Patents

Literature

538results about How to "Reduce allergies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

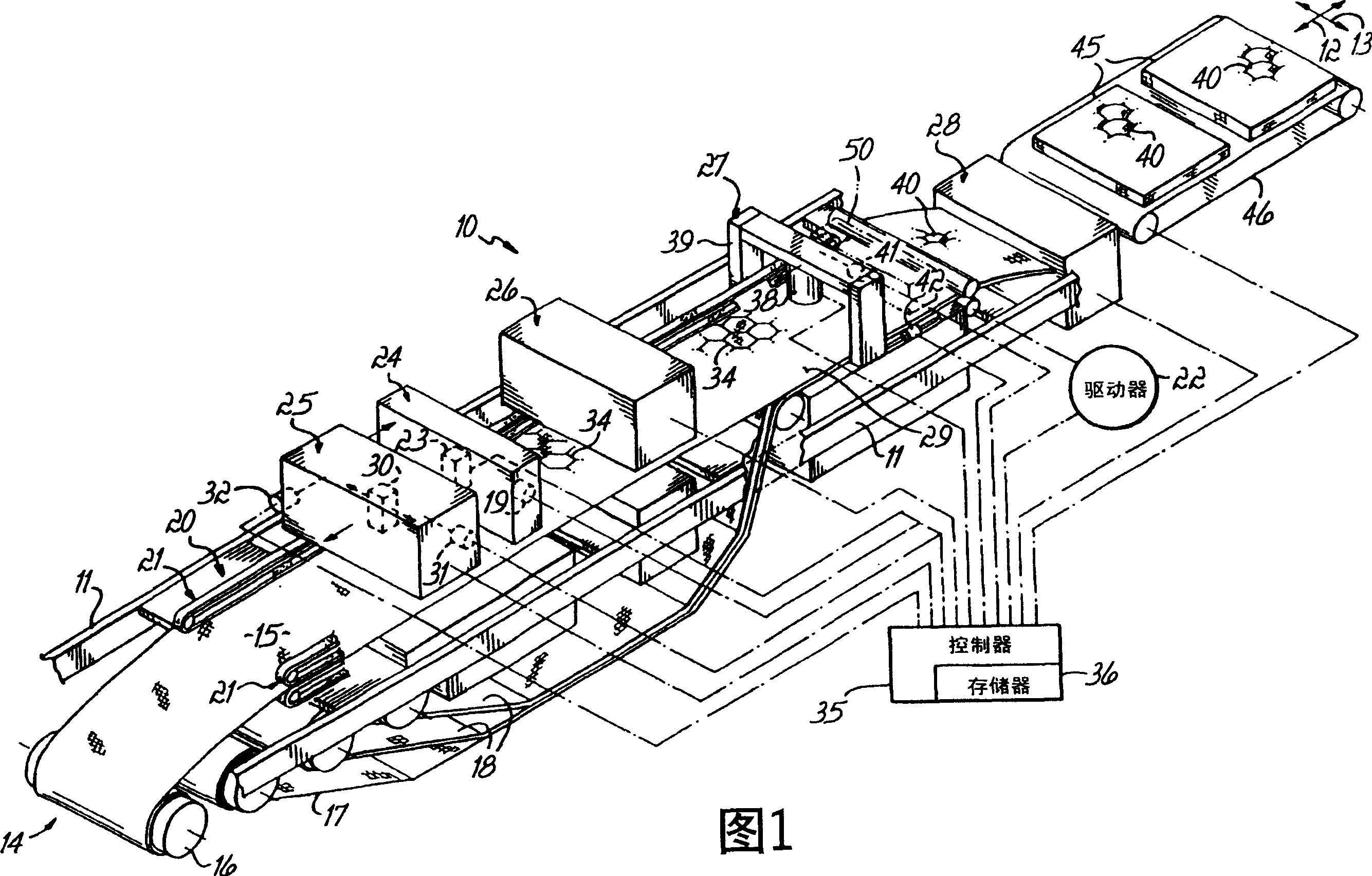

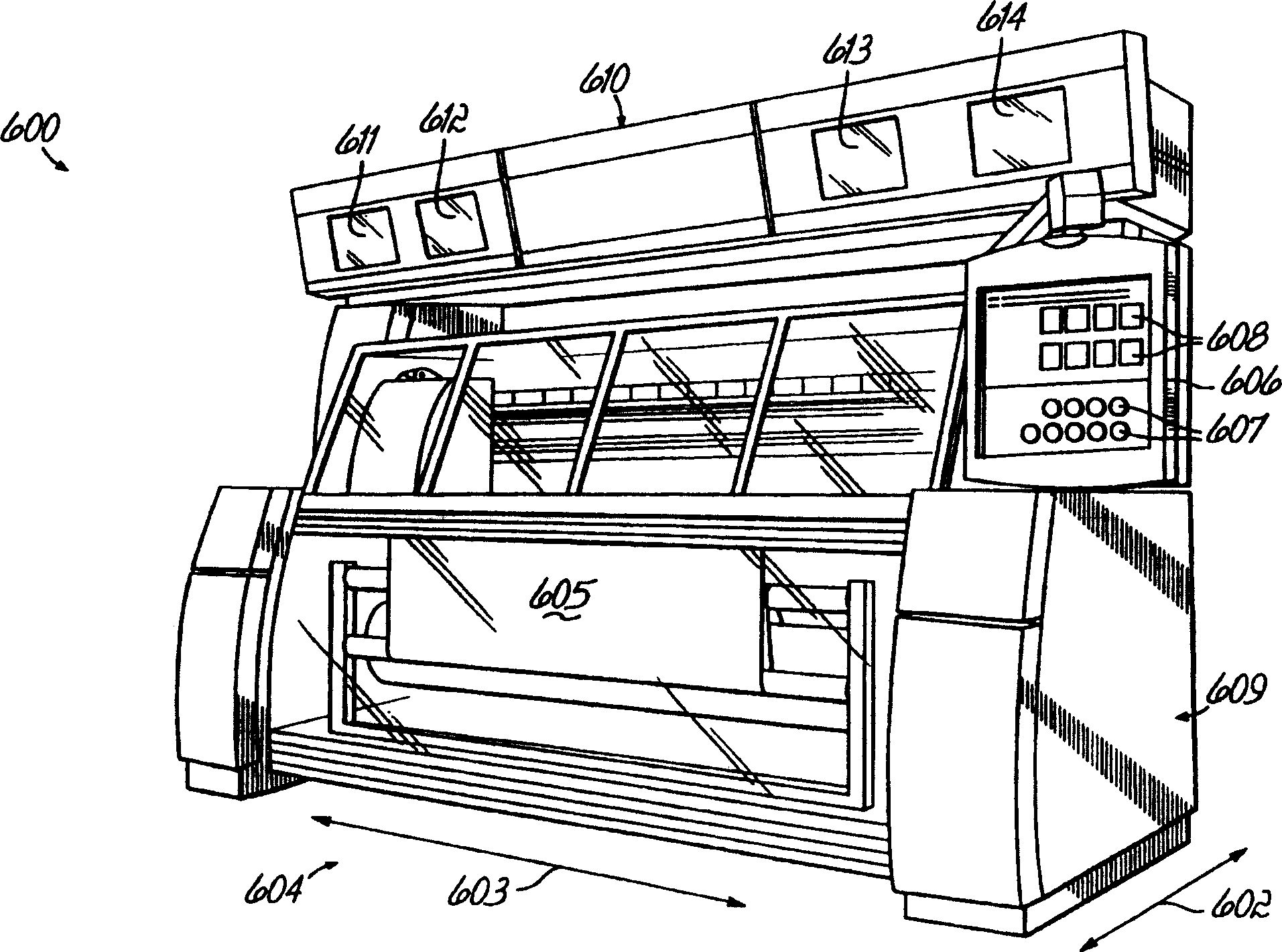

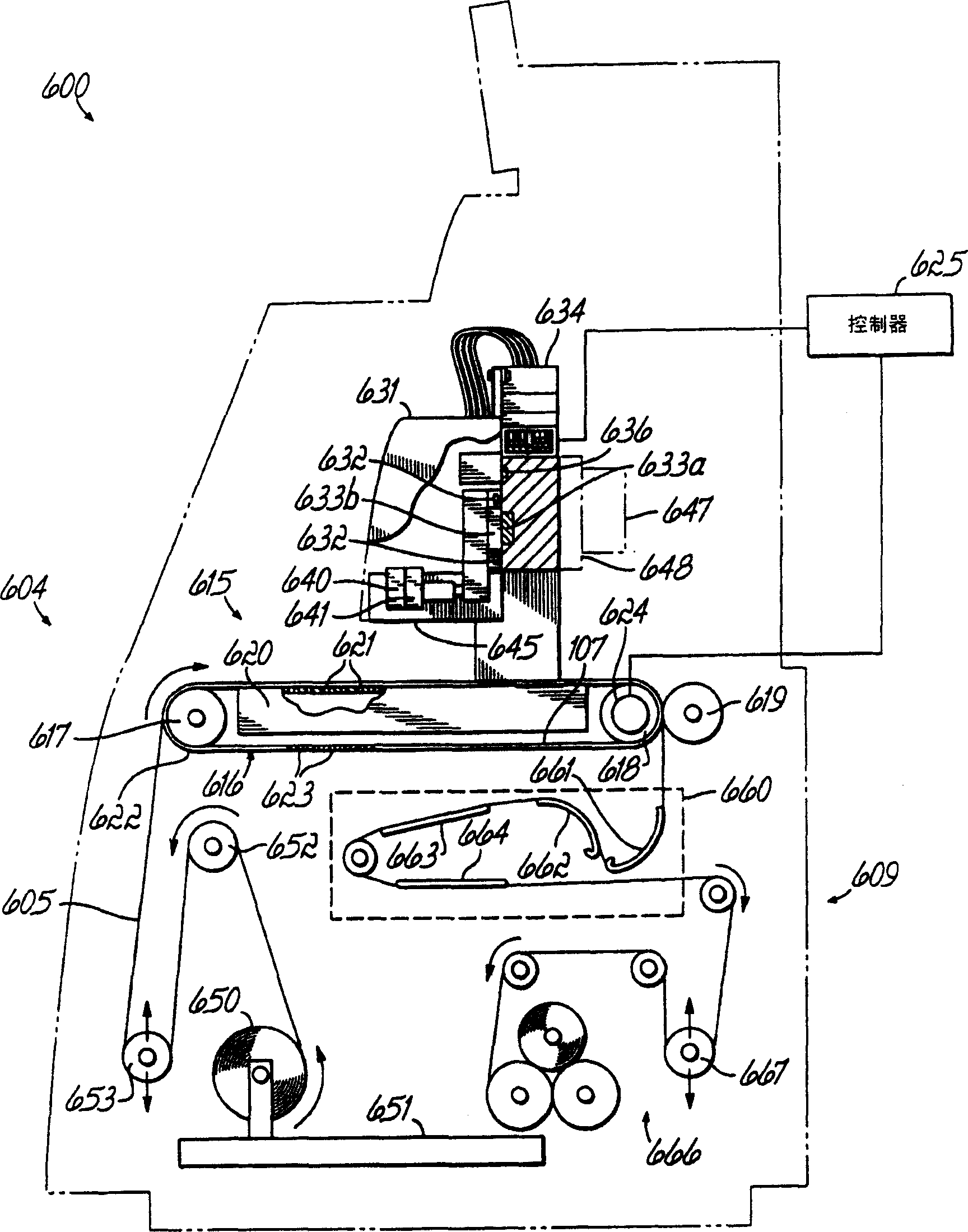

Method and apparatus for ink jet printing

InactiveCN1678458AEliminate cloggingImprove reliabilityDuplicating/marking methodsSpacing mechanismsPorous substratePolyester

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors (633) across a bridge (630) that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads (640, 641), so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light (645, 646) and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate. Preferably, the heat is applied by contacting the substrate with a heated plate (661, 662). Ink jet printing is provided using ultraviolet (UV) light curable or other curable composition or stable or other printable substance. In certain embodiments the UV ink has a dye-component therein. The ink is jetted onto a substrate, the composition is cured, then heated to set the dye. Sublimation dye-based UV ink printing onto polyester is preferred. A release layer of protective material (702, 704) such as a TEFLON film or sheet, covers a substrate support (705, 706). A porous substrate to be printed, such as a textile material (711), is supported on or above the support. Ink is jetted onto the substrate, with some of the ink passing through pores in the substrate and landing on the protective material. UV curable ink is preferably used and is exposed by UV light from a UV light curing head, which solidifies the ink on the substrate. The UV curing light has a long enough focal length to focus on the surface of the substrate and also, where it passes through pores in the substrate, on ink on the protective material, thereby solidifying the ink on the protective material. When the substrate is removed from the support, the solidified ink on the protective material may be wiped from the protective material.

Owner:L & P PROPERTY MANAGEMENT CO

Instant bellyful corn, fruit and vegetable powder and preparation method of instant bellyful corn, fruit and vegetable powder

The invention discloses an instant bellyful corn, fruit and vegetable powder and a preparation method of the instant bellyful corn, fruit and vegetable powder and belongs to the field of food processing. The corn, fruit and vegetable powder consists of natural corns, fruits and vegetables and auxiliary materials, wherein the corns mainly comprise brown rice, corns, wheat germ, oats, buckwheat and bean dregs, the fruits and vegetables mainly comprise carrot powder, banana powder, red date powder, burdock powder and tea powder, the auxiliary materials mainly comprise maltodextrin, beta-cyclodextrine, monoglyceride, lecithin, konjac glucomannan, pearl fruit and chitosan, the maltodextrin, the beta-cyclodextrine, the monoglyceride and the lecithin can improve the preparing performance and the mouth feeling, and the water absorption expansion rate of the konjac glucomannan, the pearl fruit and the chitosan is extremely high. The preparation method comprises the following main preparation steps of raw material cleaning, corn aging, processing powder preparation, crushing sieving, weighing, proportional mixing, packaging and product obtaining. The product has the characteristics that the nutrition matching is balanced, the eating is convenient, the preparing performance is good, the mouth feeling is exquisite, the bellyful feeling is instantly generated after eating, and the like.

Owner:山西智和智拓农业科技有限公司

Fucoidan compositions and methods for dietary and nutritional supplements

ActiveUS20060210609A1Promote growthHigh energyCosmetic preparationsBiocideDietary supplementAdditive ingredient

Compositions and methods relating to partially hydrolyzed fucoidan for use in dietary supplements are described. Fucoidan from brown seaweeds is partially hydrolyzed and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form. The fucoidan is partially hydrolyzed with acid and heat. The partially hydrolyzed fucoidan can also be sulfonated. Other ingredients that can be included in the dietary supplement include high-ORAC-value antioxidants, minerals, pepper extract, flavoring agents, coloring agents, and preservatives. The compositions can be in the form of beverages, tablets, capsules, powders, and the like.

