Open type test head of wafer automatic test system

An automatic test system, an open technology, applied in electronic circuit testing, components of electrical measuring instruments, measuring electricity, etc., can solve the problem that the instrument cabinet 711 takes up a lot of space, lacks the flexibility of upgrade and expansion, and the cost and price are high and other issues, to achieve the effect of improving the kinetic energy of innovation and development, easy to build, and saving development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

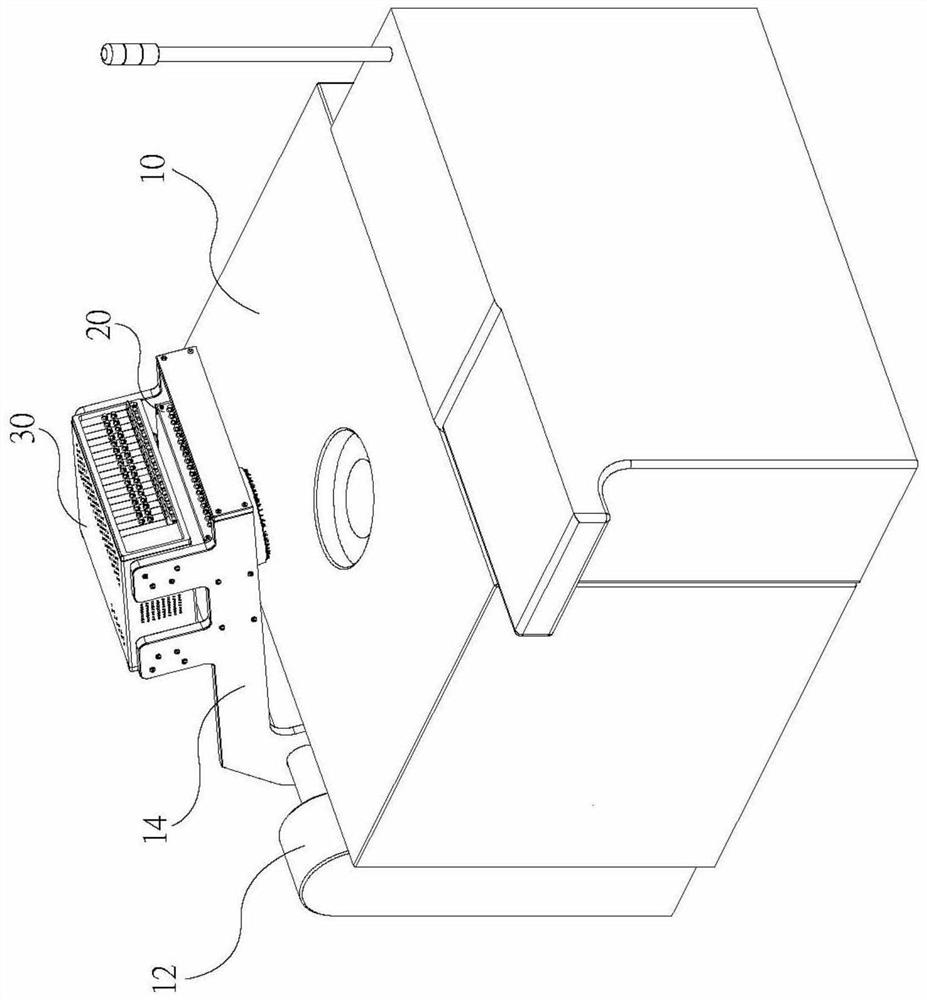

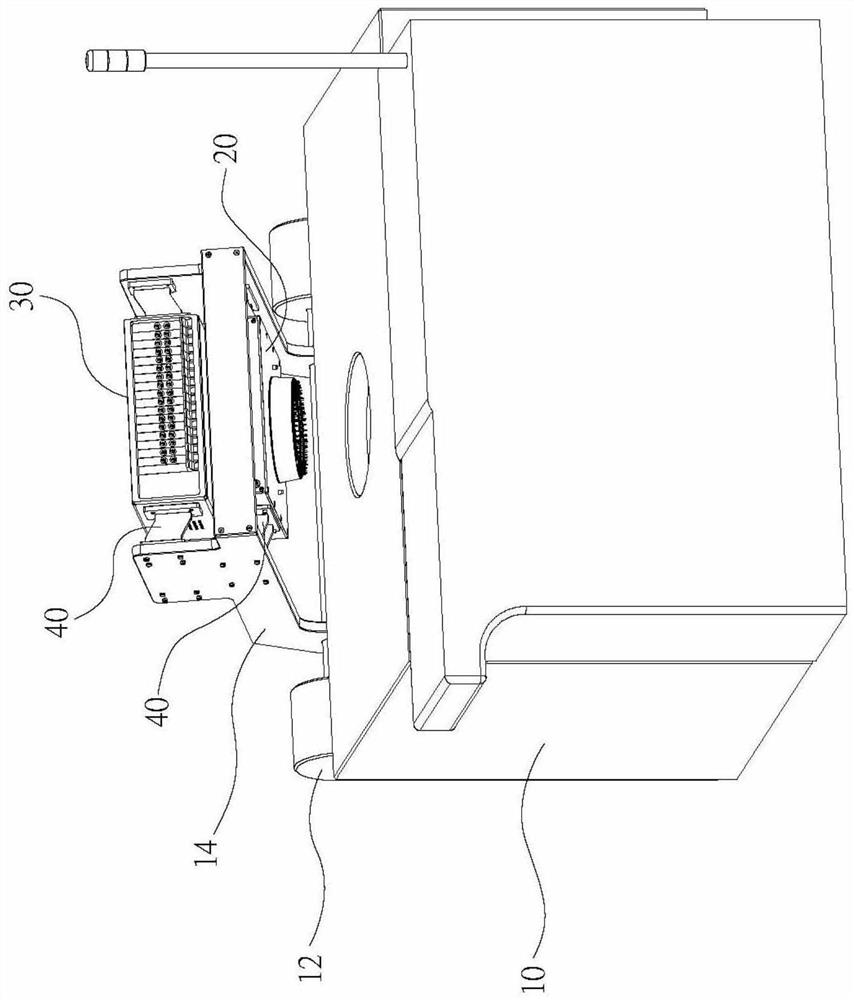

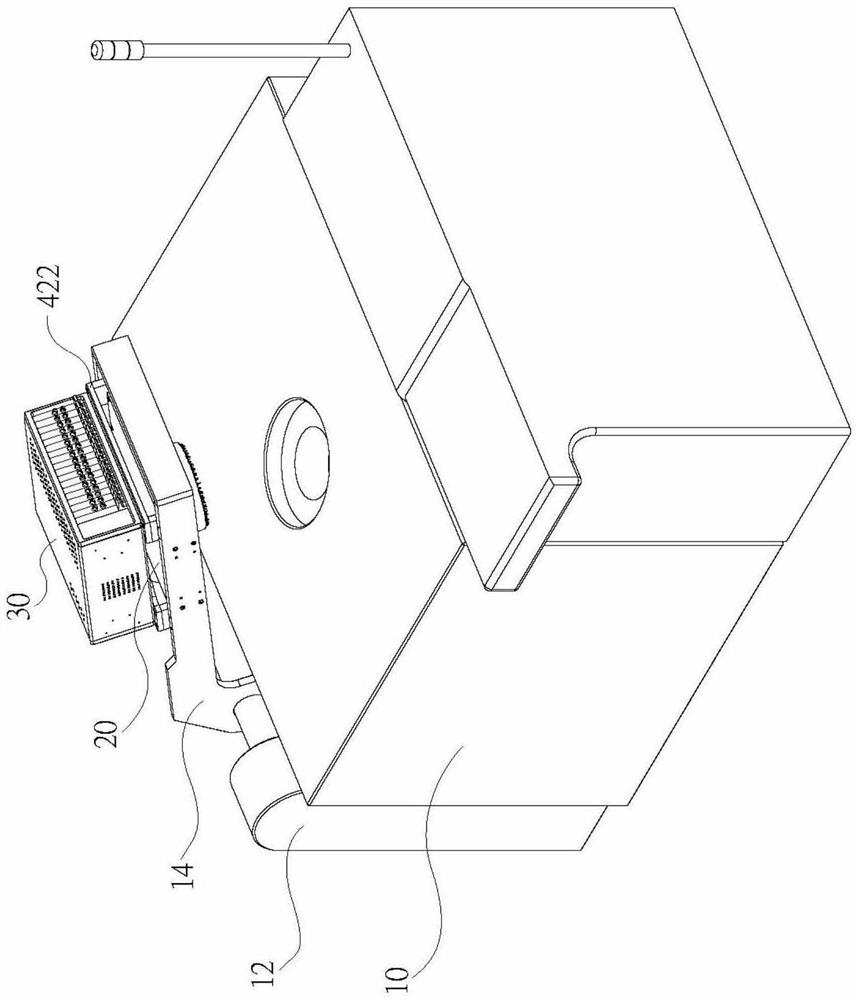

[0041] refer to figure 1 The first embodiment of the present invention discloses an open test head of a wafer automatic test system, including a wafer automatic probe station 10, a pogo pin interface module 20 and at least one instrument case 30, the wafer The circular automatic probe station 10 includes a lifting mechanism 12 and is provided with a fixed bracket 14; the pogo pin interface module 20 is arranged on the fixed bracket 14; the instrument case 30 is arranged on the fixed bracket 14, and the instrument case 30 is located at Above the pogo pin interface module 20, the instrument case 30 is electrically connected to the pogo pin interface module 20 to form a cabinetless wafer automatic test system, that is, there is no need to set a bulky wafer around the wafer automatic probe station 10. The instrument cabinet helps to save limited space in the test production line or laboratory, and the instrument case 30 is very close to the pogo pin interface module 20, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com