 parts of a colloid reinforcing agent; the base rubber is alkoxy-terminated fluorine-containing polysiloxane; and the cross-linking agent is fluoroalkylalkoxysilane. Compared with traditional dealcoholized RTV silicone rubbers, the room temperature vulcanized fluorosilicone rubber prepared in the invention has the advantages of greatly improved oil resistance, greatly improved antifouling property, greatly improved bonding property, greatly improved storage property and good processability.

Owner:GUANGZHOU DAOLIN SYNTHETIC MATERIALS CO LTD +2

Chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as passivating agent

PendingCN109778159AMeet anti-corrosion requirementsImprove anti-corrosion performanceAnti-corrosive paintsMetallic material coating processesPhosphomolybdic acidChromium free

The invention discloses a water-borne chromium-free zinc-aluminum anticorrosive paint with phosphomolybdic acid hydrate as a passivating agent. The water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent includes the following components, by mass, 250-310 parts of zinc powder, 10-30 parts of aluminum powder, 3-10 parts of the phosphomolybdic acid hydrate, 110-150 parts of polyethylene glycol, 70-140 parts of a silane coupling agent, 3-8 parts of 2-ethoxyethyl acetate, 1-18 parts of a surfactant, 1-6 parts of a defoaming agent,10-60 parts of tetraisopropyl titanate, 10-18 parts of boric acid and 380-480 parts of deionized water. The polyethylene glycol and the silane coupling agent being 35-50% of the total amount of formula, the 2-ethoxyethyl acetate, the surfactant and the defoaming agent are stirred to be made into an A component; the deionized water, the phosphomolybdic acid hydrate and the silane coupling agent inthe weight ratio and being 50-65% of the total amount of the formula, the tetraisopropyl titanate and the boric acid are stirred to be made into a B component; before use, the A component and the B component are mixed and stirred uniformly according to the weight ratio of 1:1-1.4, and the finished paint is prepared. The thermal stability of the prepared product of the water-borne chromium-free zinc-aluminum anticorrosive paint with the phosphomolybdic acid hydrate as the passivating agent is improved, and a coating after coating conforms to the comprehensive performance requirements of a thincoating, high adhesive strength, good anticorrosive performance and the like required by an automobile fastener.

Owner:沈阳市航达科技有限责任公司

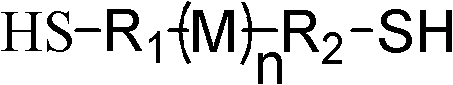

Preparation method of double-mercapto-terminal polymer

ActiveCN102924638AImprove solubilityNarrow molecular weight distributionChromatographic separationMetallic lithium

The invention relates to a preparation method of a double-mercapto-terminal polymer. The preparation method comprises the following steps: reacting a mercapto protection reagent with halomercaptan in a polar solvent according to a molar ratio of 1:1 at -5-5DEG C for 24h, extracting with a weakly-polar solvent, taking the obtained supernatant, evaporating in a rotary evaporator to remove the solvents, and carrying out column chromatography separation to obtain an initiator intermediate, wherein a catalyst used in the above reaction is imidazole, pyrimidine or pyridine; reacting the initiator intermediate with metallic lithium in a non-polar solvent at 30-70DEG C to obtain an initiator, wherein the molar ratio of the initiator intermediate to the metallic lithium is 1:6.7; sequentially adding a solvent, the initiator, a monomer and a structure adjustment agent to a reaction kettle, and reacting at 0-60DEG C to obtain an active polymer; adding a terminating reagent to the polymer, reacting, and adding methanol to terminate; and acidifying the terminated polymer by an inorganic acid to obtain the double-mercapto-terminal polymer. The obtained polymer has the advantages of narrow molecular weight distribution, controllable molecular weight, adjustable chain microstructure, and high functionalization efficiency.