Owner:SAKURA PROPERTIES LLC

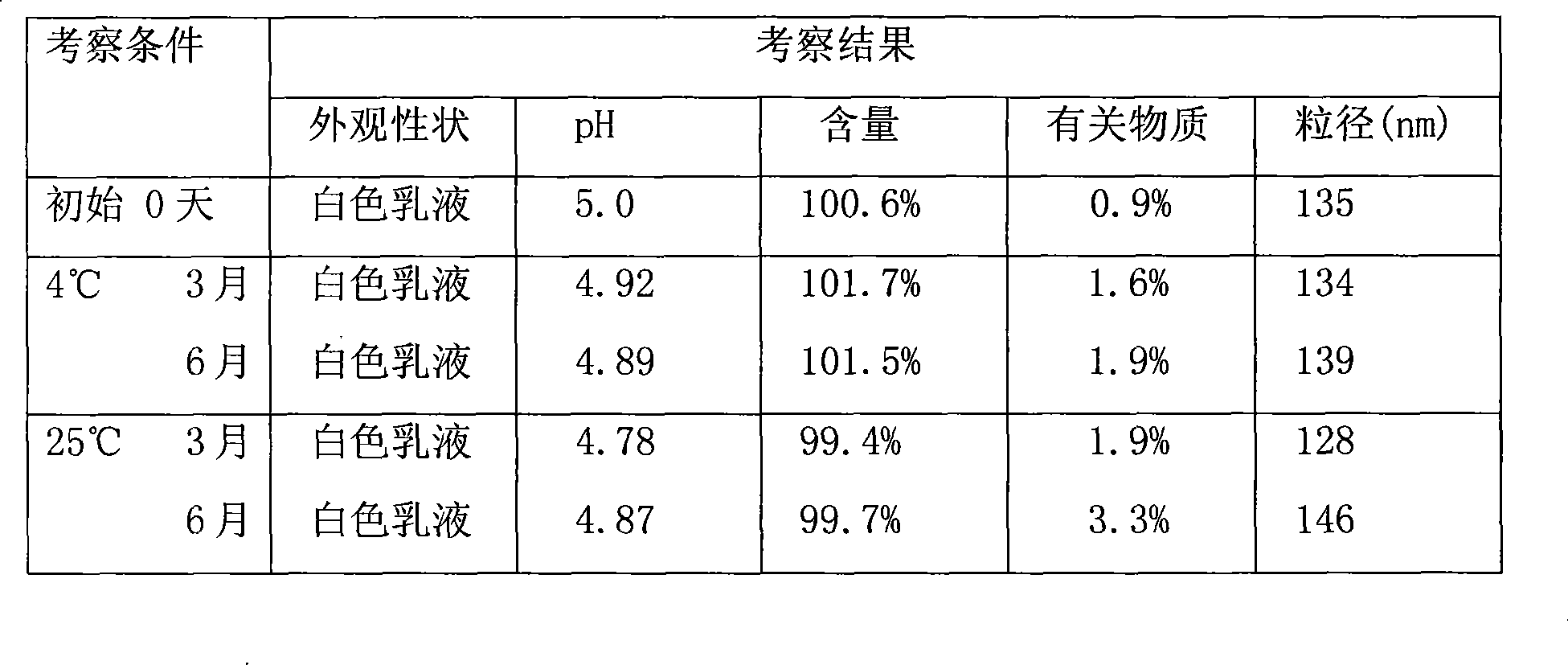

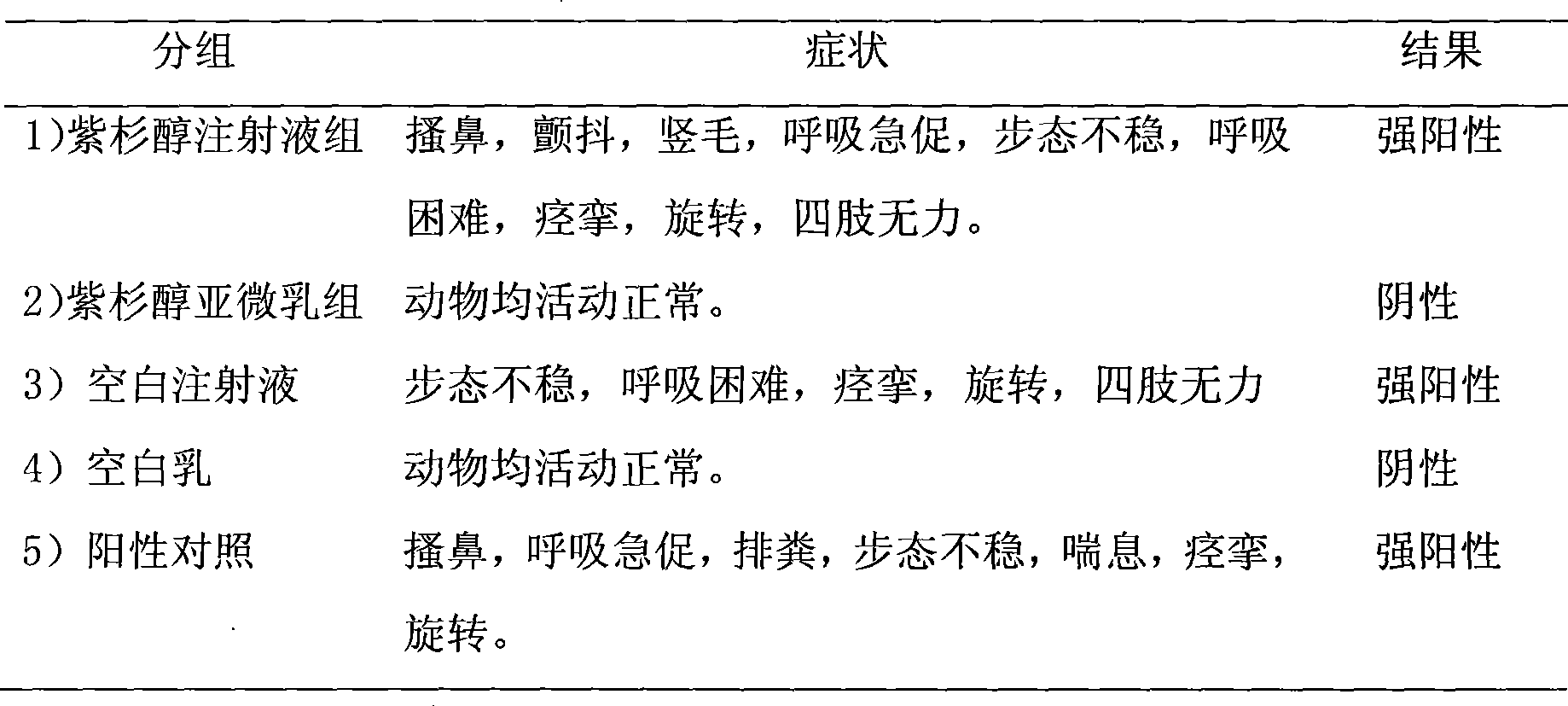

Paclitaxel lipid composite

ActiveCN101396346AImprove solubilityGood dispersionOrganic active ingredientsPharmaceutical non-active ingredientsEmulsionDrug loading dose

The invention discloses a paclitaxel lipid complex. The paclitaxel lipid complex consists of paclitaxel and lipid material. The weight proportion of the paclitaxel and the lipid material is 1 to 1 - 19, the preferential proportion is 1 to 2 - 10, and the more preferential proportion is 1 to 3 - 6. The lipid material is selected from natural lipid and synthetic lipid or the mixture thereof. The paclitaxel lipid complex can also contain antioxidation stabilizer. The invention also discloses a preparation method of the paclitaxel lipid complex and the application in the preparation of injection submicron emulsion and dry emulsion. The paclitaxel lipid complex has high solubility in oil, and the prepared submicron emulsion has the advantages of high drug loading quantity, high stability, high safety and low irritability.

Owner:BEIJING WEHAND BIO PHARMA CO LTD

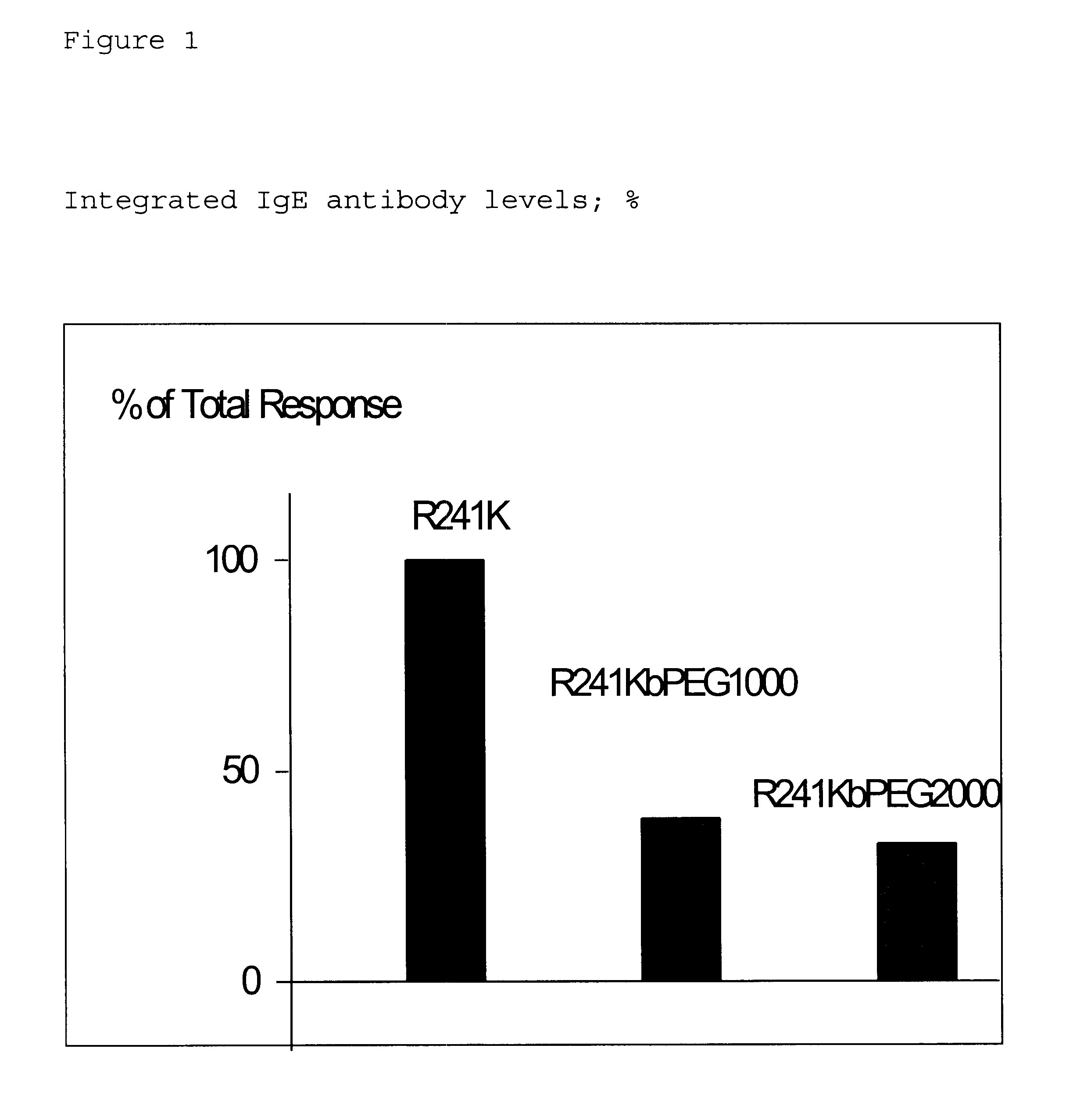

Modified polypeptide

InactiveUS6461849B1Lower immune responseRetain activityMilk preparationOrganic detergent compounding agentsVaccine ImmunogenicityAmino acid residue

The present invention relates to polypeptides with reduced immune response including reduced allergenicity having one or more amino acid residues being substituted with other amino acid residues and / or having coupled one or more polymeric molecules in the vicinity of the polypeptides metal binding site, a method for preparing modified polypeptides of the invention, the use of the polypeptide for reducing the immunogenicity and allergenicity and compositions comprising the polypeptide.

Owner:NOVOZYMES AS

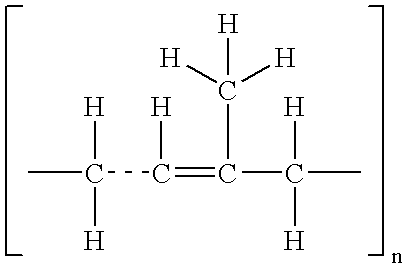

Vulcanization composition having reduced allergenic potential, and elastomeric articles formed therewith

ActiveUS20120021155A1Reduced and eliminated allergic potentialAvoid problemsTeeth fillingPretreated surfacesPolymer scienceVulcanization

The present invention generally relates to vulcanization compositions used to vulcanize elastomeric articles, where the vulcanization compositions have reduced allergenic potential as compared to elastomeric articles formed using vulcanization compositions having non-fugitive accelerators. The present invention also relates to elastomeric articles formed using the vulcanization compositions. The invention further relates to methods for making a reduced-allergenicity vulcanization composition, and to methods for using the vulcanization compositions to vulcanize elastomeric articles.

