Patents

Literature

334 results about "NATURAL LATEX RUBBER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of environment-friendly degradable dust suppressant and preparation method thereof

InactiveCN102277135ANo toxicityNot corrosiveOther chemical processesChemistryEnvironmental resistance

The invention discloses an environmentally friendly biodegradable dust suppressant and a preparation method thereof. The preparation method comprises adding natural latex, natural plant fibers, glycerol and a surfactant into a mixer, stirring fully to mix them well, adding slowly the mixture into water, and stirring fully to obtain the environmentally friendly degradable dust suppressant. The environmentally friendly biodegradable dust suppressant has the functions of film forming, wetting and coagulation, and characteristics of no ash, no toxicity, no corrosivity, no secondary pollution, favorable biodegradability, simple preparation process, and low cost. After being sprayed on the surface of a material, the environmentally friendly biodegradable dust suppressant can form a continuous, intact, strong and ductile shell film to confine dust in a shell, and thus air pollution is avoided and material loss is reduced. The environmentally friendly biodegradable dust suppressant can resist the effects of wind power, rainwater and a general external force, is suitable for dust control of road surfaces, coal piles, ore piles, building sites, heat-engine plants, steel mills and coal transportation by trains, and has broad social and economic benefits.

Owner:宁岱

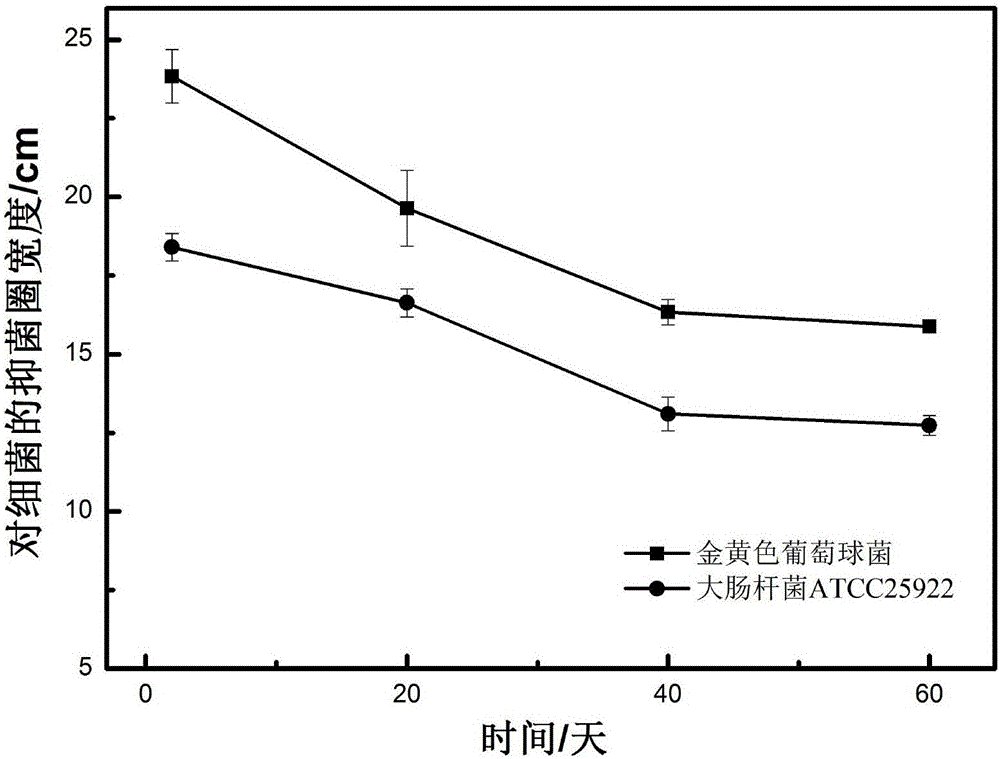

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

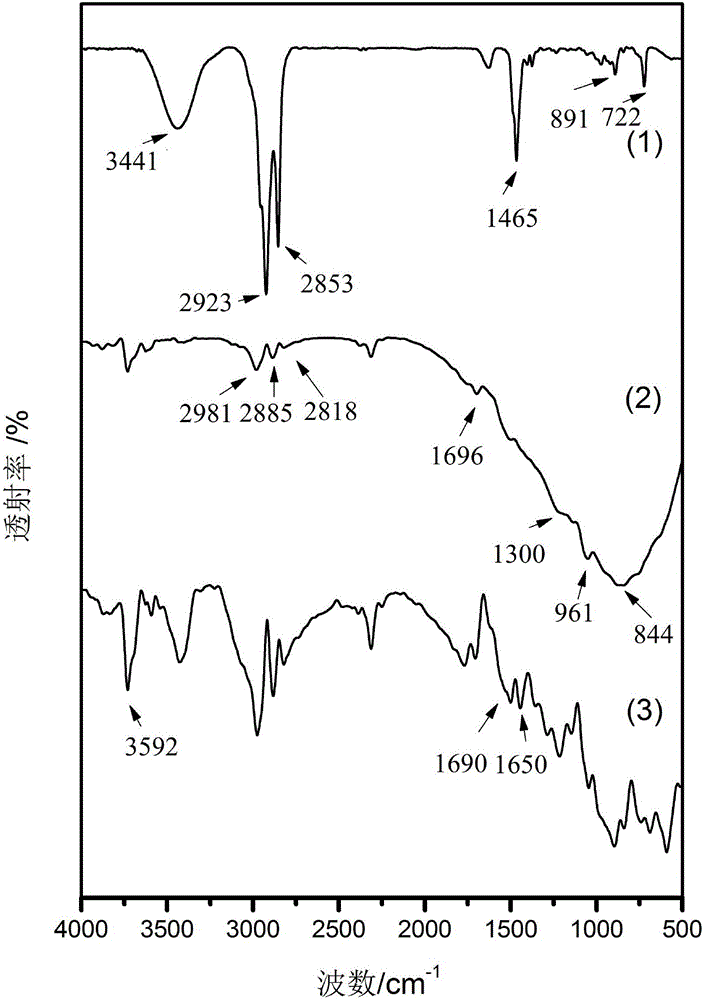

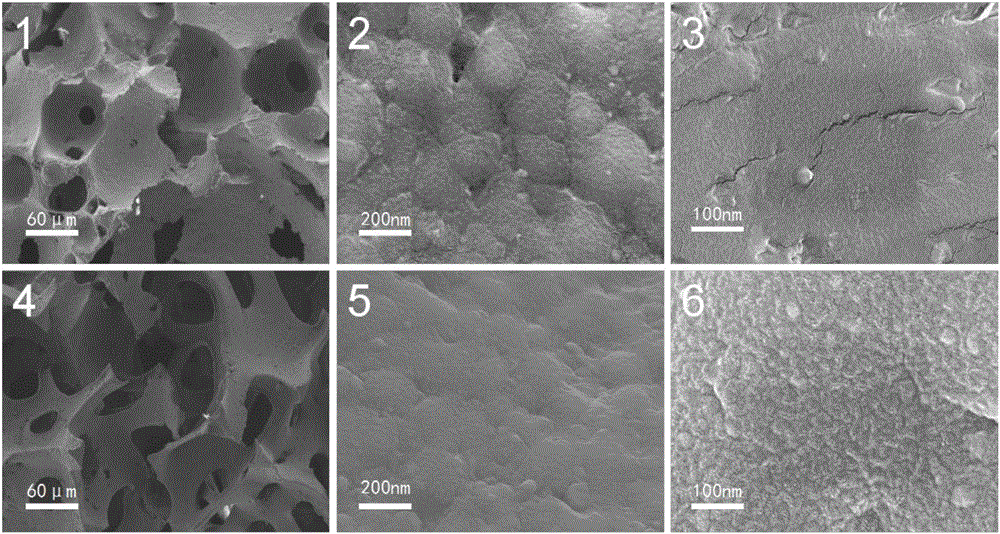

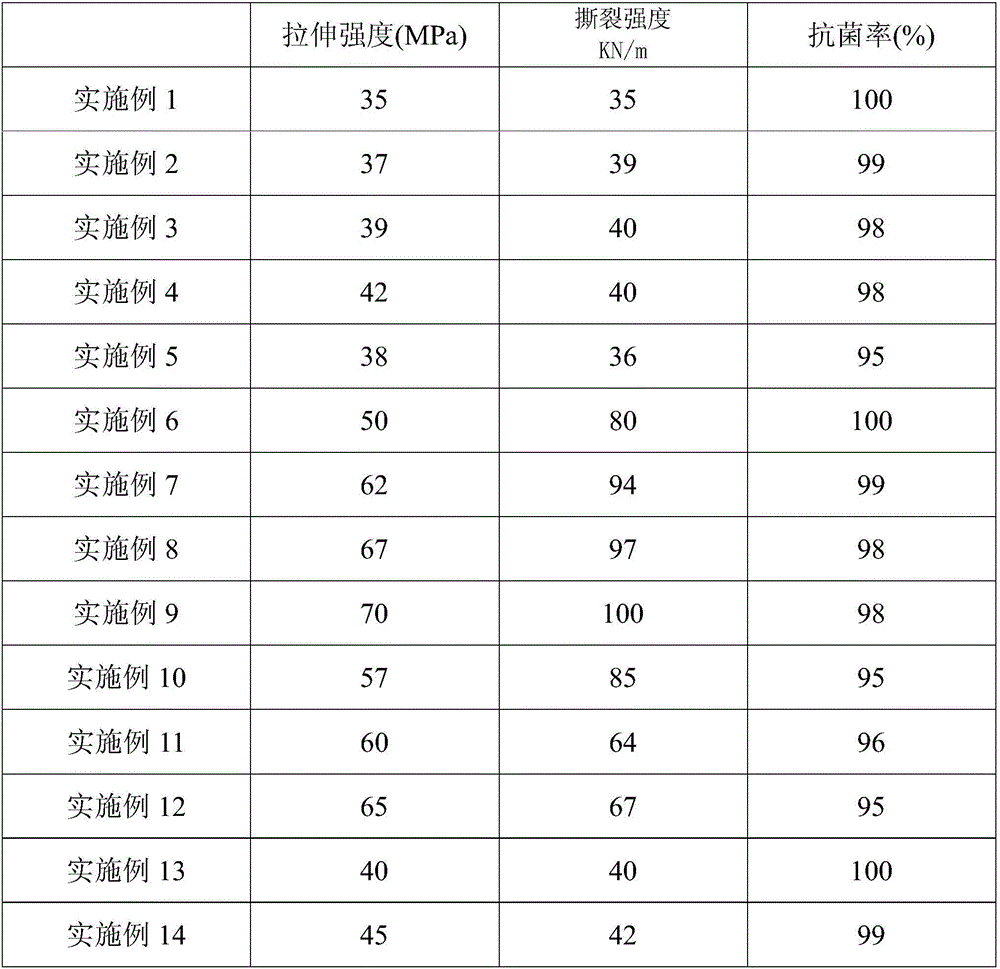

Graphene modified natural latex material as well as preparation method and application thereof

The invention provides a graphene modified natural latex material as well as a preparation method and an application thereof. The method comprises steps as follows: a graphene material and at least one auxiliary required for production of a natural latex product are mixed and ground, and a mixed material is obtained; the mixed material is mixed with natural latex, a mixture is subjected to curing, and the graphene modified natural latex material is obtained. Thegraphene material and the auxiliary are mixed firstly, so that adverse effects of the graphene material on natural latex are avoided, the graphene material is dispersed better, strength, tear resistance and antibacterial property of the material are enhanced, and the graphene modified natural latex material can be used for preparing various latex products.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Negative ion bamboo charcoal latex foamed material and preparation method thereof

The invention discloses a negative ion bamboo charcoal latex foamed material and a preparation method thereof. The foamed material comprises 10 to 15 wt% of natural latex, 60 to 70% of synthetic latex, 1 to 5 wt% of vegetable oleic acid potassium salt, 0 to 2% of castor oil potassium salt, 1 to 5% of aluminum hydroxide, 3 to 5 wt% of sulphur, 5 to 10 wt% of negative ion powder and 1 to 5 wt% of bamboo charcoal powder. According to the invention, a solid foamed material is formed through a foaming process and can be used as a support; since bamboo charcoal powder, negative ion powder, natural latex and synthetic latex are stirred and foamed at the same time, it is guaranteed that all the components undergo a same foaming procedure, so better uniformity and stability are realized; moreover, the foamed material can be poured on a planar conveyer belt except pouring into a die, so a finished product is not restricted by the size and shape of the die, thereby improving production efficiency and substantially reducing cost.

