Patents

Literature

101results about How to "High damping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid-resistant and alkali-resistant waterborne damping coating with wide temperature range and high damping capacity and method for preparing same

InactiveCN106009961AWide damping temperature rangeHigh dampingAnti-corrosive paintsEmulsionDefoaming Agents

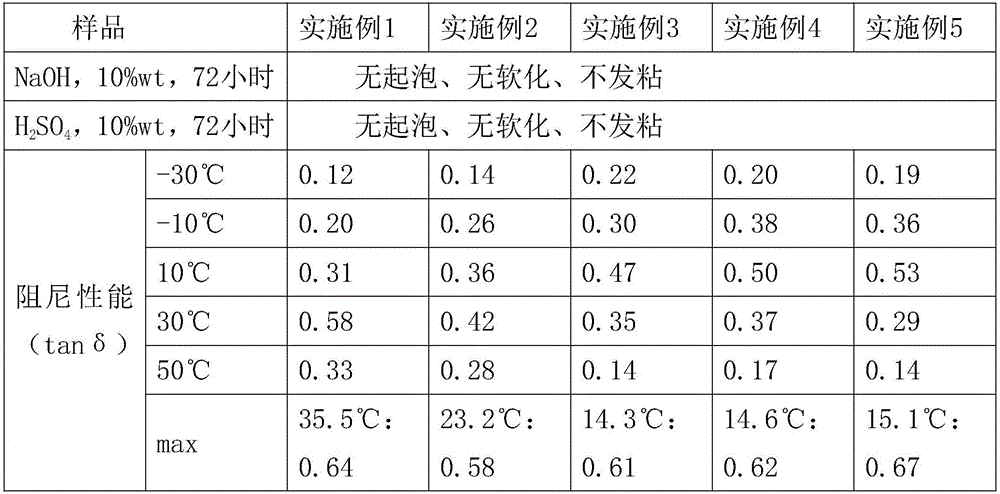

The invention discloses an acid-resistant and alkali-resistant waterborne damping coating with a wide temperature range and high damping capacity, comprising, by weight, 30-65 parts of a waterborne emulsion, 15-45 parts of a filler, 10-35 parts of a flame retardant, 0.1-2 parts of fibers, 0-5 parts of a film-forming agent, 0.1-1.5 parts of a dispersing agent, 0.1-1.5 parts of a defoaming agent, 0-4 parts of an antifreeze agent, 0.2-3 parts of a thickening agent and 1-8 parts of a multifunctional aid. The acid-resistant and alkali-resistant waterborne damping coating with wide temperature region and high damping capacity has the advantages that the acid-resistant and alkali-resistant waterborne damping coating is high in damping performance, wide in damping temperature range and excellent in acid resistance and alkali resistance; loss factors of materials in the temperature range ranges from -30 DEG C to 50 DEG C reach 72 hours as shown by acid-resistant and alkali-resistant tests on the materials by the aid of 10% NaOH solution and 10% H2SO4 solution, and the acid-resistant and alkali-resistant waterborne damping coating is free of foaming, softening and sticking and excellent in acid resistance and alkali resistance.

Owner:安徽贝卫新材料科技有限公司

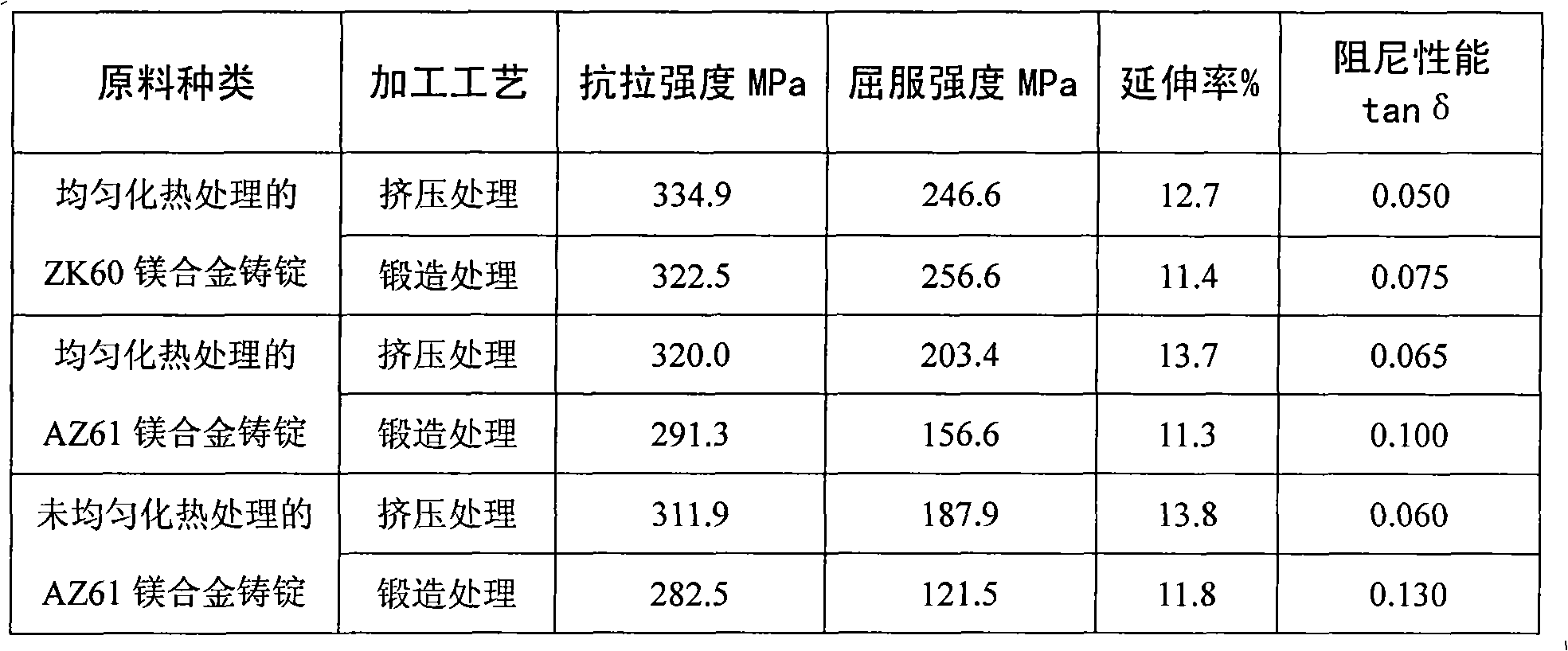

Cariaceous high-damping deformation magnesium alloy and its prepn process

The process relates to excellent magnesium base material, and is coriaceous high-damping deformation magnesium alloy and its preparation process. For obtaining both high damping performance and high mechanical performance, the present invention adds Cu, Si and other alloy element with small solid solubility into Mg material to reduce dislocation pinning points and to raise damping performance, while adding Zr, Mn and other crystal grain fining alloy element to raise the mechanical performance. Through conventional extrusion on ingot and intense plastic deformation, the alloy has regulated grain orientation, superfine crystal structure and raised toughness and damping performance. The present invention has wide application value.

Owner:HARBIN INST OF TECH

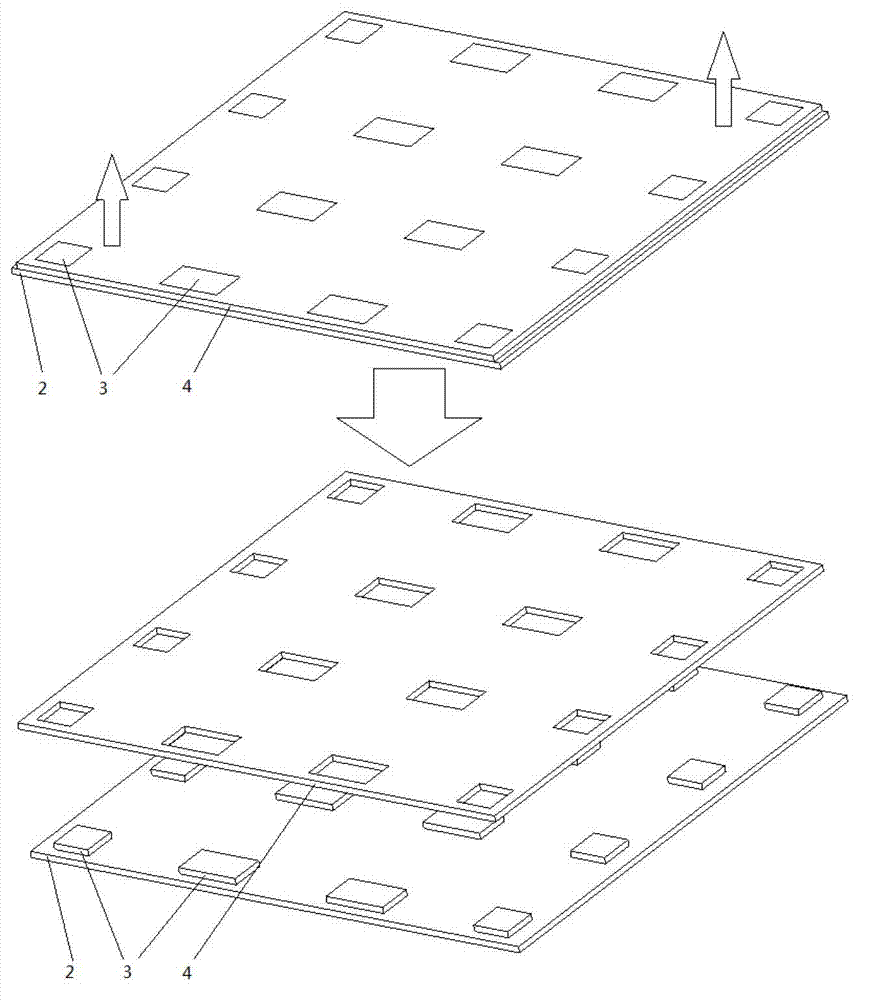

Pyramid-lattice metal sandwich plate and preparation method thereof

InactiveCN102765225AHigh specific strengthGood mechanical propertiesLamination ancillary operationsAdhesive processes with surface pretreatmentManufacturing cost reductionMetal

The invention discloses a pyramid-lattice metal sandwich plate and a preparation method of the pyramid-lattice metal sandwich plate, wherein a pyramid-lattice metal core body and a metal panel are adhered and compounded through epoxy glue to prepare an ultra-light porous material. The invention provides the preparation method of the pyramid-lattice metal sandwich plate adhered by the epoxy glue. Compared with the welding structure, the adhered pyramid-lattice metal sandwich plate has the advantages of being capable of reducing the manufacturing cost, reducing the residual stress during connection, improving corrosion and fatigue resistance and damping performance at the connection position, and effectively exerting performances of light weight, high ratio strength and high ratio rigidity, and can be widely applied to the fields such as communication and transportation and architectural decoration.

Owner:XI AN JIAOTONG UNIV

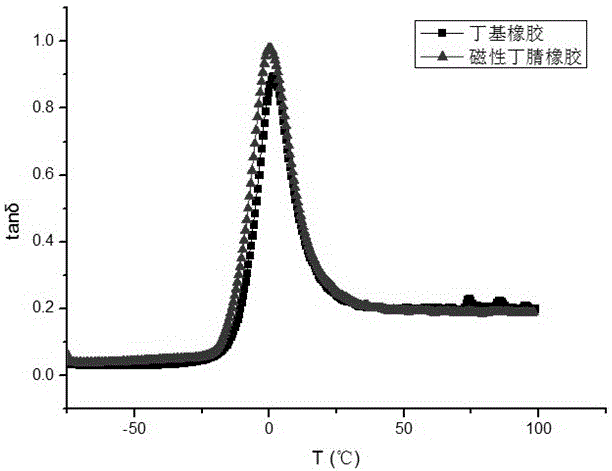

Method for enhancing damping capacity of rubber by adding neodymium-iron-boron magnetic powder

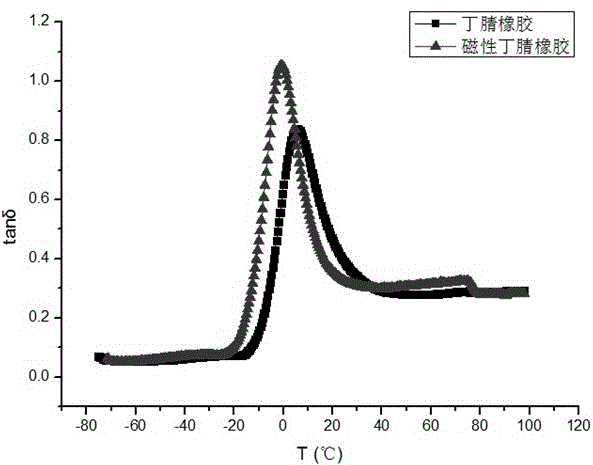

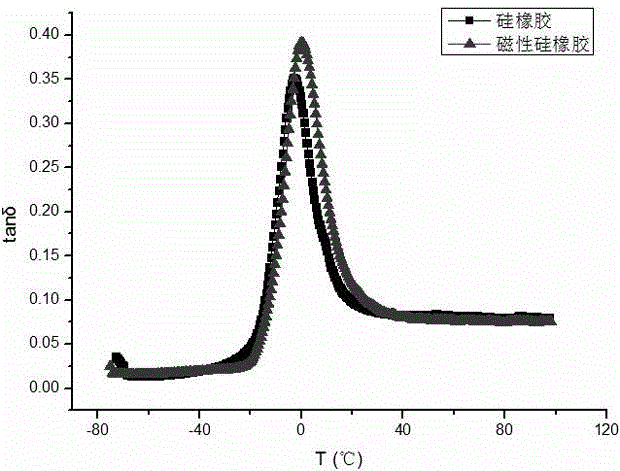

ActiveCN102875909AIncreased maximum damping factorImprove energy conversionMagnetic materialsPolymer scienceSulfur

The invention discloses a method for enhancing damping capacity of rubber by adding neodymium-iron-boron magnetic powder, which comprises the following steps: 1) plasticizing 100 parts by mass of rubber on milling equipment, sequentially adding 1-50 parts by mass of reinforcing agent, 20-120 parts by mass of neodymium-iron-boron magnetic powder, 0.1-5 parts by mass of sulfur, 0.1-5 parts by mass of zinc oxide and 0.1-5 parts by mass of stearic acid, and milling for 5-20 minutes to obtain a mixture; 2) putting the mixture in a mold, applying a pressure of 5-50Pa onto the mold, and vulcanizing at 120-200 DEG C for 5-30 minutes to obtain vulcanized rubber; and 3) putting the vulcanized rubber in a 0.5-5T magnetic field to carry out magnetization for 1-60 seconds, thereby obtaining the high-damping neodymium-iron-boron magnetic rubber. The damping capacity of the rubber obtained by adding the neodymium-iron-boron magnetic powder can be maximally enhanced by more than 25% within a wide frequency range and a wide temperature range.

Owner:ZHEJIANG UNIV +1

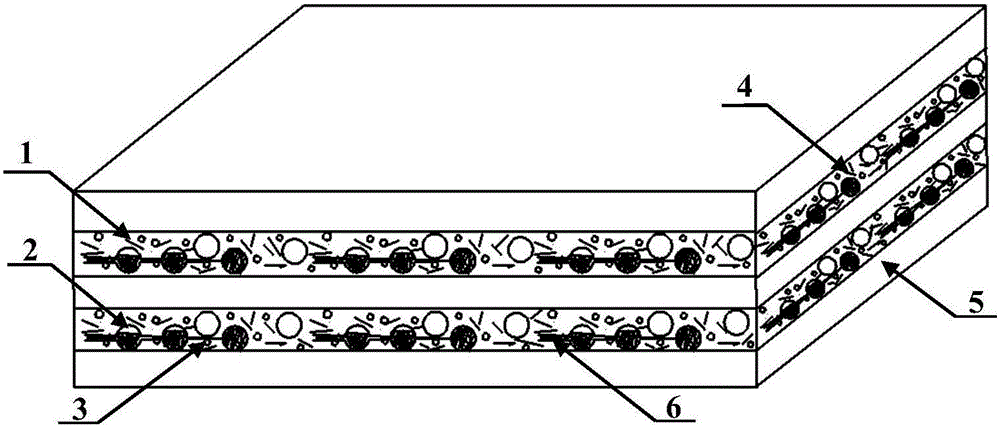

Fiber/metal layer structure composite and preparation method thereof

InactiveCN106553397AAchieve self-healingMeeting urgent needsSynthetic resin layered productsLaminationFiberPolymer science

The invention discloses a fiber / metal layer structure composite and a preparation method thereof, and relates to the field of manufacturing of functional composites. The fiber / metal layer structure composite comprises alternate fiber resin layers and metal layers; rubber layers can be further added; repairing agent microcapsules and a catalyst are added in resin; and micron strength enhanced particles can be further added. The preparation method comprises the steps of wetting fibers through resin, so as to prepare the fiber resin layers; carrying out surface treatment on metal sheets, so as to prepare the metal layers; alternately laying the fiber resin layers and the metal layers in a mold cavity; and carrying out heating, pressurization and curing treatment on the layer structures in the mold cavity. According to the fiber / metal layer structure composite, advantages of the fiber resin composite, metals and rubber are combined, the composite has relatively high designability, and the designed material is a functional composite with the prominent characteristics of high specific strength, fatigue resistance, corrosion resistance, high damping, and the like, and meets the urgent requirements of fields like aerospace, national defense, rail transit and automobiles on new materials to a certain extent.

Owner:JILIN UNIV

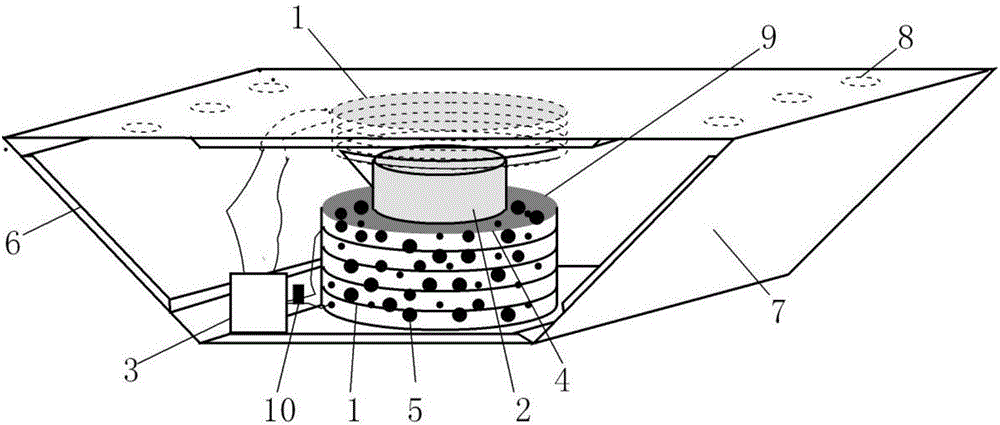

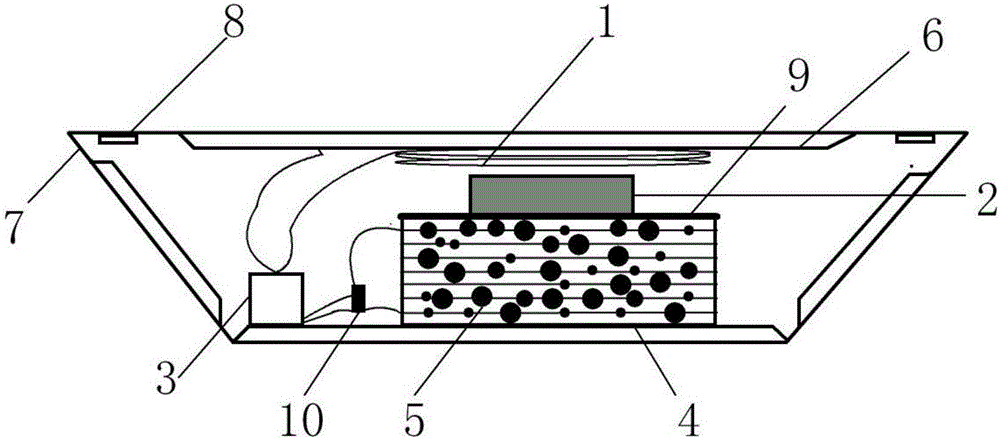

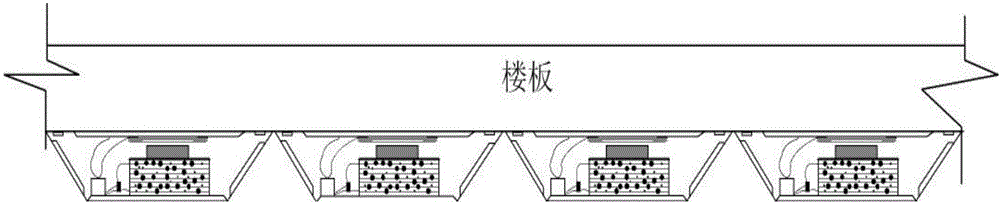

Piezoelectric-electromagnetic combined energy gathering vibration damping device

ActiveCN106499239AReduce vibrationIncrease contact pressureBatteries circuit arrangementsBridge structural detailsEngineeringLithium-ion battery

A piezoelectric-electromagnetic combined energy gathering vibration damping device is arranged below a floor or a decking, and aims to gather the kinetic energy in the floor or decking and convert same into electric power for storage; the electric power can be released so as to form a damping effect, thus alleviating the floor or decking vibrations; the piezoelectric-electromagnetic combined energy gathering vibration damping device mainly comprises an inductance coil, a permanent magnet, a lithium ion battery, a particle damping container, a multi-grading electromagnetic particle damping, a piezoelectric ceramics, a loading plate, anchoring bolts, an insulation pad, and an electric quantity identification and control induction member; anchoring bolts are reserved on the loading plate and the piezoelectric ceramics; each member is placed in the loading plate according to required positions; the whole device is fixed below the floor or decking through the anchoring bolts. The piezoelectric-electromagnetic combined energy gathering vibration damping device can gather and utilize the energy of vibrations in the environment, and can effectively alleviate the floor or decking vibrations.