Owner:ALLEGIANCE CORP

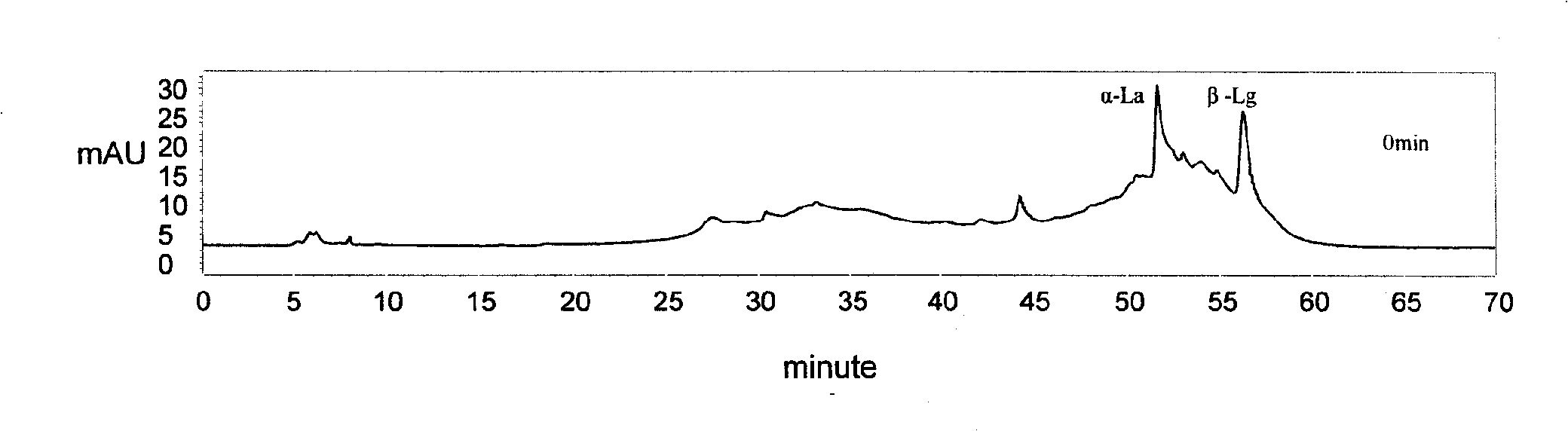

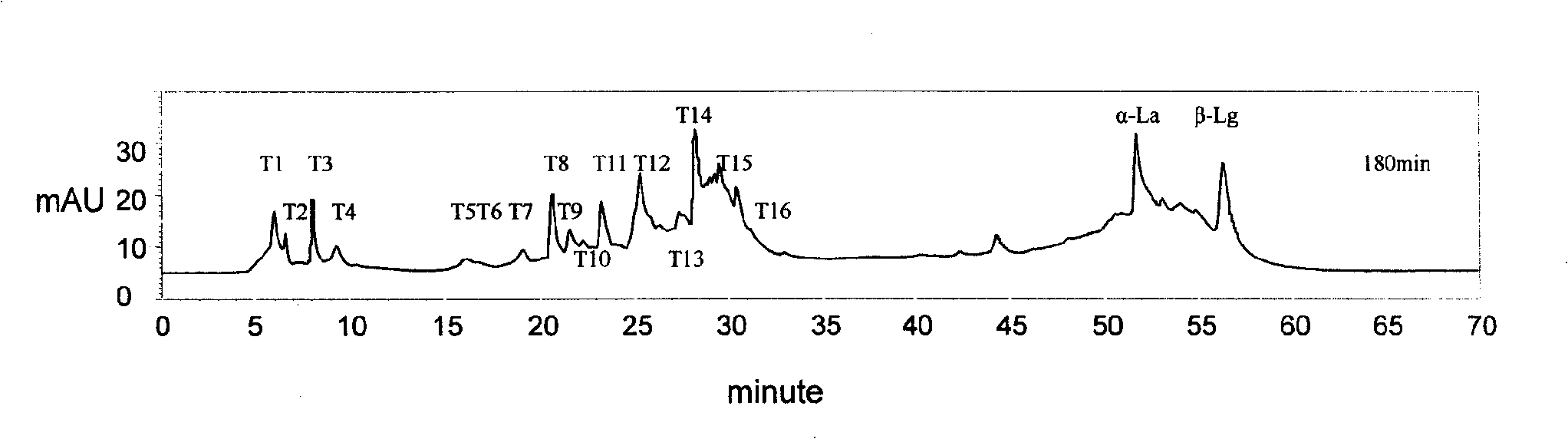

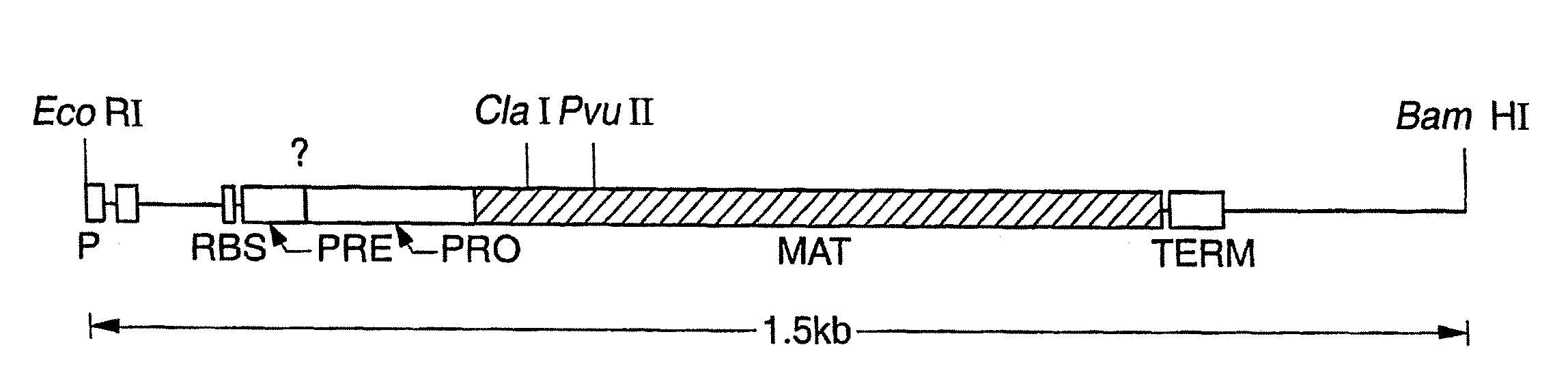

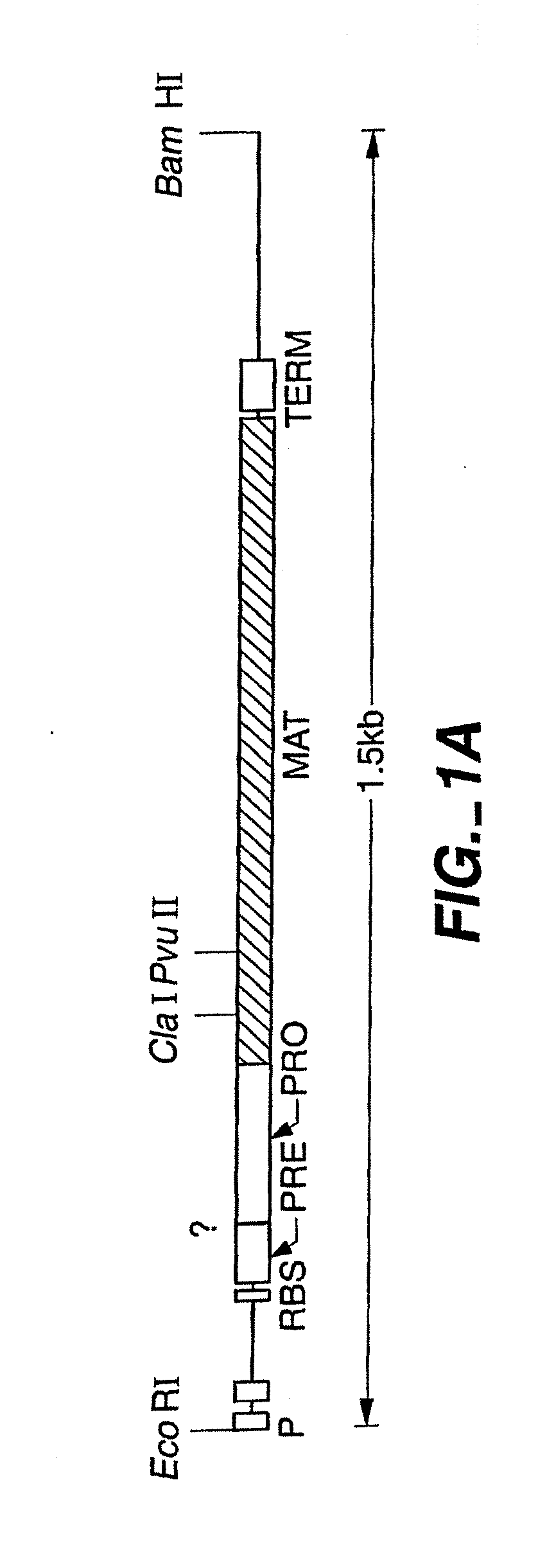

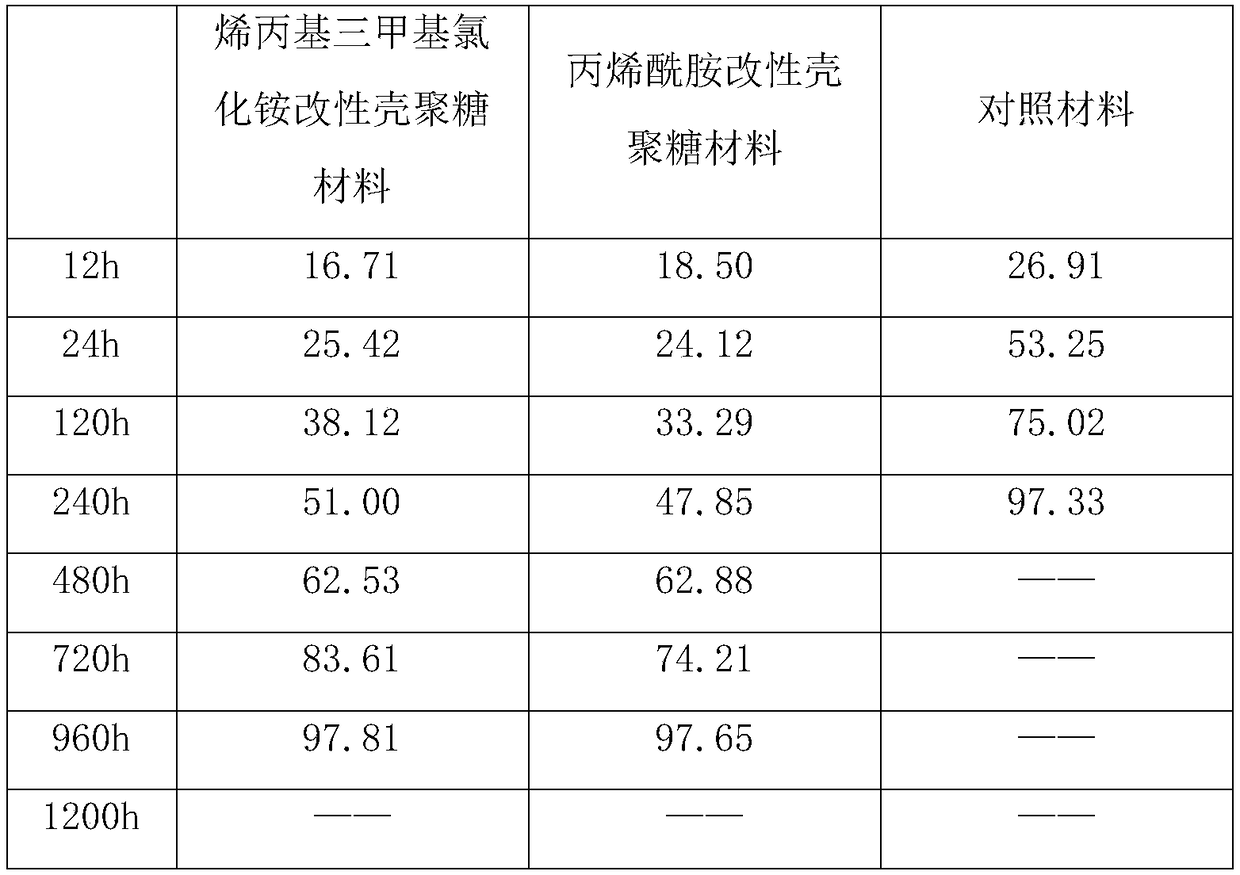

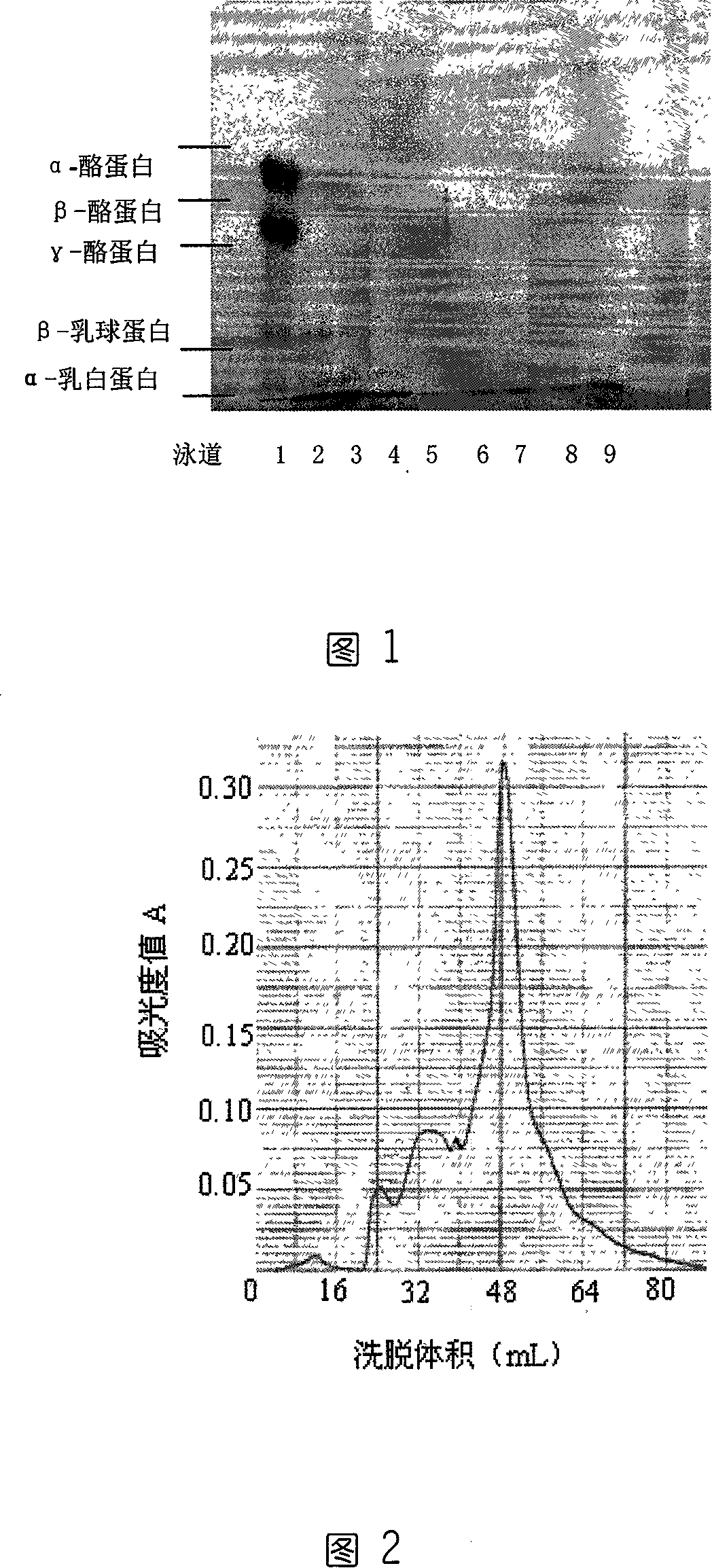

Subsensitive lactalbumin hydrolysate and preparation method thereof

The invention discloses a muting sensitive lactalbumin hydrolysate and a preparation method thereof. The method mainly comprises the following steps: dissolving condensed whey protein in the water, then carrying out denaturation under high temperature, carrying out hydrolysis by using the protamex composed of alkali protease, papain and flavourzyme, treating the lactalbumin hydrating solution with desalinization and drying to obtain the lactalbumin hydrolysate of the invention. The lactalbumin hydrolysate of the invention has high suppression ratio of Beta-lactoglobulin and Alpha- lactalbumin, can reduce or eliminate cow milk allergic reaction; furthermore, the lactalbumin hydrolysate can also produce other active materials, thus also having the functions of promoting immunity, being easy to digest and absorb and reducing blood pressure; and the lactalbumin hydrolysate has high security and no side effect, bitter taste or other bad flavors.

Owner:CHINA AGRI UNIV

Method of making a partially hydrolyzed fucoidan composition

ActiveUS20060211652A1Promote growth factorReduce or prevent inflammationCosmetic preparationsBiocideAntioxidantDietary product

Methods of making partially hydrolyzed fucoidan. Fucoidan from brown seaweeds is partially hydrolyzed and then mixed with other ingredients for use as a dietary supplement in beverage, capsule, or tablet form. The fucoidan is partially hydrolyzed with acid and heat. The partially hydrolyzed fucoidan can also be sulfonated. Other ingredients that can be included in the dietary supplement include high-ORAC-value antioxidants, minerals, pepper extract, flavoring agents, coloring agents, and preservatives. The compositions can be in the form of beverages, tablets, capsules, powders, and the like.

Owner:SAKURA PROPERTIES LLC

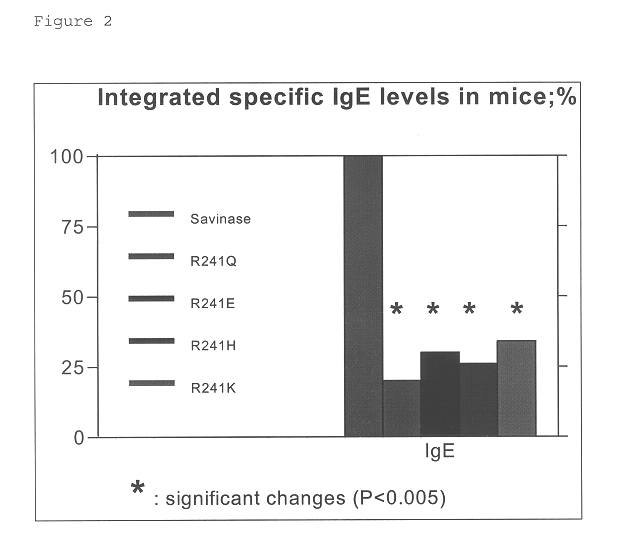

Proteases producing an altered immunogenic response and methods of making and using the same

InactiveUS20090060933A1Reduced immunogenic responseLess allergicBacterial antigen ingredientsBacteriaProteinase activityDna encoding

The present invention provides novel protein variants that exhibit reduced immunogenic responses, as compared to the parental proteins. The present invention further provides DNA molecules that encode novel variants, host cells comprising DNA encoding novel variants, as well as methods for making proteins less allergenic. In addition, the present invention provides various compositions that comprise these proteins that are less immunogenic than the wild-type proteins.