Owner:PETROCHINA CO LTD

Cationic polymerization method for vinyl monomer

The invention discloses a cationic polymerization method for vinyl monomer. In the method, a reaction medium, the vinyl monomer, an initiator, lewis acid and an additive are used, wherein the reaction medium is a mixed reaction medium comprising an organic solvent and water or completely water; the organic solvent is at least one selected from alkane, naphthenic hydrocarbon and halogenated hydrocarbon; the lewis acid is one or a mixture of substances which accord with a general formula of MXn or YRn-mXm; the additive is an oxygen atom and nitrogen atom-containing organic compound; the molar ratio of the lewis acid to the additive to the monomer is 1.0*10<-3> to 3.2*10<-2>:1.0*10<-3> to 3.0*10<-1>:1; and the materials are reacted at the temperature of between -100 and 50 DE C for 0.5 minute to 2 hours to form a polymerization product, namely polymer with molecular weight of 10<5>. The method can simplifies the process flow, saves the production cost, and has great significance and considerable market application value.

Owner:BEIJING UNIV OF CHEM TECH

Water absorbent resin for hygienic materials

Water absorbent resin for hygienic materials is prepared by mixing the following raw materials by weight: 40-70 parts of acrylic acid, 30-50 parts of modified starch, 2-10 parts of acrylamide, 2-4 parts of aminoacetic acid, 1-3 parts of talcum powder, 2-6 parts of sodium alginate, 1-3 parts of an initiator, 2-4 parts of mannitol, and 1-2 parts of lactitol. The production raw materials of the invention are simple and low in price, so that the production investment is less, and the produced super water absorbent resin has very high water absorption capacity, and no gelatin phenomenon after water absorption, is high in water absorption speed, low in price, free of pollution, and high in profit, and is suitable for large-scale popularization and application.

Owner:凯姆勒科技发展(天津)有限公司

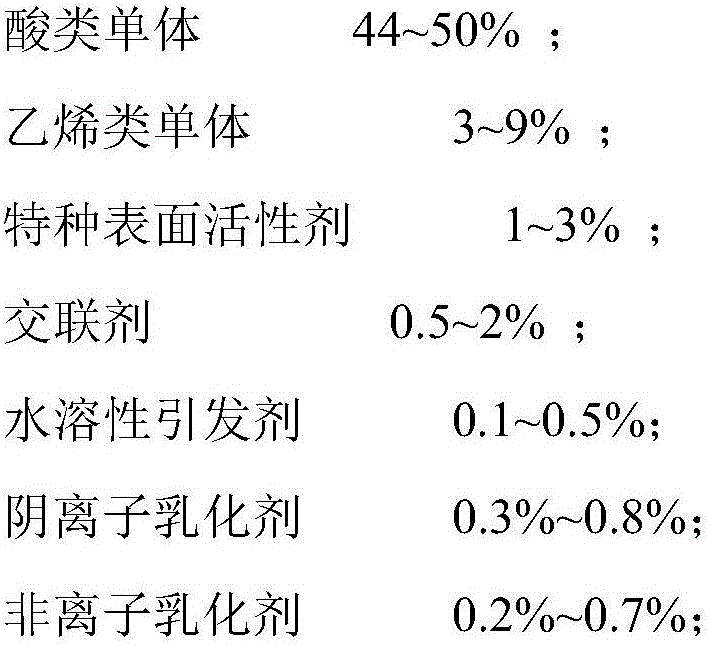

Imitated active paint printing adhesive, and preparation method and application method thereof

ActiveCN106749863AHigh solid contentAdequate follow-up responseDyeing processTextile printerPolymer science

The invention relates to an imitated active paint printing adhesive, and a preparation method and an application method thereof. The adhesive is prepared from the preparation raw materials: 44 to 50 percent of acrylic monomers, 3 to 9 percent of ethyl monomers, 1 to 3 percent of special surfactants, 0.5 to 2 percent of cross-linking agents, 0.1 to 0.5 percent of water-soluble initiators, 0.3 to 0.8 percent of anionic emulsifiers, 0.2 to 0.7 percent of nonionic emulsifiers and the balance of deionized water, wherein the raw ingredient percentage is the weight percentage.