Owner:北京东方中恒科技发展有限公司

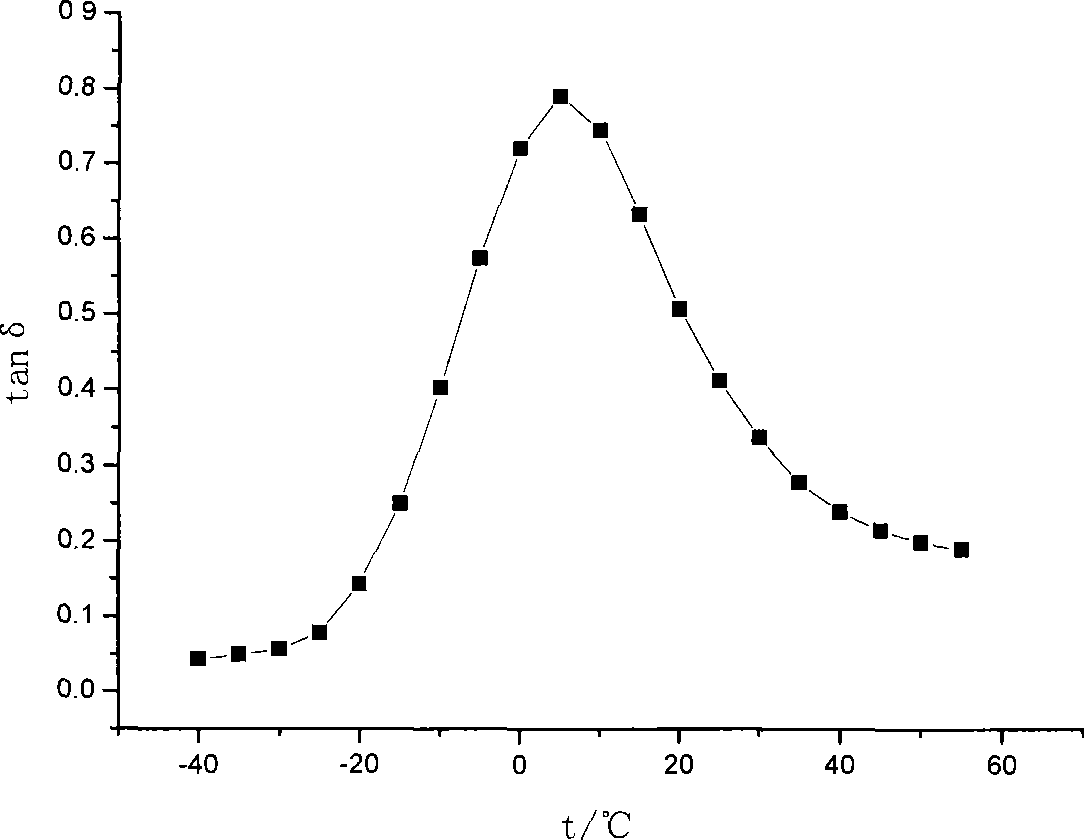

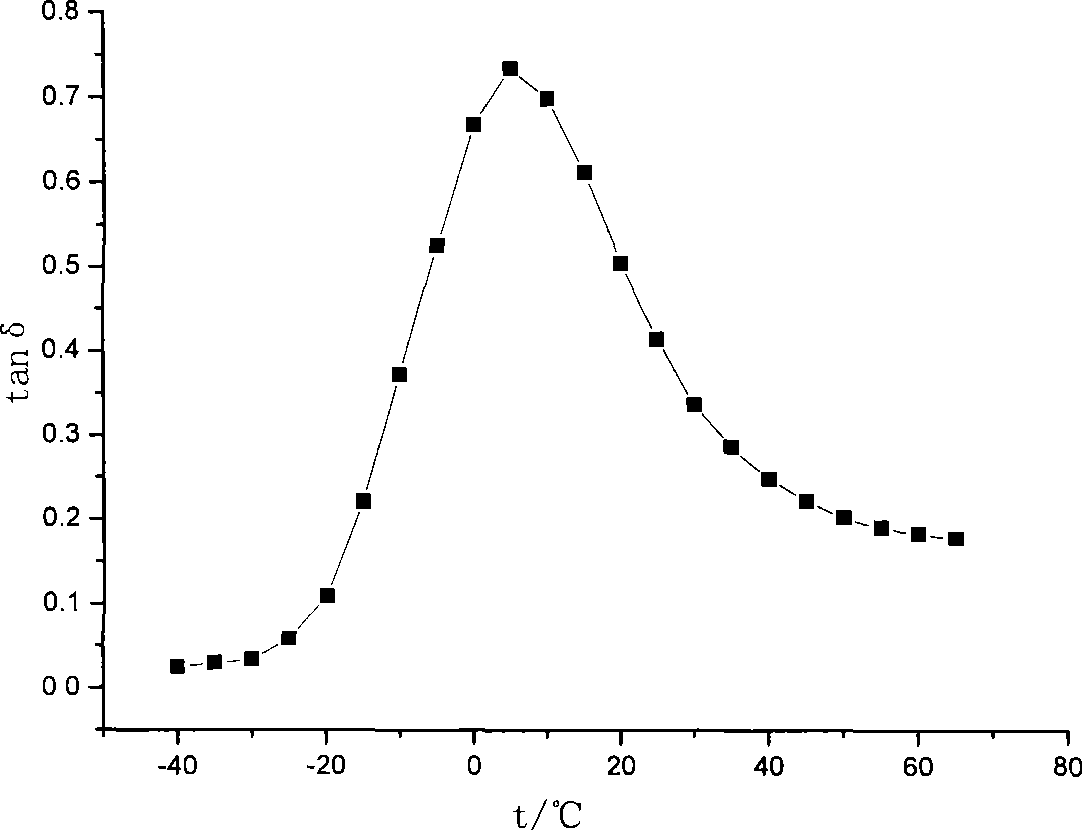

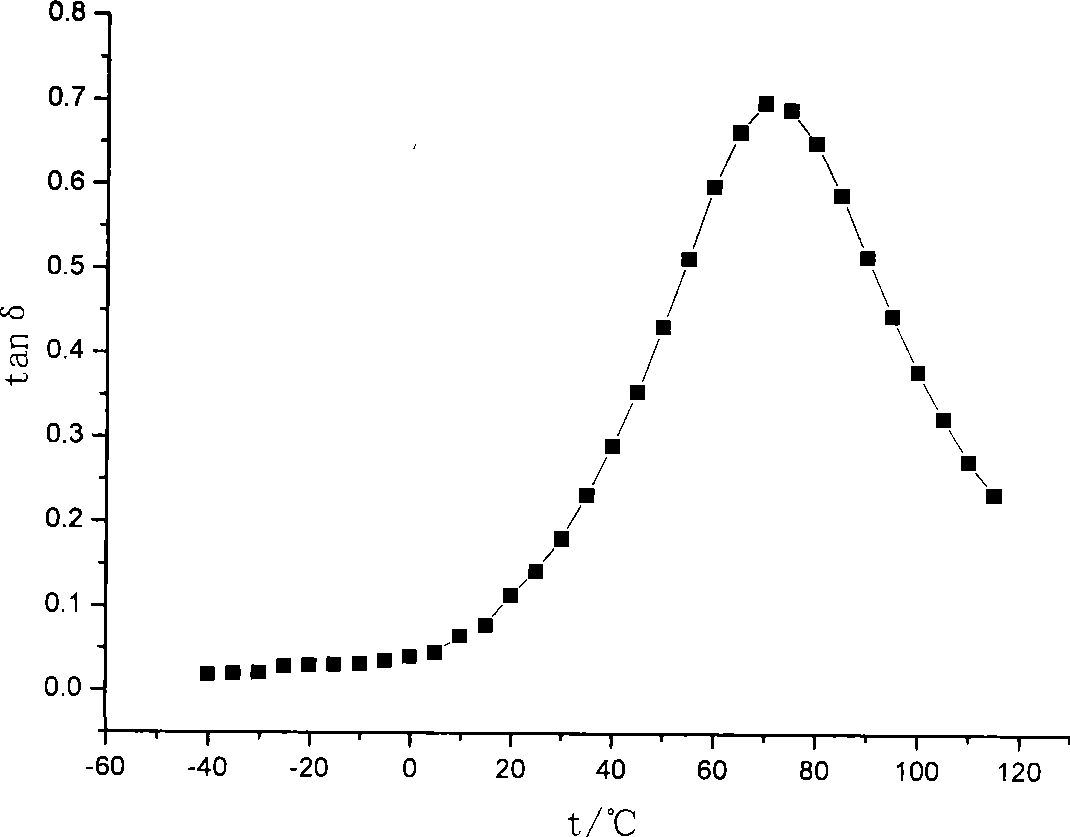

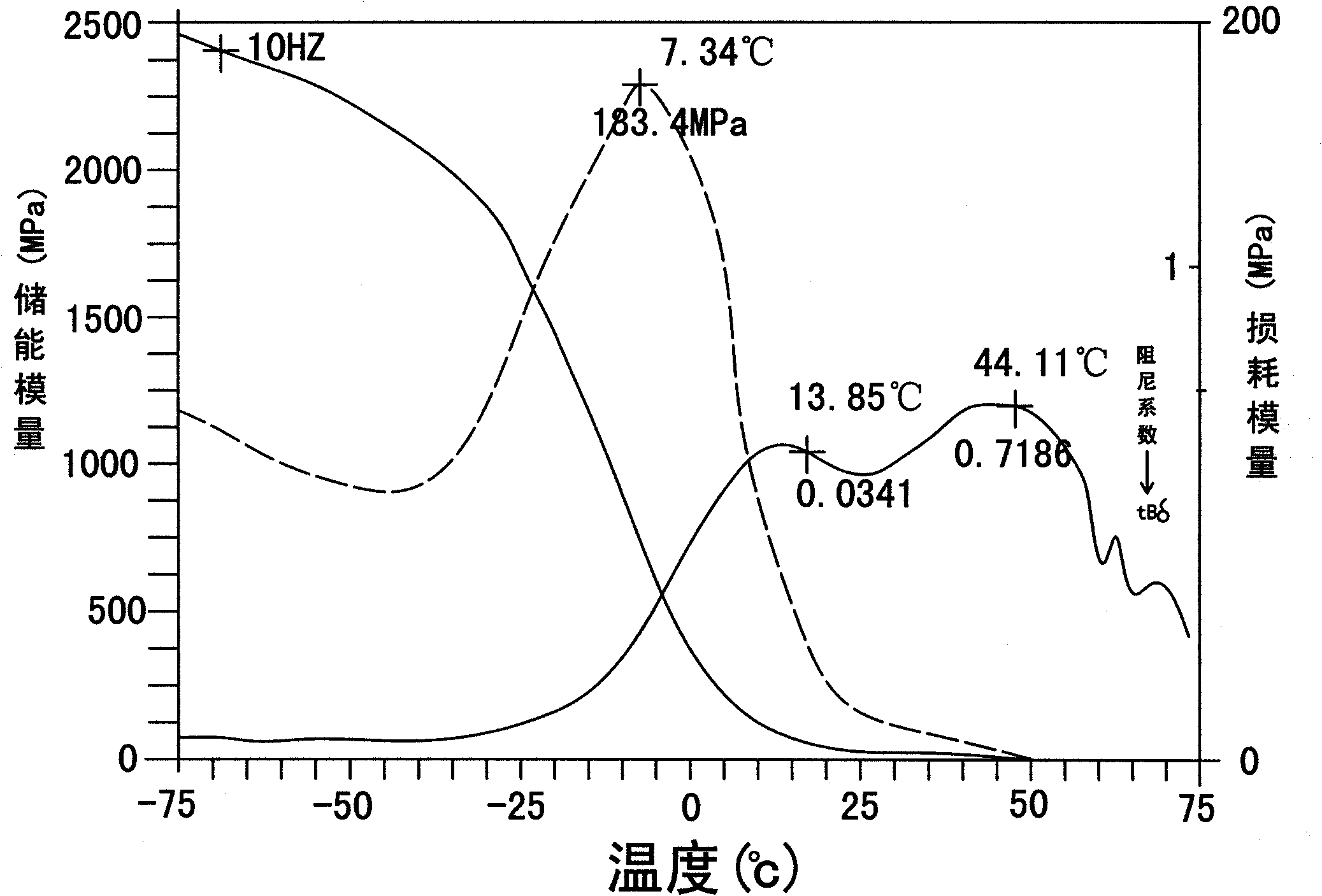

Polyester type polyurethane damping material and preparation method

The invention provides a polyester polyurethane damping material with dimethyl structure with the same carbon number on main chain and a preparation method thereof. The preparation method comprises the following steps: A. allowing polyester glycol dehydrated in vacuum to react with diisocyanate to synthesize a prepolymer; and B. allowing the prepolymer to react with a chain extender or block and graft to synthesize the polyester polyurethane damping material with dimethyl structure with the same carbon number on the main chain; choosing 3,3'-dichloro-4,4'-diaminodiphenylmethane, 3,5- dimethythiotoluene diamine, 1,4-butanediol or trimethylolpropane as the chain extender for room temperature vulcanization. The polyester polyurethane damping material has good thermal stability, acid and alkali resistance, hydrolytic resistance, weatherability and high damping property. Meanwhile, the polyester main chain contains ester group with strong polarity, and forms a plurality of hydrogen bonds with urethane group to improve intermolecular acting force, thus the polyester polyurethane has good mechanical property. High-performance damping materials for use under different temperature can be obtained by adjusting position of damping peak by changing molecular weight of the polyester glycol and by adding liquid packing. The preparation method is simple with low energy consumption.

Owner:HEBEI ENERGY RES INST

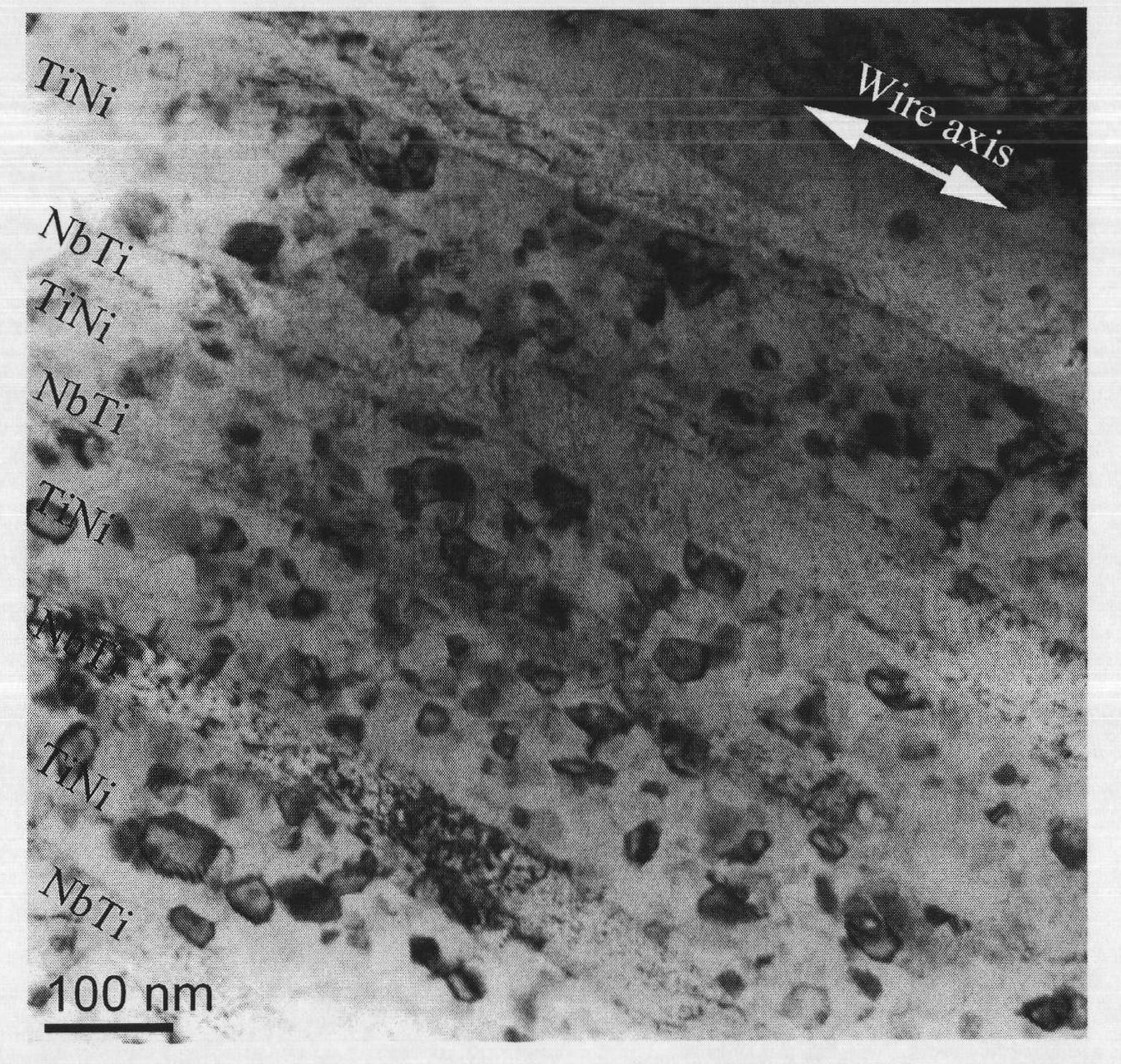

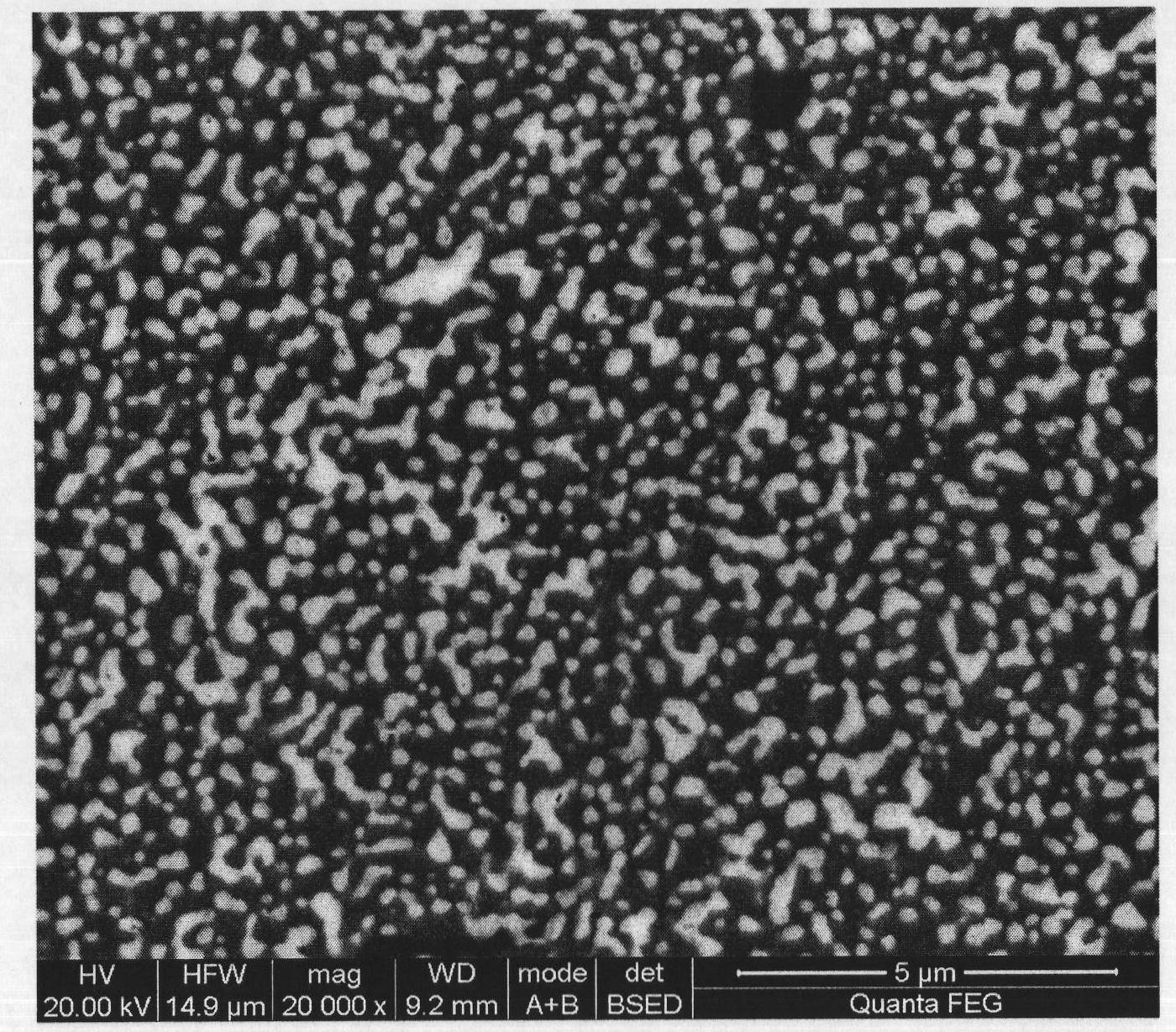

NbTi/TiNi memory alloy composite material and preparation method thereof

InactiveCN101805843AEnhanced interface bindingImprove the bonding strength of the interfaceNiobiumAlloy composite

The invention relates to an NbTi / TiNi memory alloy composite material and a preparation method thereof. The memory alloy composite material comprises the following components calculated by the total weight of the memory alloy composite material: Nb element with the atomic percentage of 18-22%, and Ti element and Ni element with the atomic rate of 0.3: 1-1.5: 1, wherein the sum of the atomic percentage of the three elements of Ti, Ni and Nb is 100%. The memory alloy composite material has the special functional features of high yield strength, strain soft mode, linear super-elasticity, double-stress platform and the like. The invention further relates to the preparation method of the NbTi / TiNi memory alloy composite material, which comprises the following steps: selecting elementary substances of niobium, titanium and nickel with the purity of above 99.0% by weight according to the mixture ratio of the components of the NbTi / TiNi memory alloy composite material, placing the elementary substances of niobium, titanium and nickel into a smelting furnace with the vacuum degree of being higher than 10-1Pa or inert gas protection, and smelting for forming the NbTi / TiNi memory alloy composite material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Damping glue for vibration reducing plate and preparation method thereof

ActiveCN102115647AHigh dampingGood damping propertiesConjugated diene hydrocarbon adhesivesEpoxyMixed materials

The invention discloses damping glue for a vibration reducing plate and a preparation method thereof. The component formula of the damping glue is as follows: 3 to 10 parts of nitrile-butadiene rubber 26 (NBR 26), 5 to 7 parts of nitrile-butadiene rubber 40 (NBR 40), 2 to 4 parts of additive, 2 to 12 parts of epoxy resin (EP), 1 to 5 parts of phenol formaldehyde resin (PF), 1 to 2 parts of curingagent, 0.3 to 0.5 part of peroxide, 0.5 to 1 part of zinc oxide, and 65 to 75 parts of solvent. The preparation process of the damping glue is as follows: the NBR 26 is firstly plasticated on a double-roll machine for 5 to 10 minutes, and then the zinc oxide is added and mixed with the NBR26 until the Williams plasticity is between 0.2 and 0.3; then the NBR40 is plasticated on the double-roll machine until the Williams plasticity is between 0.3 and 0.4; the mixed material is added to the solvent being stirred and stirred until being completely dissolved; and afterwards, the PF, the additive, the EP or a compound thereof, the curing agent and the peroxide are stirred until being completely dissolved into an evenly thick liquid, and then the normal-temperature damping glue for the vibrationreducing plate can be acquired. The main performances of the manufactured damping glue are as follows: the solid content is 25 to 35 percent; the glue solution viscosity (measured by a rotational viscometer) is 3.5 to 7 Pa.S (25 DEG C); the T-peel strength is larger than 20N / cm; the tensile shear strength is larger than 7MPa; tangent Delta is larger than or equal to 0.20; and the temperature range is minus 10 DEG C to 75 DEG C.

Owner:SHANGHAI PLASTICS RES INST CO LTD

High-intensity high-damping deforming magnesium alloy with rear earth yttrium

The invention discloses a high-intensity high-damping deforming magnesium alloy with rear earth yttrium, which is characterized by comprising the following components by weight percent: 2.9-3.1 percent of Al, 0.9-1.1 percent of Zn, 0.5-2 percent of Y, 0.29-0.31 percent of Mn and the rest of Mg and unavoidable impurities. The high-intensity high-damping deforming magnesium alloy with rear earth yttrium can greatly increase the mechanical property and the damping performance of the high-intensity AZ series deforming magnesium alloy, successfully solve the conflict of the mechanical property andthe damping performance of the magnesium alloy and satisfy the actual requirements for a high-intensity high-damping light-weight material in the fields of very high-speed trains, automobiles, aerospace, national defense war industry, and the like, moreover, the magnesium alloy material has lower cost, and a technical device is the normal universal device with strong portability and easy operation.