Owner:ESTELL DAVID A +1

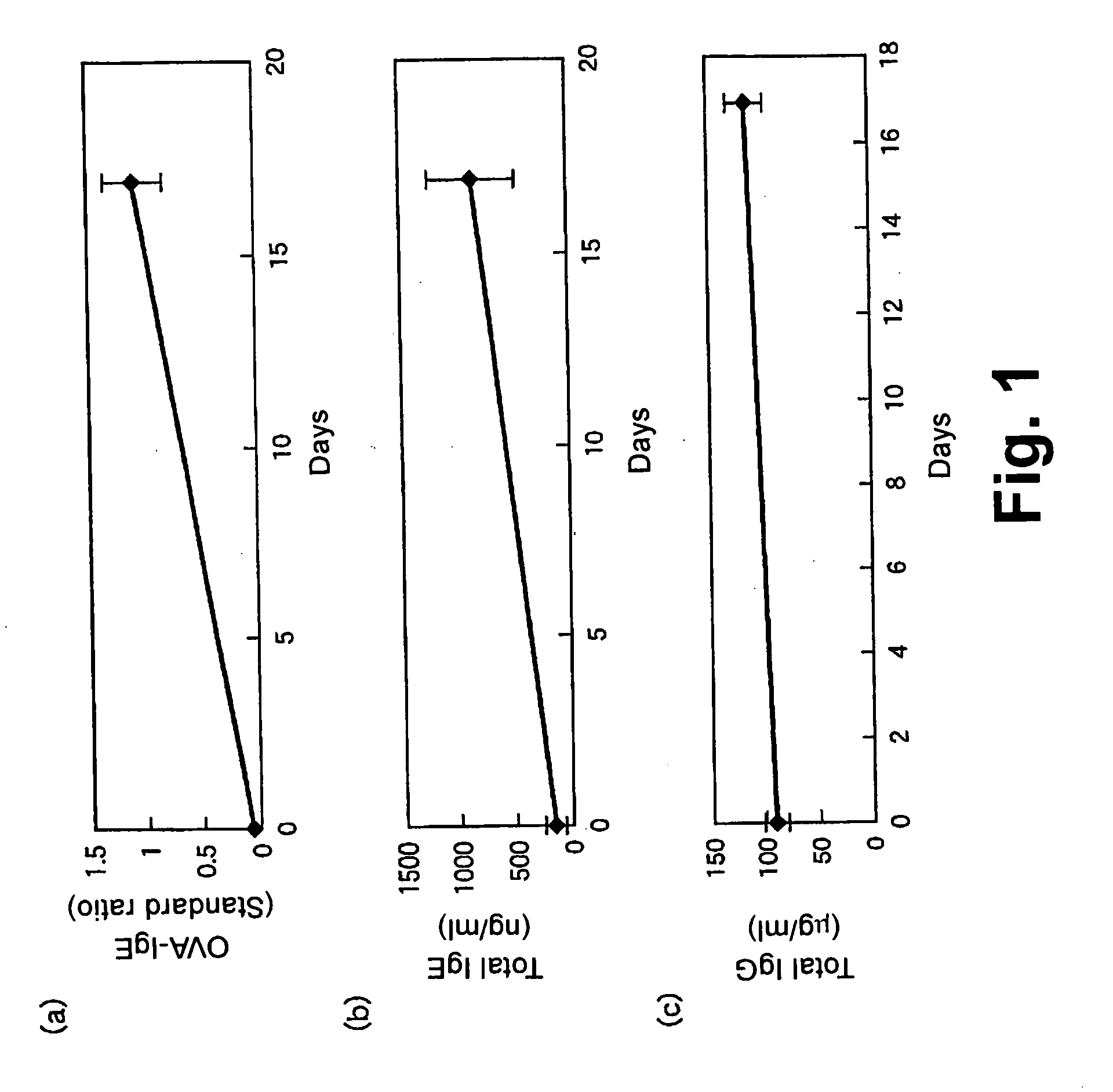

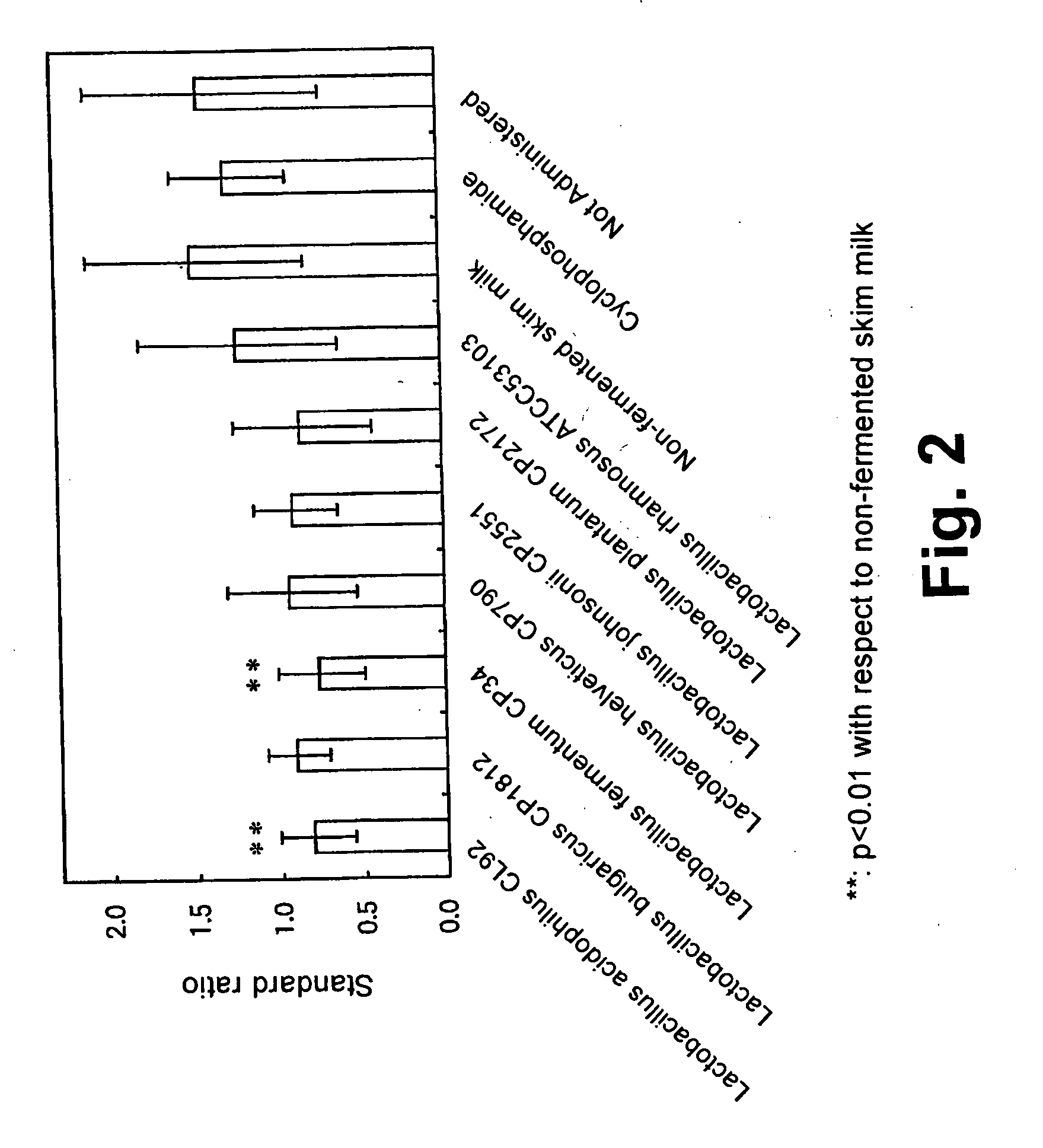

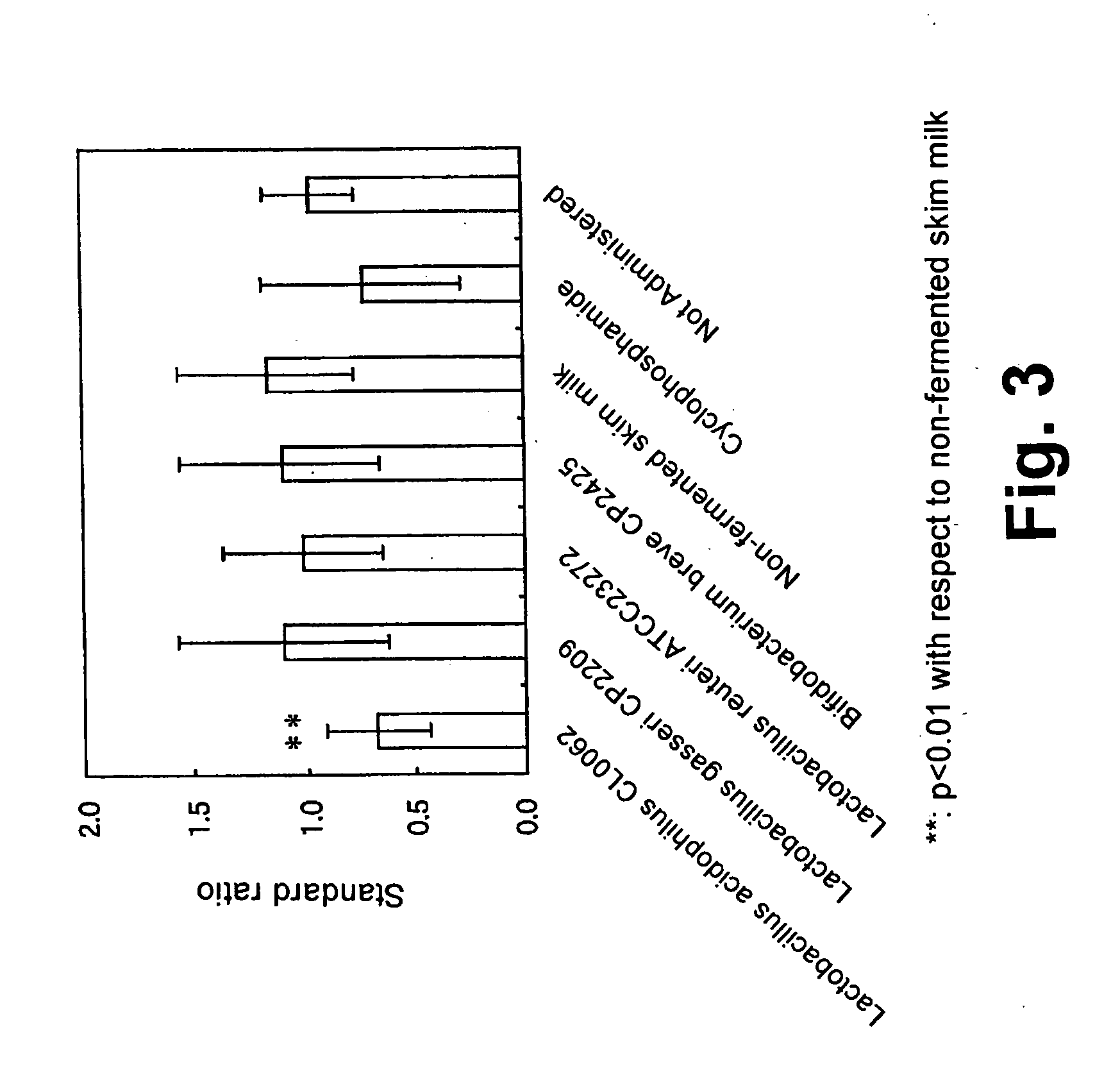

Antiallergic agent, utilization thereof for reducing allergy and method of reducing allergy

The present invention provides an antiallergic agent containing, as an active ingredient, lactic acid bacteria selected from the group consisting of lactic acid bacteria of the species Lactobacillus acidophilus, Lactobacillus fermentum, and combinations thereof. The antiallergic agent is capable of improving allergic diathesis by reducing the IgE level, which is contributive to development of Type I allergy, and is easy to take and highly safe. The present invention also provides use of the antiallergic agent for reducing allergy, and a method for reducing allergy using the antiallergic agent.

Owner:CALPIS

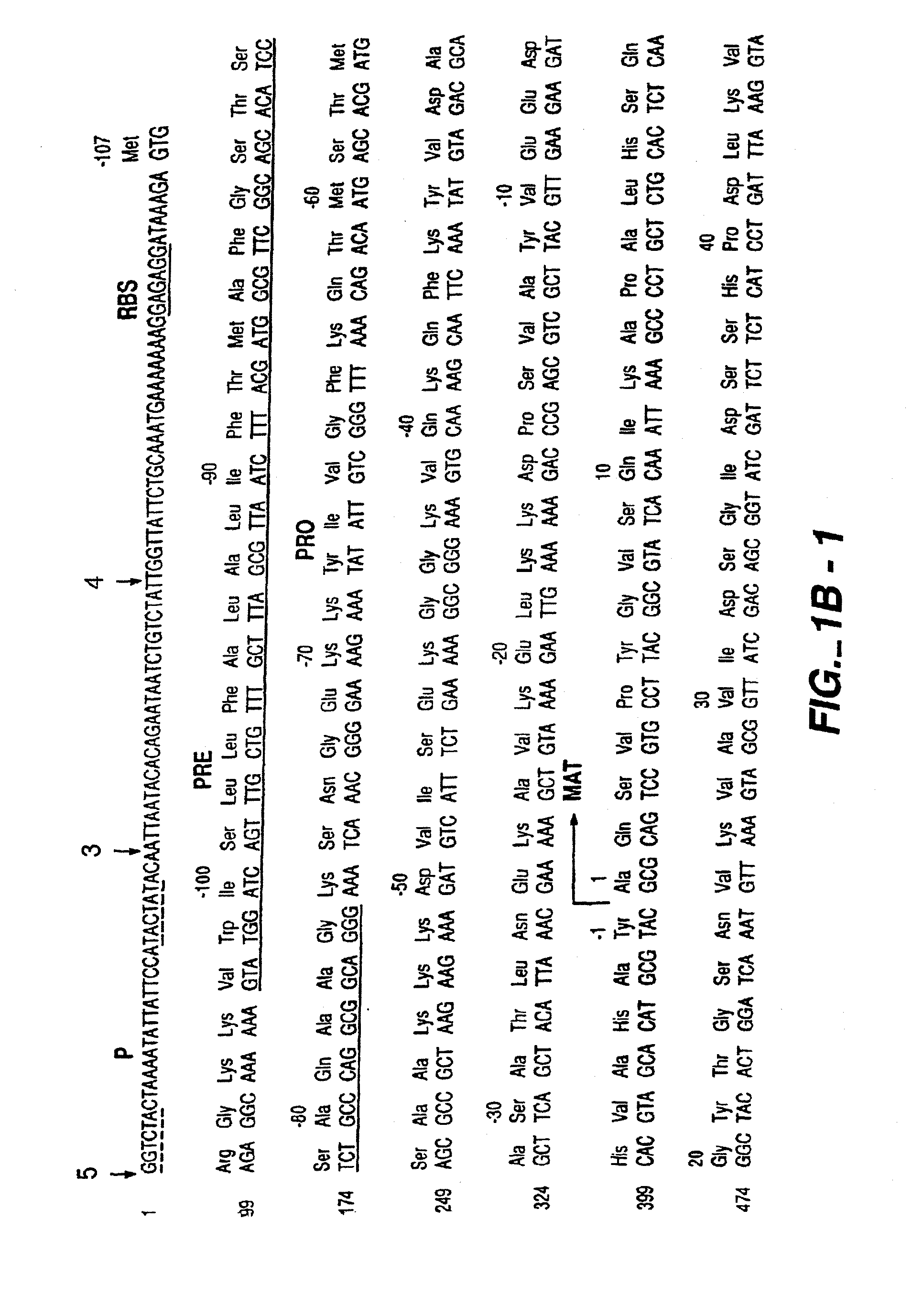

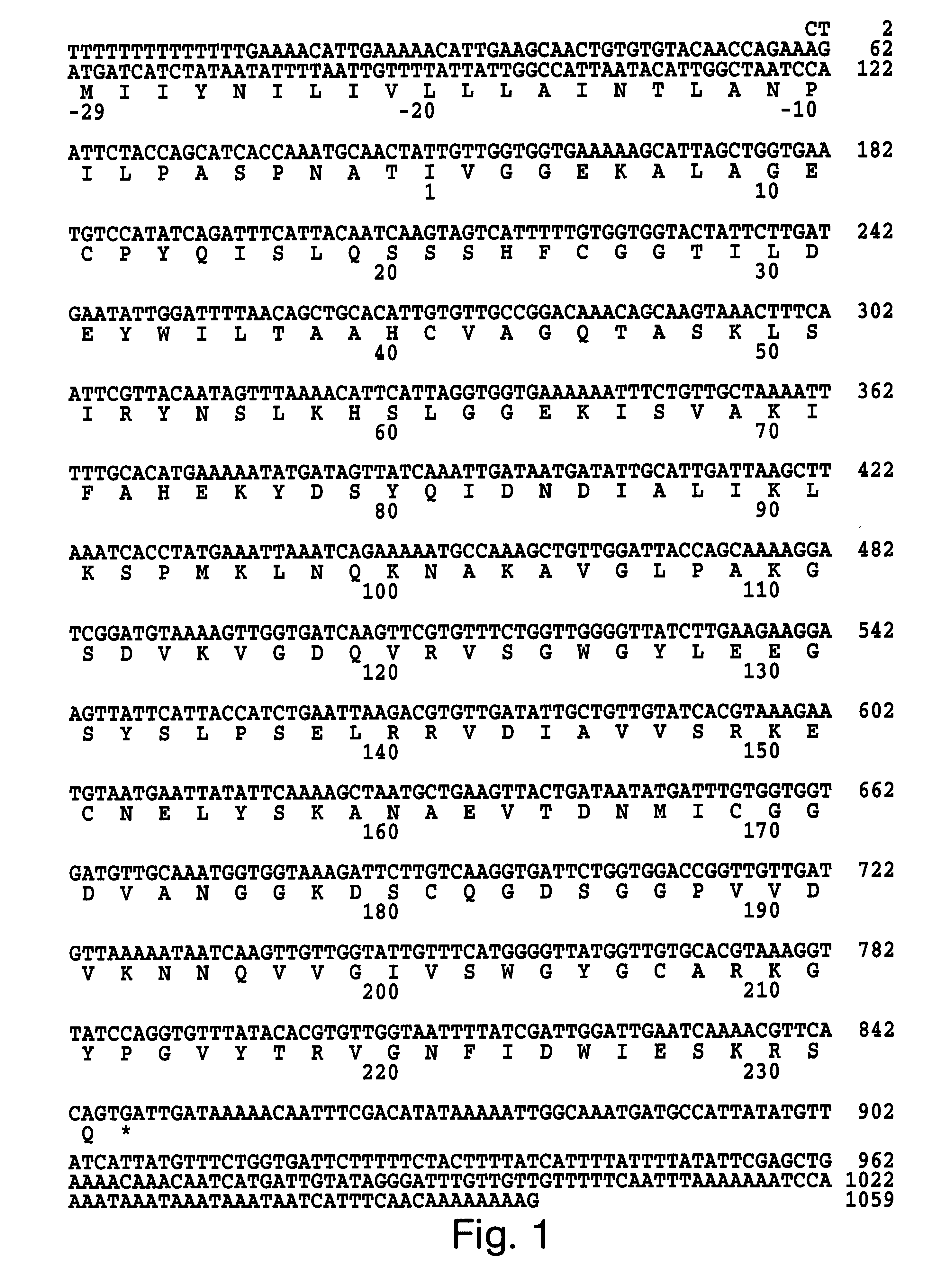

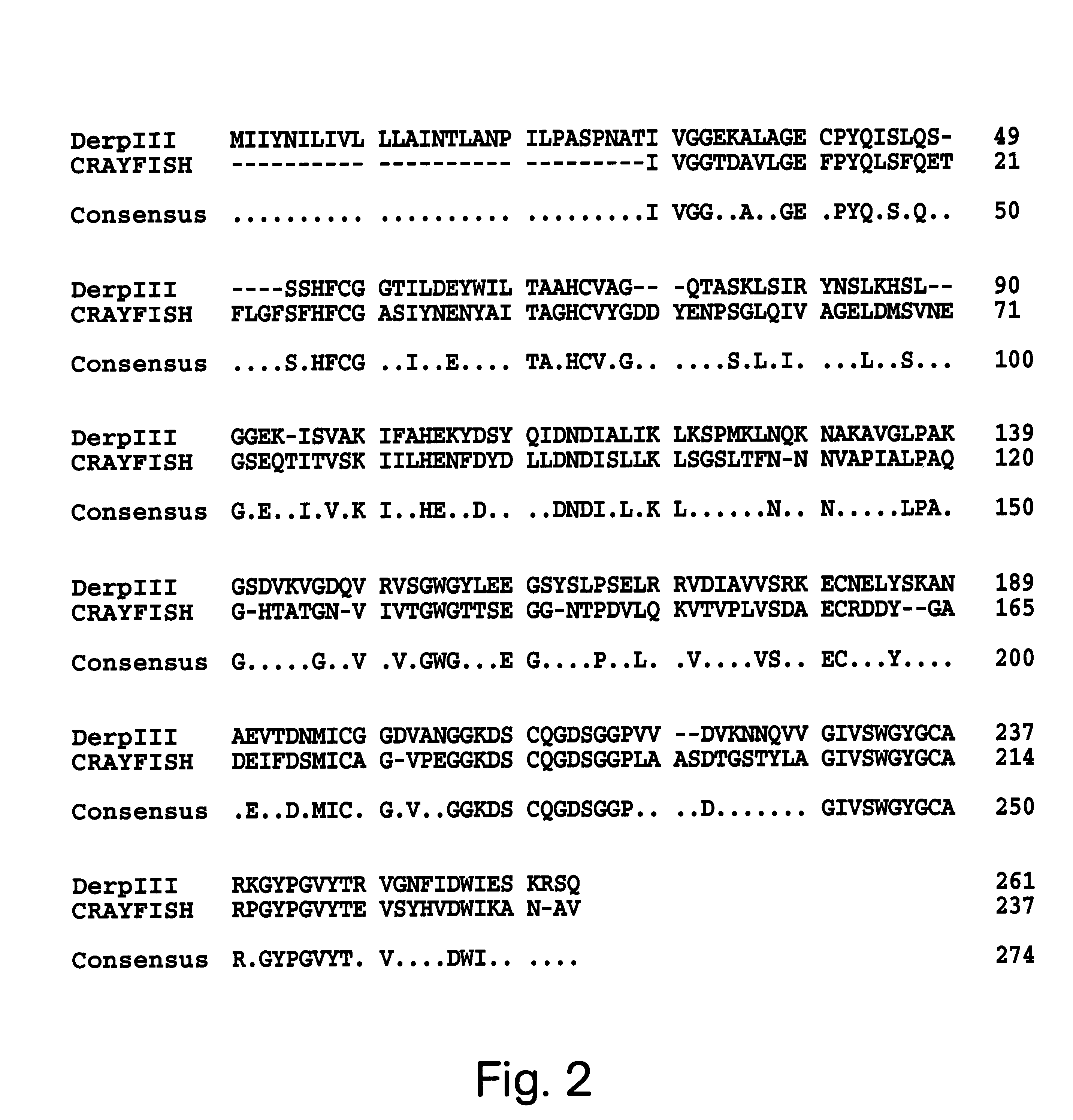

Nucleic acids encoding a house dust mite allergen, Der p III, and uses therefor

InactiveUS6180771B1Few anticipated side effectSymptoms improvedSugar derivativesBacteriaDust mitesPeptide

Isolated nucleic acids encoding an allergen of Dermatophagoides pteronyssinus, Der p III, are disclosed. A cDNA encoding a peptide having a Der p III activity and a predicted molecular weight of about 24,985 daltons is also described. The nucleic acids can be used as probes to detect the presence of Der p III nucleic acid in a sample or for the recombinant production of peptides having an activity of Der p III. Peptides having an activity of Der p III can be used in compositions suitable for pharmaceutical administration or methods of diagnosing sensitivity to house dust mites.