Owner:苏州联胜化学有限公司

Muscle therapy mineral bath salt

InactiveCN103845256AReduce surface tensionNo cloud pointCosmetic preparationsAntipyreticMedicineSea salt

The invention discloses a muscle therapy mineral bath salt. The muscle therapy mineral bath salt is prepared from the following components in parts by weight according to a conventional method: 800 parts of sea salt, 20 parts of C8-10 alkyl glucoside, 10 parts of sandalwood, 5 parts of clove, 15 parts of wrinkled giant hyssop, 2 parts of eucalyptus essential oil and 3 parts of rosemary essential oil. The muscle therapy mineral bath salt disclosed by the invention can effectively relieve muscle pain as well as whiten, exfoliate and moisturize the skin. The muscle therapy mineral bath salt is rich in pure natural traditional Chinese medicine raw materials, and can enable body skin to enjoy bath salt essential nourishing every day and take good care of every inch of the skin. The muscle therapy mineral bath salt is particularly suitable for people with neck and shoulder pain or various muscle pains.

Owner:叶海涛

High-speed filling line lubricant and preparation method thereof

ActiveCN108085119AInhibitionImprove the lubrication effectLubricant compositionPhosphateFatty alcohol

The invention belongs to the technical field of lubricants, and particularly relates to a high-speed filling line lubricant and a preparation method thereof. The high-speed filling line lubricant comprises the following raw materials in parts by weight: 5-15 parts of trans block polyether, 4-12 parts of alkyl glycoside, 2-10 parts of fatty alcohol ether phosphate, 1-5 parts of disodium ethylene diamine tetraacetate, 1-5 parts of isothiazolinone, 1-8 parts of ethanol and 45-86 parts of water. The high-speed filling line lubricant abandons the conventional aliphatic amine system, uses the transblock polyether as a main lubricant which is compounded with the alkyl glycoside and the fatty alcohol ether phosphate, has excellent anti-blocking performance and lubricating performance, and solvesthe shaking problem during filling on a high-speed line; the high-speed filling line lubricant is compounded at room temperature, and has no peculiar smell in the production process; a preparation technology is simple and easy to operate, low in energy consumption, environment-friendly and pollution-free.

Owner:河南昊化黎明智能清洗科技有限公司

Waterless nano laundry detergent and manufacturing technique thereof

InactiveCN104962401ANo pollutionReduce wasteSurface-active detergent compositionsDetergent compounding agentsActive matterPropanediol

The invention discloses a waterless nano laundry detergent and a manufacturing technique thereof. The waterless nano laundry detergent comprises the following components in parts by weight: 50-65 parts of fatty acid methyl ester polyethenoxy ether, 10-20 parts of alkyl synthol alkoxy compound, 7-9 parts of coconut oil acetal amide, 5-7 parts of sodium lauryl sulfate, 7-9 parts of palm-kernel oil acetal amide and 5-7 parts of propanediol. The manufacturing technique comprises the following steps: adding the sodium lauryl sulfate into the propanediol, stirring uniformly, and heating to 75 DEG C; adding the fatty acid methyl ester polyethenoxy ether, stirring uniformly, and cooling to room temperature; adding the coconut oil acetal amide and palm-kernel oil acetal amide, and stirring uniformly; and detecting to obtain the acceptable product, and packaging. The waterless nano laundry detergent uses plant-derived raw materials, and does not need water as the basic raw material; the active matter content can reach 95%; and the waterless nano laundry detergent is green and environment-friendly, can perform deep cleaning, is easy for rinsing without residues, can be naturally biodegraded, does not pollute the environment, saves abundant transportation resources, and reduces the waste of packaging.

Owner:广州市拓瑞科技有限公司

Body-clearing and toxin-removing mineral bath salt

InactiveCN103845257AReduce surface tensionNo cloud pointCosmetic preparationsToilet preparationsBlackheadsDiuresis

The invention discloses a body-clearing and toxin-removing mineral bath salt. The body-clearing and toxin-removing mineral bath salt is prepared from the following components in parts by weight according to a conventional method: 800 parts of sea salt, 20 parts of C8-10 alkyl glucoside, 10 parts of cassia seed, 5 parts of senna leaf, 15 parts of mulberry leaf and 10 parts of liquorice root. The body-clearing and toxin-removing mineral bath salt disclosed by the invention can promote diuresis, remove toxins as well as whiten, exfoliate and moisturize the skin. The body-clearing and toxin-removing mineral bath salt is rich in pure natural traditional Chinese medicine raw materials, and can enable body skin to enjoy bath salt essential nourishing every day and take good care of every inch of the skin. The body-clearing and toxin-removing mineral bath salt is particularly suitable for people who are prone to growing acnes and blackheads on the backs.

Owner:叶海涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com