Owner:CHONGQING UNIV

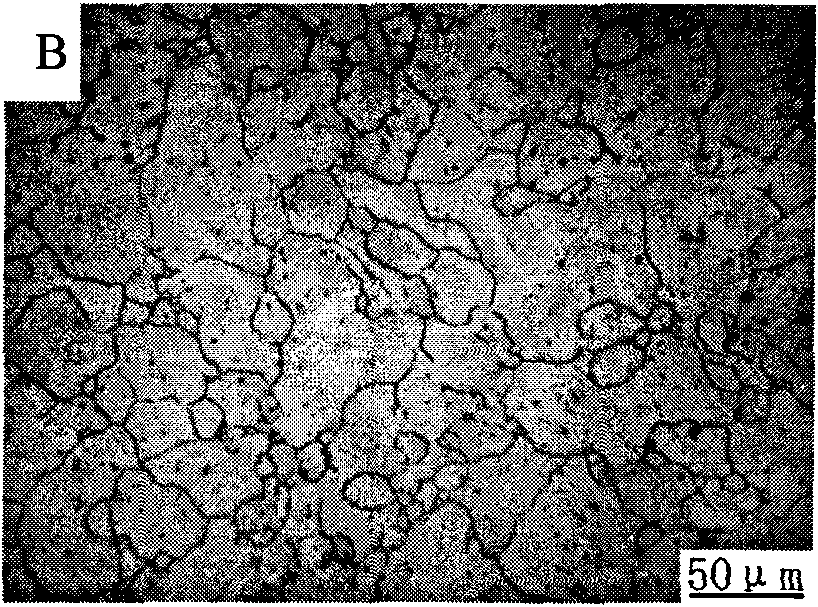

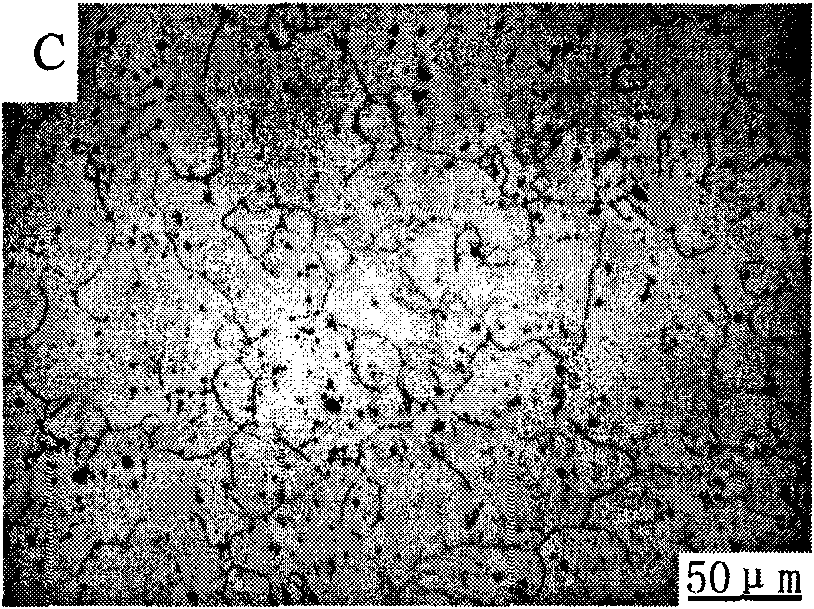

Plastic working technique for increasing damping performance of high-strength wrought magnesium alloys

InactiveCN101332560AHigh dampingImprove mechanical propertiesMetal-working apparatusIngotUltimate tensile strength

Owner:CHONGQING UNIV

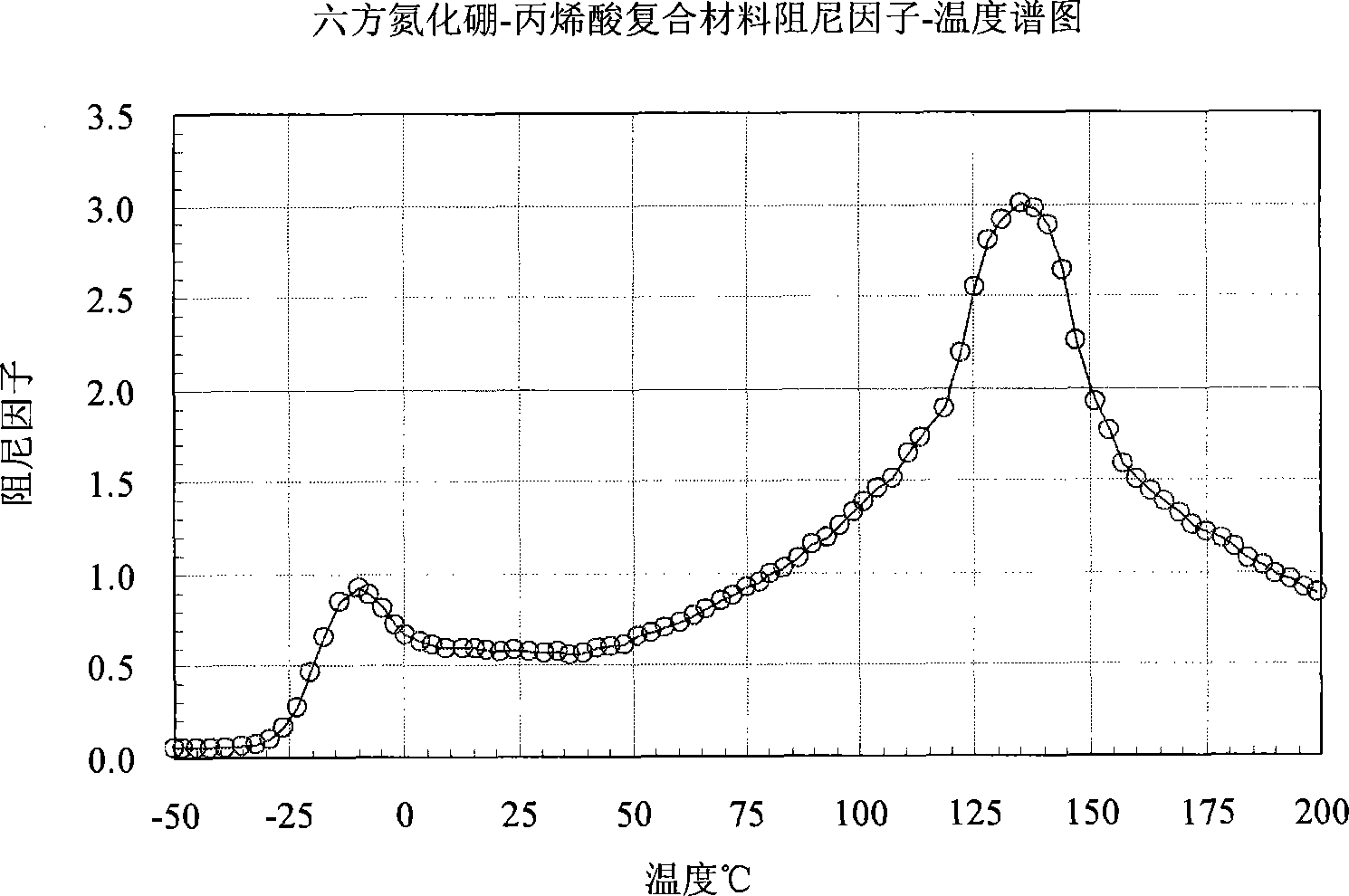

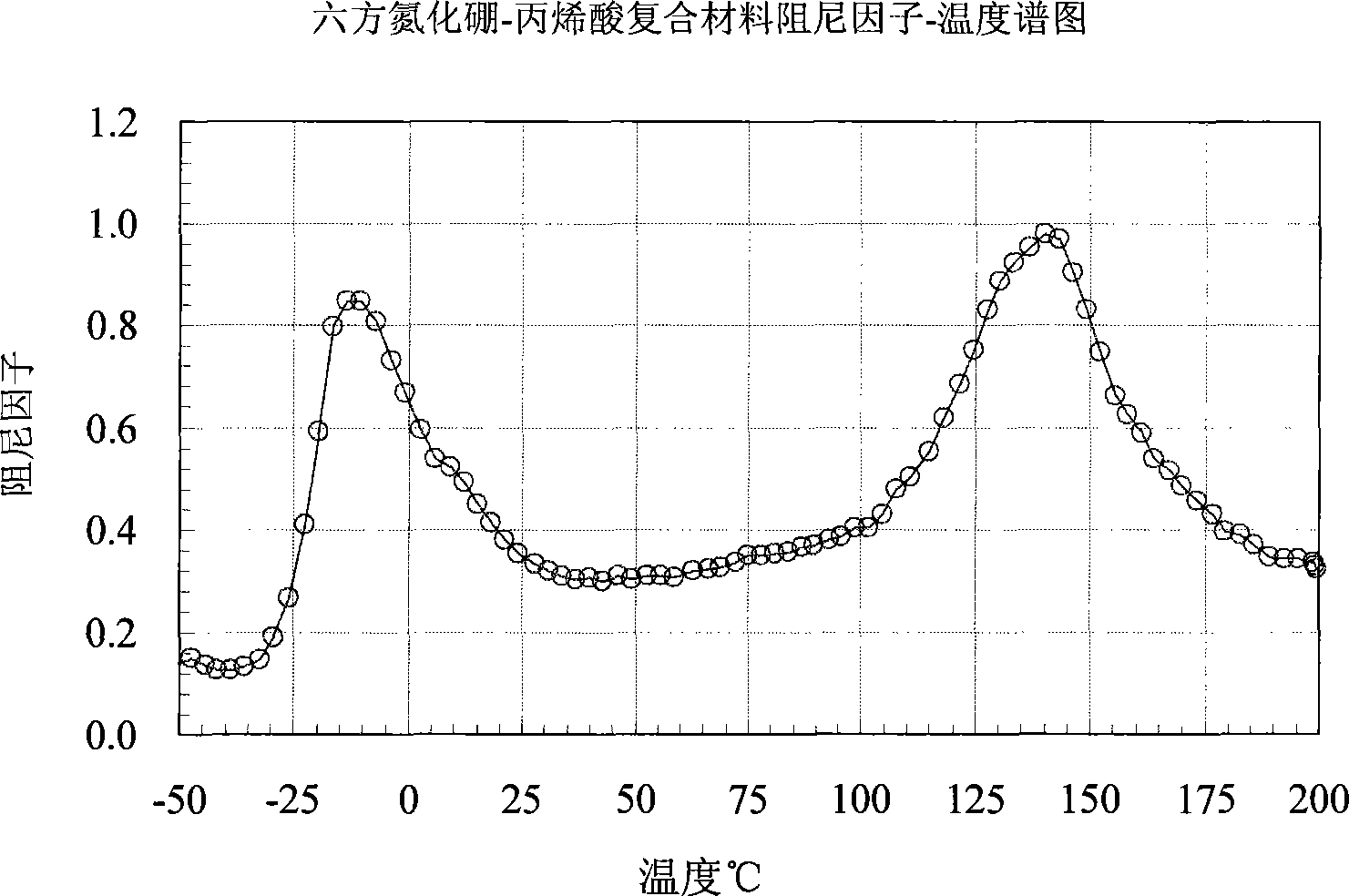

Method for preparing wide temperature range high damping acrylic emulsion material

InactiveCN101250246AThe synthesis process is simpleDoes not affect the preparation methodDamping factorSynthesis methods

The invention relates to a preparation method of acrylic emulsion function material which is composited from inorganic and organic, with wide temperature range and high damping property, belonging to the technical field of organic polymer material. The invention is characterized in that the invention uses acrylate as polymerization monomer, uses organic silicon as organic composite material, and uses nanometer boron nitride and mica as inorganic composite materials, without changing the synthesis of emulsion to prepare a serial of polymer material whose damping temperature is higher than 135DEG C and damping factor is higher than 0.30, wherein the damping factor of the best material is higher than 0.5 when in the damping temperature higher than 135DEG C. The polymerization method is characterized in that the invention can prepare interpenetrating network polymer damping material in short reaction via simple synthesis method.