Owner:MERCK PATENT GMBH

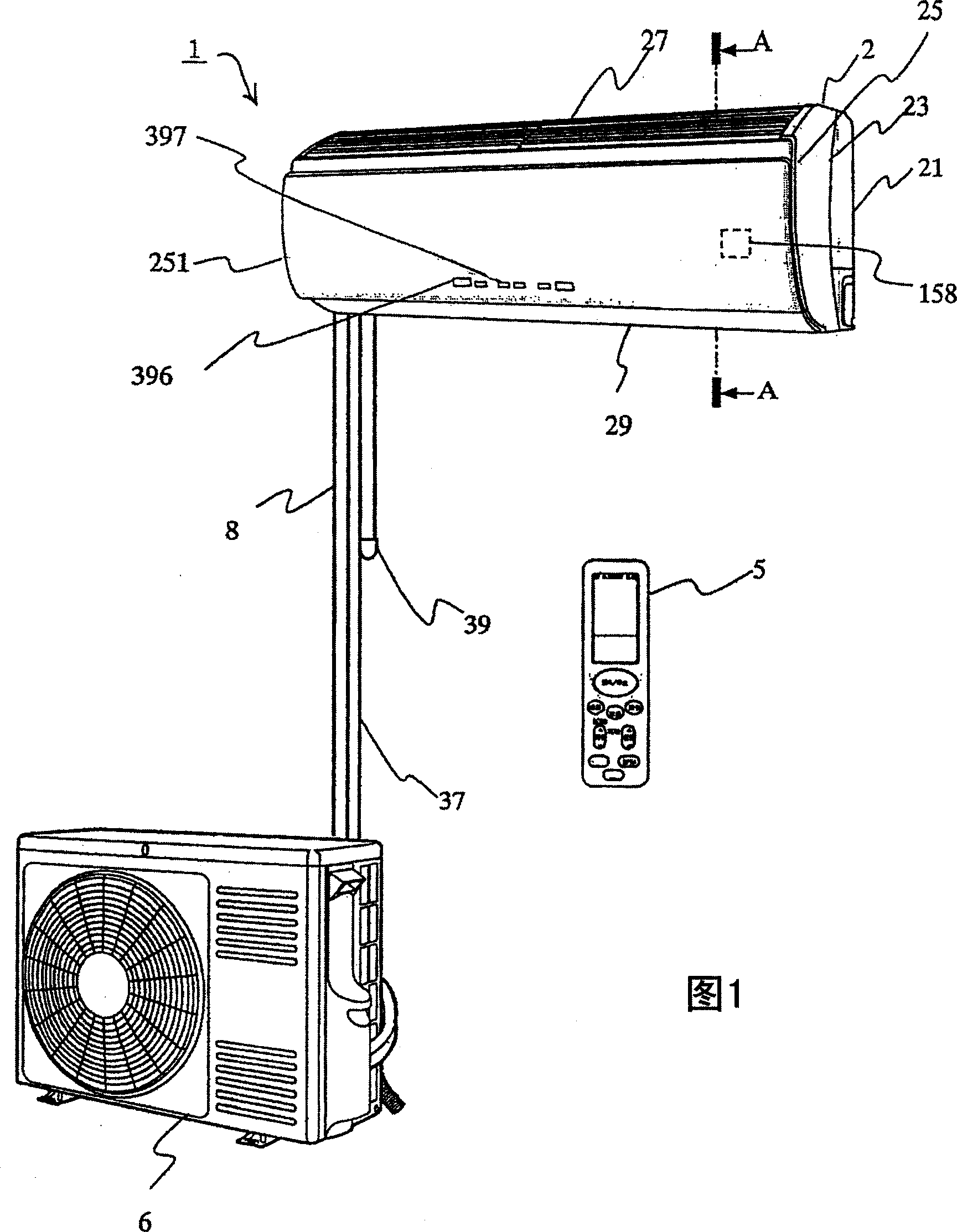

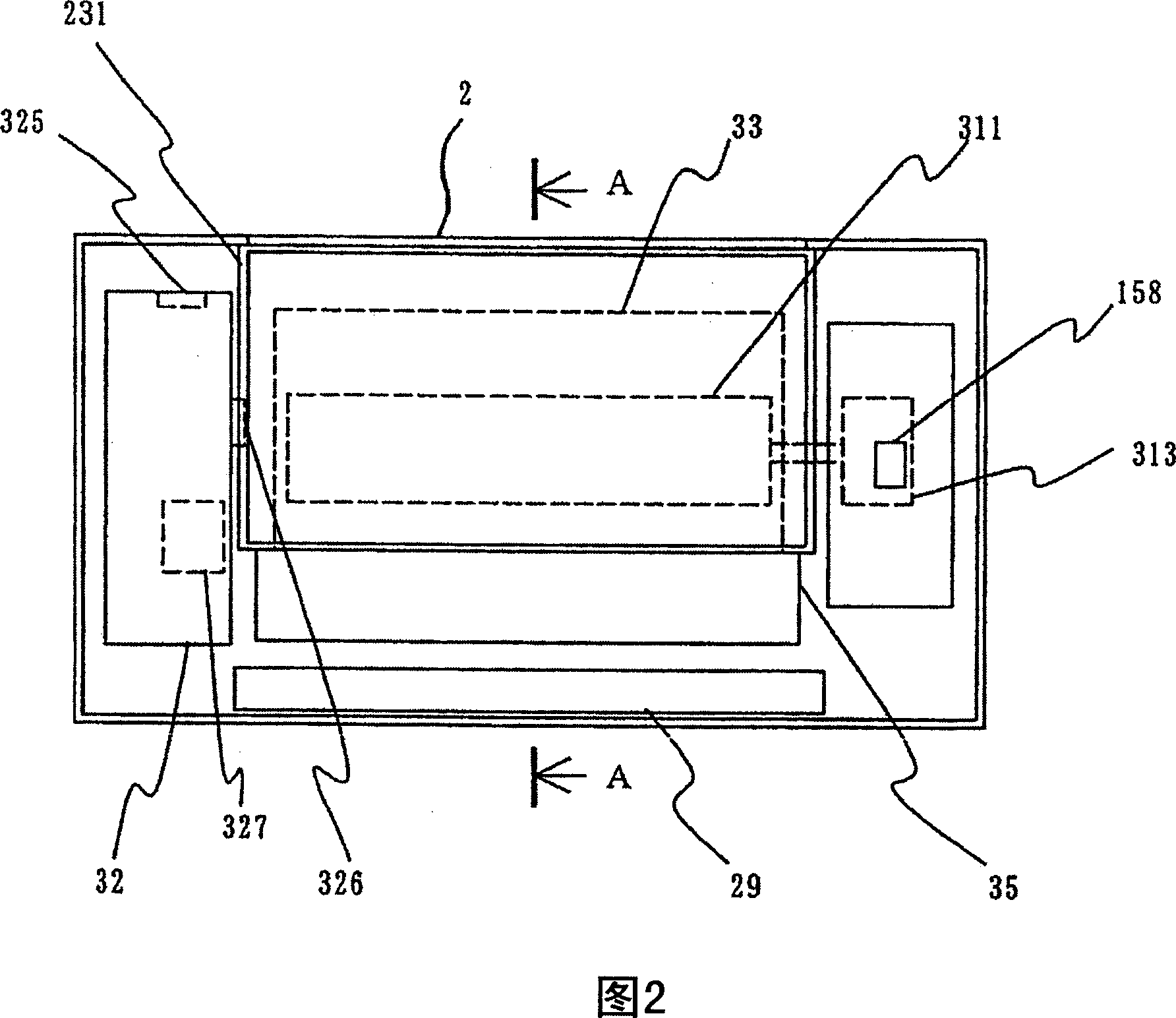

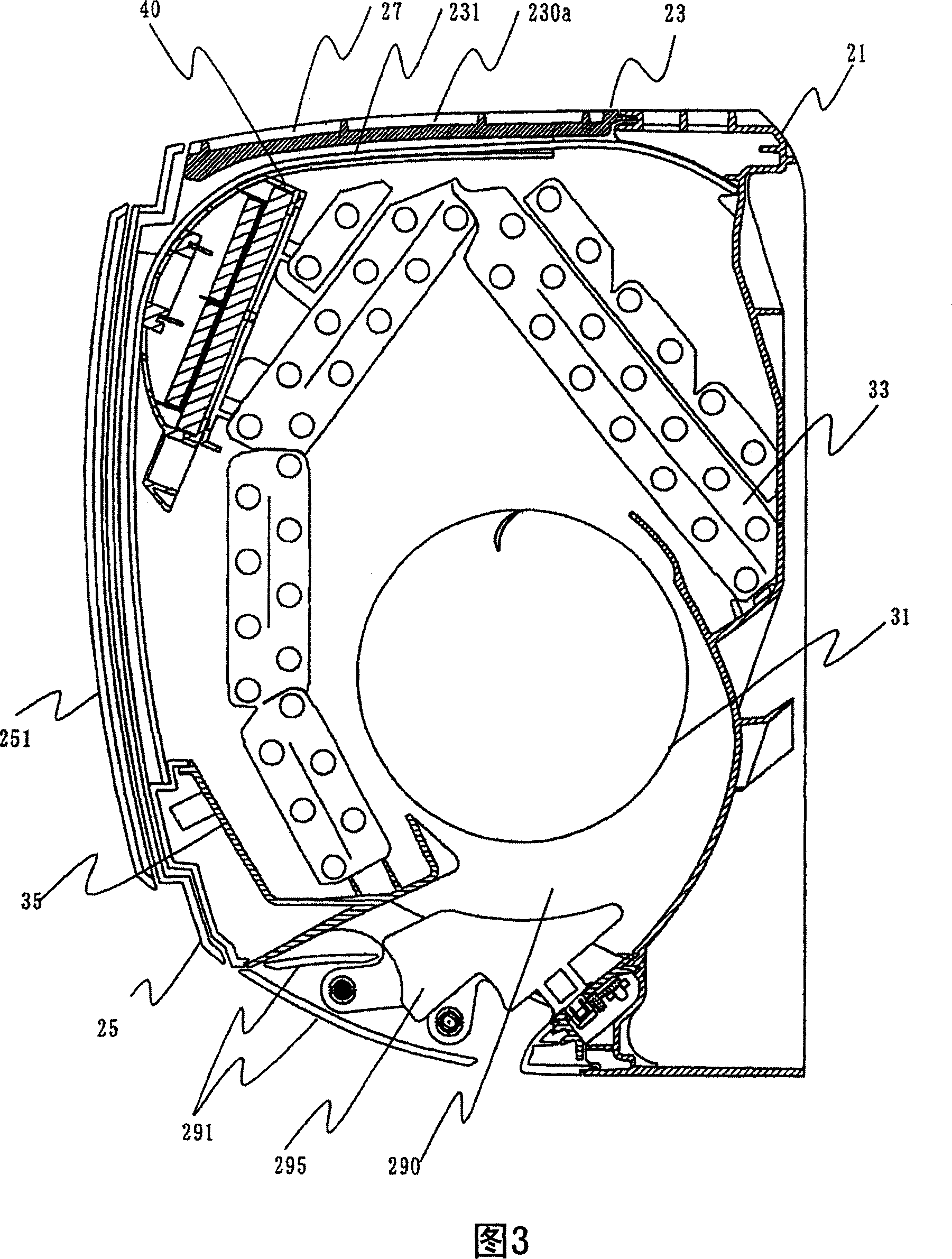

Air conditioner

InactiveCN1948840ARelaxReduce dustHuman health protectionMechanical apparatusAllergic reactionElectric power

Provided is an air conditioner, capable of maintaining the inside of a room with a dust-minimized state by detecting specific dust containing pollen that is a substance generated outdoors and causing seizures by allergic reaction or promoting the seizures, and performing dust removing operation. This air conditioner (1) comprises an indoor unit (2) including an electric dust collecting and cleaning unit provided with a dielectric filter, a ventilating device capable of performing air supply operation for taking outside air into the room, a cleaning filter provided in an suction passage of the outside air by the ventilating device, a dust sensor (158) capable of discriminating dust floating in the air. A control device of the air conditioner (1) controls, when the dust sensor detects dust of a specific group including pollen, so as to perform operation of the electric dust collecting and cleaning unit and the air supply operation of the ventilating device.

Owner:HITACHI HOME & LIFE SOLUTIONS INC

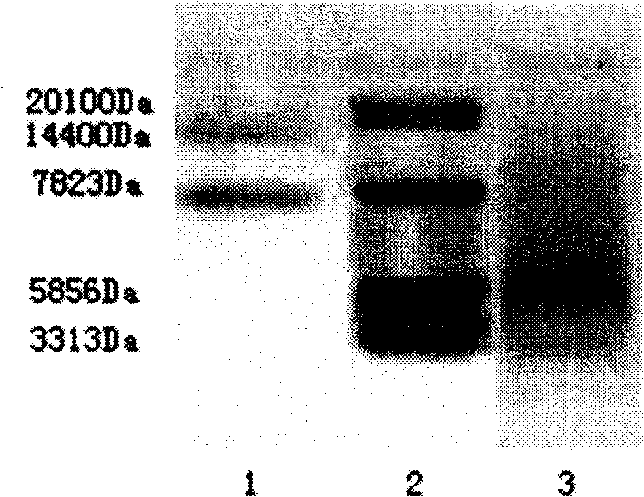

Extraction of activated micromolecular sheept germine from sheep embryo and its use

ActiveCN1896268APlay the role of beauty and anti wrinkleImprove absorption rateCosmetic preparationsToilet preparationsIntestinal structureSide effect

The extraction of active small molecular placentin from lamb embryo and its purpose that belongs to the bioengineering field includes the following steps: removing stomach and intestine from fresh lamb embryo of 40-90 days and cutting up, homogenizing with distilled water, frost thawing repeatedly at -20DEG C, filtrating, heating the filtrate and obtaining Filtrate A and Sediment A; ultra-filtrating Filtrate A and obtaining the transparent primrose yellow Filtrate B and Sediment B; mingling Sediment A and Sediment B, modifying pH to 2.0, adding pepsin, then modifying pH to 7.0, incubating at 100 +-2DEG C and preserving Filtrate C; active small molecular placentin is obtained by mingling Filtrate B and C that can be used in the preparation of skin care product. The placentin prepared in this invention has the molecular weight of 3000-6000 and contains mainly cytokines and small peptides, has high activity, low side-effect such as anaphylactic response, and increased skin absorption ratio.

Owner:YANGZHOU YANGDA LIANHUAN PHARMA GENE ENG

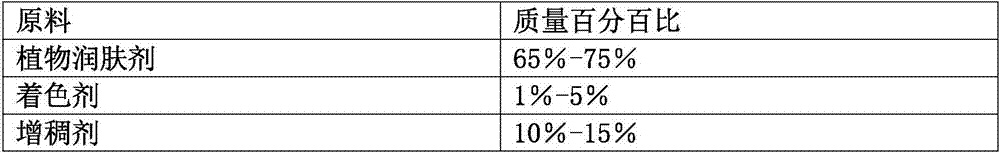

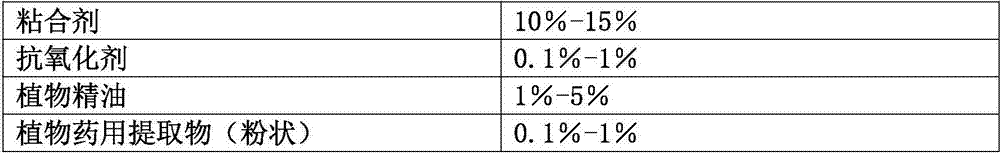

Medicinal lipstick and preparing method thereof

InactiveCN107184502ATo promote metabolismImprove immunityCosmetic preparationsAntipyreticAdhesiveDesiccation

The invention discloses a medicinal lipstick. The medicinal lipstick is prepared from, by mass, 65%-75% of plant emollient, 1%-5% of colorant, 10%-15% of thickener, 10%-15% of adhesive, 0.1%-1% of antioxidant, 1%-5% of plant essence and 0.1%-1% of medicinal plant extracts. In the medicinal lipstick, the medicinal plant extracts have medicinal plant components, can restore the lip, prevent lip desiccation and decrustation, promote metabolism of the tender skin, inhibit the occurrence of lip inflammation and maintain the lip skin, and has remarkable functions to treatment of cheilitis.

Owner:QINZHOU UNIV

Pharmaceutical compositions comprising docetaxel and methods for preparation thereof

InactiveUS20080306137A1High stability and solubilityEasy to makeBiocideOrganic active ingredientsSolubilityDocetaxel-PNP

A pharmaceutical composition of docetaxel comprising an effective amount of docetaxel, a polysorbate (TWEEN® compound) and a co-solvent, wherein the co-solvent is at least one member selected from the group consisting of glycerol and polyethylene glycol. The composition is an injectable solution or a freeze-dried powder for injection. The solubility of decetaxel is improved by adding a polysorbate and a co-solvent. Methods of preparation of the pharmaceutical composition are also disclosed.

Owner:BEIJING CENTURY BIOCOM PHARMA TECH

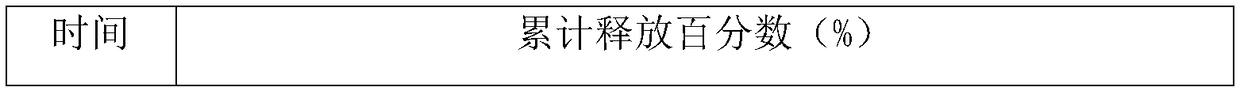

Alveolar bone repair material containing BMP-2 as well as preparation method and application of alveolar bone repair material

ActiveCN109464702ASignificant progressReduce allergiesTissue regenerationProsthesisRepair materialDentistry

The invention provides an alveolar bone repair material. The repair material contains hydroxyapatite, allyl trimethyl ammonium chloride or acrylamide modified chitosan, hydroxypropyl methyl celluloseand BMP-2 polypeptide. The material can be applied to alveolar bone repair and dental implantation.

Owner:ZHEJIANG RISING BIOTECH CO LTD

Babies' formula milk powder restructured composition of protein and producing method thereof

InactiveCN101107946AImprove digestibilityReduce allergiesMilk preparationOther dairy technologyNutritive valuesProtein composition

The invention, based on the character of nutrient content in breast milk, provides a infant formula milk powder constituted by reconstructed infant formula milk powder proteide. The main raw materials for preparing the reconstructed infant formula milk powder are as follows; fresh milk hydrolyzed by Neutrase enzyme with the degree of hydrolysis achieves 3 per cent to 12 per cent, lactalbumin hydrolysate, lactose, palm oil, soybean oil, low polysaccharide and one or several kinds of compound nutriment 1000 kg concentrated as dry matter. The invention utilizing the Neutrase enzyme to hydrolyze milk casein difficult for digesting by infant into micromolecule peptide and also replacing the whey mist used in traditional milk powder with the lactalbumin hydrolysate to reconstruct the infant formula milk powder proteide with the combination of the two technologies, thus improving the digestibility of milk protein, lowing the irritability of the milk protein and enabling the product has enhanced nutritive value and more easily being accepted by consumers, which is significant for practical application.

