Method for preparing emulsion for self-crosslinked waterborne wood coating

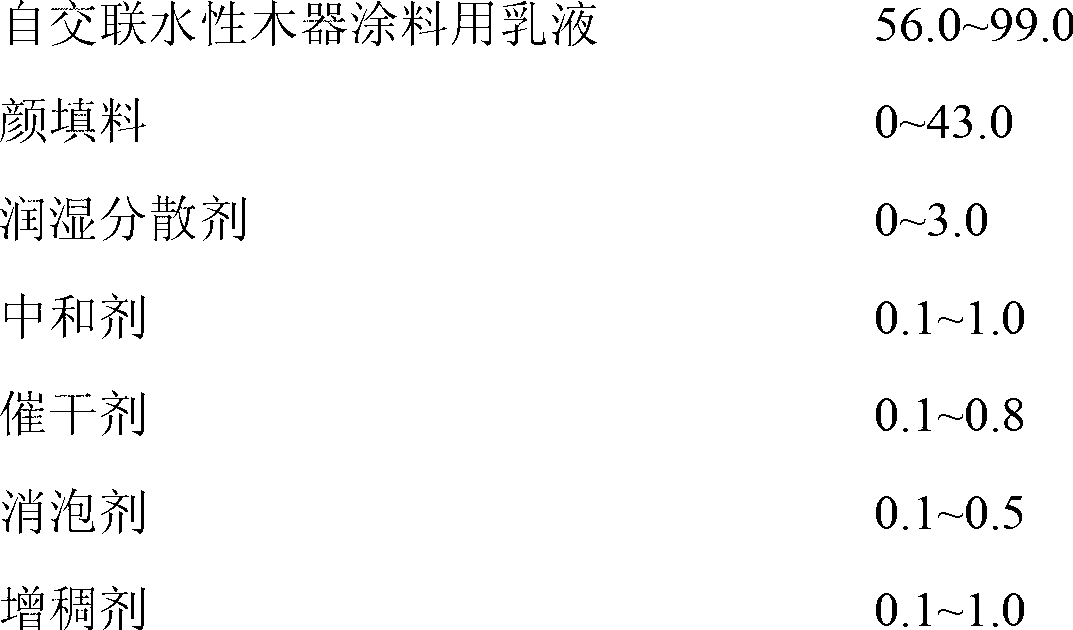

A wood coating and self-crosslinking technology, which is applied in the direction of coating, etc., can solve the problems of insufficient adhesion between the coating film and the substrate, poor water resistance and solvent resistance, and poor permeability of the coating to the substrate. Easy quality control, good adhesion, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare high acid value acrylic resins A1~A4 containing unsaturated fatty acid components.

[0028] Put the unsaturated fatty acid into the reaction bottle, gradually raise the temperature to 140°C~145°C while stirring, and add the monomer mixture dropwise continuously and evenly for 5~8 hours. Hours, until the conversion rate is above 97%, as evidenced by the solid content. The formulations and acid values of high acid value acrylic resins A1-A4 are listed in Table 1.

Embodiment 2

[0030] Prepare high hydroxyl value acrylic resins B1~B3, the formula is shown in Table 2.

[0031] The formula of the acrylic resin A1~A4 of table 1 high acid value

[0032] A1 A2 A3 A4 unsaturated fatty acid Linoleic Acid 65.5 65.5 Linoleic acid 65.5 tall oil 65.5 monomer mixture Methyl methacrylate 9 7 Isobutyl methacrylate 9 8.5 7 Styrene 9 vinyl toluene 9 13 7.5 Methacrylate 15 15 11.5 11.5 Di-tert-butyl peroxide 1.5 1.5 tert-butyl peroxybenzoate 1.5 1.5 Acid value (mgKOH / g) 229 229 206 206

[0033] The formula of the acrylic resin B1~B3 of table 2 high hydroxyl value

[0034] B1 B2 B3 Styrene 60 70 80 Allyl alcohol 40 30 20 Hydroxyl content (%) 7.7 6.4 3.8 Hydroxyl value (mgKOH / g) 255 210 12...

