Fluorosilicon modified polyether polymer and preparation method thereof

A polyether polymer, fluorosilicone modified technology, applied in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesive types, etc., can solve problems such as insufficient heat resistance and UV resistance, and achieve construction Convenience, good preparation reproducibility, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

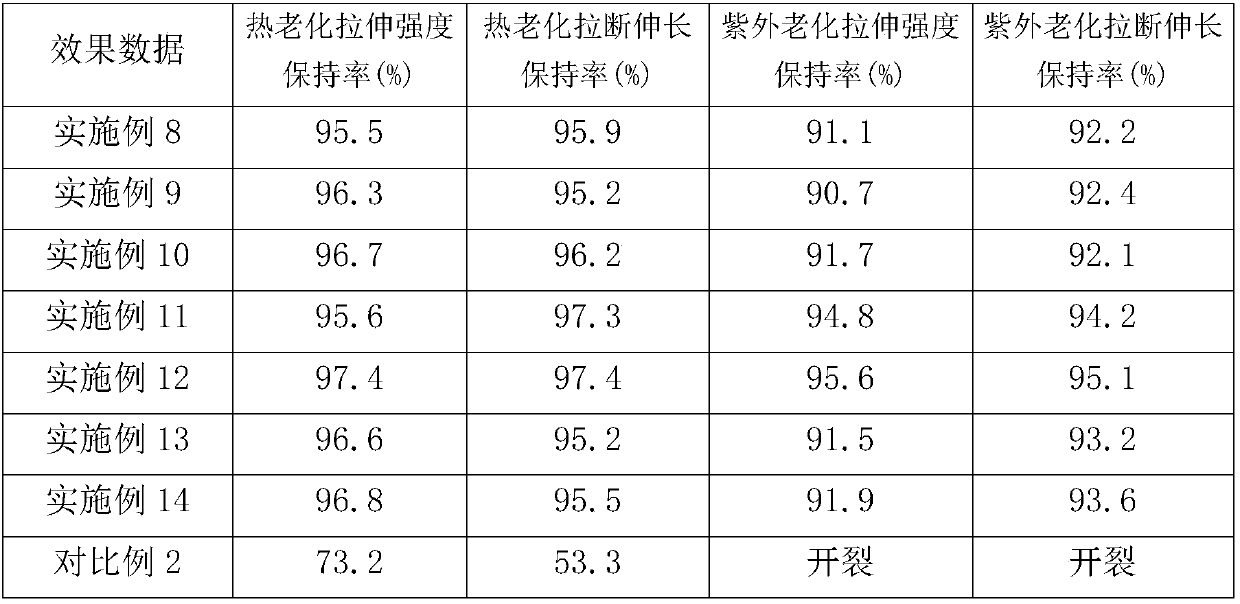

Examples

preparation example Construction

[0037] In a specific embodiment, the present invention provides a method for preparing a fluorosilicon-modified polyether polymer, comprising the steps of:

[0038] (1) Dehydrate and degas the polyether polyol under vacuum conditions at 90-130°C for 1-4 hours, then lower the temperature to 50-80°C, add diisocyanate and catalyst to the polyether polyol to control the isocyanate of the diisocyanate The molar ratio of cyanate groups to hydroxyl groups of polyether polyols is 1.1-2:1; high-purity nitrogen gas is introduced, stirred evenly, and then reacted at 50-90°C for 1-6 hours to obtain isocyanate-terminated polyether prepolymers.

[0039] (2) Mix the isocyanate-terminated polyether prepolymer with the fluorine-containing secondary aminosilane coupling agent according to the molar ratio of the amino group to the isocyanate group of 0.9-1.2:1. Under protection, react for 1-6 hours until the system is titrated without the presence of isocyanate to end the reaction, and then remo...

Embodiment 1

[0055] (1) Add 100 parts of γ-aminopropyltrimethoxysilane to a four-necked flask equipped with a stirrer, a constant pressure dropping funnel and an air duct, feed in nitrogen and start stirring, and add an equimolar amount of A certain amount of trifluoroethyl acrylate was added dropwise within 30 minutes, then the temperature was raised to 90°C, and the reaction was carried out for 4 hours to obtain a fluorine-containing secondary aminosilane coupling agent.

[0056] (2) Dehydrate and degas 100 parts of polyether polyol (C2160, Shanghai Dongda Chemical Co., Ltd.) with a number average molecular weight of 16000 under vacuum conditions at 110°C for 2 hours, then cool down to 60°C, and add TDI (diisocyanate) in sequence The molar ratio of isocyanate to the hydroxyl group of polyether polyol is 2:1), dibutyltin dilaurate (accounting for 0.1% of the mass of polyether polyol), feed high-purity nitrogen as reaction protection gas, stir evenly, and React at 90°C for 1 hour to obtain...

Embodiment 2

[0059] (1) Add 100 parts of γ-aminopropyltriethoxysilane into a four-necked flask equipped with a stirrer, a constant pressure dropping funnel and an air duct, feed nitrogen gas and start stirring, dropwise at 40°C, etc. The molar amount of tetrafluoropropyl acrylate was added dropwise within 30 minutes, then the temperature was raised to 90°C, and the reaction was carried out for 4 hours to obtain the fluorine-containing secondary aminosilane coupling agent;

[0060] (2) Dehydrate and degas 100 parts of polyether polyol (C2060, Shanghai Dongda Chemical Co., Ltd.) with a number average molecular weight of 6000 under vacuum conditions at 110°C for 2 hours, then cool down to 60°C, and add TDI (diisocyanate) in sequence The molar ratio of isocyanate to the hydroxyl group of polyether polyol is 1.3:1), dibutyltin dilaurate (accounting for 0.1% of the mass of polyether polyol), feed high-purity nitrogen as reaction protective gas, stir evenly, in React at 50°C for 6 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com