Preparation method of starch-grafted dicyandiamide formaldehyde polycondensate flocculants

A technology of dicyandiamide formaldehyde and starch grafting, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of poor storage stability, small molecular weight, and low starch content, achieve excellent storage stability, and facilitate subsequent industrial application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

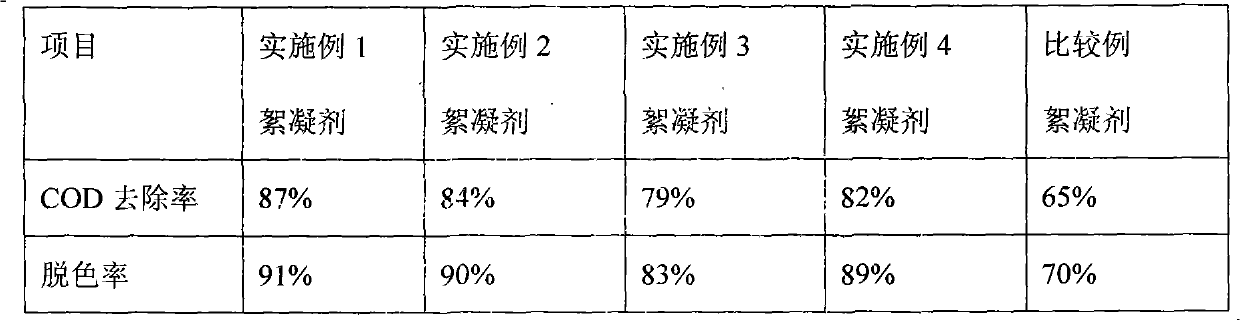

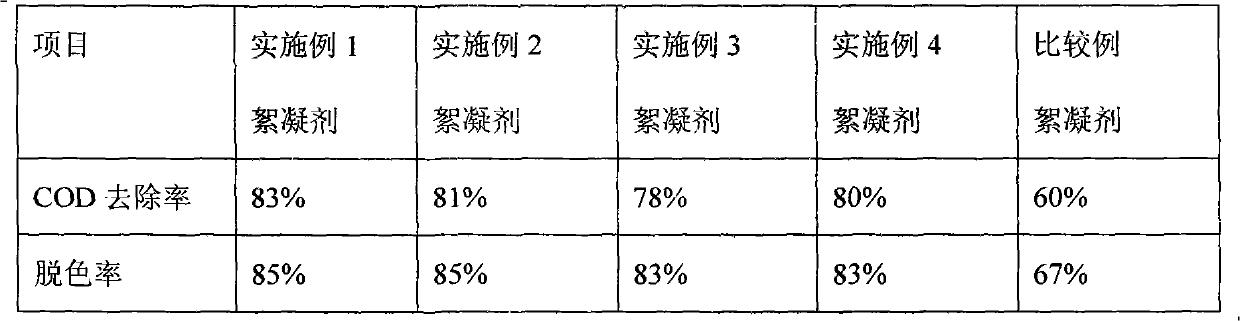

Examples

Embodiment 1

[0018] (1) Take 32.4g of formaldehyde and 10.7g of ammonium chloride in a 250ml four-neck flask, heat and react in a water bath at 70°C for half an hour, then add 16.8g of dicyandiamide and 1.4g of acrylamide, and stir and react at 70°C for 2 hours, After cooling a cationic polymer containing C=C double bonds is obtained.

[0019] (2) Take 10g of starch and 90g of deionized water in a 250ml four-neck flask, heat it in a water bath at 80°C to fully gelatinize the starch, add a certain amount of ammonium cerium nitrate initiator (concentration 1.0×10 -3 mol / L), add 40g cationic polymers containing C=C double bonds after reacting under nitrogen for half an hour, and cool in a water bath to obtain a novel starch-grafted dicyandiamide-formaldehyde polycondensate flocculant product after 2 hours of reaction.

Embodiment 2

[0021] (1) Take 24.3g of formaldehyde and 10.7g of ammonium chloride in a 250ml four-necked flask and heat it in a 70°C water bath for half an hour, then add 16.8g of dicyandiamide, 1.4g of acrylamide and a small amount of formaldehyde, and stir the reaction at 70°C After cooling for 2 hours, a cationic polymer containing C=C double bonds was obtained.

[0022] (2) Take 10g of starch and 90g of deionized water in a 250ml four-neck flask, heat in a water bath at 80°C to fully gelatinize the starch, and add potassium persulfate initiator (concentration 2.5×10 -3 mol / L), add 40g cationic polymers containing C=C double bonds after reacting under nitrogen for half an hour, and cool in a water bath to obtain a novel starch-grafted dicyandiamide-formaldehyde polycondensate flocculant product after 2 hours of reaction.

Embodiment 3

[0024] (1) Take 35.6g of formaldehyde and 10.7g of ammonium chloride in a 250ml four-neck flask, heat and react in a water bath at 70°C for half an hour, then add 16.8g of dicyandiamide and 0.7g of acrylamide, and stir and react at 70°C for 2 hours, After cooling a cationic polymer containing C=C double bonds is obtained.

[0025] (2) Take 5g of starch and 95g of deionized water in a 250ml four-necked flask, heat it in a water bath at 85°C to fully gelatinize the starch, add 0.5g of potassium permanganate initiator after cooling down to 70°C, and react halfway under nitrogen. Add 20 g of cationic polymers containing C=C double bonds after 1 hour, heat and react in a water bath for 2.5 hours, then cool to obtain a novel starch-grafted dicyandiamide-formaldehyde polycondensate flocculant product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com