Owner:UNIV OF SCI & TECH BEIJING

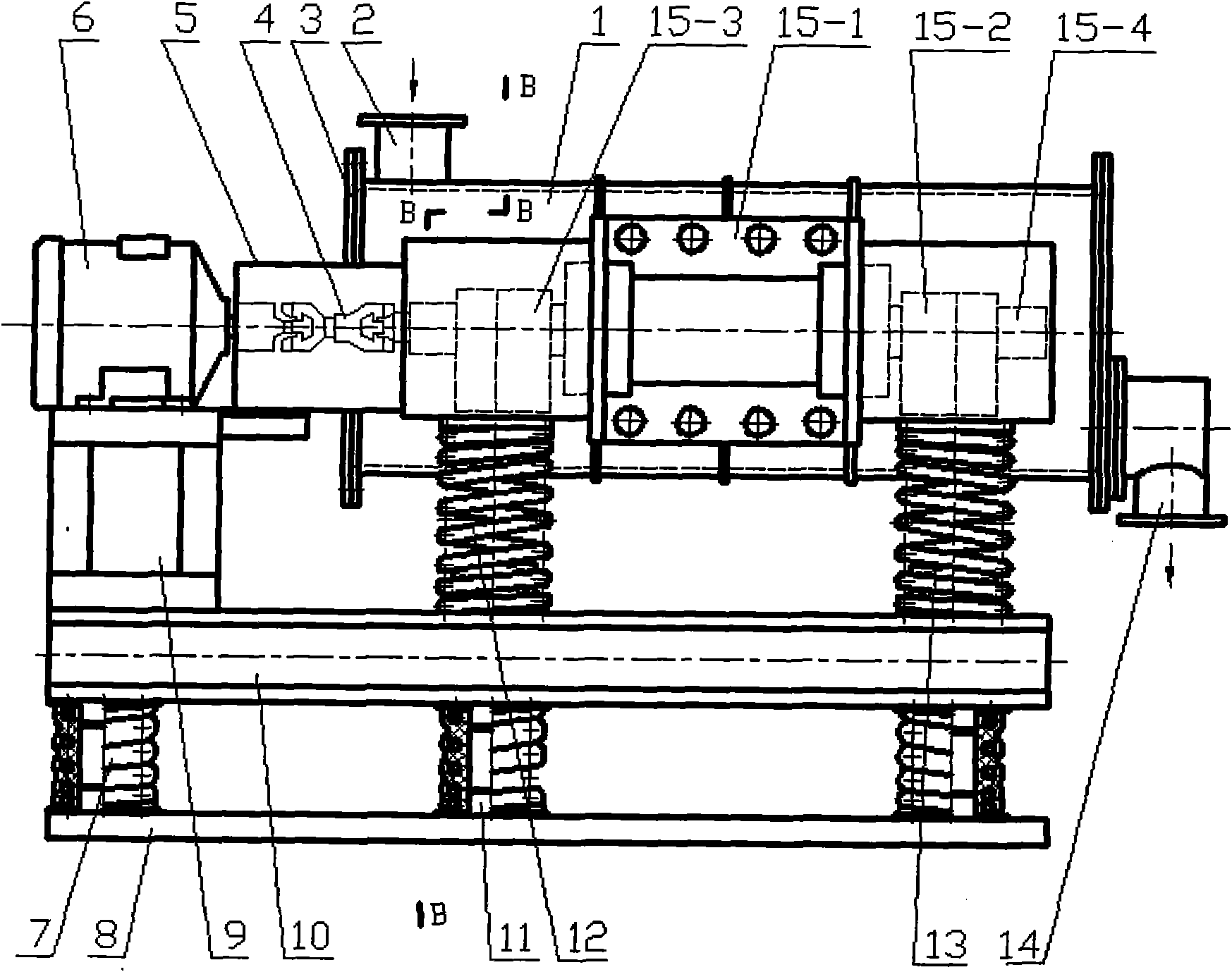

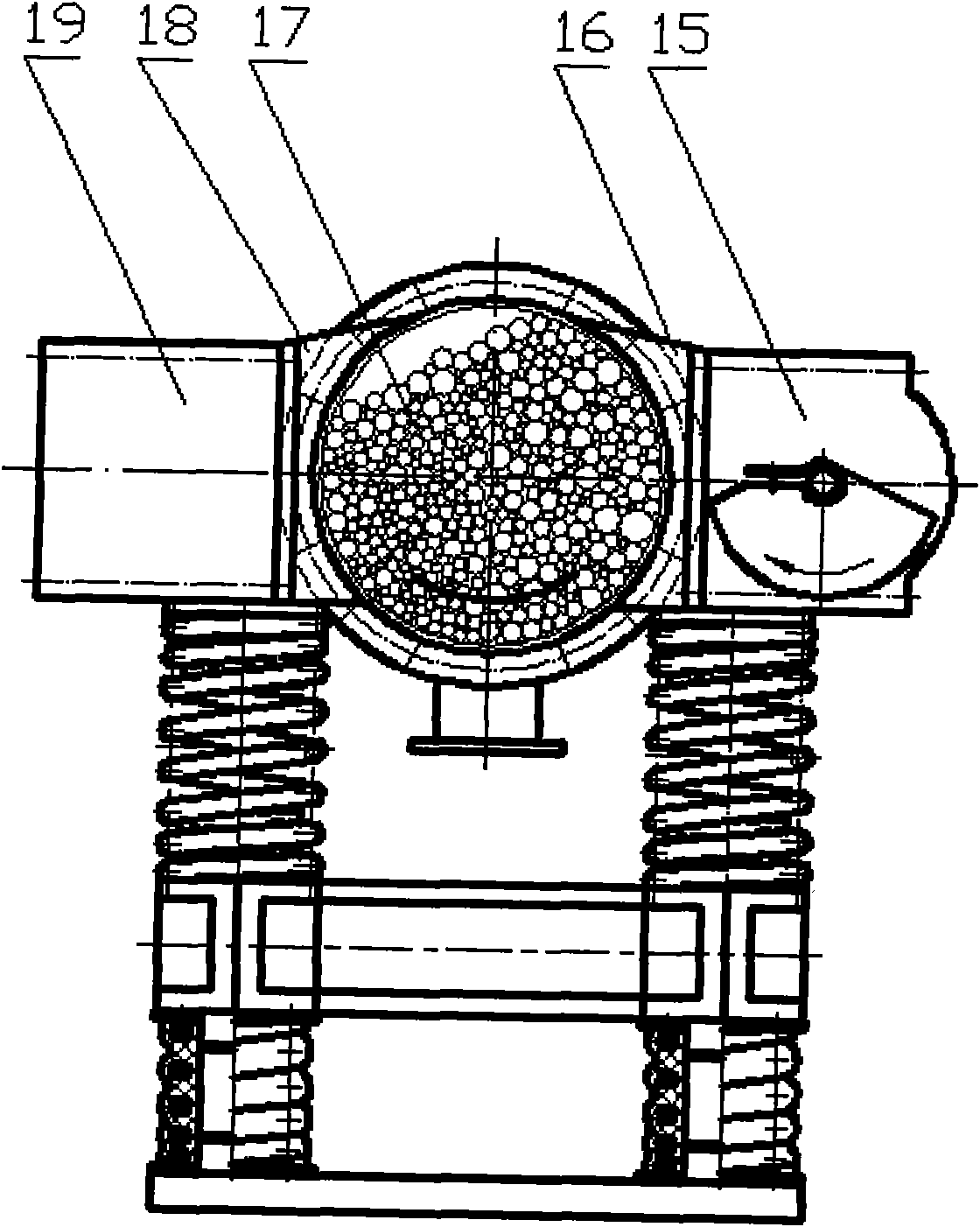

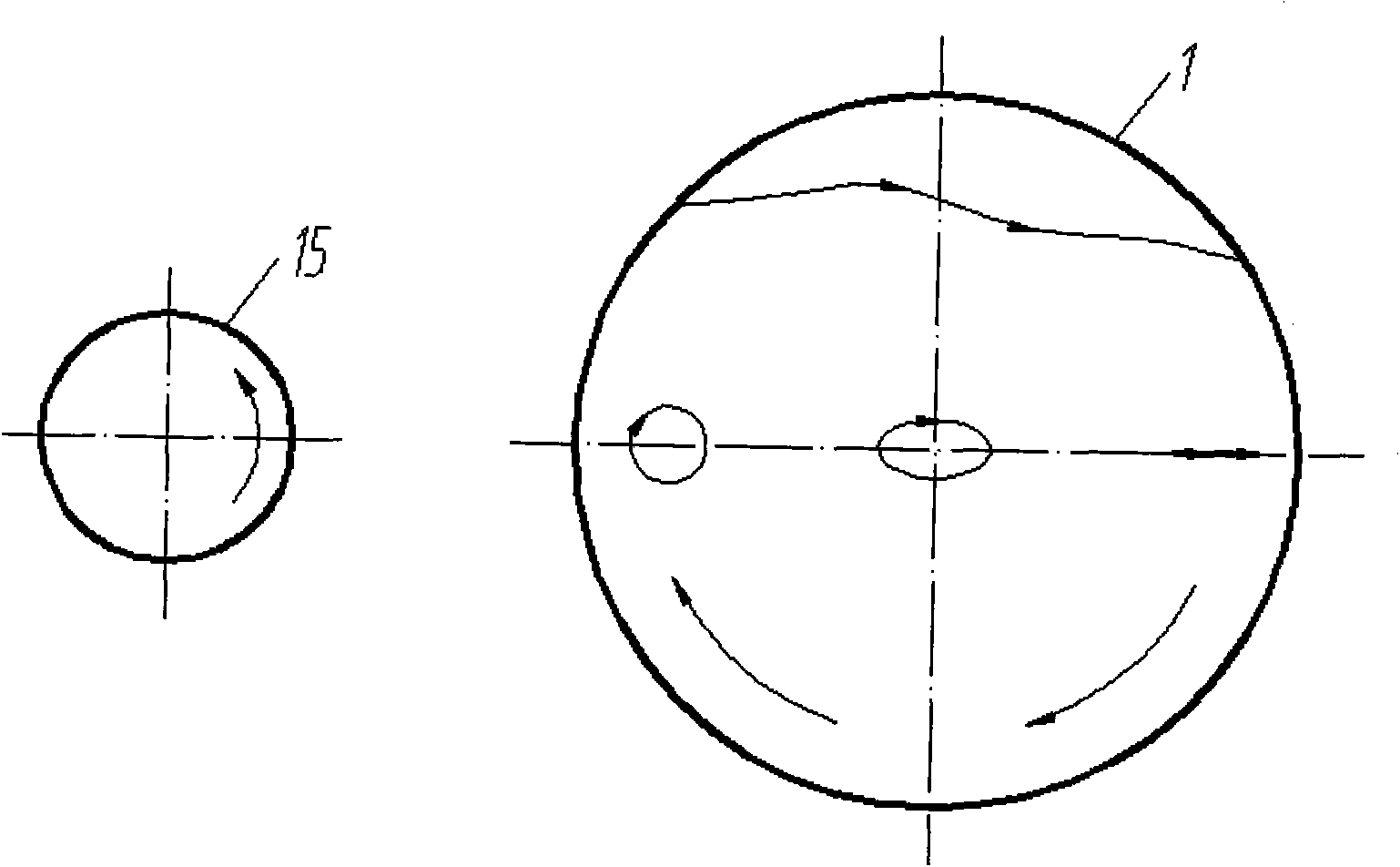

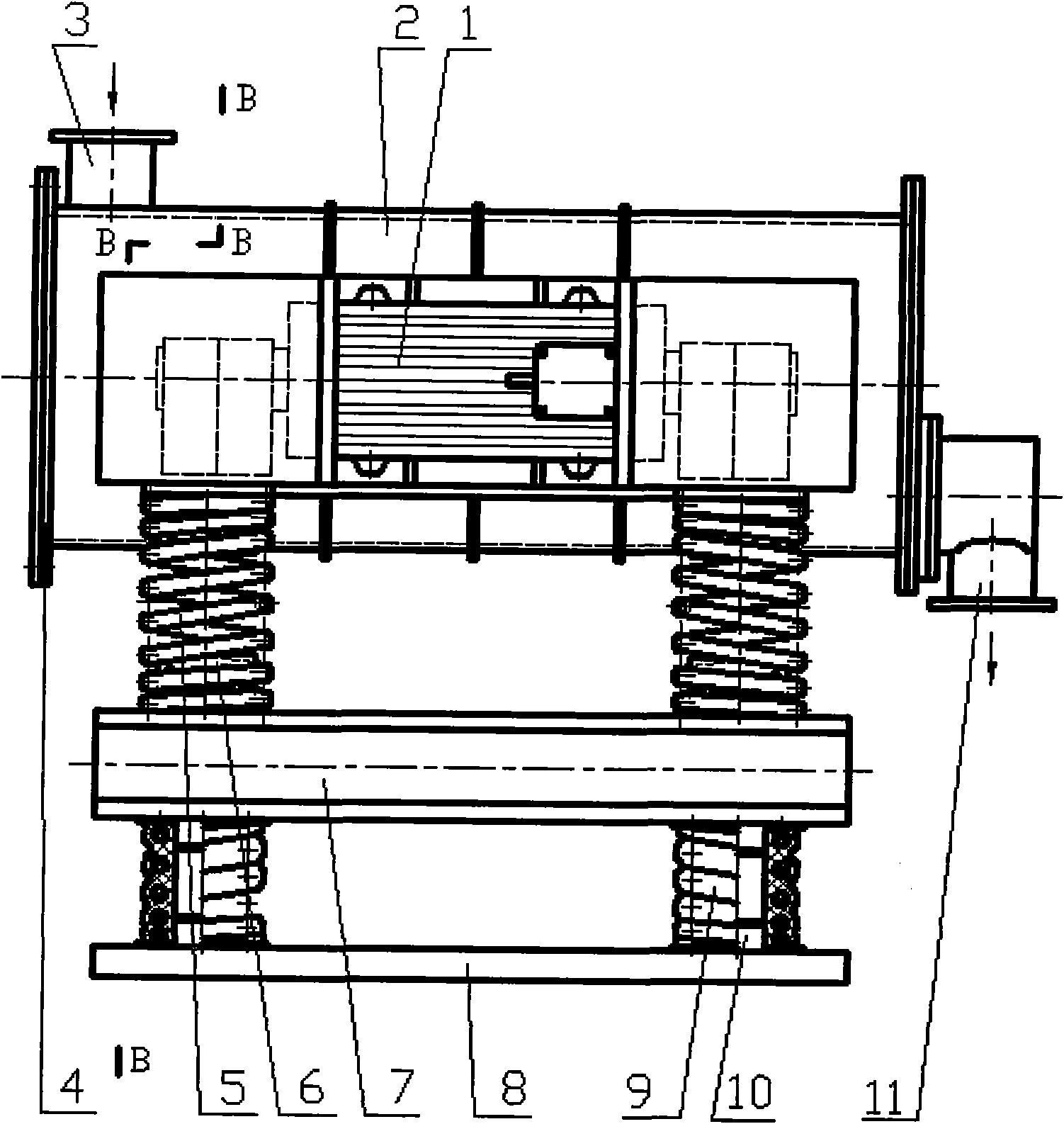

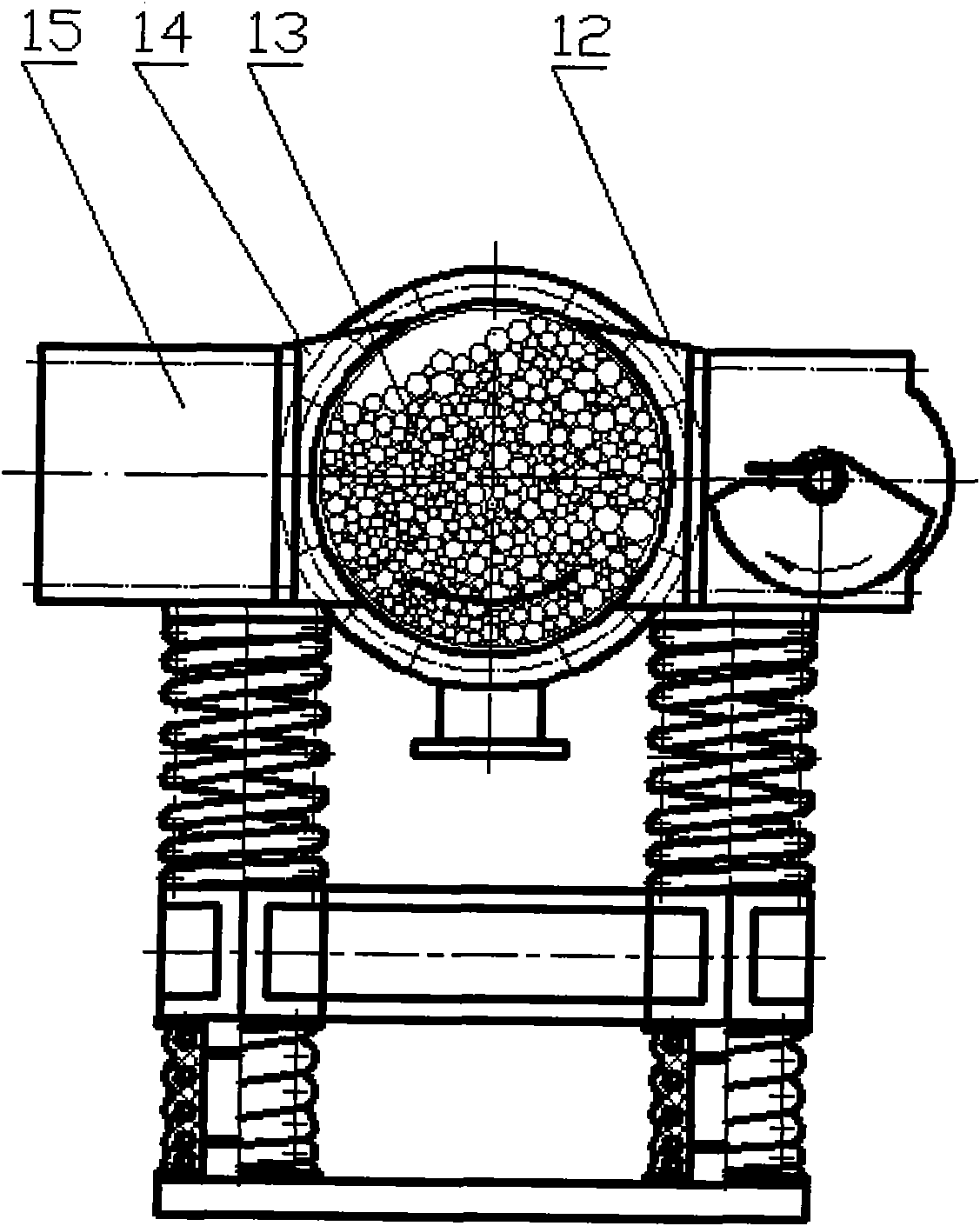

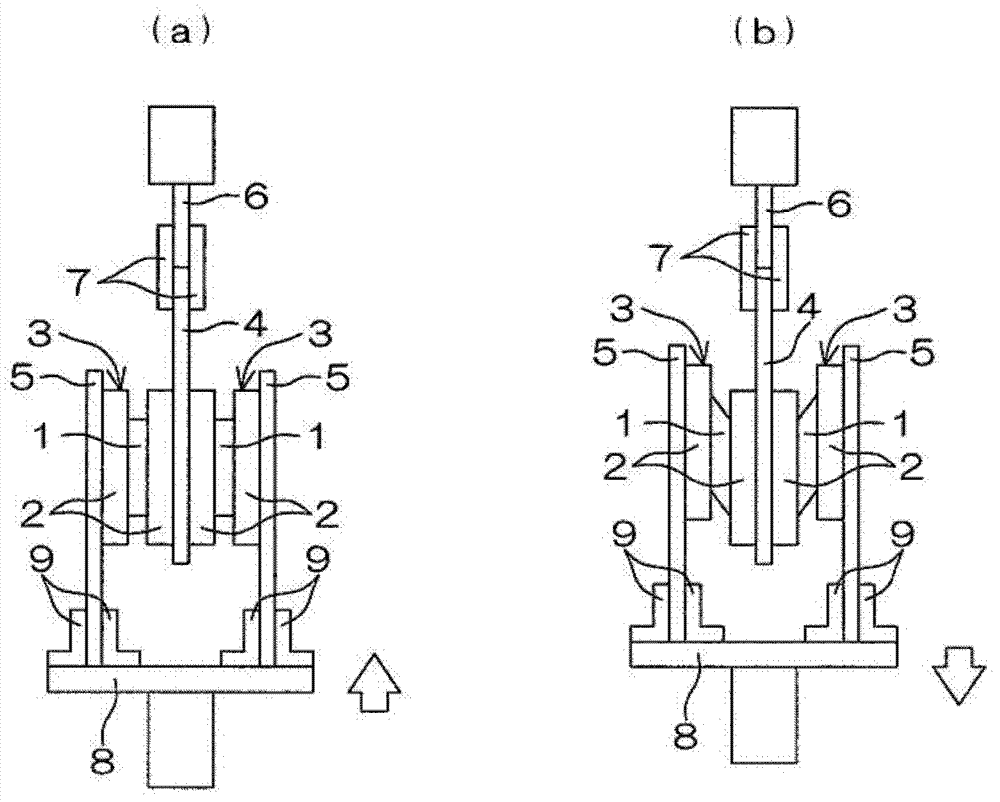

Variable-rigidity double-mass vibration exciter type super-huge vibration mill

InactiveCN101961671AReduce the ratioImprove energy utilizationGrain treatmentsCouplingVibration exciter

The invention relates to a vibration mill, in particular to a variable-rigidity double-mass vibration exciter type common vibration mill or super-huge vibration mill, belonging to the technical field of vibration utilization engineering. The vibration mill comprises an upper mass, a lower mass, a motor, a motor base, a coupling, a coupling guard, a master vibration spring, a vibration isolation spring and a base, wherein the upper mass comprises a barrel, a feed port, an end cap, a discharge port, a vibration exciter, a right connecting frame, a milling medium, a left connecting frame and a counterweight body; the upper mass and the lower mass are connected through the master vibration spring, and the inner diameter of the master vibration spring is matched with the outer diameter of a guide pillar of the master vibration spring on the upper mass and the lower mass; and the lower mass is supported on the base through the vibration isolation spring. The barrel can be actively supported on the lower mass through the master vibration spring, and the vibration exciter is rigidly solidified on the right side of the barrel by using a right coupling bracket.

Owner:NANJING INST OF TECH

High damping metal porous material and preparation method thereof

The invention discloses a high damping metal porous material and a preparation method thereof. The material comprises the following components in percentage by weight: 40 to 90 percent of Al powder, and the balance of Mg powder. The preparation method comprises the following steps of: (1) pretreating powder, namely drying the Al powder for 1 to 2h at the temperature of between 150 and 200 DEG C, and drying the Mg powder for 1 to 2h at the temperature of between 100 and 120 DEG C; (2) mixing, namely stirring and mixing the dried Al powder and the dried Mg powder in a mixer for 40 to 60min; (3) performing compression molding, namely performing compression molding on mixed materials in a molding press under the pressure of between 300 and 400Mpa; (4) sintering, namely sintering at the temperature of between 450 and 500 DEG C in in-situ sintering equipment, and keeping the temperature for 10 to 15min; and (5) performing thermal deformation aging treatment, namely heating at the temperature of between 430 and 460 DEG C, keeping the temperature for 5 to 10min, extruding and deforming, wherein the deformation amount is 10 to 90 percent. The material is a porous material with low density, high strength and high damping performance; and the preparation process is simple, the preparation method is convenient to operate, and production efficiency is high.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

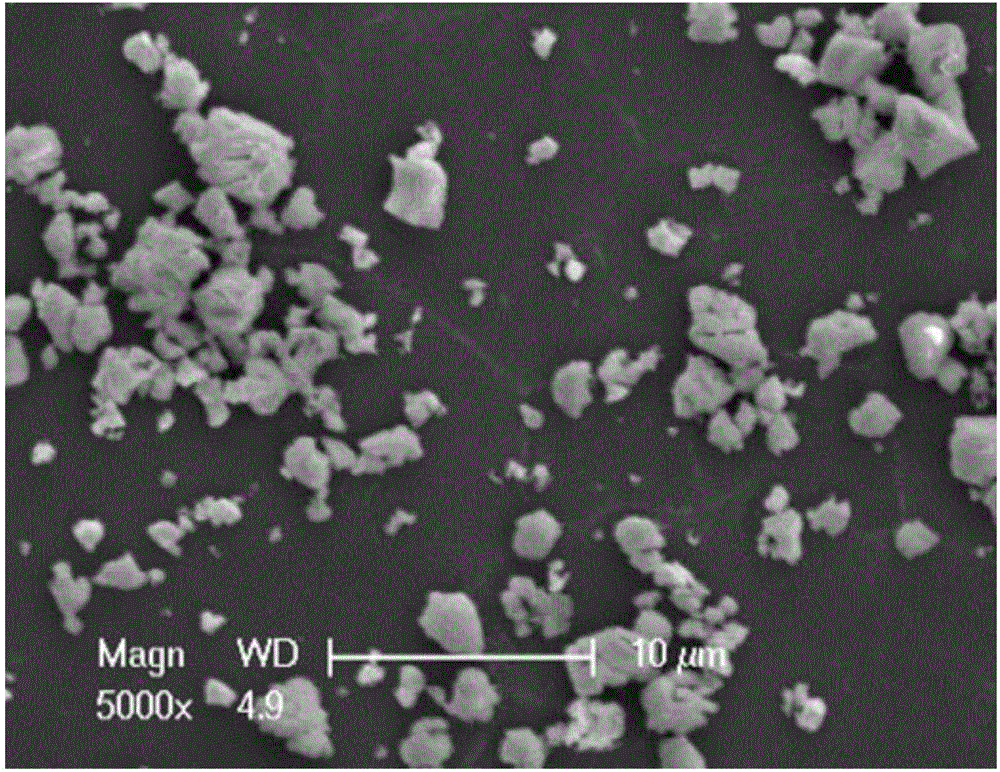

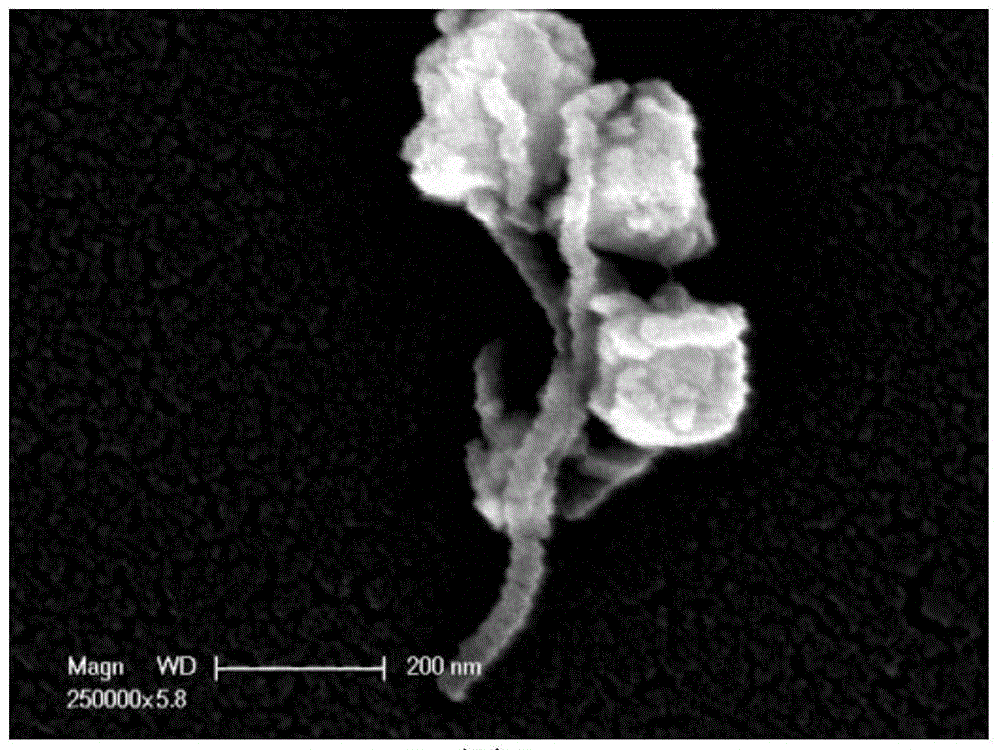

Compound preparation method for piezoelectric ceramic and carbon material

ActiveCN104059247AHigh dampingComposite preparationPigment treatment with non-polymer organic compoundsFiberCarbon fibers

The invention provides a compound preparation method for piezoelectric ceramic and a carbon material. Compound preparation of the piezoelectric ceramic and the carbon material (a carbon nano tube, carbon fibers or graphene and the like) is realized by adopting cis-butenedioic acid to respectively carry out surface modification on the piezoelectric ceramic particles and the carbon material (the carbon nano tube, the carbon fibers or graphene and the like) by means of the characteristic that cis-butenedioic acid has double carboxylic acid, so as to realize improvement of the damping performance of the piezoelectric ceramic and the carbon material as a macromolecular composite material with piezoelectric and conductive phases. The technology compensates for the deficiencies of doping the piezoelectric phase and the conductive phase in existing macromolecular materials and reduces the randomness of contact of the two phases, so that the two phases are more effectively contacted.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Vulcanized silicone rubber and preparing method thereof

The invention provides vulcanized silicone rubber and a preparing method thereof. The vulcanized silicone rubber is obtained by conducting vulcanizing treatment on 8-22 parts by weight of crude silicone rubber through 1-90 parts by weight of a damping modifier and 0.1-0.3 part by weight of peroxide. The damping modifier comprises polyborosiloxane. The crude silicone rubber is adopted as the base rubber, the peroxide serves as a vulcanizing agent, the damping modifier comprises polyborosiloxane, the damping modifier can form a stable chemical crosslinking network together with the base rubber,and the mechanical performance of the vulcanizing rubber is improved; meanwhile, in the vulcanizing treatment system, reversible breakage and recombination happen to non-covalent bonds, the reversiblephysical crosslinking network structure is formed, great energy is absorbed, the damping performance of the material is improved, and moreover, the mechanical performance of the material is good.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

