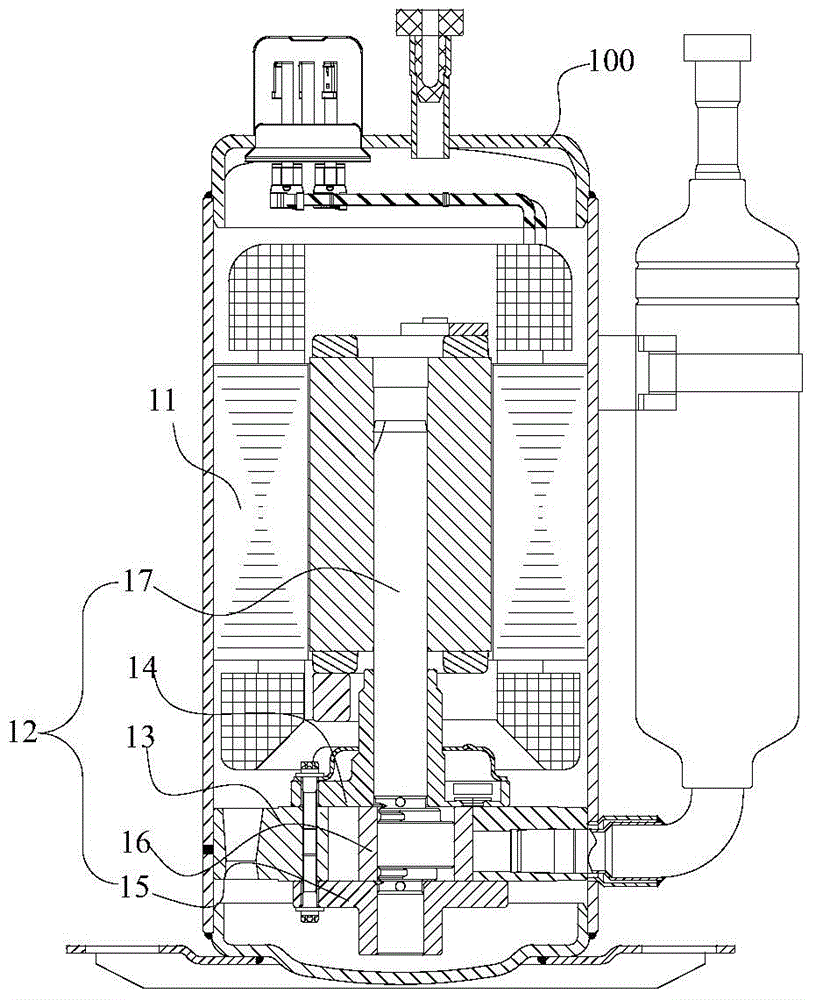

Rotary compressor and refrigeration equipment containing rotary compressor

A rotary compressor and refrigerant technology, applied in the field of compressors, can solve problems such as vibration energy reduction, air conditioner sound quality degradation, radiation noise, suction and exhaust port noise, suction and exhaust pipe vibration, base vibration, suction and exhaust pipe vibration, etc. Achieve the effects of reducing noise and vibration, improving noise quality, and reducing the transmission of vibration energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

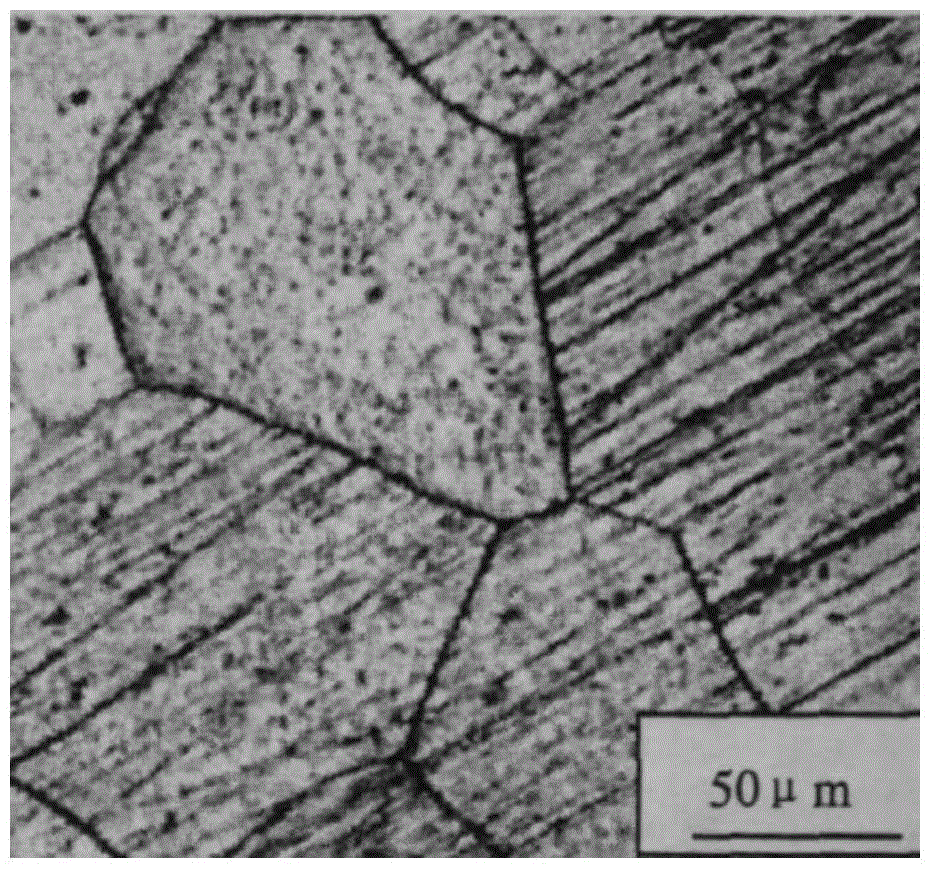

[0037] The damping alloy contains: 0.3wt% C, 0.5wt% Si, 5.8wt% Al, 0.03wt% S, 0.03wt% P and the balance Fe.

[0038] The above-mentioned damping alloy is used to prepare cylinders and bearings, and the mechanical properties and damping performance of the cylinders and bearings are tested. The tensile strength is 410MPa, and the specific damping value S.D.C% is 20.

Embodiment 2

[0040] The damping alloy contains: 0.7wt% C, 1wt% Si, 7wt% Al, 2wt% Mo, 0.03wt% S, 0.03wt% P and the balance Fe.

[0041] The above-mentioned damping alloy was used to prepare cylinders and bearings, and the mechanical properties and damping performance of the cylinders and bearings were tested. The tensile strength was 460MPa, and the specific damping value S.D.C% was 32.

Embodiment 3

[0043] The damping alloy contains: 1.5wt% C, 0.5wt% Si, 13wt% Cr, 2wt% Al, 0.03wt% S, 0.03wt% P and the balance Fe.

[0044] The above-mentioned damping alloy was used to prepare cylinders and bearings, and the mechanical properties and damping performance of the cylinders and bearings were tested. The tensile strength was 480 MPa, and the specific damping value S.D.C% was 45.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com