Owner:SANLU GROUP

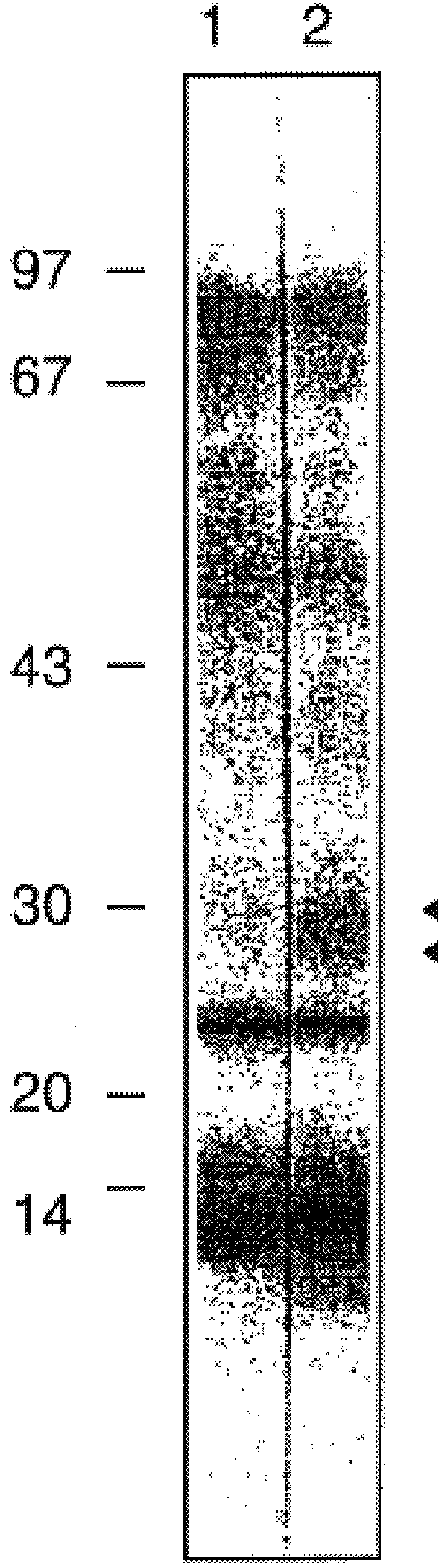

Recombinant animal-free food compositions and methods of making them

ActiveUS20200138066A1Reduce allergiesImprove digestibilityDough treatmentTransferrinsBiotechnologyAnimal science

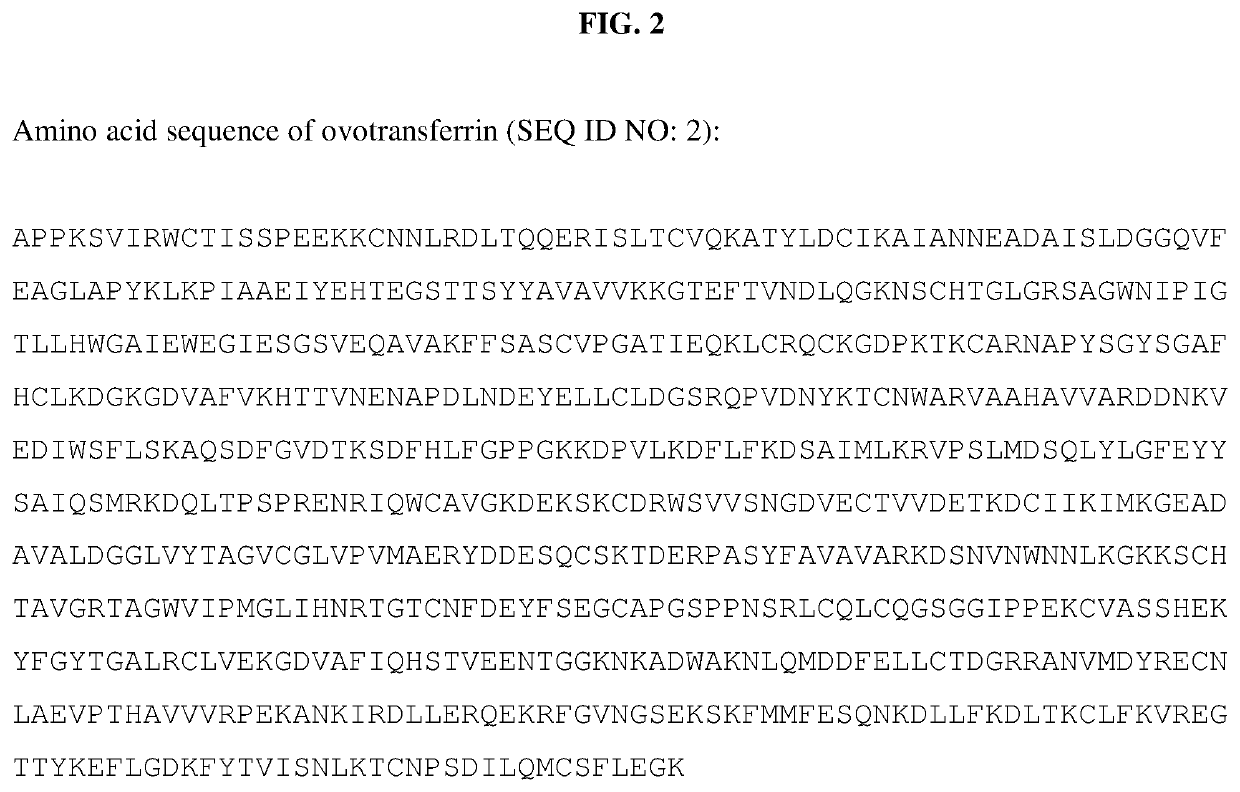

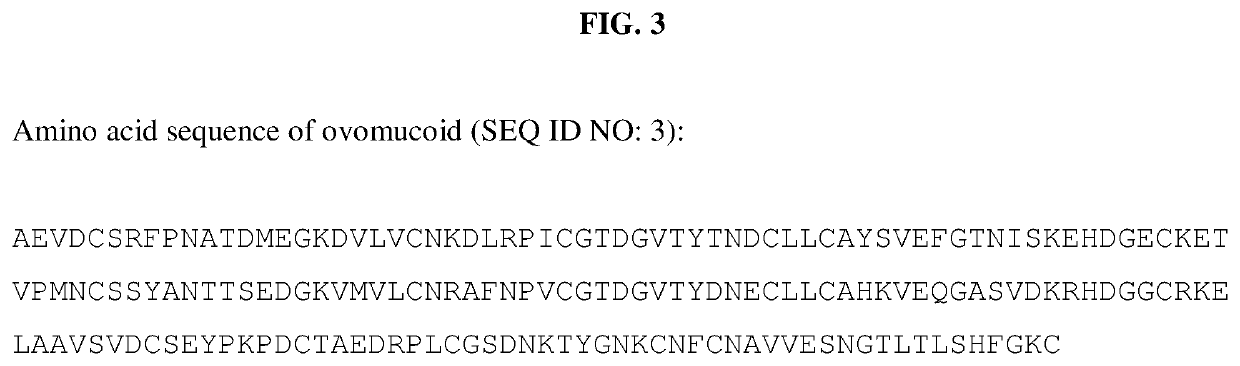

Provided herein are recombinant animal-free food compositions comprising egg-white proteins such as ovalbumin, ovotransferrin and lysozyme and methods of making such food compositions.

Owner:CLARA FOODS

Health-care plaster for hyperosteogeny

InactiveCN101480474AReduce allergiesLeave no residueAnthropod material medical ingredientsHydroxy compound active ingredientsDiseaseLumbar intervertebral disc

The invention relates to a hyperosteogeny health-care paste which is a novel product for treating and relieving pains caused by hyperosteogeny, lumbar intervertebral disc protrusion and the like. The hyperosteogeny health-care paste is improved into an adhesive plaster by combining clinical efficacy and high and new technology according to the folk remedy. The hyperosteogeny health-care paste comprises lining materials, a plaster material layer and plaster surface materials, wherein the lining materials are non-woven fabrics or knitted fabrics, the plaster material layer is a medicament containing layer to which a transdermal enhancer and slow control technique are added, and the plaster surface materials are release paper or release film.

Owner:张志明

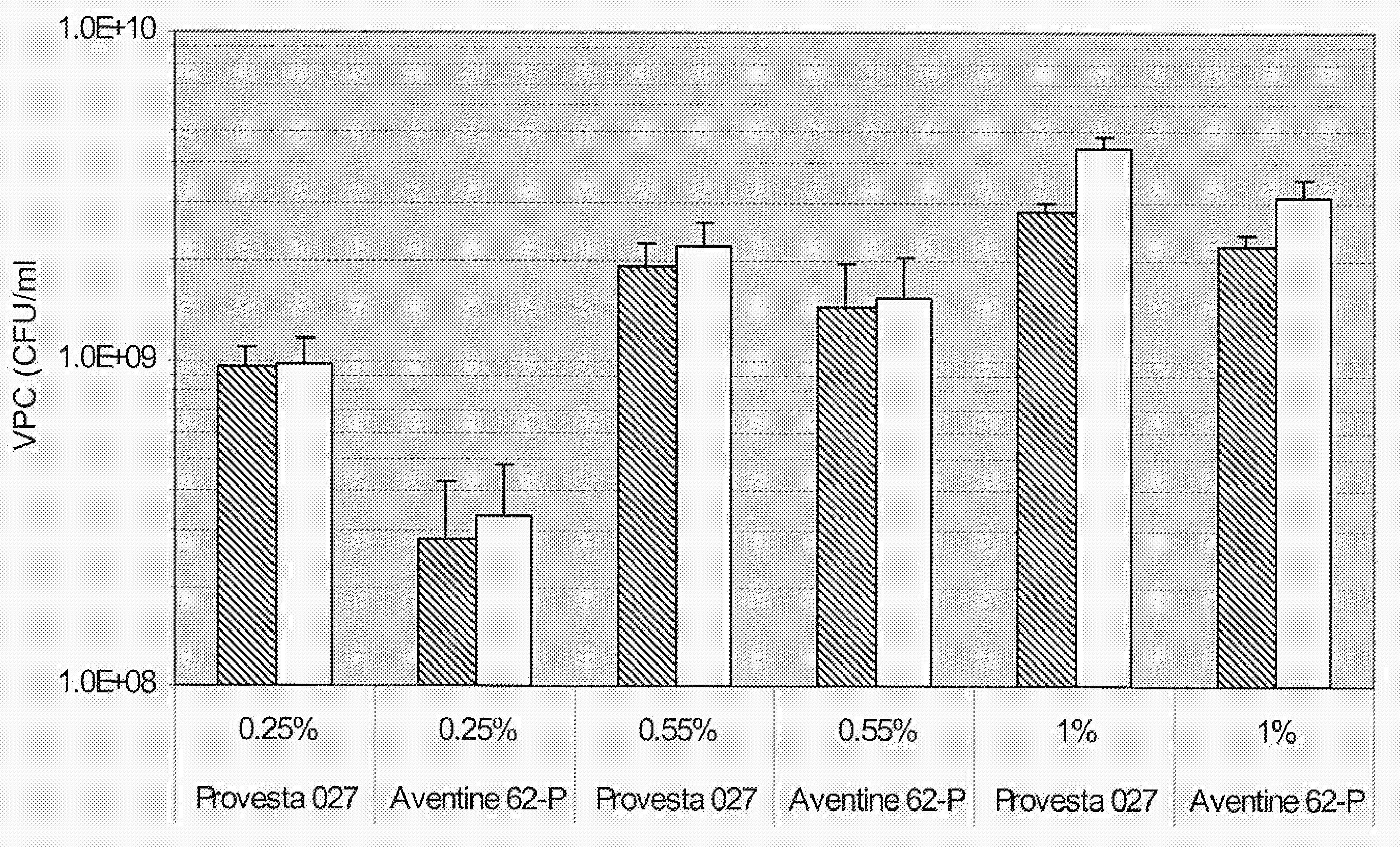

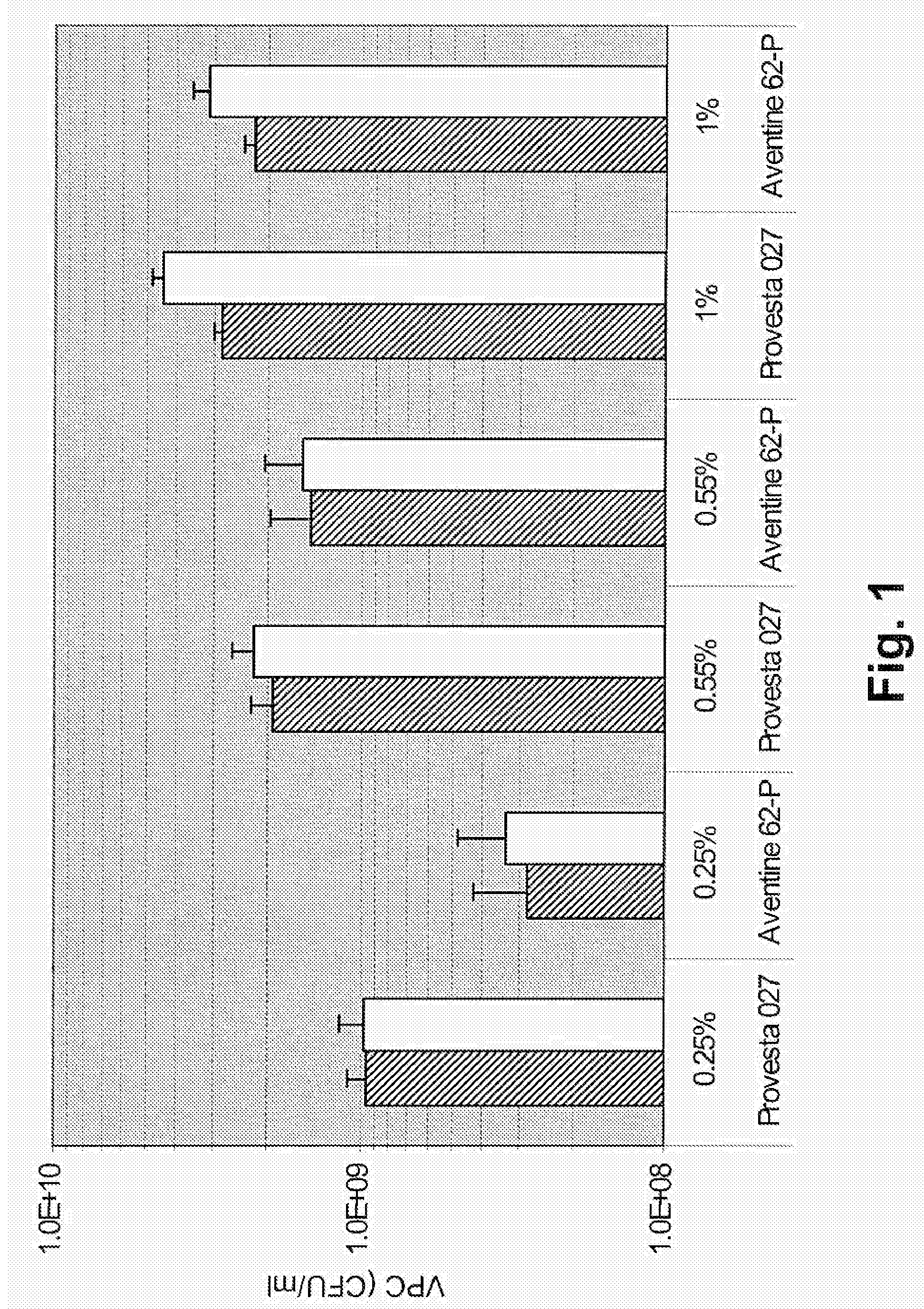

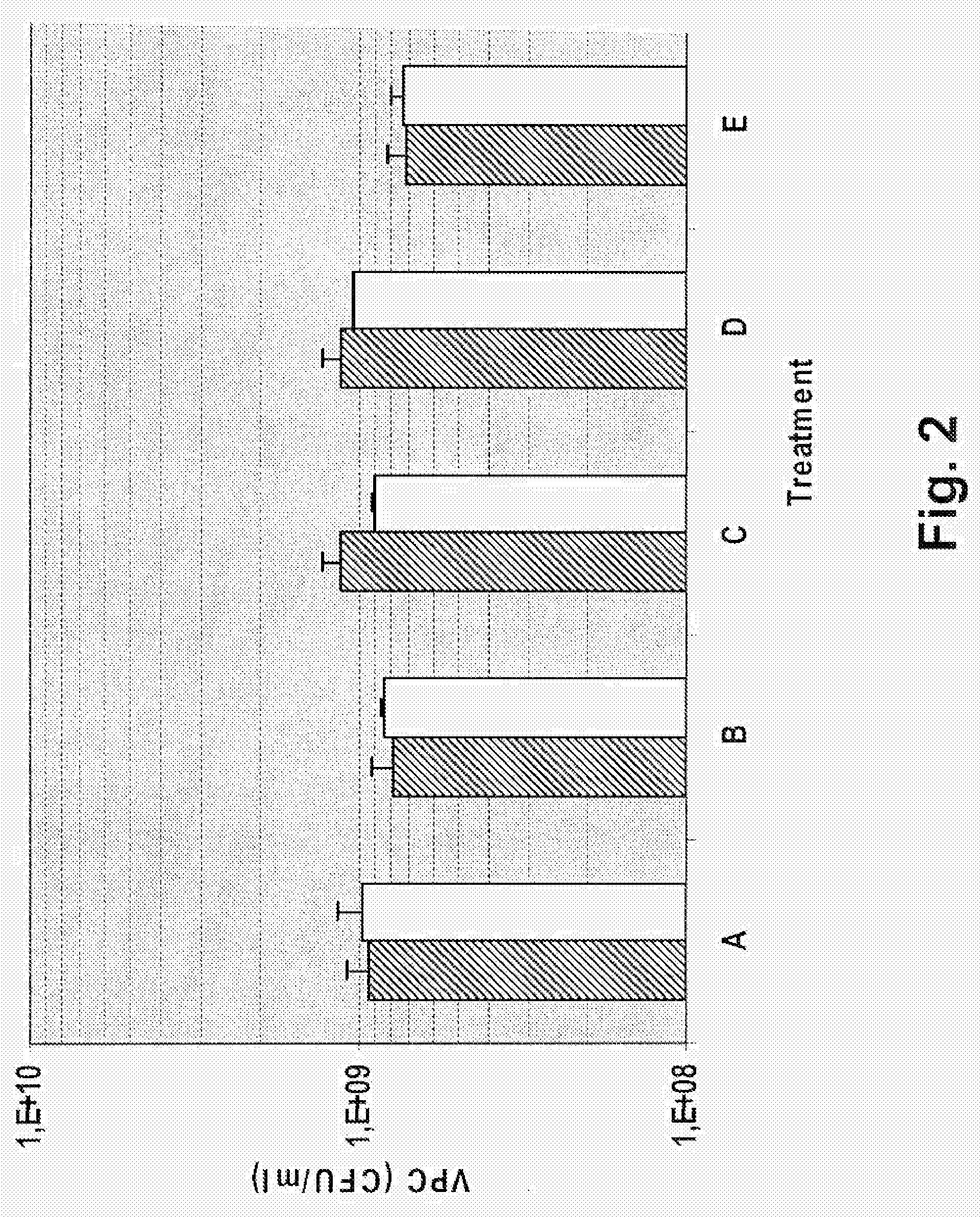

Composition comprising enzymatically digested yeast cells and method of preparing same

The present invention relates to the field of fermentation media. More specifically, the invention provides a method for preparing a composition useful for culturing microbial cells wherein whole and / or autolysed yeast cells are enzymatically treated to obtain the composition. The microbial cultures obtained have increased stability and are useful in the manufacturing of food, feed and as a pharmaceutical product.

