Ultraviolet-curing liquid optical silica gel used for reworkable gluing as well as preparation method and application thereof

An optical silica gel, ultraviolet light technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of small odor, low internal stress and elastic modulus, and high elongation at break, etc. Small shrinkage, low elastic modulus, and good rework performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

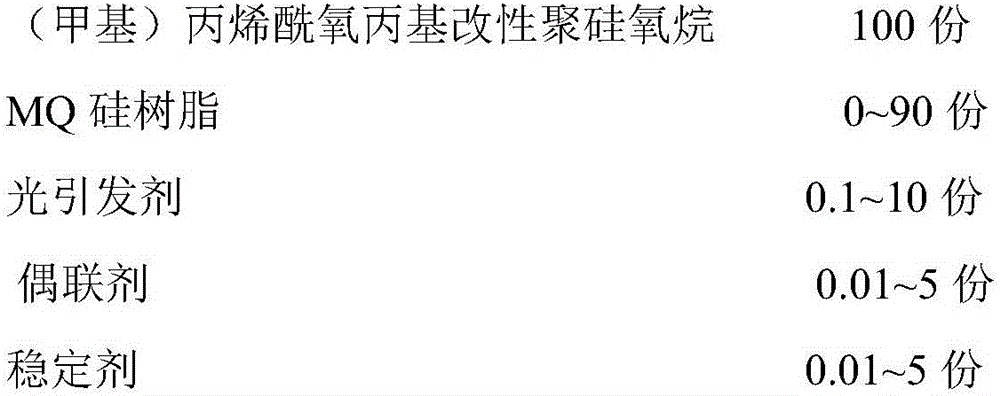

[0037] Get the following components according to parts by weight:

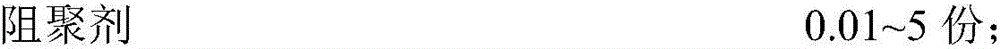

[0038] Methacryloxypropyl modified polysiloxane (refer to the above method for preparation): 30 parts of 500cp polysiloxane, 70 parts of 25000cp polysiloxane, the structural formula is as follows:

[0039]

[0040] Wherein, R is a methacryloxypropyl group, l is an integer from 50 to 5000, and m is an integer from 1 to 150;

[0041] MQ silicone resin: 28 parts of commercially available methyl-terminated MQ silicone resin;

[0042] Photoinitiator: 0.15 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone;

[0043] Coupling agent: 0.2 part of methacryloxypropyltrimethoxysilane, 0.1 part of methyltrimethoxysilane;

[0044] Stabilizer: 0.1 parts of 1-(methyl)-8-(1,2,2,6,6-pentamethyl-4-piperidine) sebacate

[0045] Inhibitor: 0.2 parts of hydroquinone;

[0046] Step 1: Add 30 parts of 500cp polysiloxane, 70 parts of 25000cp polysiloxane, 28 parts of methyl MQ silicone resin, and 0.2 parts of hydroquinone into a pl...

Embodiment 2

[0049] Get the following components according to parts by weight:

[0050] Methacryloxypropyl modified polysiloxane: 40 parts of 3000cp polysiloxane, 60 parts of 18000cp polysiloxane, the structural formula is as follows:

[0051]

[0052] Wherein, R is a methacryloxypropyl group, l is an integer from 50 to 5000, and m is an integer from 1 to 150;

[0053] MQ silicone resin: 20 parts of commercially available vinyl MQ silicone resin;

[0054] Photoinitiator: 0.20 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, diphenyl-(2,4,6-trimethylbenzoyl)phosphine bis(2,4, 0.1 part of 6-trimethylbenzoyl) phosphine oxide;

[0055] Coupling agent: 0.1 part of allyltrimethoxysilane, 0.05 part of γ-[(2,3)-glycidoxy]propyltrimethoxysilane;

[0056] Inhibitor: 0.06 part of p-hydroxyanisole;

[0057] Step 1: Add 40 parts of 3000cp polysiloxane, 60 parts of 18000cp polysiloxane, 20 parts of vinyl MQ silicone resin, and 0.06 part of p-hydroxyanisole into the planetary mixer. The base MQ ...

Embodiment 3

[0060] Get the following components according to parts by weight:

[0061] Methacryloxypropyl modified polysiloxane: 55 parts of 2500cp polysiloxane, 45 parts of 11000cp polysiloxane, the structural formula is as follows:

[0062]

[0063] Wherein, R is a methacryloxypropyl group, l is an integer from 50 to 5000, and m is an integer from 1 to 150;

[0064] Photoinitiator: 0.6 parts of 2,2-dimethoxy-2-phenylacetophenone;

[0065] Coupling agent: 0.35 parts of γ-mercaptopropyltrimethoxysilane;

[0066] Stabilizer: 0.025 parts of bis(1-octyloxy-2,2,6,6-tetramethyl-4-piperidinyl) sebacate;

[0067] Inhibitor: 0.4 parts of methyl hydroquinone;

[0068] Step 1: Add 55 parts of 2500cp polysiloxane, 45 parts of 11000cp polysiloxane, and 0.4 part of methyl hydroquinone into the planetary mixer, heat the material to 75°C, and stir thoroughly to make the material evenly mixed;

[0069] Step 2: Add 0.6 parts of 2,2-dimethoxy-2-phenylacetophenone and 0.025 parts of bis(1-octyloxy-2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com