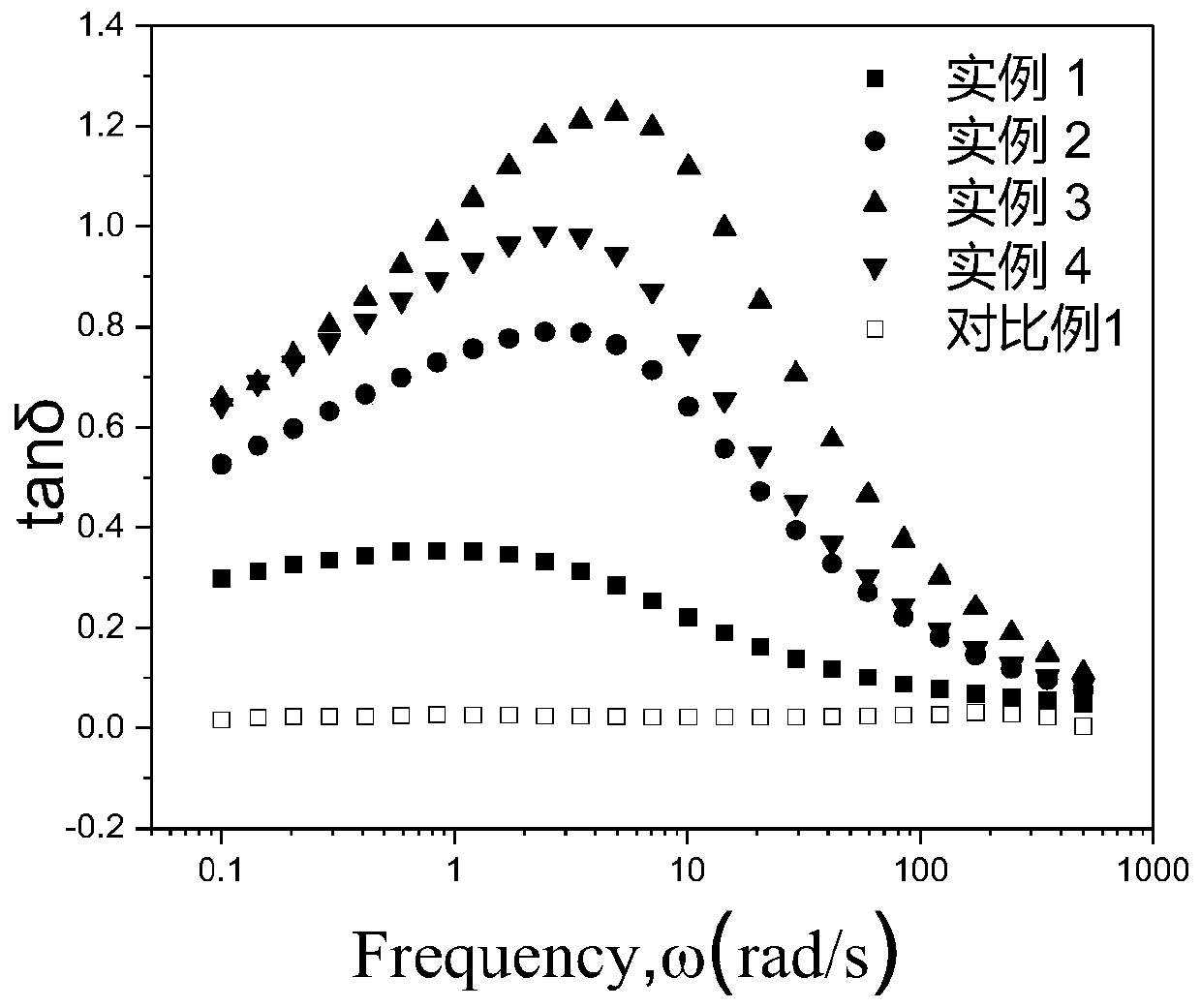

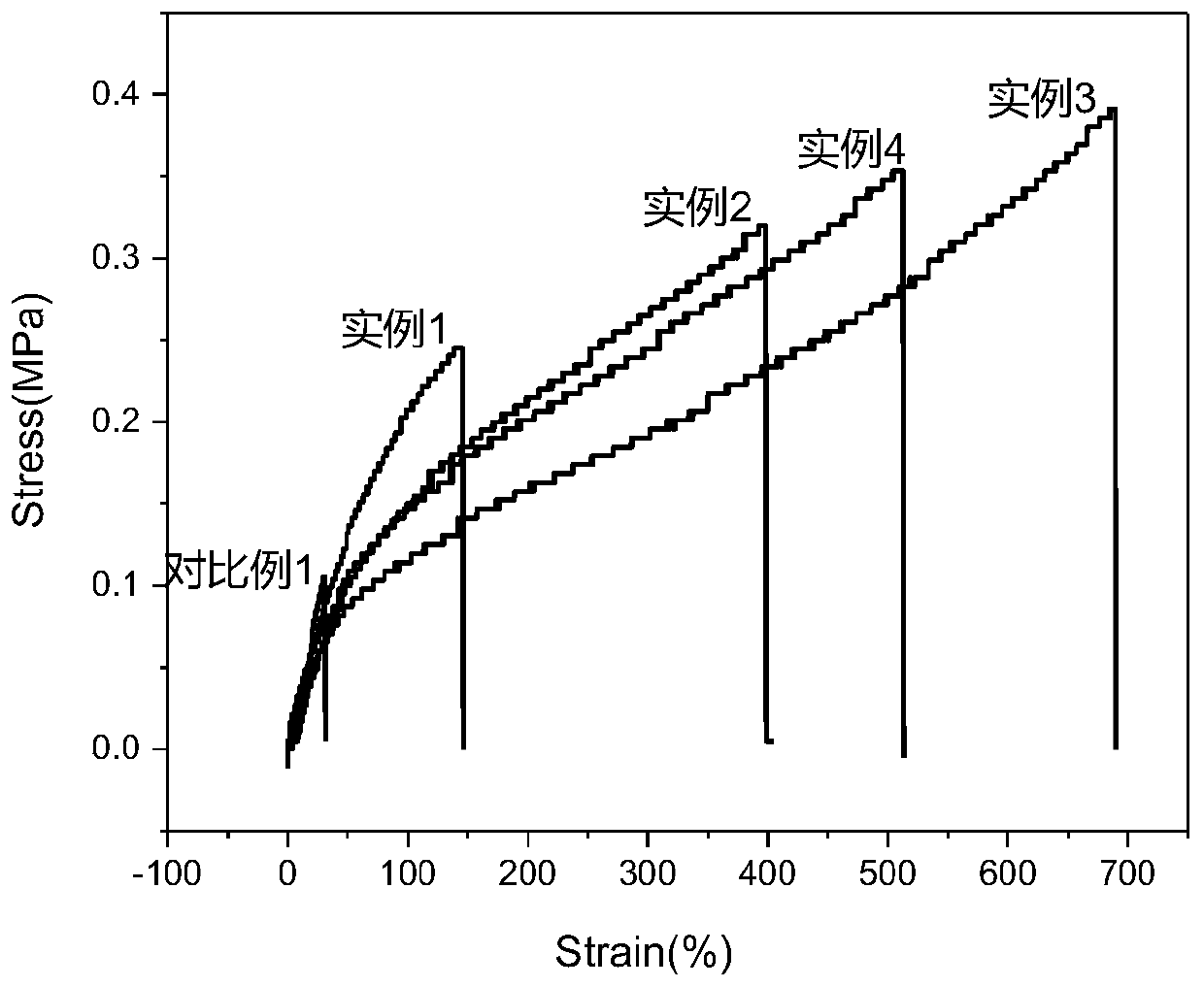

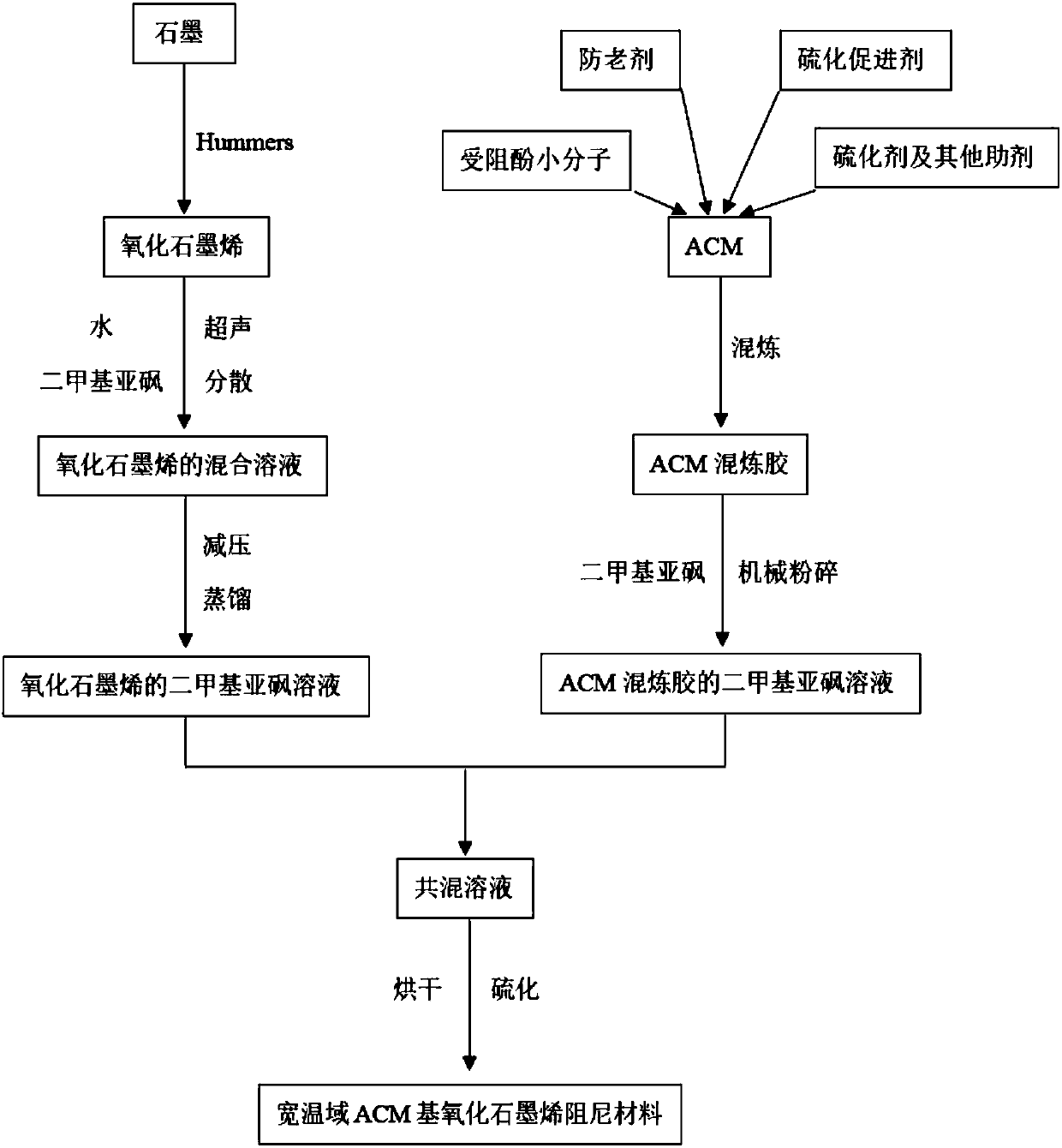

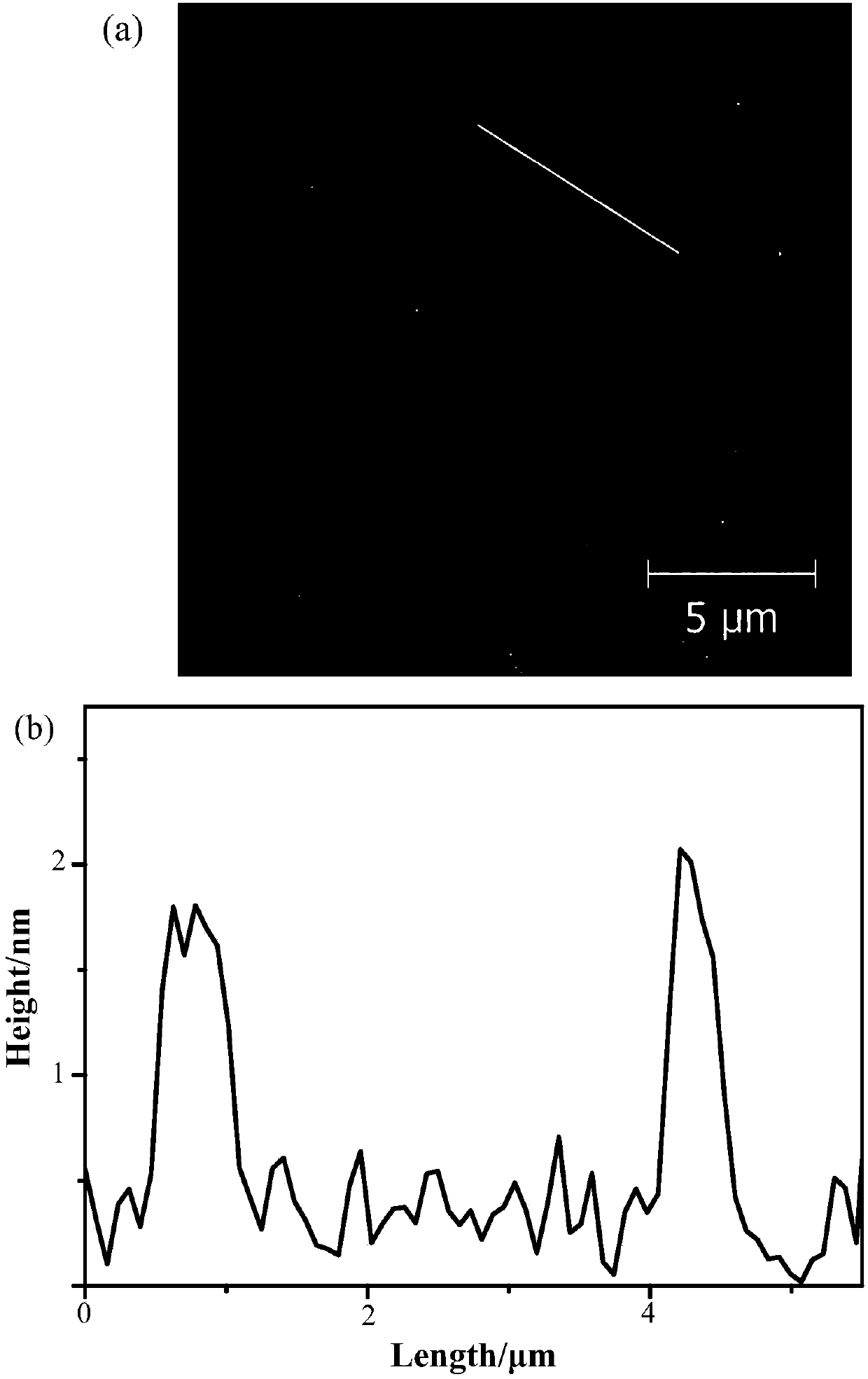

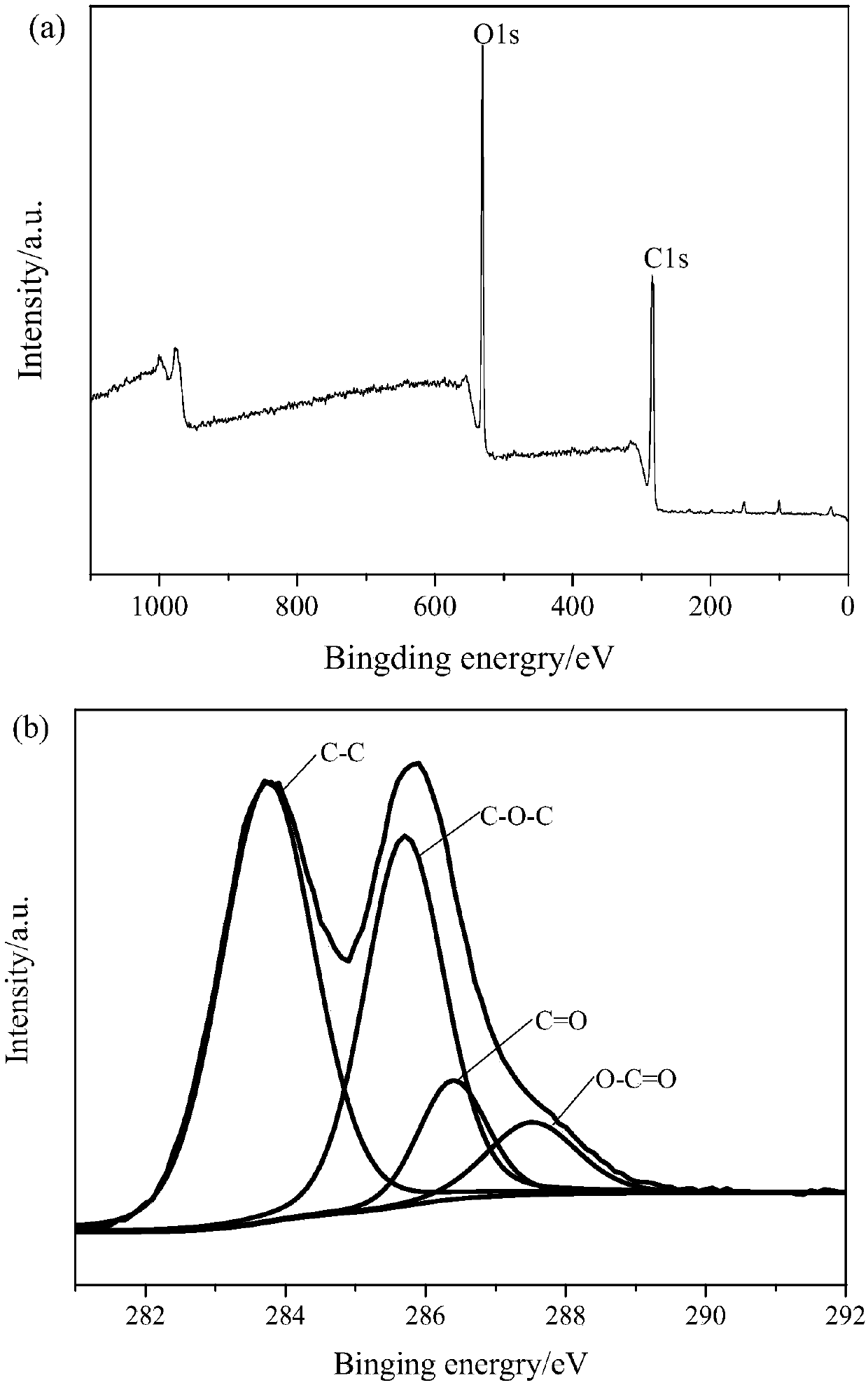

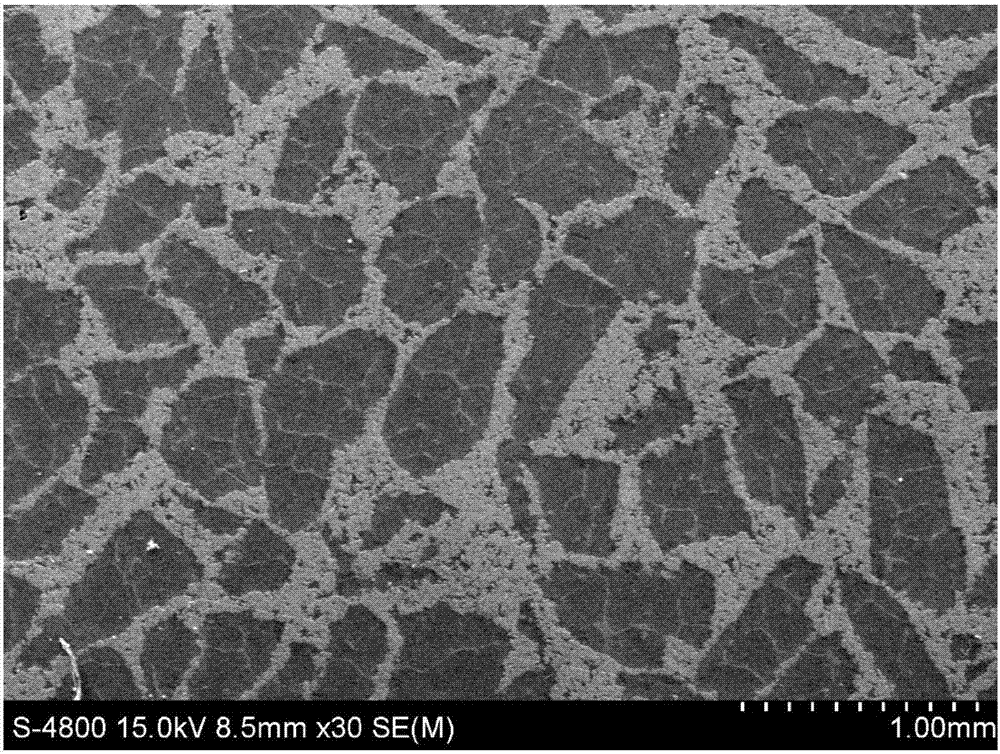

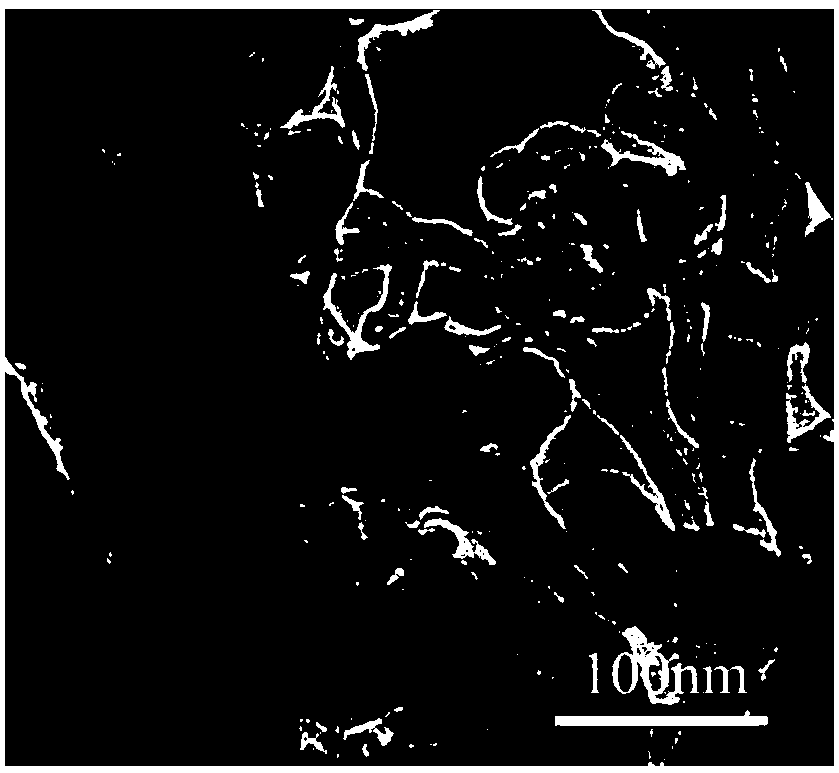

Wide temperature range acrylate rubber based graphene oxide damping material and preparation method thereof

The invention discloses a wide temperature range acrylate rubber (ACM) based graphene oxide damping material and a preparation method thereof. The method comprises the steps of: adjusting the dosage of oxidant to prepare of a graphene oxide dispersion liquid with certain size and a lot of polar groups on the surface; using mechanical blending method to blend ACM with hindered phenol small molecules, a curing agent and other compounding agents, then performing mixing with graphene oxide by solvent blending method, and conducting drying and vulcanizing so as to obtain the wide temperature rangeACM based damping rubber containing graphene oxide. According to the invention, graphene oxide with a lot of polar groups on the surface, hindered phenol small molecules and ACM are utilized to form astrong hydrogen bond, at the same time, the barrier properties of graphene oxide are utilized to greatly improve the effective damping temperature range of the ACM based graphene oxide damping material (with tan delta being greater than or equal to 0.3) and the damping properties after aging.

Owner:NANJING UNIV OF SCI & TECH

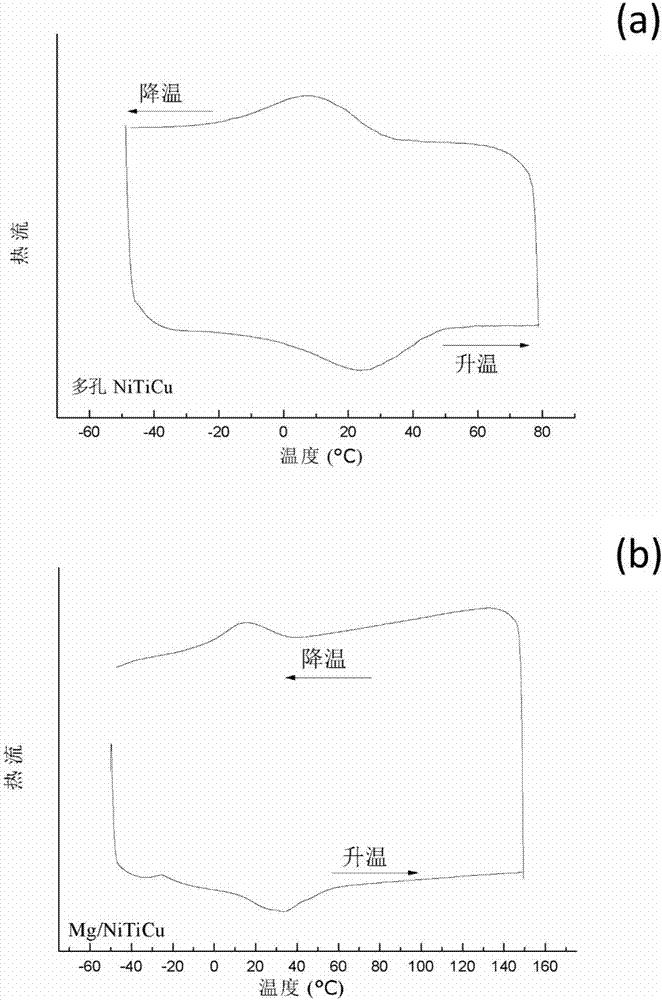

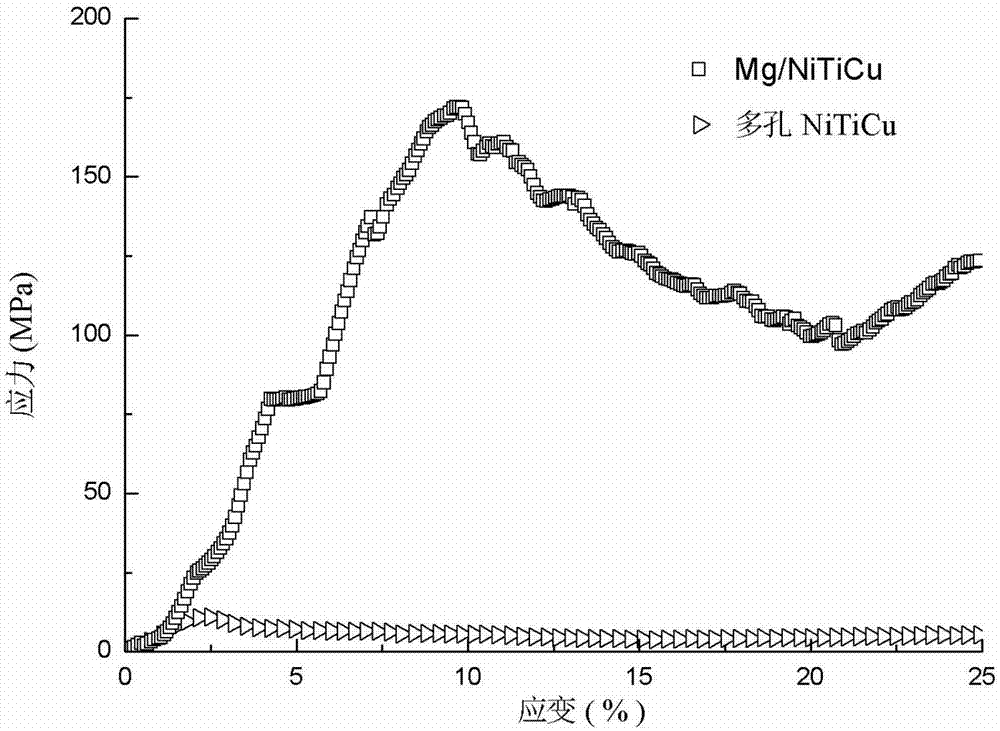

Method for preparing TiNiCu shape memory alloy damping composite

The invention relates to manufacturing of a damping material, in particular to a method for preparing a TiNiCu shape memory alloy damping composite. A porous TiNiCu shape memory alloy is prepared, holes of the TiNiCu shape memory alloy are filled with metal Mg, and the TiNiCu shape memory alloy damping composite, namely, Mg / TiNiCu is prepared. The defects that in an existing porous TiNiCu shape memory alloy preparation method, the porosity, the aperture and the hole type are all hard to control; and an existing technology of introducing Mg into the porous alloy cannot be used for filling porous TiNiCu alloy with Mg, and the damping performance and other mechanical performance of an alloy product need to be improved are overcome.