Owner:CHR HANSEN AS

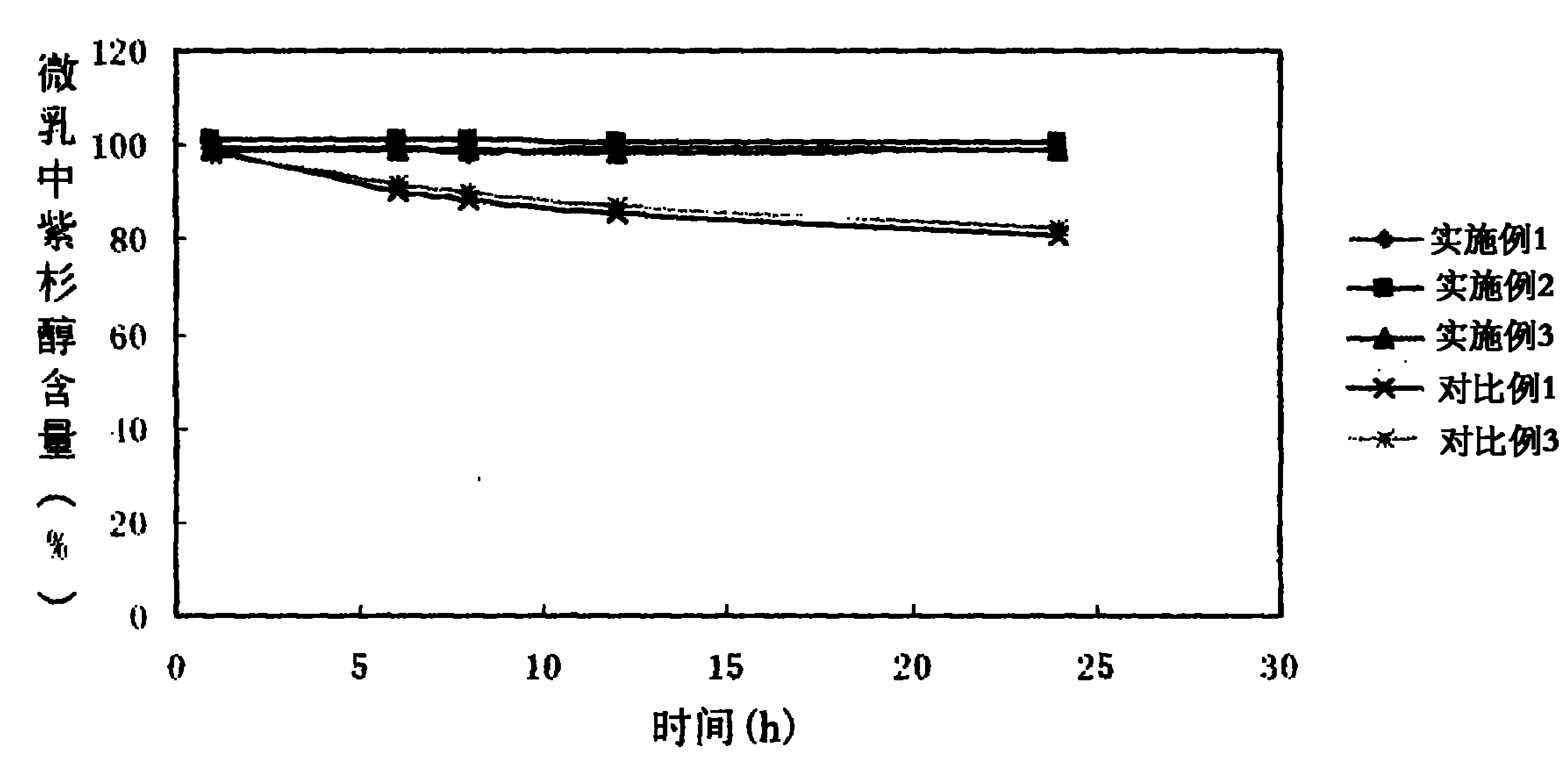

Self-emulsifying preparation of taxane compound and preparation method thereof

ActiveCN101829052ASimple production processEase of industrial productionOrganic active ingredientsEmulsion deliveryPhospholipidSurface-active agents

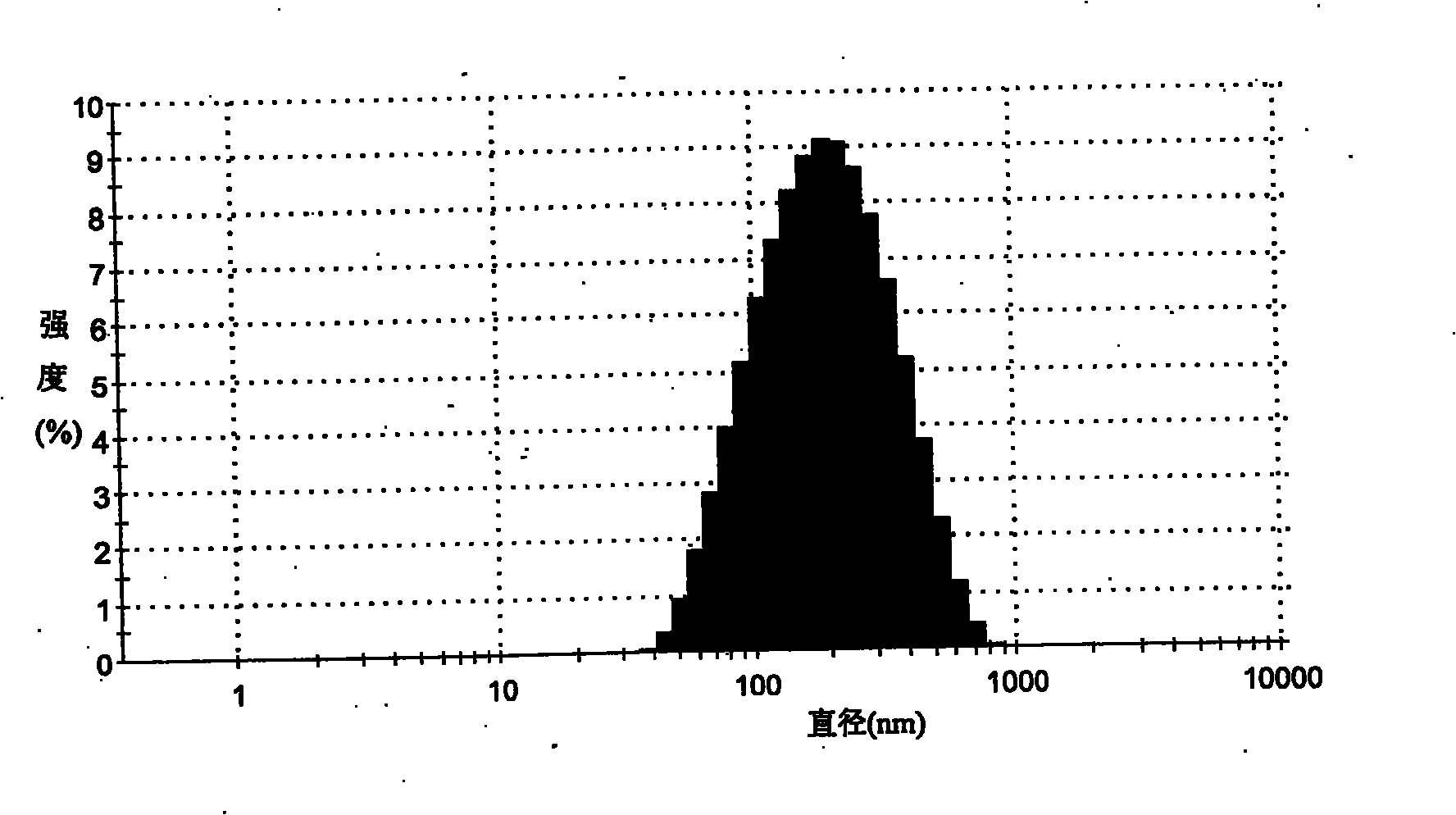

The invention provides a self-emulsifying medical composition for delivering taxane medicaments and a preparation method thereof. The self-emulsifying medical composition is transparent liquid, comprises an effective dose of taxane compound, an oil component, a surface active agent and alcohol and preferentially comprises lactic acid, wherein the surface active agent consists of phospholipid and polyoxyethylenated castor oil. After the self-emulsifying composition is added to a glucose injection, the composition can self-emulsify into micro emulsion the mean grain size of which is 50-300nm, and the micro emulsion can stabilize for more than 12 hours at room temperature. The preferential taxane compound in the invention is taxol.

Owner:YINGU PHARMA

House dust mite allergen, Der p VII, and uses thereof

InactiveUS6077517AModify lymphokine secretion profileDiminution in allergic symptomFungiBacteriaNucleic acid sequencingBULK ACTIVE INGREDIENT

A novel protein allergen Der p VII of Dennatophagoides pteronyssinus is described. A cDNA clone encoding Der p VII was isolated from a lambda gt11 library of D. pteronyssinus cDNA. The nucleic acid sequence of der p VII encodes a 198 residue mature processed protein having a predicted molecular weight of 22,177 daltons. Der p VII protein may be used as the active ingredient in therapeutic composition for the treatment of sensitivity to house dust mites. The protein may also be used in methods of diagnosing such sensitivity.

Owner:MERCK PATENT GMBH

Methods and compositions for egg white protein production

ActiveUS20180355020A1Reduce allergiesImprove digestibilityDough treatmentTransferrinsExpression vectorBiotechnology

Provided herein are compositions, proteins, polynucleotides, expression vectors, host cells, kits, and systems for producing egg white proteins, as well as methods of using the same.

Owner:CLARA FOODS

Tea salt and preparation method thereof

The invention relates to a table salt into which black tea or green tea is added and a preparation method thereof, belonging to the technical field of foods. The table salt is prepared by adding black tea powder or green tea powder of which the tea polyphenol content is 16-26.7 percent into an iodine-free table salt, wherein the total content of the tea polyphenol is 0.1-0.4 g / kg. The table salt prepared with the preparation method is taken as a seasoning, can bring the original nutritional function of black tea or green tea into full play, and has a simple preparation method and low cost.

Owner:JIUDA PINZHONG SALTS SICHUAN +2

Method for producing glucose bulk drug for injection by using rice

ActiveCN102703547AHigh biological potencyImprove saccharification puritySugar derivativesFermentationIon exchangeChemistry

The invention provides a method for producing a glucose bulk drug for injection by using rice. The method comprises the following steps of: soaking and defibrination, size mixing, liquefaction and slag removal, saccharification, primary decoloration and filtration, secondary decoloration and filtration, ion exchange, concentration and refining, primary crystallization, primary centrifugation, sugar solution, sugar concentration and decoloration, secondary sugar boiling and crystallization, secondary centrifugation, drying, packaging and the like. The method has the following advantages: (1), a two-time crystallization process is adopted, the quality is high, and a filtration speed is quick; (2), the problem that a raw material for producing an injection glucose in the south does not existis solved by using the rice as the raw material, and the blank of the production of a crystalline glucose in the south is filled; (3), the crystalline glucose produced by using the rice as the raw material has low-irritability in absorption property and is high in biological value; and (4), a breeding fermentation problem in a production procedure is solved successfully, the sugar concentration and the filtration are added, the quality of a finished product is greatly improved, and the clarity and the filtration speed of the product are guaranteed. The continuous feed and the continuous discharge can be carried out; the crystallization and fermentation contamination is stopped; the quality can be guaranteed; and the continuous production is guaranteed.

