Low foam lubricating liquid for food beverage chain conveying belt

A low-foam lubricating fluid and conveyor belt technology, applied in the field of low-foaming lubricating fluid, can solve the problems of reduced production efficiency, unqualified, etc., and achieve the effects of excellent lubricating effect, reduced foam, and easy dilution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

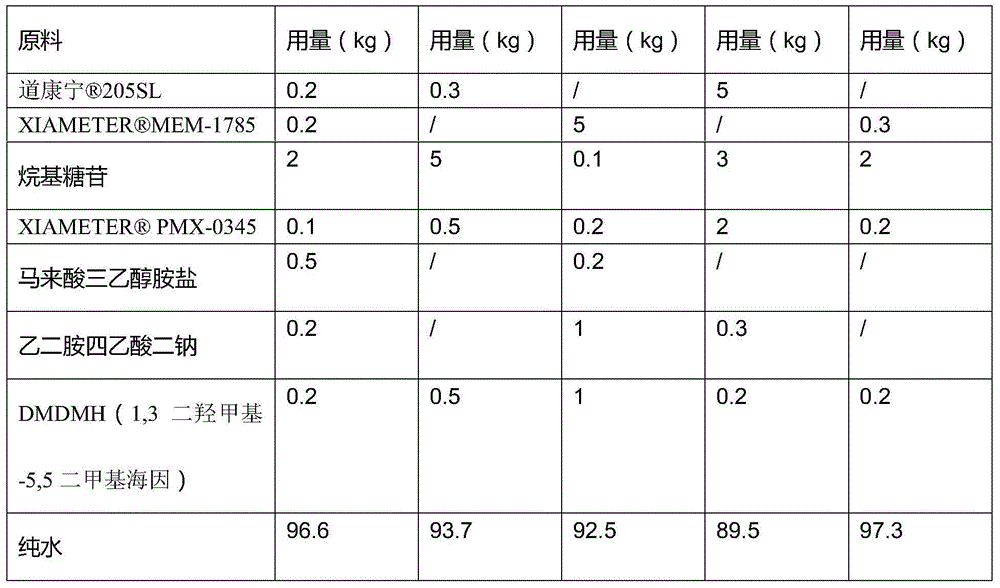

Embodiment 1

[0030] A kind of low-foaming lubricating liquid that is used for food and beverage chain conveyor belt, water-soluble emulsified silicone oil (commercially available), alkyl glucoside (commercially available), defoaming lubricant (commercially available), antirust (commercially available), antiscalant (commercially available), preservative (commercially available) and water were stirred and mixed evenly at room temperature, and then a pH regulator (citric acid monohydrate) was added to adjust the pH to 6.0.

Embodiment 2

[0032] A kind of low-foaming lubricating liquid that is used for food and beverage chain conveyor belt, water-soluble emulsified silicone oil (commercially available), alkyl glucoside (commercially available), defoaming lubricant (commercially available), antirust (commercially available), antiscalant (commercially available), preservative (commercially available) and water were stirred and mixed evenly at room temperature, and then a pH regulator (citric acid monohydrate) was added to adjust the pH to 7.0.

Embodiment 3

[0034] A kind of low-foaming lubricating liquid that is used for food and beverage chain conveyor belt, water-soluble emulsified silicone oil (commercially available), alkyl glucoside (commercially available), defoaming lubricant (commercially available), antirust (commercially available), antiscalant (commercially available), preservative (commercially available) and water were stirred and mixed evenly at room temperature, and then a pH regulator (citric acid monohydrate) was added to adjust the pH to 6.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com