Owner:HEBEI UNIV OF TECH

High-damping rubber composition and application thereof to vibration isolating supporting seat

InactiveCN102336934AHigh strengthHigh bonding strengthBridge structural detailsShock proofingRubber materialAging resistance

The invention discloses a high-damping rubber composition and application thereof to a vibration isolating supporting seat, relating to improvement on a high-damping rubber formula and application thereof to a vibration isolating supporting seat. According to the invention, the intensity and high damping performance are ensured, high damping performance is achieved, framework bonding strength is high, and aging resistance is realized. The high-damping rubber composition comprises 100 parts of smoke sheet rubber, 1-2.5 parts of vulcanizing agent, 5-10 parts of crosslinking aid, 20-35 parts of high-damping additive, 10-15 parts of plasticizing agent and 40-50 parts of reinforcing agent. The composition is taken as a rubber overlay of the vibration isolating supporting seat. In the invention, the smoke sheet rubber is taken as a main body and the high-damping additive is used, so that a rubber material with high strength, high framework bonding strength, aging resistance and high damping performance can be prepared under the actions of the crosslinking aid, the vulcanizing agent, the reinforcing agent and the plasticizing agent. The high-damping rubber composition is particularly suitable to be applied to a shockproof vibration isolating supporting seat. Compared with the prior art, the invention has the advantages: the damping performance is enhanced while the strength and aging resistance of a product are ensured, and the cost is reduced greatly.

Owner:JIANGSU YANGZHOU HELI RUBBER PROD

Variable-rigidity double-mass vibration motor type super-huge vibration mill

InactiveCN101972690AReduce the ratioImprove energy utilizationGrain treatmentsVibration controlEngineering

The invention relates to a vibration mill, in particular to a variable-rigidity double-mass vibration motor type super-huge vibration mill, more particularly to a variable-rigidity double-mass vibration motor type common vibration mill or super-huge vibration mill. The vibration mill comprises an upper mass, a lower mass, a master vibration spring, an isolation vibration spring and a base plate, wherein the upper mass comprises a barrel body, a feed port, an end cover, a discharge port, a vibration motor, a right connecting rack, a milling medium, a left connecting rack and a counterweight body; the barrel body can be actively supported on the lower mass through the master vibration spring, the right side of the barrel body is rigidly and fixedly connected with the vibration motor by using the right connecting rack, and the axis of the drive side master vibration spring is located between the gravity axis of the barrel and the gravity axis of the vibration motor; and the lower mass is supported on a pedestal through the isolation vibration spring, and the left side of the barrel is rigidly and fixedly connected with the counterweight body with mass balanced to the right side.

Owner:NANJING INST OF TECH

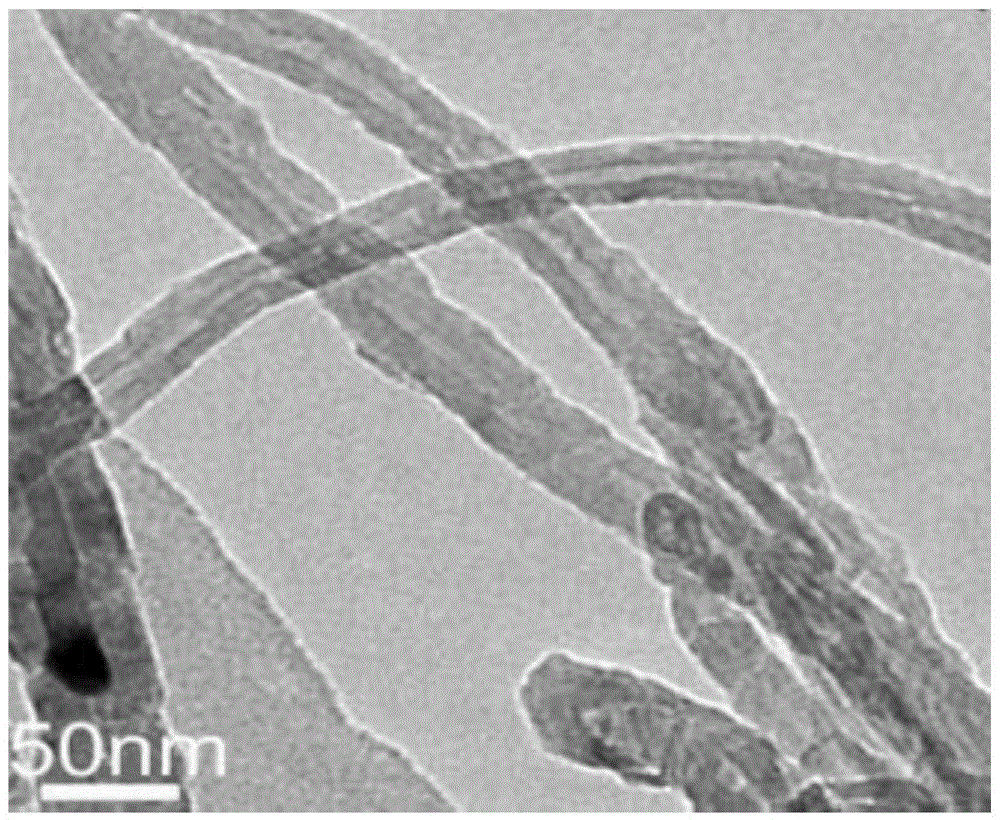

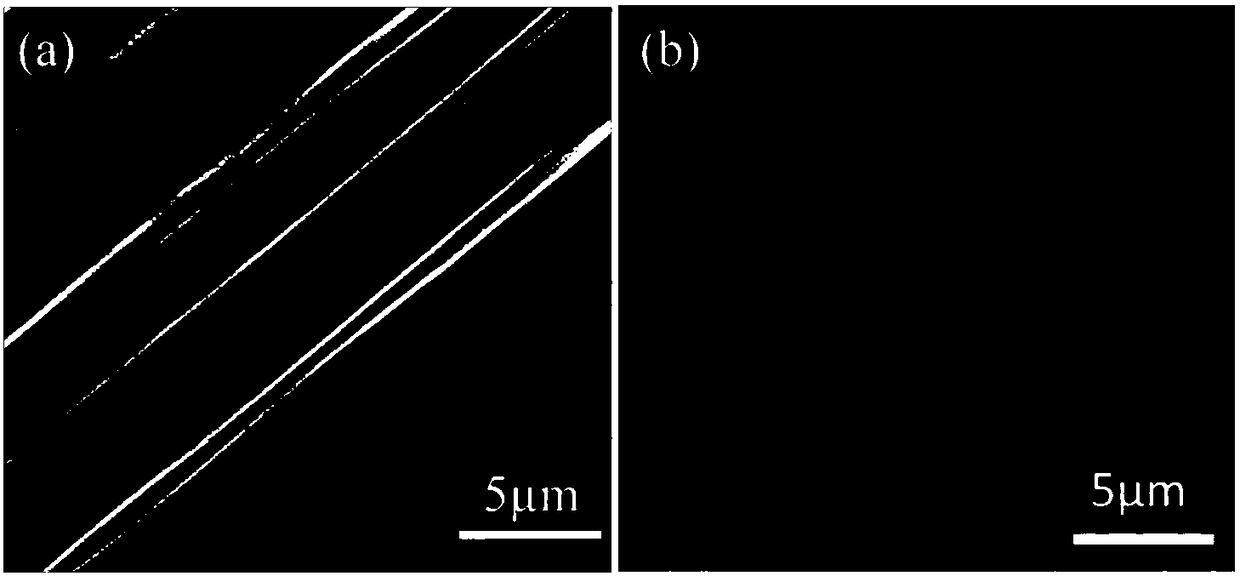

Preparation method for in-situ synthesis of CNT (carbon nano tube) modified carbon fiber reinforced resin structure-damping composite material

InactiveCN108360250ASynthetic distribution is evenHigh dampingCarbon fibresChemical vapor deposition coatingFiberCarbon fibers

The invention relates to a preparation method for in-situ synthesis of a CNT (carbon nano tube) modified carbon fiber reinforced resin structure-damping composite material. The preparation method comprises following steps: 1), the surfaces of carbon fibers are degummed; 2), a catalyst precursor solution is prepared from Fe(NO3)3 as a precursor of a nano-metal catalyst; 3), the carbon fibers are soaked in the catalyst precursor solution for 0.5-1 h, and then the carbon fibers are taken out and dried for 0.5-1 h at the temperature of 90-120 DEG C; 4), the dried carbon fibers are put in a tube furnace and heated to 250-450 DEG C under the condition of 240-400 sccm argon, are subjected to thermal-insulating reduction for 2-4 h under the condition of 150-200 sccm hydrogen and are heated to 560-800 DEG C under the condition of 240-400 sccm argon, and the carbon fibers are subjected to thermal insulation for 0.5-1 h with introduction of 20-40 sccm acetylene.

Owner:TIANJIN UNIV

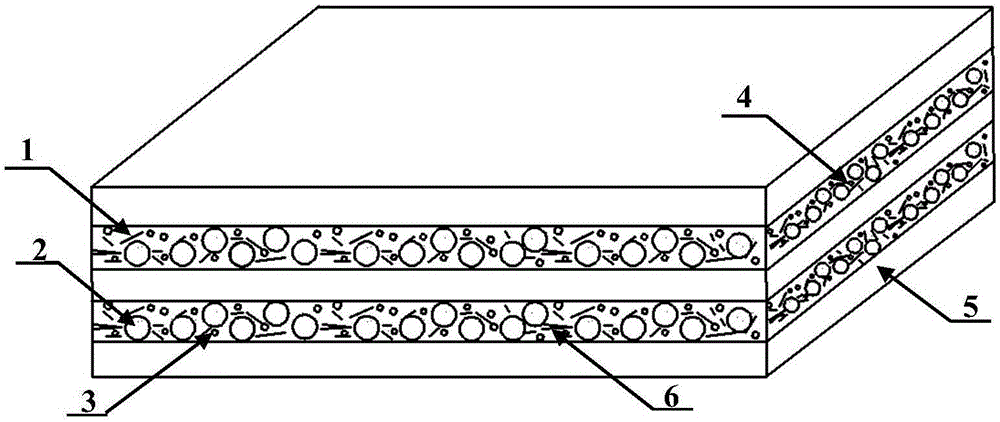

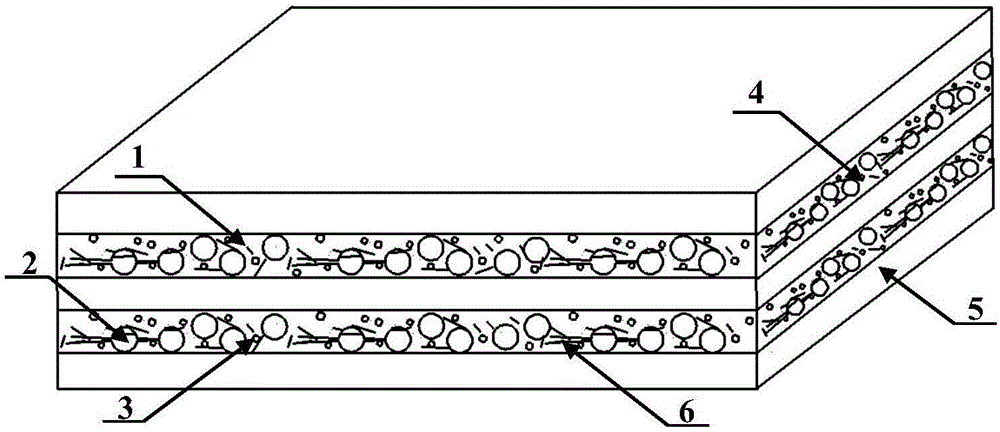

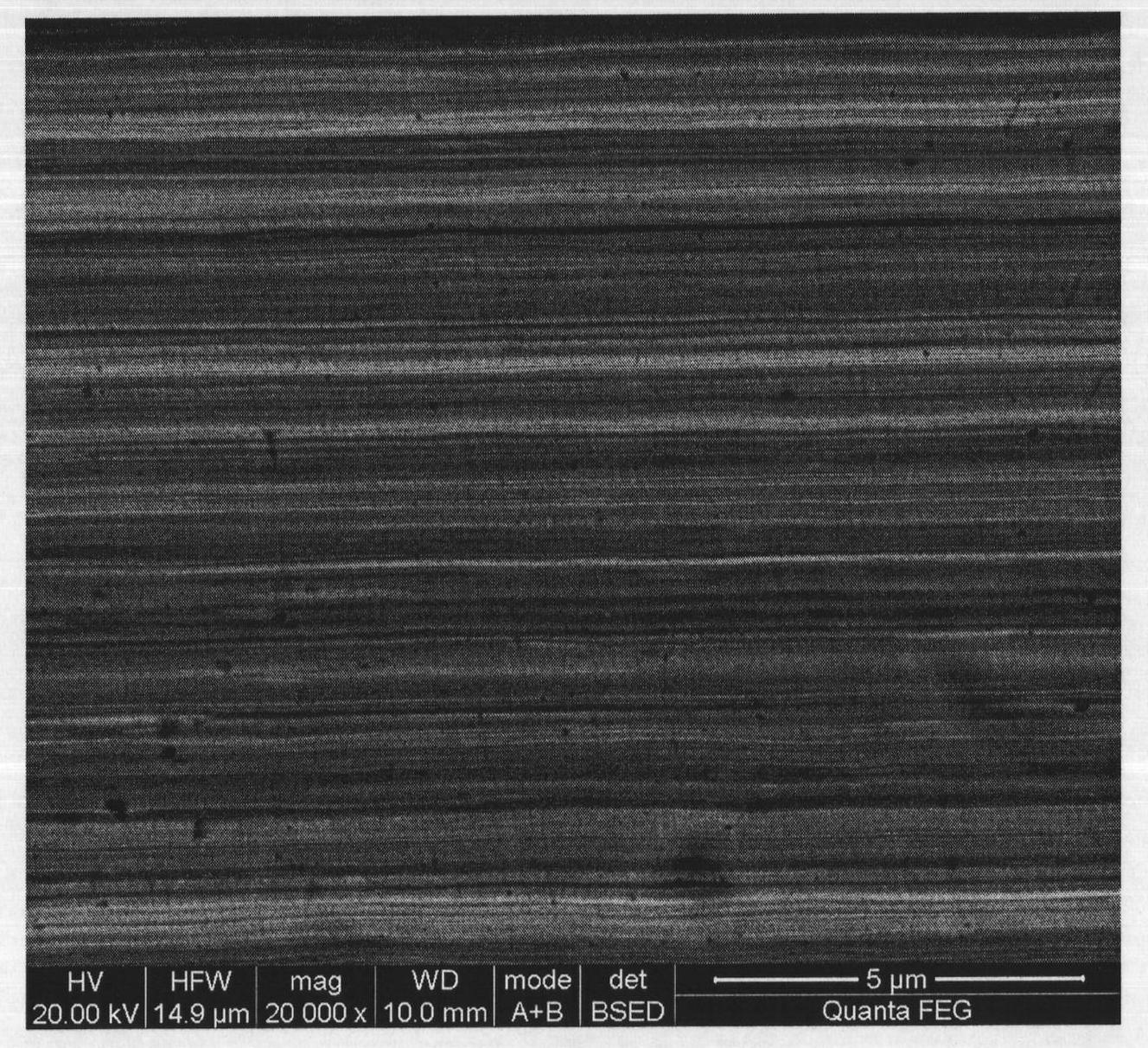

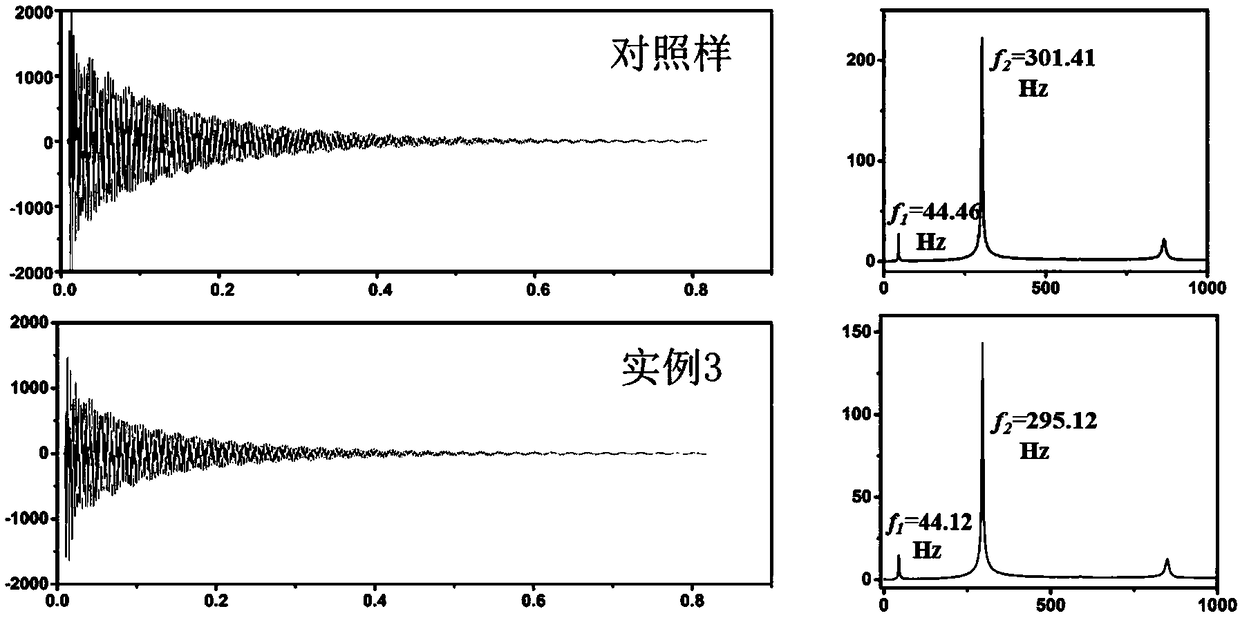

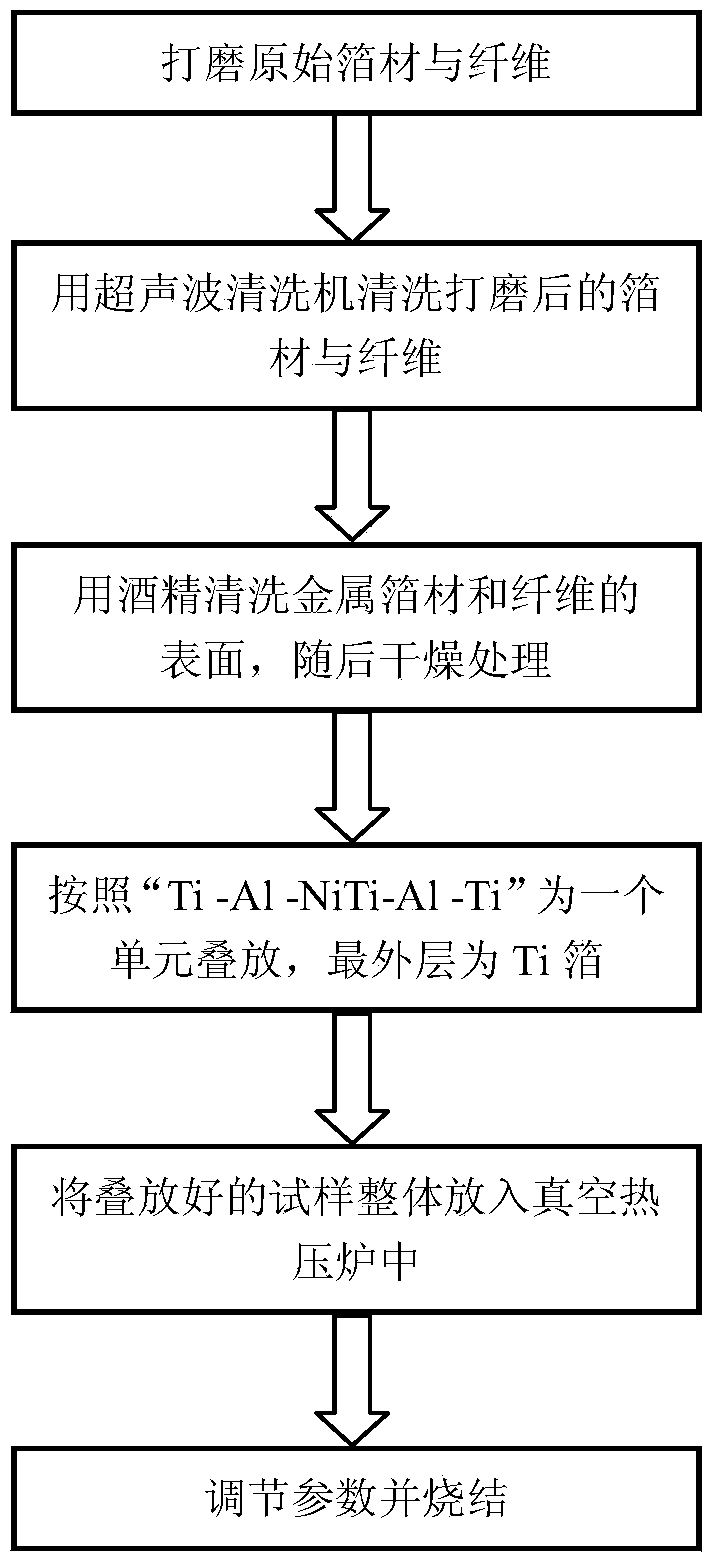

Preparation method of NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction

ActiveCN104099540ASpecial high energy-absorbing laminated structureImprove performanceNiti alloyStructure function

The invention provides a preparation method of a NiTi fiber reinforced intermetallic compound-based laminar composite material for vibration and noise reduction. The preparation method comprises the steps of polishing Ti foils, Al foils and NiTi alloy fibers by use of abrasive paper to remove oxide layers, next, cleaning by use of an ultrasonic cleaner and then cleaning by use of alcohol, drying, stacking by the unit of Ti foil-Al foil-NiTi fibers-Al foil-Ti foil with the Ti foils as the outmost layers, and putting the entire stacked material in a vacuum hot pressing furnace for sintering. The prepared fiber reinforced laminar composite material is highly damped (the loss modulus can be 3500MPa under the conditions of a temperature ranging from a room temperature to 50 DEG C and 1Hz, and the loss modulus can be 4100MPa under the conditions of the same temperature range and 20Hz) and has high strength (the compressive strength can be 1400MPa), and therefore, the prepared fiber reinforced laminar composite material is a high-performance structure-function integrated composite material.