Embodiment 3

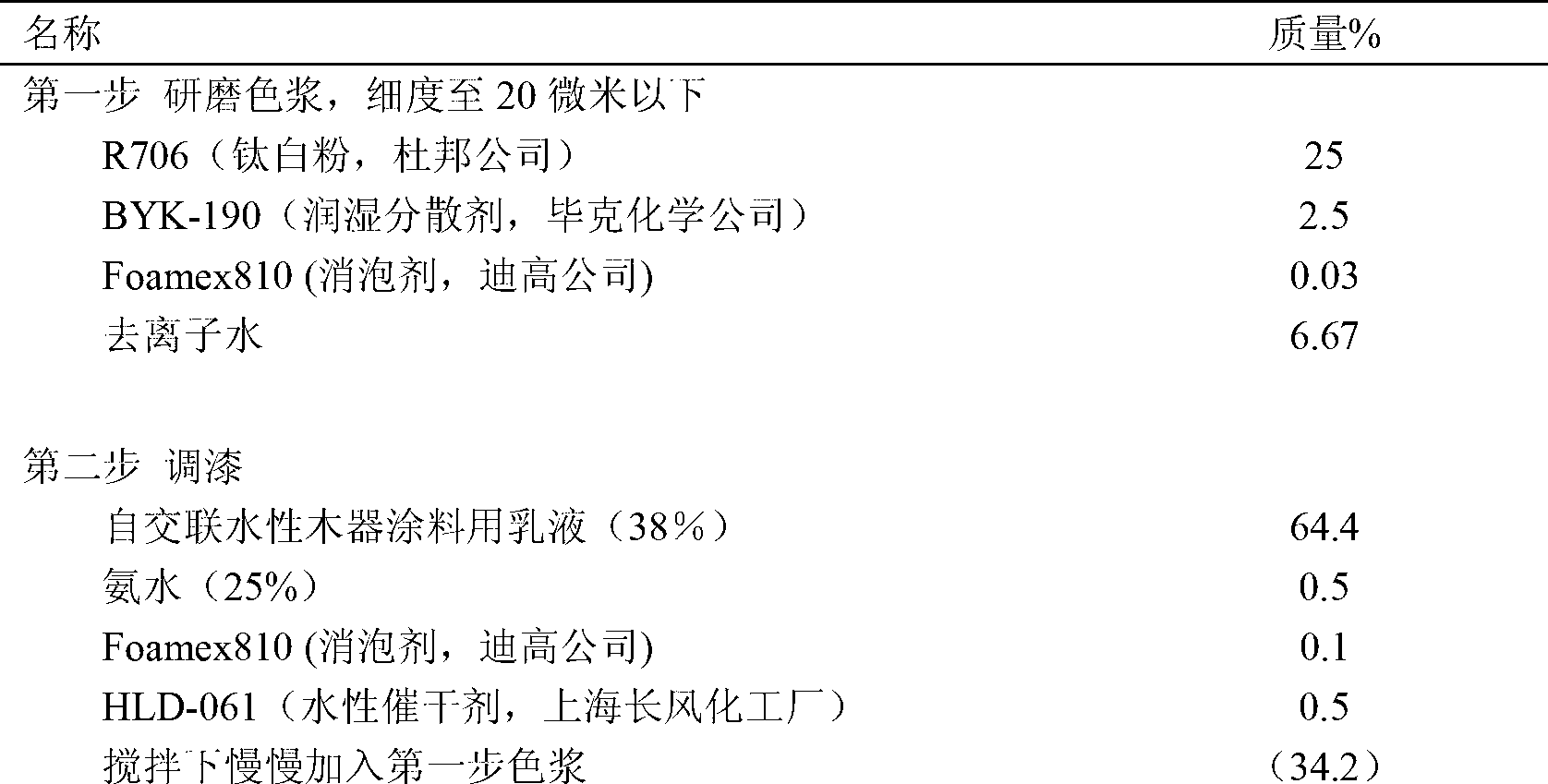

[0036] Preparation of emulsions C1-C4 for self-crosslinking waterborne wood coatings.

[0037] According to the data in Table 3, carry out the esterification reaction between the high acid value acrylic resin (component A) and the high hydroxyl value acrylic resin (component B) at 190~200°C until the desired final acid value is reached until.

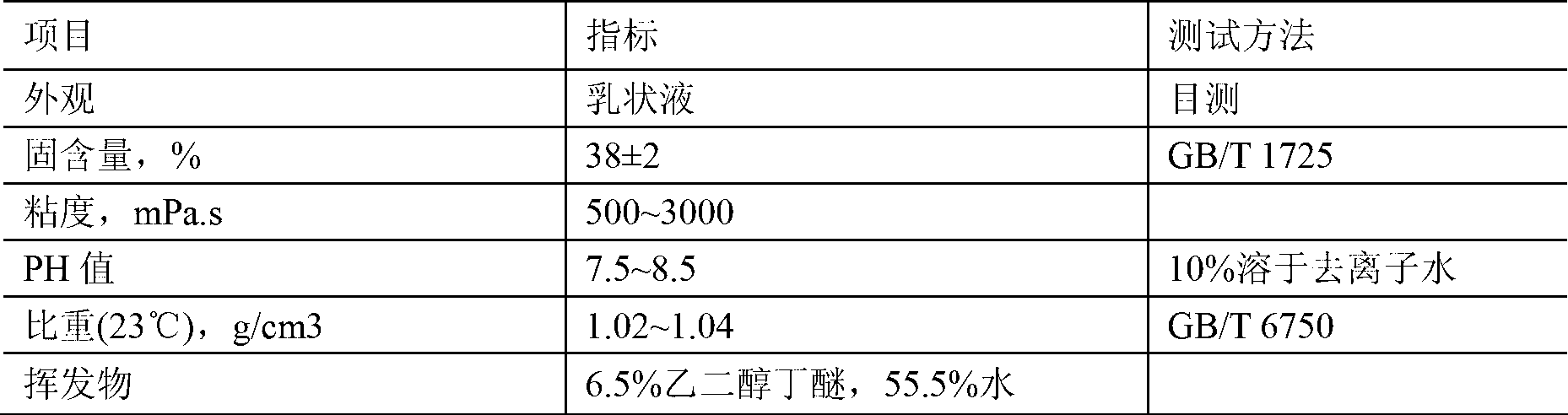

[0038]Mix 38g of the resin prepared from the formula in Table 3 with 6.5g of ethylene glycol butyl ether, neutralize with 1.5g of ammonia water (concentration: 25%) at 50°C, and then emulsify with 54g of deionized water to obtain Emulsion for self-crosslinking waterborne wood coatings. Table 4 lists the technical indicators of emulsions for self-crosslinking waterborne wood coatings.

[0039] Table 3 Formulas of emulsions C1-C4 for self-crosslinking waterborne wood coatings

[0040] C1 C2 C3 C4 Acrylic resin with high acid value (component A) A1 52.6 A2 57.8 A3 52.6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com