Wide-temperature-range impact-resisting waterborne damping coating and preparation method thereof

A damping coating and impact-resistant technology, applied in the field of damping coatings, can solve the problems of film-forming performance, impact resistance and flexibility decline, poor high-temperature damping performance of polymer emulsion, and reduce the damping performance of the coating film in high-temperature areas, etc., to improve Effects of glass transition temperature, improvement of impact resistance and flexibility, and improvement of damping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

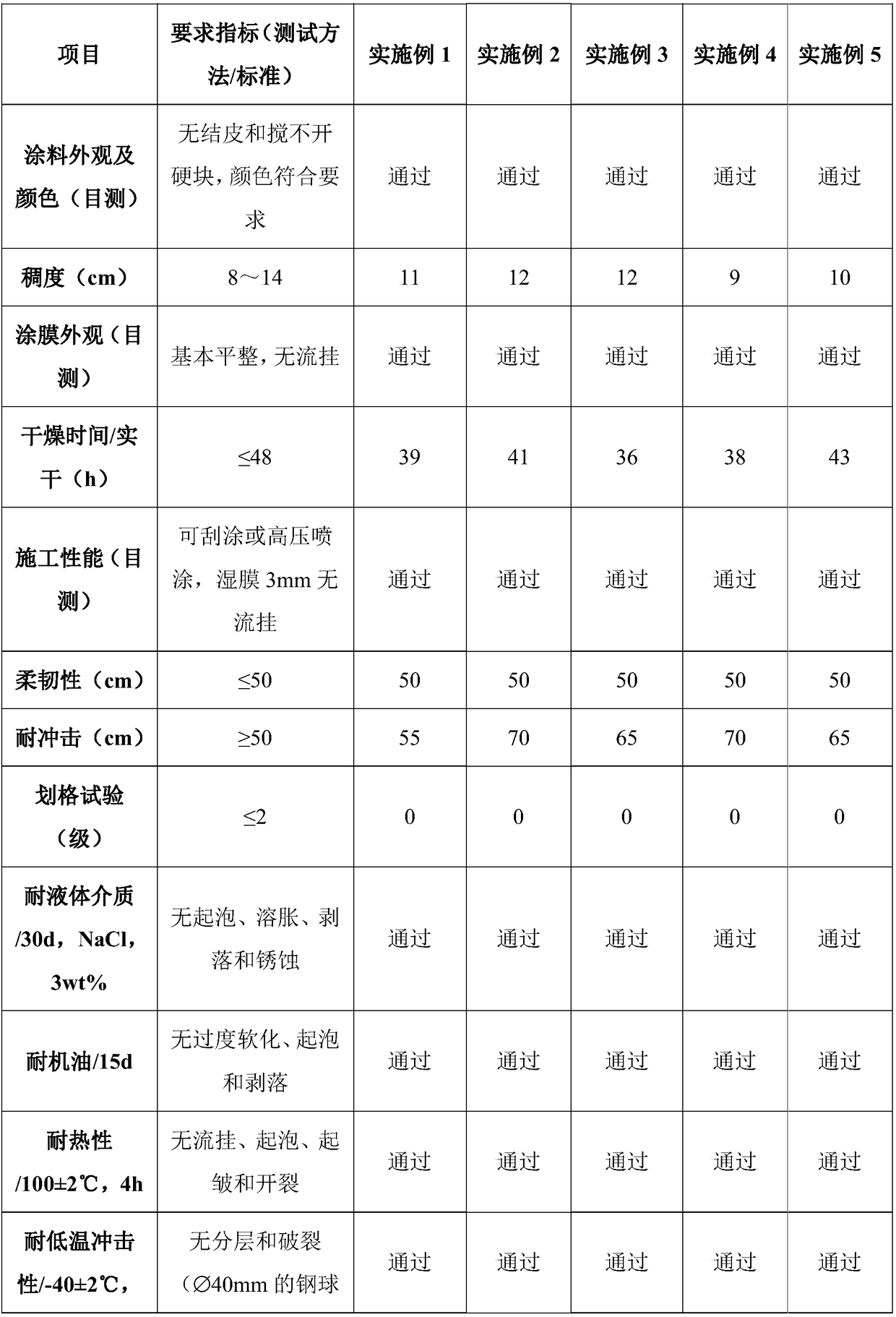

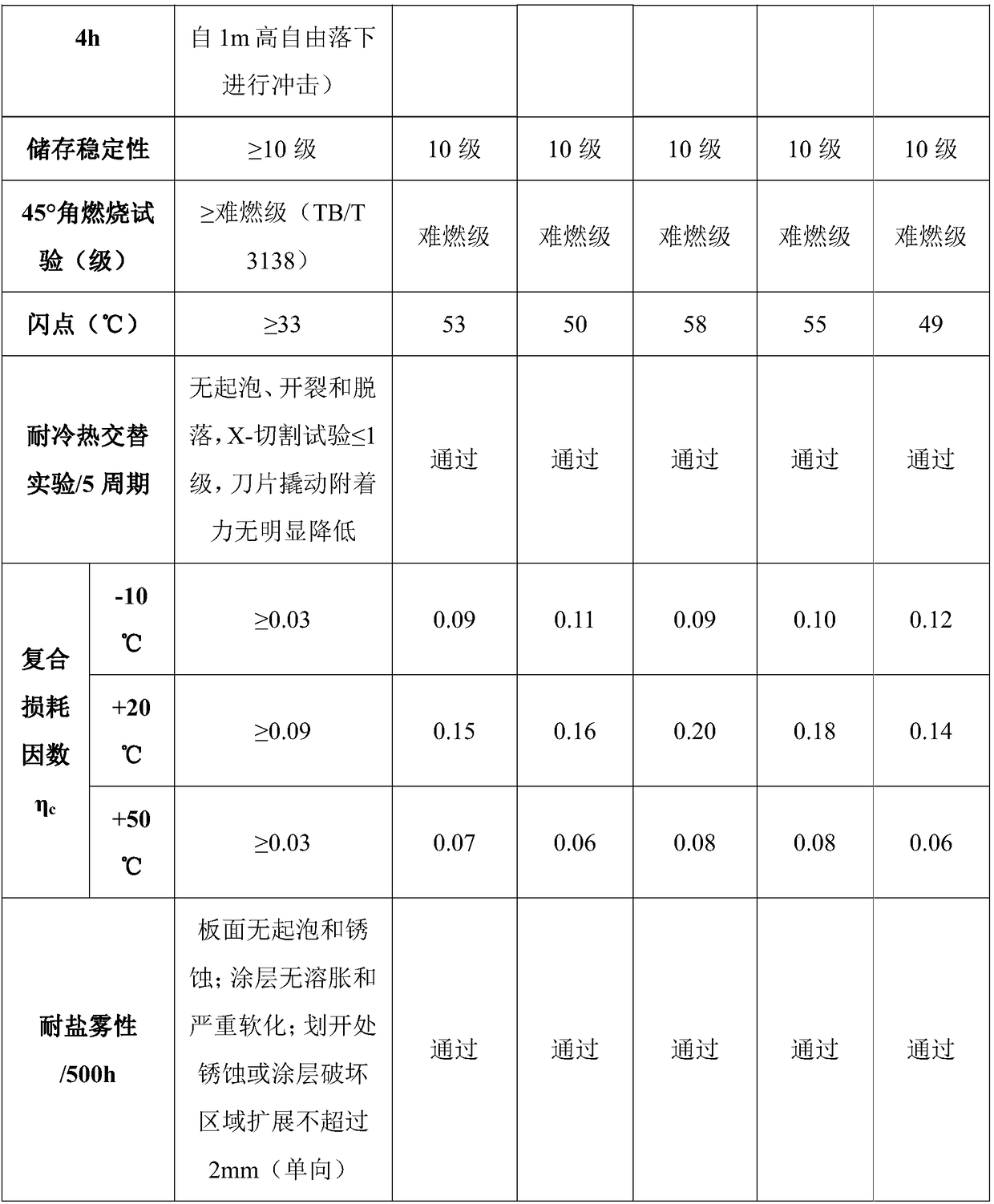

Examples

preparation example Construction

[0062] The preparation method of the above-mentioned wide temperature range impact-resistant water-based damping coating comprises the following steps:

[0063] 1) Preparation of slurry: Mix hard-core soft-shell acrylic emulsion, propylene glycol, film-forming aids and water evenly, then add wetting and dispersing agent, defoamer, multifunctional additives and fibers in sequence, and mix evenly;

[0064] 2) Mixing of filler and slurry: add inorganic filler to the slurry and mix evenly;

[0065] 3) Consistency adjustment: adding a thickener to adjust the consistency of the system to obtain a wide temperature range impact-resistant water-based damping coating.

Embodiment 1

[0068] A preparation method of a wide temperature range impact-resistant water-based damping coating, comprising the following steps:

[0069] 1) Preparation of slurry: Mix 40 parts of hard-core soft-shell acrylic emulsion, 2.5 parts of propylene glycol, 3 parts of dodecyl alcohol ester and 10 parts of deionized water, and then add 0.5 parts of polycarboxylate sodium salt, 0.5 parts 1 part of nonionic polysiloxane defoamer, 0.5 part of 2-amino-2-methyl-1-propanol and 5 parts of tetraneedle zinc oxide whiskers, stirred at low speed and mixed evenly;

[0070] 2) Mixing of filler and slurry: add 10 parts of 200 mesh flake mica powder, 10 parts of 600 mesh flake mica powder, 15 parts of 1250 mesh quartz powder, 30 parts of 1250 mesh wollastonite and 5 parts of 1250 mesh into the slurry Talcum powder, stir at high speed to mix evenly;

[0071] 3) Consistency adjustment: first add 0.5 parts of polyurethane thickener to adjust the consistency of the system, then add 0.3 parts of acr...

Embodiment 2

[0074] A preparation method of a wide temperature range impact-resistant water-based damping coating, comprising the following steps:

[0075] 1) Preparation of slurry: mix 50 parts of hard-core soft-shell acrylic emulsion, 0.5 parts of propylene glycol, 1 part of dodecyl alcohol ester and 5 parts of deionized water, and then add 0.5 parts of acrylate copolymer ammonium salt , 0.5 parts of mineral oil defoamer, 1 part of 2-amino-2-methyl-1-propanol and 5 parts of tetraneedle zinc oxide whiskers, stirred at low speed and mixed evenly;

[0076] 2) Mixing of filler and slurry: Add 15 parts of 100-150 mesh flake mica powder, 15 parts of 600 mesh flake mica powder, 20 parts of 700 mesh diatomite, 20 parts of 1250 mesh wollastonite and 5 Part 1250 mesh talcum powder, high-speed stirring and mixing;

[0077] 3) Consistency adjustment: first add 0.5 part of polyurethane thickener to adjust the consistency of the system, then add 0.2 part of acrylic thickener, stir and disperse at med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com