Owner:HARBIN ENG UNIV

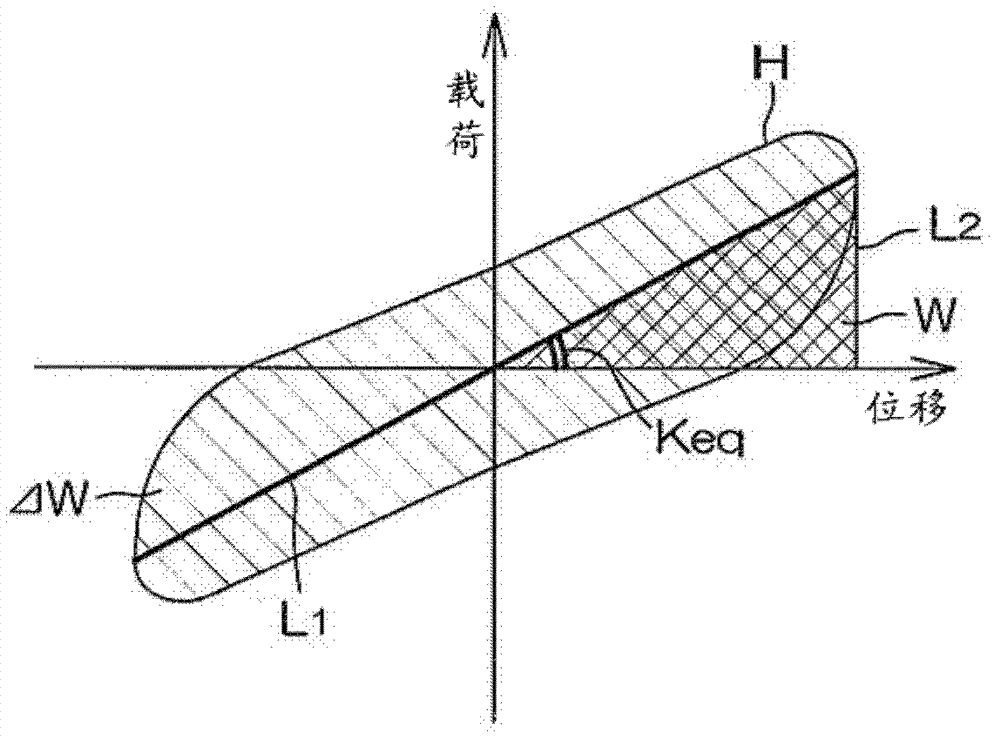

High-damping composition

InactiveCN102731875AHigh dampingEvenly dispersedRubber-like material springsLow internal friction springsNitrogenSilicon dioxide

The invention provides a novel high-damping composition. The novel high-damping composition can make high-damping components with high-damping performances and no requirements for deformation experiences due to low rigidity when newly produced before a delivery. The novel high-damping composition is formed by making deproteinized nature rubbers with less than 0.3 mass percent of nitrogen contents as the basic polymer and then adding 100 to 170 weight parts of silicon dioxide relative to 100 weight parts of the deproteinized nature rubbers.

Owner:SUMITOMO RUBBER IND LTD

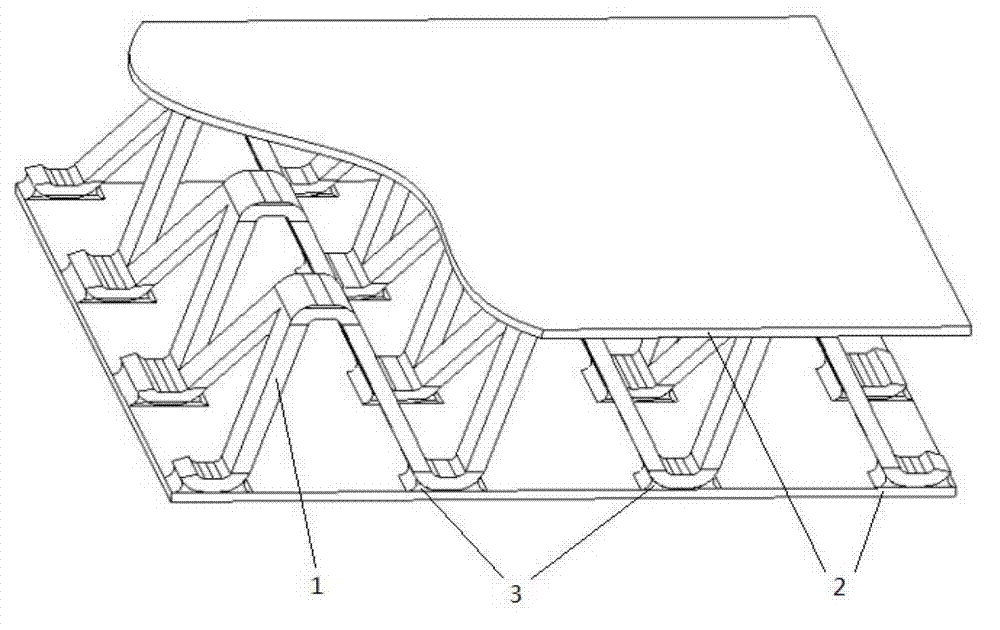

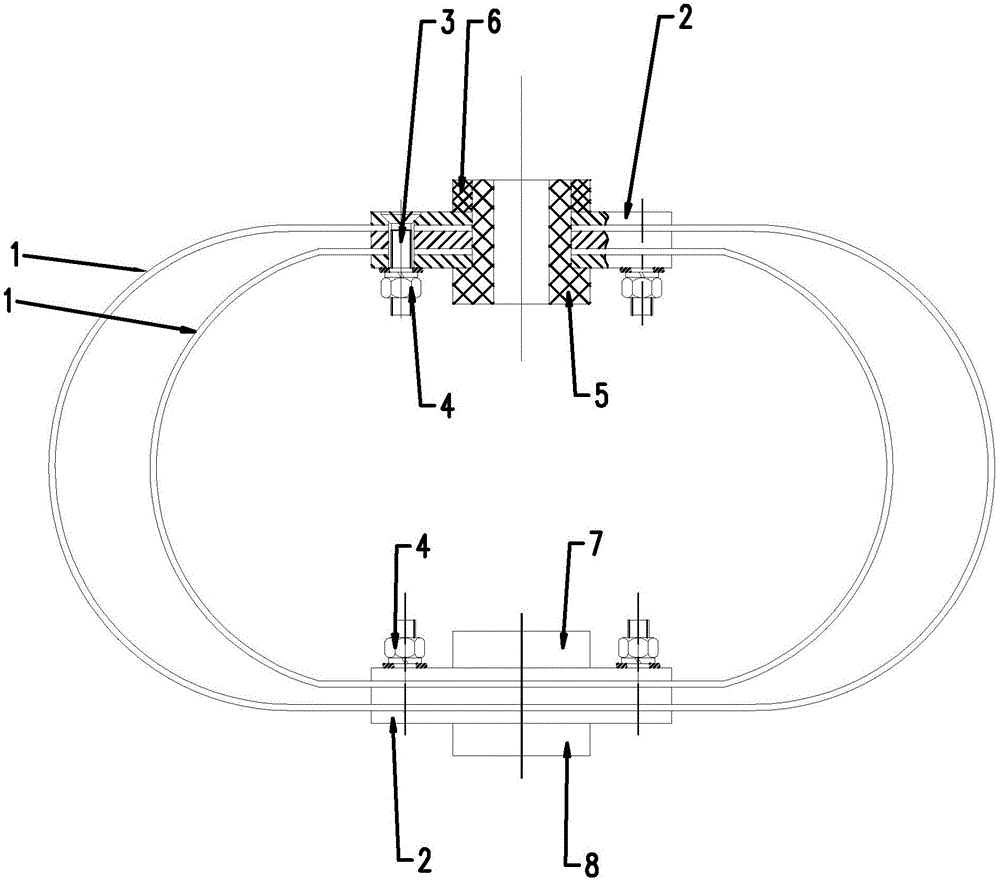

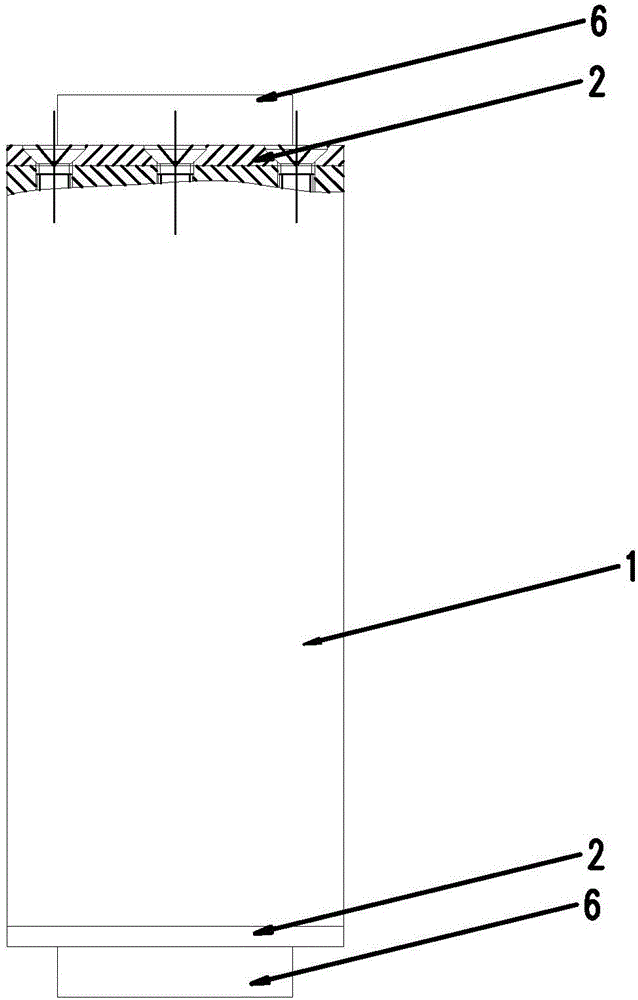

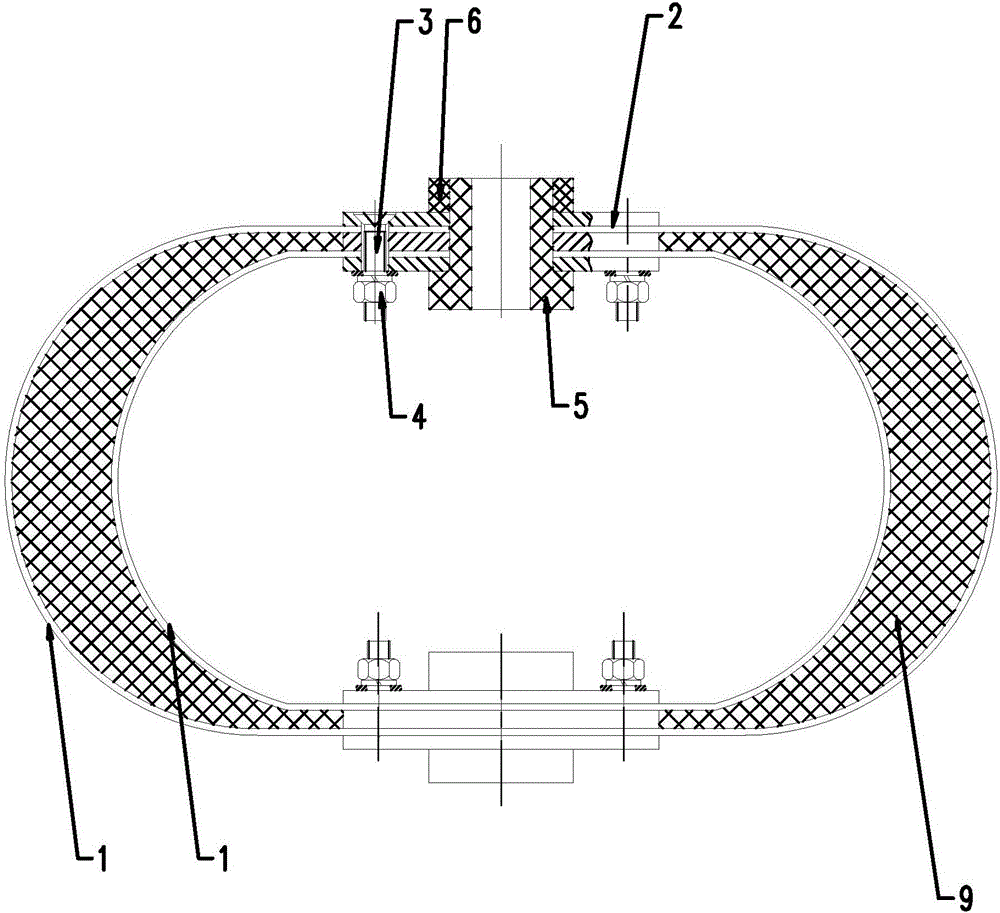

Spring steel plate vibration isolator

The invention relates to a spring steel plate vibration isolator, and particularly relates to a spring steel plate vibration isolator which can play roles in isolating vibration, buffering and reducing structure noise of marine, vehicular, airborne, engineering machinery, radar, electronic control and other equipment, belonging to the technical field of damping apparatuses. The spring steel plate vibration isolator comprises at least two damping steel plates bent to be arc-shaped, two ends of the at least two damping steel plates are connected as a whole through a first pressing plate connecting structure, and the middles of the two damping steel plates are connected as a whole through a second pressing plate connecting structure. The spring steel plate vibration isolator can give consideration to the performances of vibration isolation, shock resistance, buffering and the like, is good in environment adaptability, long in service life and low in cost; the spring steel plate vibration isolator has good environment adaptability, can effectively work under various severe environments, and can be widely applicable to vehicular, airborne, ship-borne and other environments.

Owner:WUXI HONGYUAN DEVFLEX

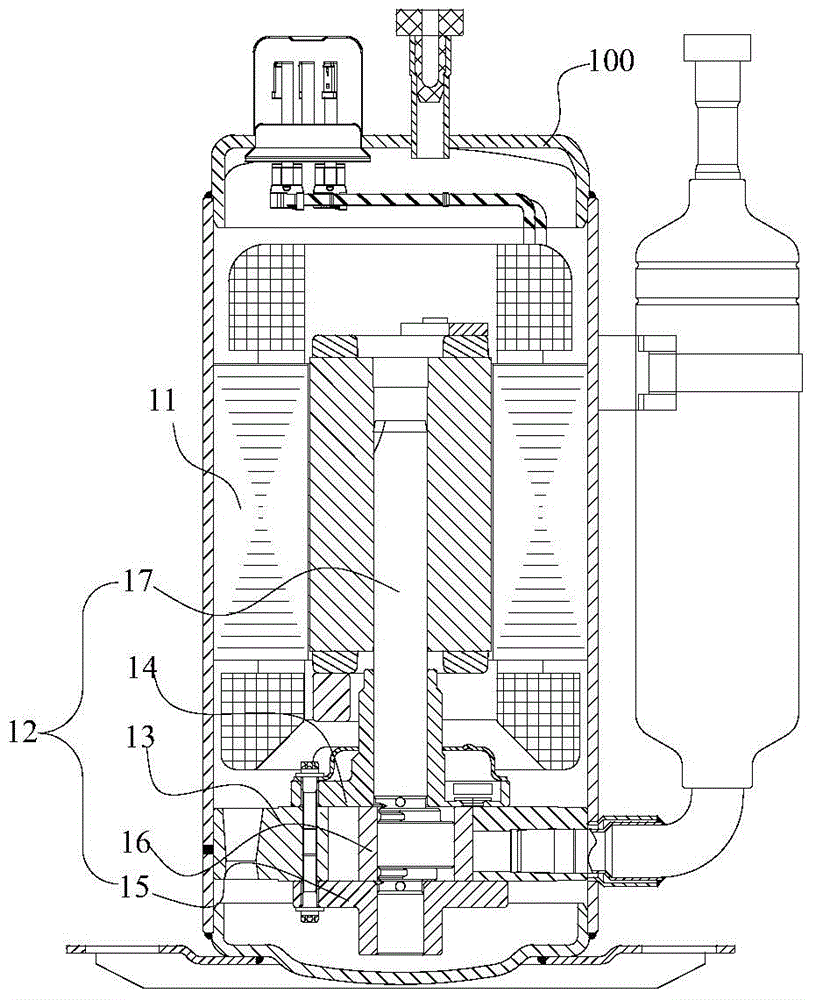

Rotary compressor and refrigeration equipment containing rotary compressor

ActiveCN104832431ALow noise and vibrationHigh dampingRotary piston pumpsRotary piston liquid enginesGas cylinderAlloy

The present invention discloses a rotary compressor and refrigeration equipment containing the rotary compressor. According to the rotary compressor, a lubricating oil and a refrigerant are packaged in the housing of the rotary compressor, the rotary compressor comprises a motor and a compression assembly, the compression assembly comprises a gas cylinder, an upper bearing, a lower bearing, a piston, a sliding sheet, and a crankshaft, at least one selected from the gas cylinder, the upper bearing, the lower bearing, the piston, the sliding sheet and the crankshaft is made from a damping alloy, and the specific damping value of the damping alloy is not less than 10. According to the present invention, the compression assembly of the rotary compressor has a high damping performance so as to minimize the noise vibration of the compressor body, such that the noise quality of the refrigeration equipment can be improved.

Owner:GUANGDONG MEIZHI COMPRESSOR +1

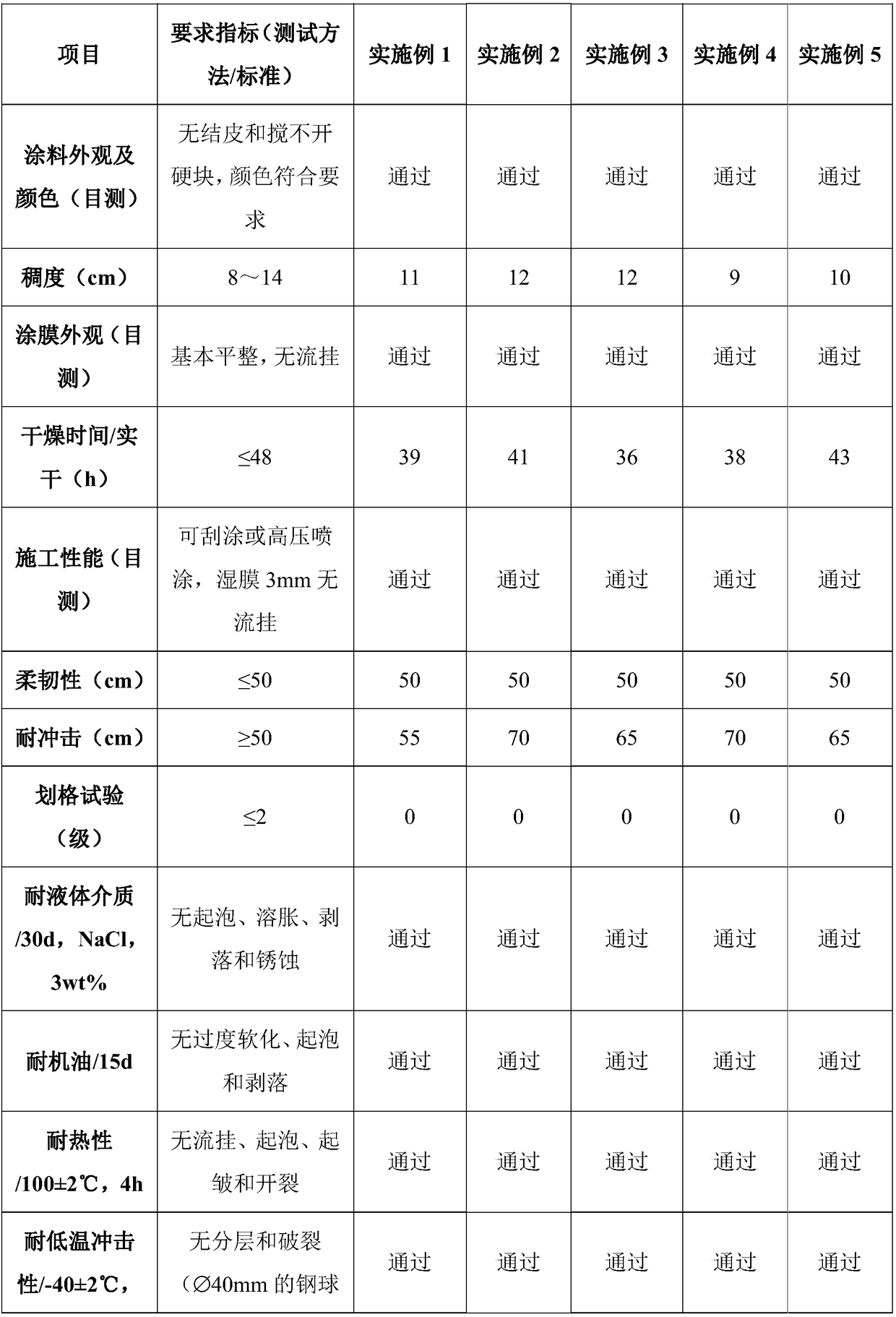

Wide-temperature-range impact-resisting waterborne damping coating and preparation method thereof

The invention discloses wide-temperature-range impact-resisting waterborne damping coating and a preparation method thereof. The waterborne damping coating is prepared from the following raw materialsin parts by mass: 35 to 65 parts of hard-core and soft-shell type acrylic emulsion, 40 to 80 parts of inorganic filler, 0.5 to 3 parts of propylene glycol, 2 to 5 parts of fibers, 0.5 to 3 parts of film forming auxiliary agent, 0.1 to 1 part of wetting dispersant, 0.1 to 1 part of de-foaming agent, 0.1 to 2 parts of thickening agent, 0.3 to 1 part of multifunctional auxiliary agent and 3 to 10 parts of water. The preparation method of the waterborne damping coating disclosed by the invention is simple; all components are uniformly mixed in sequence and in batches to obtain the waterborne damping coating. The waterborne damping coating disclosed by the invention has the advantages that a preparation technology is simple and a coating layer formed by curing the coating to form a film has excellent impact-resisting performance, good toughness and uneasiness for cracking; the waterborne damping coating has wide-temperature-range high damping performance.