Owner:孙隽毅

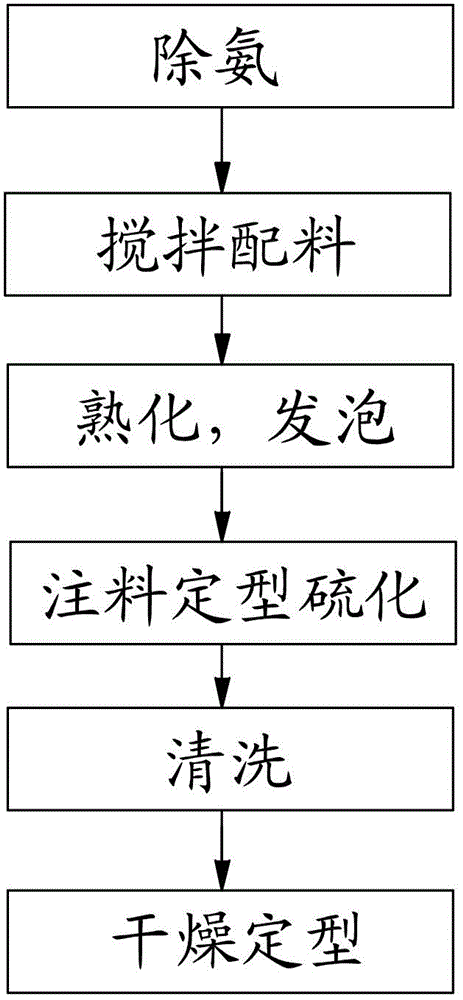

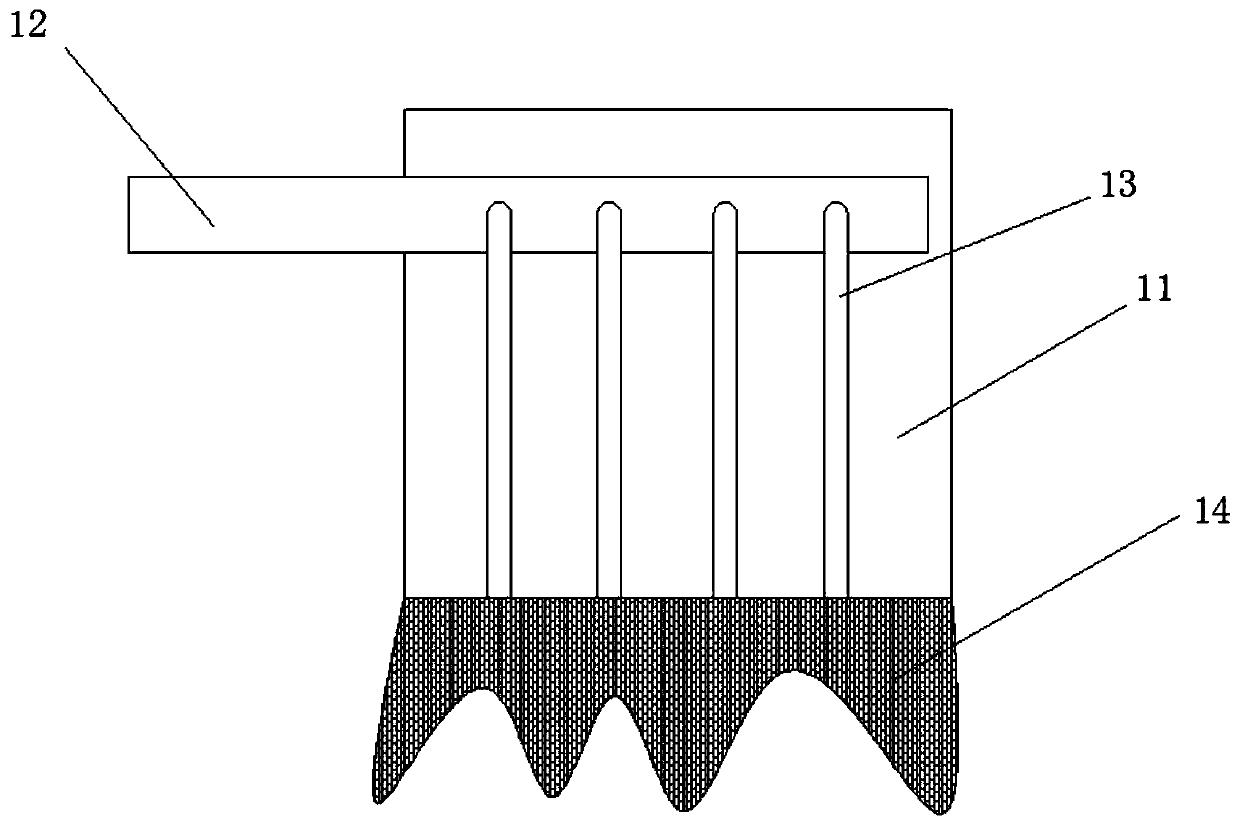

Making technology of natural latex pillow

InactiveCN104400956AReduce stuffinessImprove experienceMetal working apparatusPunchingMaterials science

The invention discloses a making technology of a natural latex pillow. The technology comprises the following steps: mixing raw materials, foaming, putting the obtained foam in a die, heat-curing, punching, forming uniformly distributed micropores on a latex pillow through a needle plate, putting the latex pillow in a heating chamber, introducing high temperature steam, taking out the latex pillow 3min later, cleaning, and drying to obtain the highly breathable latex pillow. The making technology of the natural latex pillow brings the latex pillow with the uniformly distributed micropores in the above mode, so stuffy feeling of the neck and the head during sleep is reduced, fragrance is radiated, and the experience and the satisfaction of clients are improved.

Owner:SUZHOU HEMAS DRESS

Environmental-friendly ventilation type composite natural emulsion product as well as preparation method and application thereof

ActiveCN104987551AImprove toughnessImprove wear resistanceInsolesBrassieresPotassium hydroxideOleic Acid Triglyceride

The invention relates to an environmental-friendly ventilation type composite natural emulsion product as well as a preparation method and application thereof, and belongs to the technical field of emulsion products. The environmental-friendly ventilation type composite natural emulsion product is prepared from the following raw materials in parts by weight: 190-210 parts of natural emulsion, 20-24 parts of sulphur, 11-13 parts of an oxidizer, 1-1.7 parts of a dispersing agent, 95-105 parts of an accelerant, 36-39 parts of a hardener, 2-3 parts of castor oil, 5-7 parts of oleic