Owner:北京佳沃臻诚科技有限公司

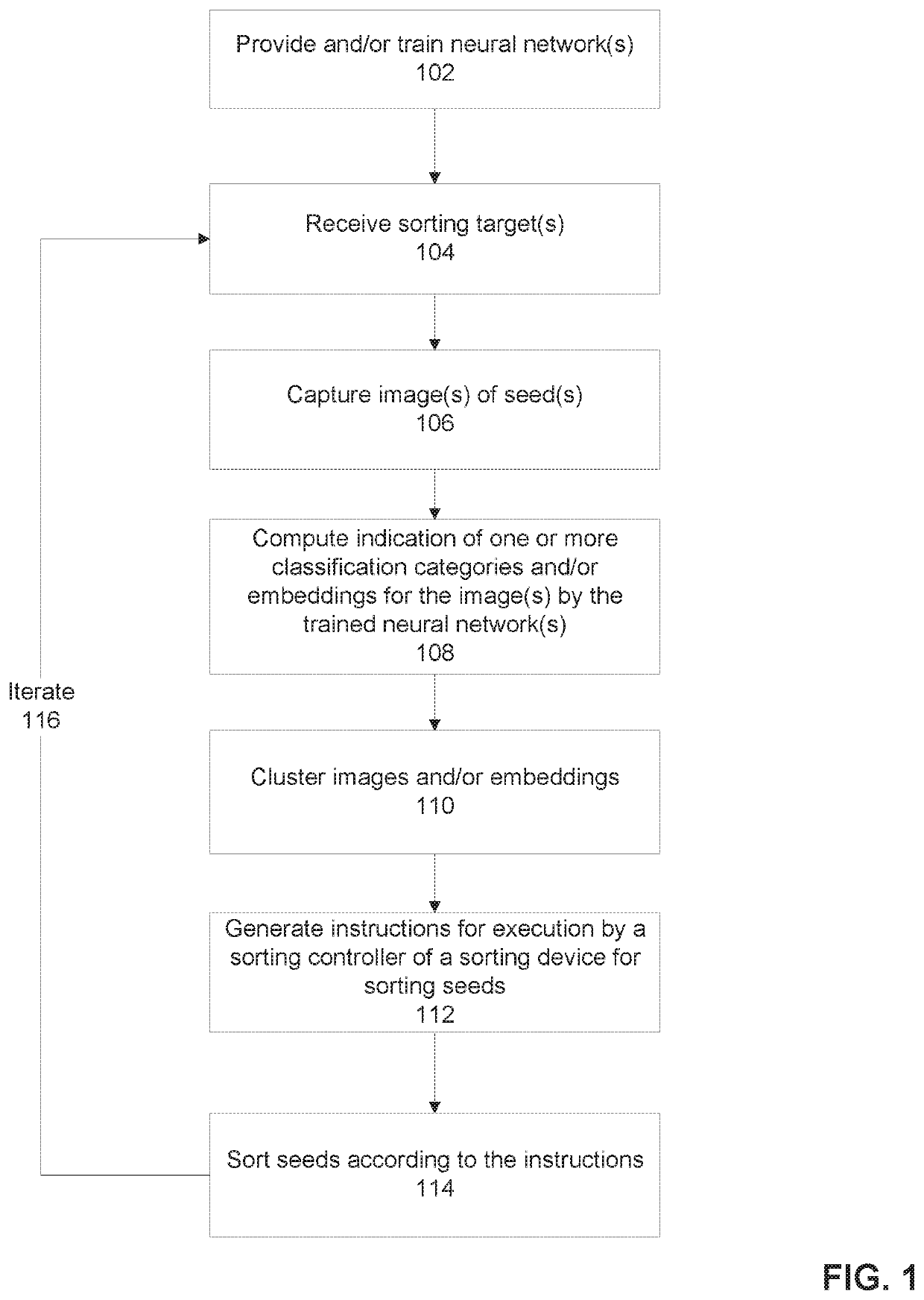

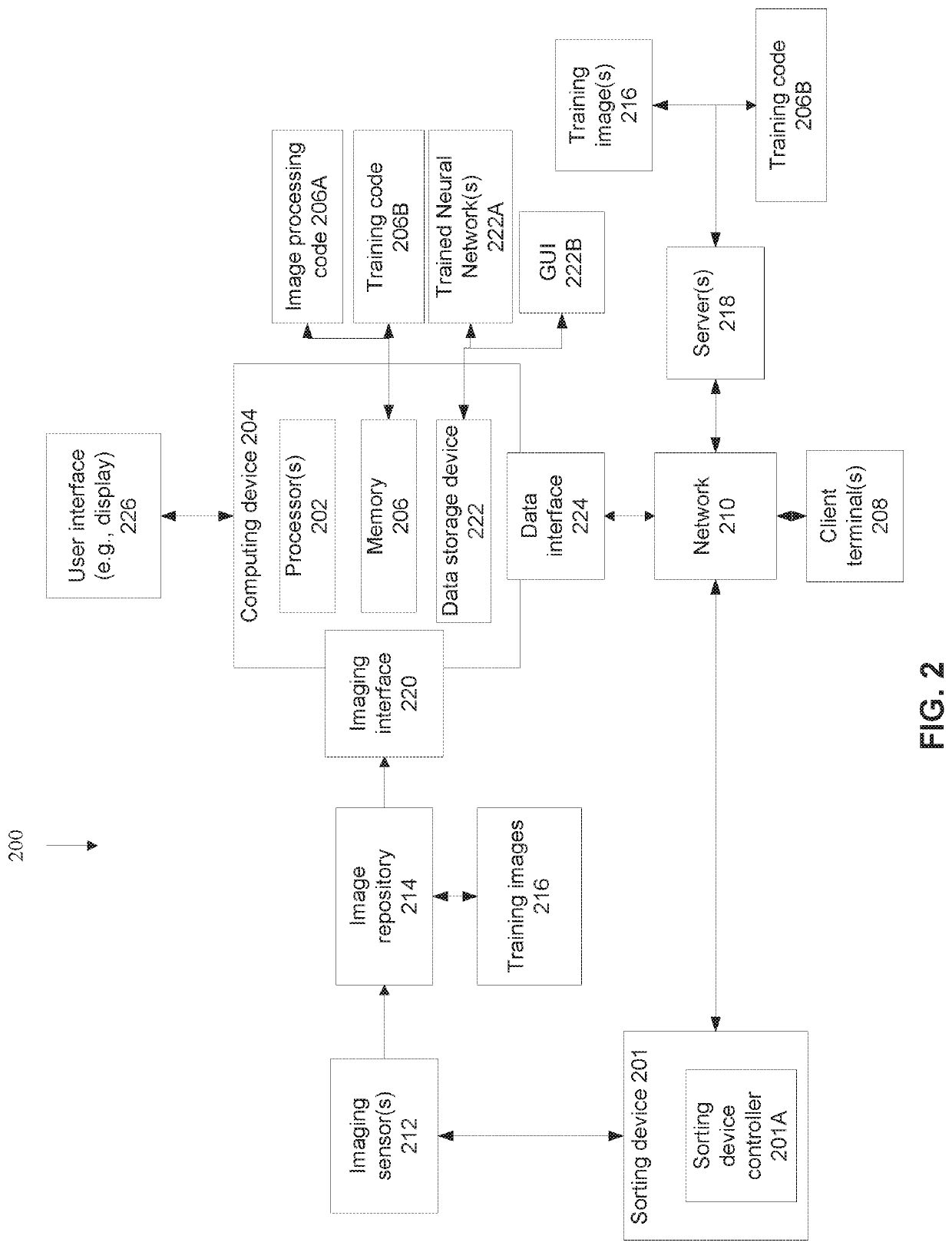

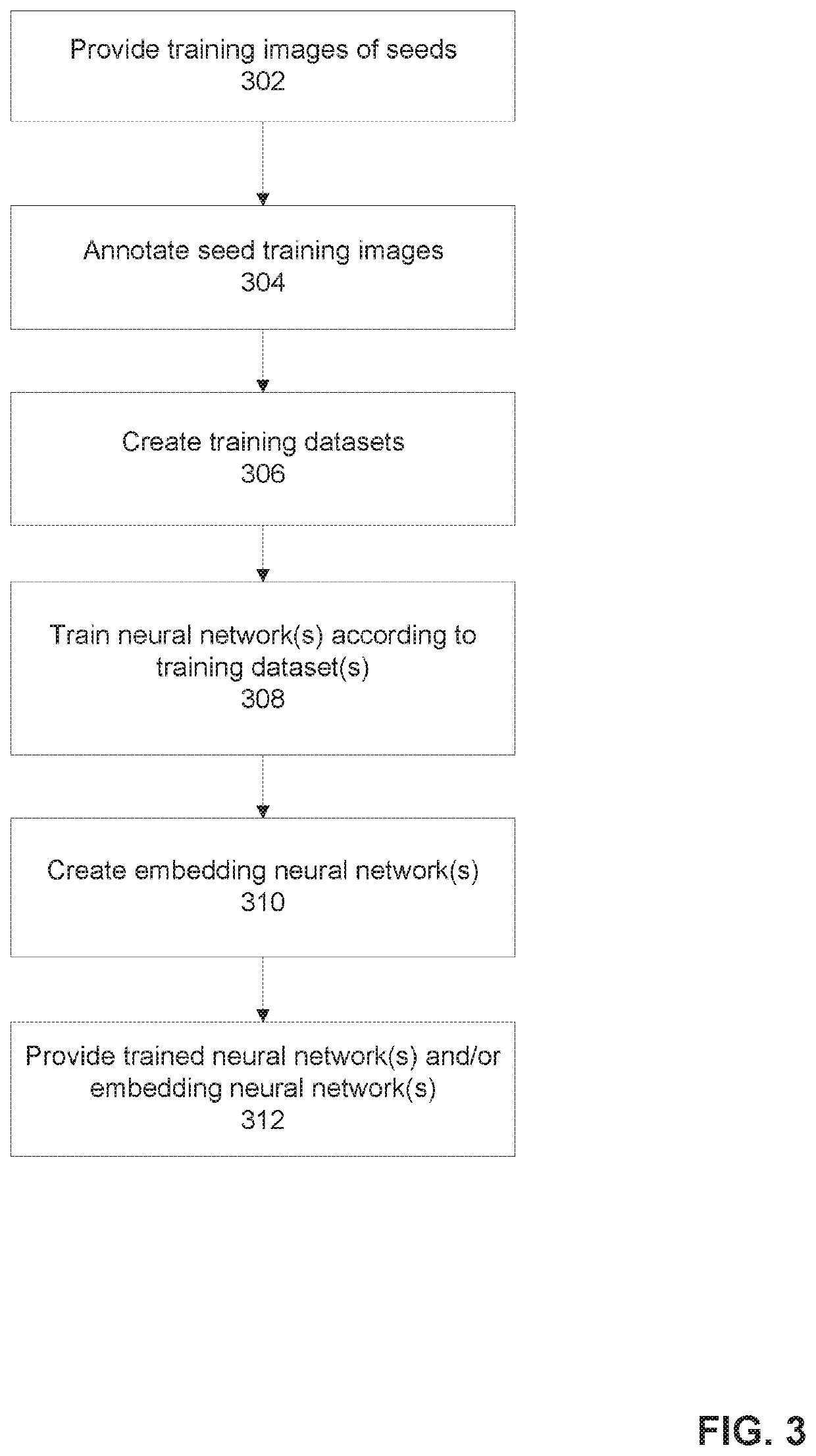

Systems and methods for sorting of seeds

ActiveUS20200338599A1Increase oilIncrease nitrogen use efficiencySeed and root treatmentCharacter and pattern recognitionHorticultureBotany

Owner:SEEDX TECH INC

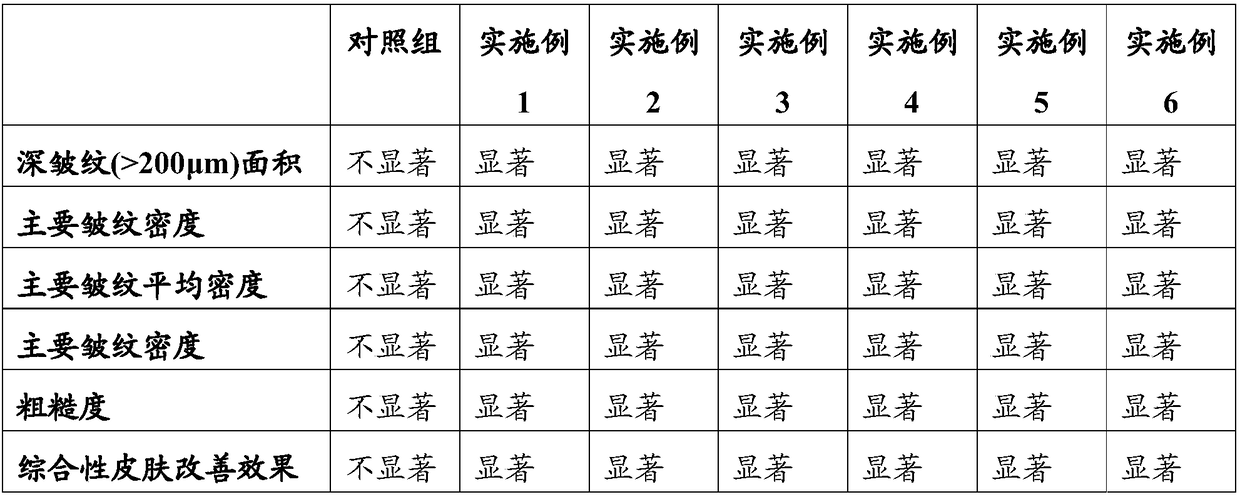

Anti-aging skin care hydrogel facial mask matrix and preparation method thereof

InactiveCN109498481AImprove water retentionExcellent adhesionCosmetic preparationsToilet preparationsWrinkle skinAdditive ingredient

The invention discloses an anti-aging skin care hydrogel facial mask matrix containing various natural extracts and bioactive polypeptide and a preparation method thereof. According to the anti-agingskin care hydrogel facial mask matrix and the preparation method thereof, disclosed by the invention, the hydrogel facial mask matrix is formed by combining a wetting agent with the bioactive polypeptide and various natural extracts according to appropriate using amounts by utilizing the characteristics of compatibility combination of traditional Chinese herbal medicine, good water retention and attachment of hydrogel can be fully expressed, nutritional ingredients in a facial mask can be slowly released so as to be effectively absorbed by skin, allergy can be reduced, multiple functions of moisturizing, water replenishing, inflammation resisting, oxidation resisting, skin repairing and the like are combined, and epidermal tissues can be repaired while nutrition metabolism of the skin is improved and the elasticity of the skin is kept, so that multiple effects of moisturizing, wrinkle resisting and aging resisting can be achieved.

Owner:北京赛尔佳人化妆品有限公司

Maize-fiber cashmere shell-fabric and producing method

InactiveCN101070660AImprove flame retardant performanceSolve brittle, hardWarp knittingHeating/cooling textile fabricsFiberEngineering

The invention relates to a plush shell fabric manufactured by unmixed corn fiber and its production method. It is made by 100 percent corn fiber. Its production way is composed by spinning and dyeing two sections. Said spinning part is that as following: first make corn fiber yarn unreeled and warped; then make corn fiber yarn spun into plush gray fabric according to spinning parameter using warp knitting loom; finally cut it off and pack it. Said dyeing part comprises plush fabric's repacking and suturing the end, pilling, preheating stereotypes, overflowing and scouring at normal temperature, dyeing, cleaning, drying, finalizing the size, scalding brightly, shearing, packing into final goods. And temperature of preheating stereotypes is 115 Deg.C to 130 Deg.C, the time is 20 to 30 seconds; the dyeing temperature is 80 Deg.C to 110 Deg.C, the dyeing time is 30 to 40 minutes; the temperature of stereotype is 115 Deg.C to 130 Deg.C, stereotype time is 20 to 30 seconds. The invention solves the problem of art temperature after corn fiber dyed when arranging it, also solve the problem of corn fiber's crisp, hard and easily fracture.

Owner:SHANGHAI SHUIXING HOME TEXTILE

Decreasing allergenicity of natural latex rubber prior to vulcanization

A method for reducing allergenicity of natural latex rubber. The natural latex rubber, prior to its vulcanization, is admixed with aluminum hydroxide to denature the antigenic protein thus reducing the total protein level considerably. Lignin or fumed silica can also be mixed with the aluminum hydroxide to reduce the protein value in latex. Ideally, the aluminum hydroxide is characterized as having a density of approximately 2.42 g / cm3 and molecular weight of 78.00.

Owner:VYSTAR CORP

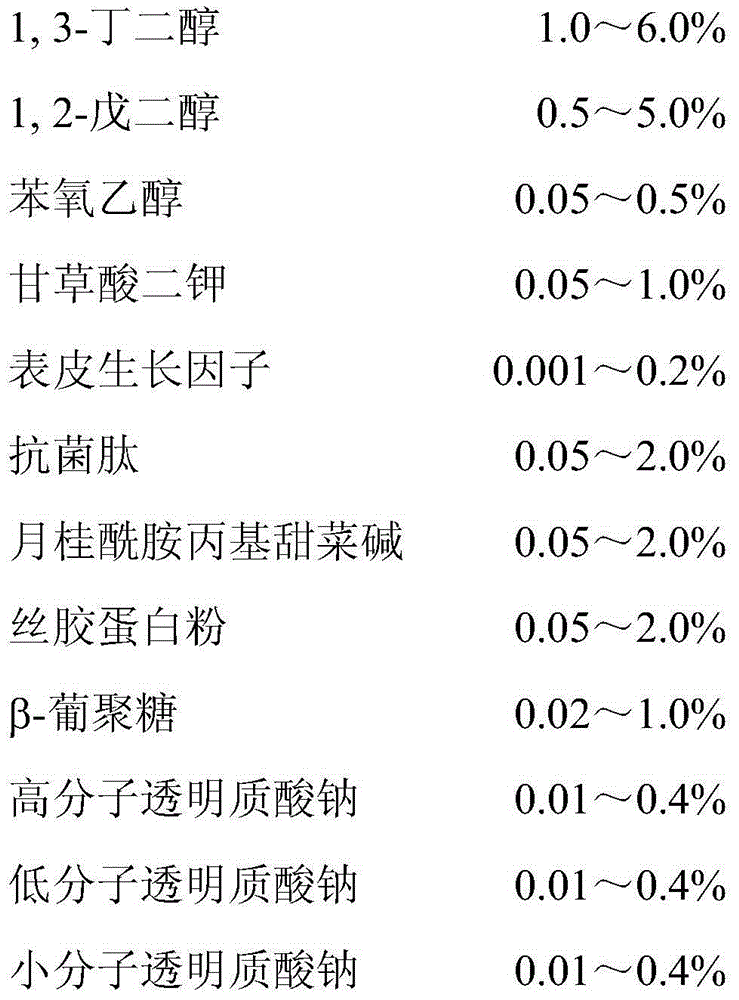

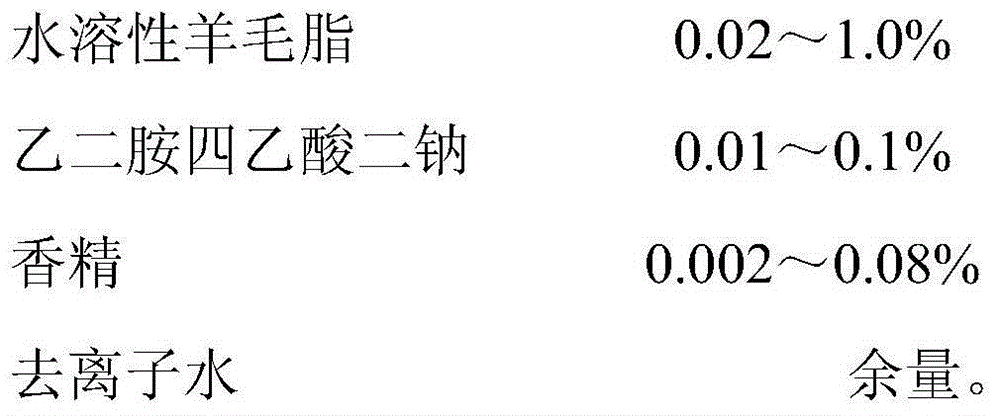

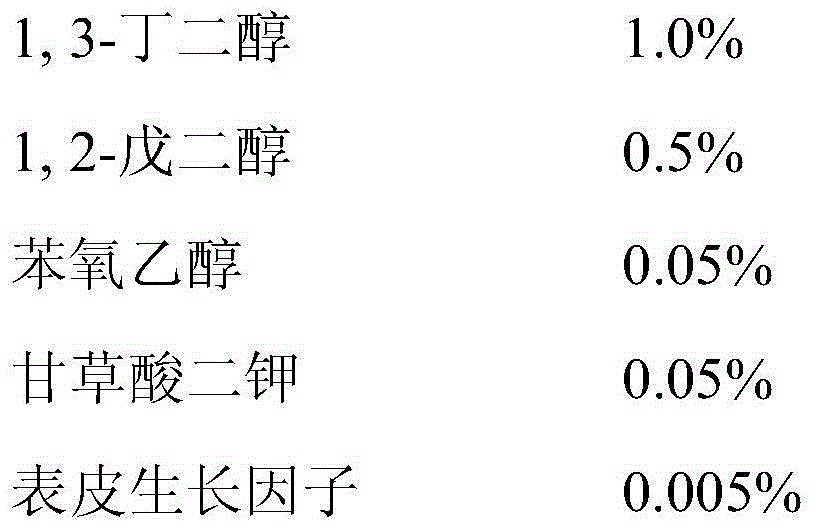

Dry-type film containing antibacterial peptide and epidermal growth factor, as well as preparation method and application thereof

ActiveCN104546560AGrowth inhibitionReduce stimulationCosmetic preparationsToilet preparationsBeta-glucanBULK ACTIVE INGREDIENT

The invention belongs to the technical field of cosmetics, and discloses a dry-type film containing antibacterial peptide and an epidermal growth factor, as well as a preparation method and application. The dry-type film mainly comprises the following active ingredients by weight percentage: 0.05-2.0% of antibacterial peptide, 0.001-0.2% of the epidermal growth factor, 0.01-0.4% of sodium hyaluronate, 0.05-1.0% of dipotassium glycyrrhizinate, 0.05-2.0% of sericin powder and 0.02-1.0% of Beta-glucan. The preparation method comprises the following steps: preparing dry film essence; spraying the dry film essence onto a dry film active ingredient carrier; stoving; packaging. Since the dry-type film does not contain moisture, the growth of fungi is inhibited; chemical preservatives are avoided, the side effect is reduced, and the dry-type film is safe, environment-friendly and long in guarantee period; the weight of a single dry-type film is reduced by 70-85%, and the dry-type film is low in transportation cost, convenient to carry and convenient to use.

Owner:WEIGUAN BIOLOGICAL SCI & TECH GUANGZHOU +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com