Preparation method of lithium ion battery high-nickel positive electrode material slurry

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of battery slurry gel, inability to make batteries, and inability to coat, and achieve good slurry fluidity and good electrical properties. Excellent chemical properties and processing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Add 88 g of the binder polyvinylidene fluoride (HSV761) to 1143 g of the solvent NMP (N-methylpyrrolidone) at one time, stir evenly at room temperature for 2 hours to completely dissolve the binder, then add 25 g of acetone, and control the temperature at 45 ℃, stirred for 4 hours, then added 2.6 g of the additive perfluorooctane sulfonate ammonium at one time, stirred at room temperature for 1 hour to completely dissolve the additive, and obtained a mixed glue with the additive and the binder after vacuum defoaming. The stirring speed during the glue stirring process was controlled at 800r / min. Then add SuperP (54.95g), KS-6 (54.95g) and positive electrode material NCA (Li1.052Ni0.814Co0.150Al0.037O2) (2000g) into the glue; first stir at a low speed of 600r / min for 30min, then 2000r Stir for 7 hours per min, and keep the vacuum <-0.090Mpa during the high-speed stirring process; after the stirring is completed, pass the slurry through a 150-mesh sieve for filtration, th...

Embodiment 2

[0017] Add the binder PVDF (HSV761) (88g) to the solvent NMP (N-methylpyrrolidone) (1143g) at one time, stir evenly at room temperature for 2 hours to completely dissolve the binder, then add 25g of acetone, and control the temperature at Stir at 45°C for 4 hours, then add 1.6 g of ammonium perfluorooctane sulfonate and 1.0 g of polyethylene glycol ether at one time, stir at room temperature for 1 hour to completely dissolve the additives, and vacuum defoam to obtain the additives and For the mixed glue of the binder, the stirring speed during the glue making and stirring process is controlled at 800r / min. Then add SuperP (54.95g), KS-6 (54.95g) and positive electrode material 811 (Li1.039Ni0.804Co0.100Mn0.095O2) (2000g) into the glue; first stir at low speed 600r / min for 30min, then 2000r Stir for 7 hours per min, and keep the vacuum <-0.090MPa during the high-speed stirring process; after the stirring is completed, pass the slurry through a 150-mesh sieve for filtration, the...

Embodiment 3

[0019] Add the binder PVDF (HSV761) (88g) to the solvent NMP (N-methylpyrrolidone) (1143g) at one time, stir evenly at room temperature for 2 hours to completely dissolve the binder, then add 25g of acetone, and control the temperature at Stir at 45°C for 4 hours, then add 2.6g of additive perfluorosulfonic acid resin, stir at room temperature for 1 hour to completely dissolve the additive, and obtain a mixed glue with additive and binder after vacuum defoaming. The stirring speed is controlled at 800r / min. Then add SuperP (54.95g), KS-6 (54.95g) and positive electrode material NCA (Li1.052Ni0.814Co0.150Al0.037O2) (2000g) into the glue; first stir at a low speed of 600r / min for 30min, then 2000r Stir for 7 hours per min, keep the vacuum degree <-0.090MPa during the high-speed stirring process; after the stirring is completed, pass the slurry through a 150-mesh sieve for filtration, the slurry has good fluidity, no gel phenomenon, and can be coated normally.

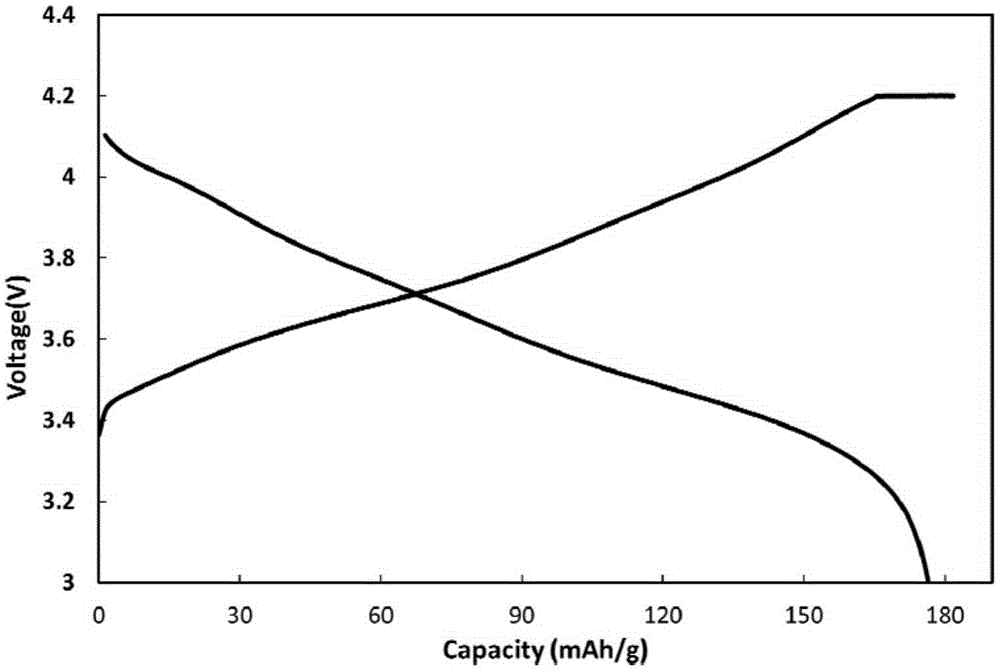

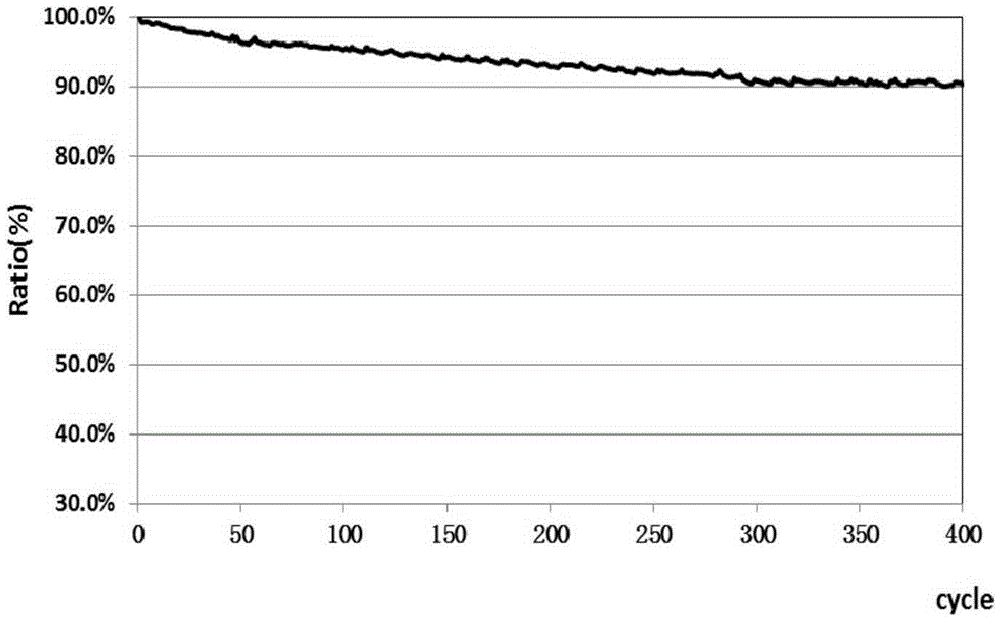

[0020] The slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com