Room temperature vulcanized fluorosilicone rubber and preparation method thereof

A technology of fluorosilicone rubber and room temperature vulcanization, which is applied in the field of silicone rubber, which can solve the problems of rising colloidal temperature, rubber cross-linking and scrapping, and system viscosity rising, so as to improve oil resistance, enhance bonding performance, improve dispersibility and compatibility capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

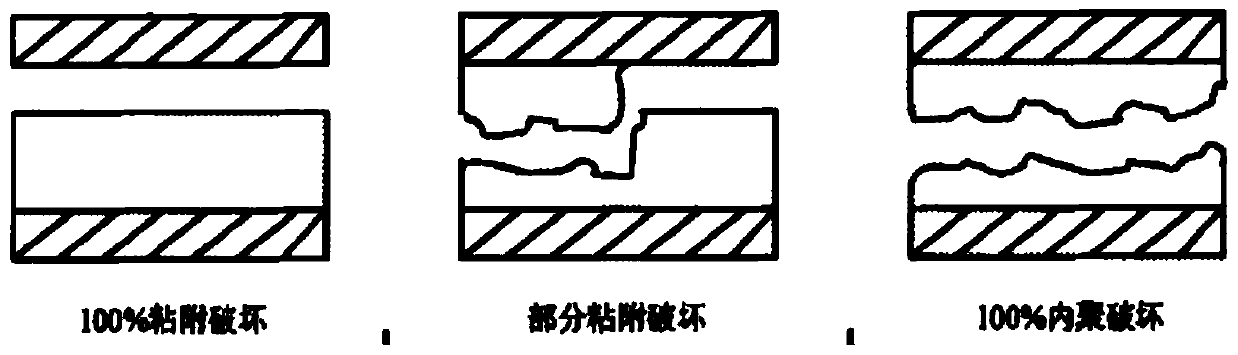

Image

Examples

Embodiment 1

[0055] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0056] (1) Preparation of methoxy-terminated fluoropolysiloxane

[0057] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, then add macroporous cation exchange resin D002 to carry out polymerization reaction, after the reaction, filter and remove In addition to low-molecular reactants, vinyl-terminated fluorosilicone oil can be obtained; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0058] Mix the vinyl-terminated fluorosilicone oil and trimethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. Removal of small molecule reactants to prepare methoxy-terminated fluorine-containing polysiloxane.

[0059] (2) Prepare substrate tackifier

[0060] (3,3,3-trifl...

Embodiment 2

[0070] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0071] (1) Preparation of ethoxy-terminated fluoropolysiloxane

[0072] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, and then add tetramethylammonium hydroxide to carry out polymerization reaction. In addition to low-molecular reactants, vinyl-terminated fluorosilicone oil can be obtained; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0073] Mix the vinyl-terminated fluorosilicone oil and triethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. After the reaction, vacuumize, at 130°C, -0.1Mpa The small molecular reactant is removed under the condition of ethoxy-terminated fluorine-containing polysiloxane.

[0074] (2) Prepare substrate tackifier

...

Embodiment 3

[0085] This embodiment provides a room temperature vulcanized fluorosilicone rubber and its preparation method, the steps are as follows:

[0086] (1) Preparation of methoxy-terminated fluoropolysiloxane

[0087] Mix trifluoropropyltrimethylcyclotrisiloxane, octamethylcyclotetrasiloxane and vinyl double head, then add trifluoromethanesulfonic acid to carry out polymerization reaction, after the reaction, add sodium bicarbonate After neutralization, the low-molecular reactants are removed to obtain vinyl-terminated fluorosilicone oil; understandably, products with different fluorine contents can be prepared by adjusting the ratio of raw materials.

[0088] Mix the vinyl-terminated fluorosilicone oil and trimethoxyhydrogensilane, add a platinum catalyst, and carry out a hydrosilylation reaction at 65°C. The reaction time is 4h. Removal of small molecule reactants to prepare methoxy-terminated fluorine-containing polysiloxane.

[0089] (2) Prepare substrate tackifier

[0090] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com