Owner:广州化工研究设计院有限公司 +1

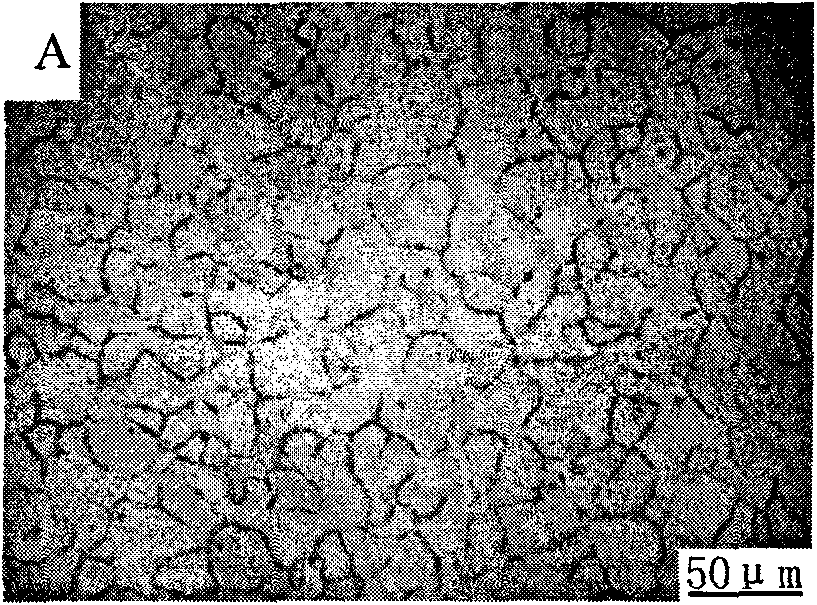

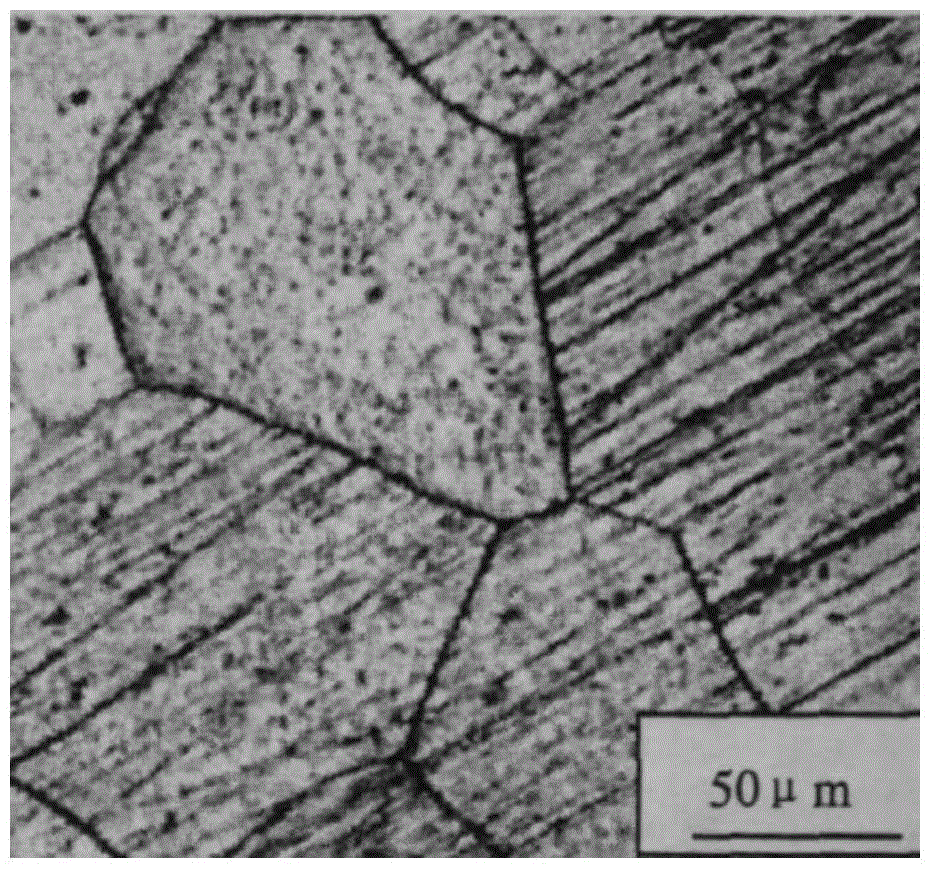

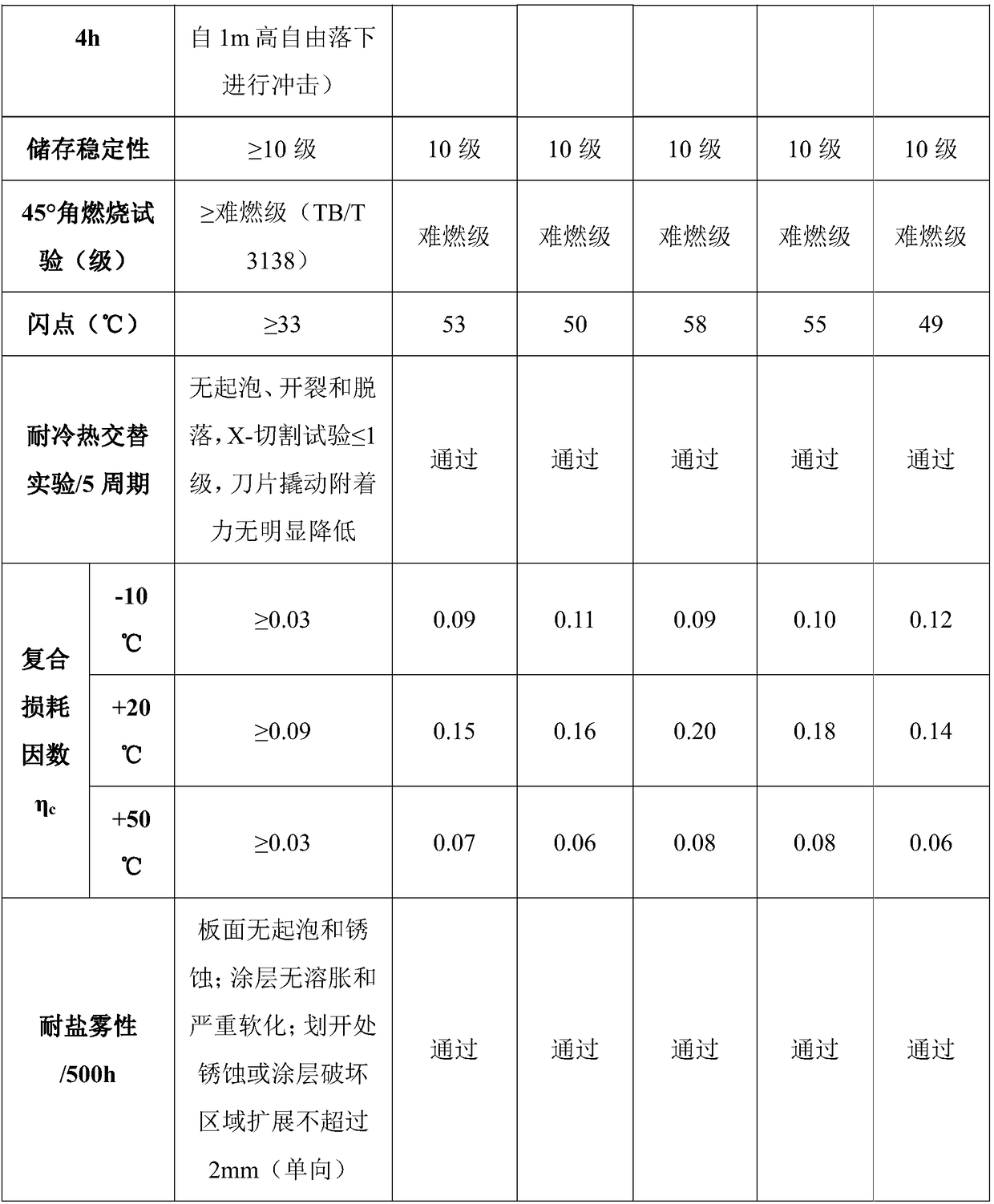

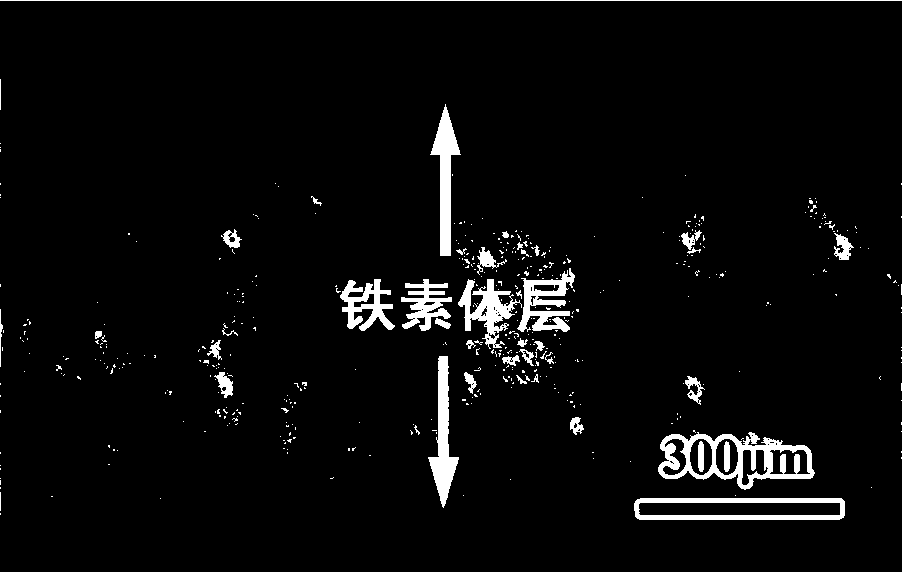

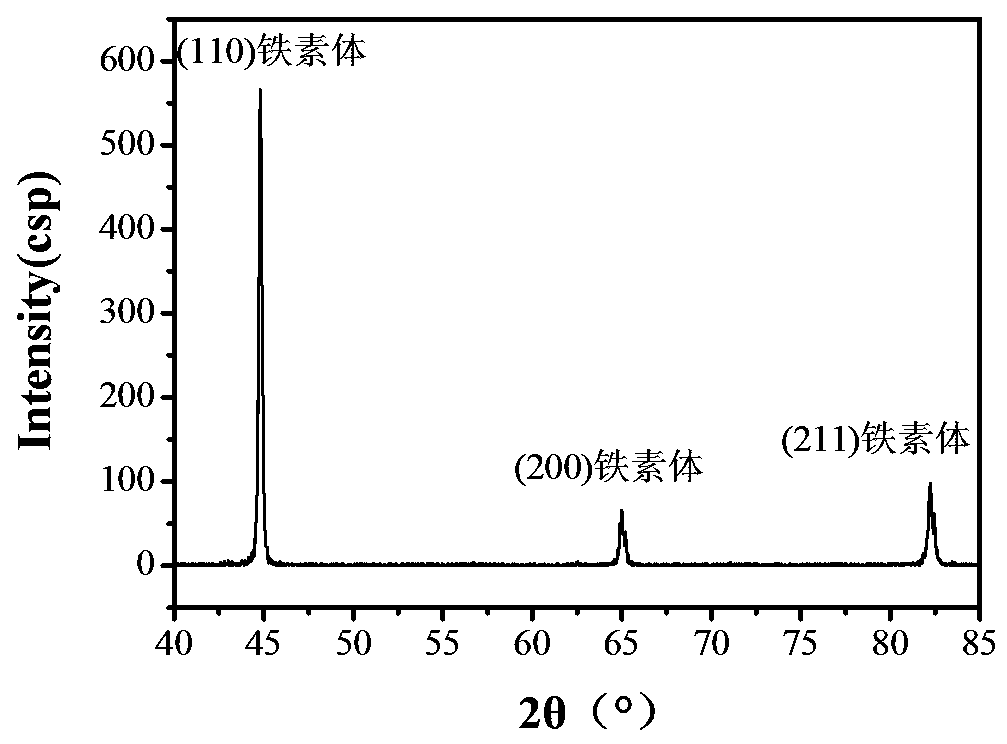

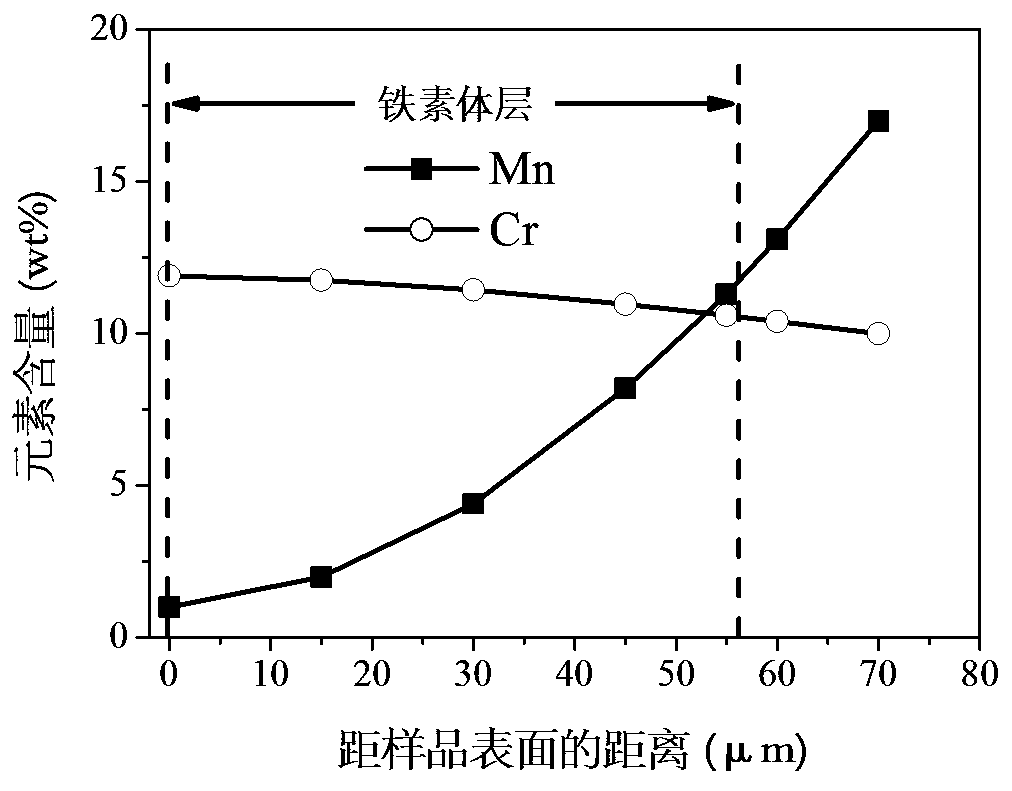

Wide-strain amplitude high-damping iron-based composite alloy and preparation method thereof

InactiveCN107641769ASolve the problem of rapid decay of damping performanceHigh dampingFerrite layerManganese

The invention discloses a wide-strain amplitude high-damping iron-based composite alloy and a preparation method thereof and belongs to the field of damping alloys. The surface of the iron-based composite alloy disclosed by the invention adopts a layer of ferrite; the core part of the iron-based composite alloy consists of austenite of a face-centered cubic structure and martensite of a close-packed hexagonal structure; the weight percentage content of chromium in the ferrite layer is greater than or equal to 4%. The preparation method of the iron-based composite alloy specifically comprises the following steps: firstly, treating a ferro-manganese chromium based alloy in a vacuum environment for a time greater than or equal to 15 minutes at 900-1200 DEG C, performing furnace cooling to theroom temperature, finally treating for 2-48 hours at 200-500 DEG C, and performing furnace cooling to the room temperature, wherein the ferro-manganese chromium based alloy comprises the following elements in percentage by weight: 12-25% of Mn, 3-25% of Mg, 0-0.1% of C, 0-0.1% of N and the balance of Fe and inevitable impurities.

Owner:SICHUAN UNIV

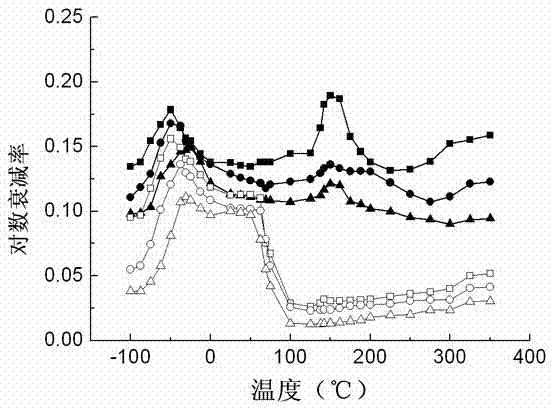

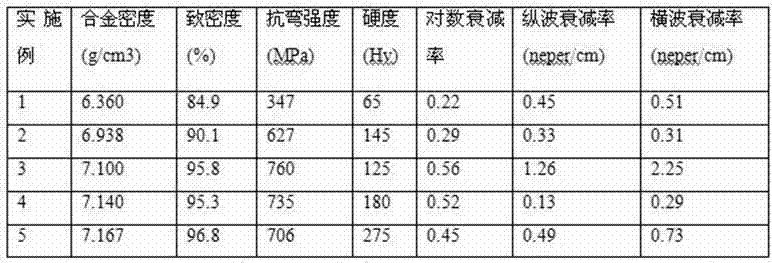

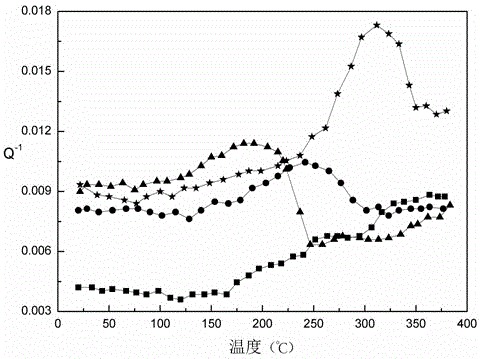

High-damping MnCu alloy and powdery metallurgy preparation technology thereof

The invention discloses a high-damping MnCu alloy and a powdery metallurgy preparation technology thereof. According to the high-damping MnCu alloy, Mn, Cu, Al, Ni and Fe are used as main components, the damping property can be enhanced by adding one or more of strongly magnetic particles Co3B, Co2B, Fe2B, FeB and MnB, and the sintering performance of the high-damping MnCu alloy can be effectively improved by adding one or more of Bi, Si, Sn and B as a sintering auxiliary. Compared with the traditionally cast MnCu-based damping alloy, the high-damping MnCu alloy has the characteristics of being higher in damping property, wider in damping temperature range, more flexible in formability and the like, and further the energy consumption can also be decreased. The formability of the prepared high-damping alloy is more flexible, so that the processing load of the subsequence procedures of rolling, grinding, cutting and the like can be reduced, and the cost reduction and mass production can be facilitated.

Owner:TIANJIN YINLONG HIGH TECH NEW MATERIAL RES INST

Hard high-damping coating preparation process used for surface of high-temperature damping part

InactiveCN105132853AHigh dampingImprove mechanical propertiesMolten spray coatingMetallurgySand blasting

The invention discloses a hard high-damping coating preparation process used for the surface of a high-temperature damping part. According to the process, firstly, the surface of the part is subjected to decontamination treatment; secondly, the surface of the part is coarsened by adopting surface sand blasting treatment; then the part subjected to sand blasting is preheated; the surface of the part is subjected to spraying by adopting a low-pressure plasma spraying method, wherein the material system of a coating is any one of an NiCr system high-temperature alloy coating, an FeCr system ferromagnetic coating and a YSZ ceramic coating; and subsequently, the coating is subjected to vacuum annealing treatment. A coating composite structure prepared by adopting the process not only has high damping performance, but also has high mechanical performance, can bear large stress, and meanwhile is wide in temperature application range; and the damping performance of the damping structure is obviously higher than that of a bulk damping material. The coating is uniform; and the bonding strength of the coating with a matrix is high. The process has the advantages that the implementation cost is low; the operation is simple and convenient; the yield is high; the comprehensive performance of products is high; and the like.

Owner:TIANJIN UNIV

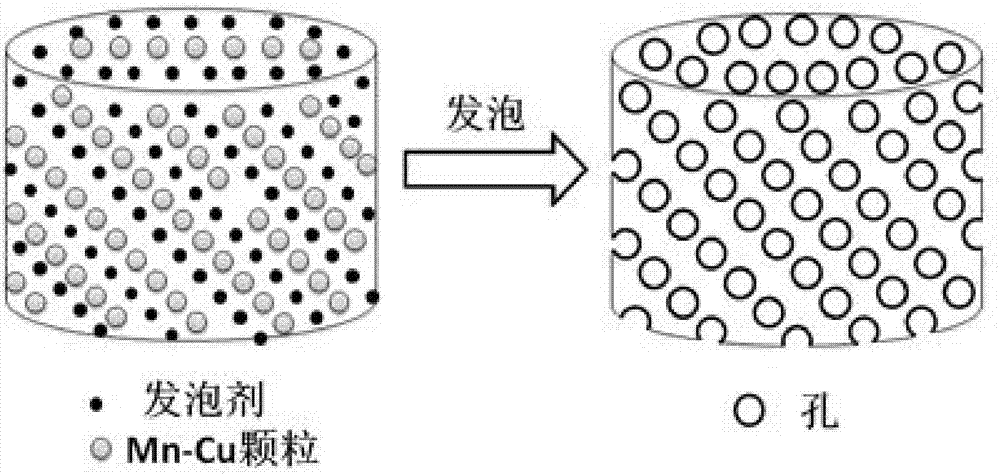

Light foam Mn-Cu alloy high-damping material and preparation method thereof

The invention discloses a light foam Mn-Cu alloy high-damping material. The light foam Mn-Cu alloy high-damping material is a binary alloy formed by metal manganese and copper or a multicomponent alloy formed by manganese, copper and one or more of iron, nickel and aluminum. A preparation method of the light foam Mn-Cu alloy high-damping material comprises the following steps of mixing Mn-Cu alloy particles and a foaming agent evenly; putting mixed powder into a mold and conducting cold-press molding to obtain a blank body for standby application; conducting hot-press molding on the blank body to obtain a high-compactness blank body with the density greater than 80%; putting the high-compactness blank body into the mold, conducting foaming and then cooling, and finally obtaining the foam Mn-Cu alloy high-damping material with the uniform aperture. By means of the light foam Mn-Cu alloy high-damping material and the preparation method thereof, the defect that the density of a traditional high-damping Mn-Cu alloy is large is overcome; the damping property of the Mn-Cu alloy is effectively improved through the porosity and the high-density defect around cavities. Besides, by means of the method, the problems that the foaming temperature is high, the size distribution of pores is non-uniform and the technological operation is difficult are solved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com