High-damping MnCu alloy and powdery metallurgy preparation technology thereof

A powder metallurgy and preparation process technology, applied in the field of damping materials and their preparation, can solve the problems of insufficient damping performance and casting formability of MnCu damping alloys, and achieve the effects of flexible formability, flexible formability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

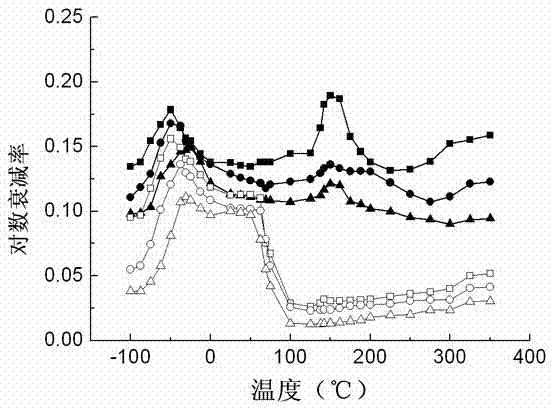

Image

Examples

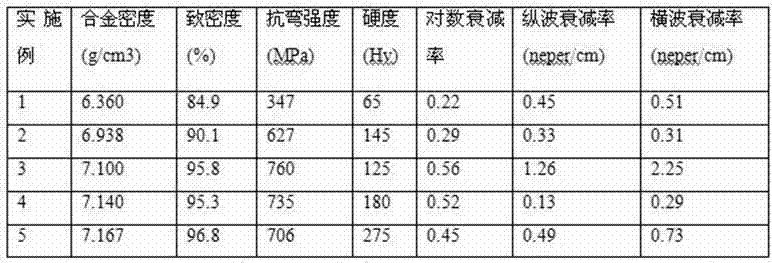

Embodiment 1

[0021] Example 1: The mass percentages of the high-damping MnCu alloy in the matrix alloy powder, ferromagnetic particles and sintering aids are as follows: the matrix alloy powder is Mn: 80%, Cu: 10%, Fe: 6%; strong The magnetic particles are Co 3 B: 2%; the sintering aid is Bi: 2%. The matrix alloy powder, strong magnetic particles and sintering auxiliary agent are fully mixed in the ball mill for 1h, the forming pressure of the cold press molding machine is 290MPa, the sintering temperature is 1000°C, sintering in vacuum, the sintering time is 1h, and the solid solution time is 6h .

Embodiment 2

[0022] Example 2: The mass percentages of the high-damping MnCu alloy in the matrix alloy powder, ferromagnetic particles and sintering aids are as follows: the matrix alloy powder is Mn: 75%, Cu: 15%, Al: 2%; strong The magnetic particles are Co 2 B: 5%; sintering aid is Si: 3%. The matrix alloy powder, strong magnetic particles and sintering auxiliary agent are fully mixed in the ball mill for 1.2h, the forming pressure of the cold press molding machine is 300MPa, the sintering temperature is 950°C, sintering in vacuum, the sintering time is 1h, and the solid solution time is 7h.

Embodiment 3

[0023] Example 3: The mass percentages of the high-damping MnCu alloy in the matrix alloy powder, ferromagnetic particles and sintering aids are as follows: the matrix alloy powder is Mn: 69%, Cu: 10%, Ni: 5%; strong The magnetic particle is MnB: 12%; the sintering auxiliary agent is Bi: 4%. The matrix alloy powder, strong magnetic particles and sintering auxiliary agent are fully mixed in the ball mill for 1.5h, the forming pressure of the cold press molding machine is 295MPa, the sintering temperature is 950°C, the sintering atmosphere is Ar (one atmospheric pressure), and the sintering time is 1.5h , The solid solution time is 9h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| damping ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com