acid, 1.6-2.4 parts of potassium hydroxide, 14-16 parts of styrene-butadiene co-polymerized rubber emulsion and 130-142 parts of water. The environmental-friendly ventilation type composite natural emulsion product disclosed by the invention not only has favorable ventilation perspiration properties and favorable bacterial inhibition, but also has excellent toughness, excellent wear resistance and favorable density and hardness, so that emulsion products are soft and comfortable, are favorable in hand feel, can effectively protect skins and are environmental-friendly and healthy.

Owner:晋江金飞鞋材有限公司

PET release film

InactiveCN104961869AImprove mechanical propertiesHigh light reflectivityPolymer sciencePolyethylene glycol

The present invention provides a PET release film, wherein the thin film layer comprises, by weight, 100 parts of PET, 8-12 parts of PP, 15-20 parts of barium sulfate, 15-20 parts of titanium dioxide, 3-5 parts of 3-aminopropyltriethoxysilane, 10-16 parts of butyl acrylate, 15-20 parts of methyl methacrylate, 1-2 parts of octadecyl methylacrylate, 10-20 parts of polyethylene glycol, 10-20 parts of ethanol, 20-30 parts of deionized water, 5-10 parts of natural latex, 0.3-0.5 part of a defoamer, and 0.3-0.5 part of a thickener. According to the release film, the thin film layer is added with the barium sulfate and the titanium dioxide inorganic filler, such that the prepared release film has characteristics of excellent adhesion (peel strength), excellent mechanical property, good light-reflecting property, and wide application range.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Latex mattress production process

The invention discloses a latex mattress production process. The process is characterized by comprising the following steps: preparing a latex solution containing negative ion powder, then adding the latex solution, zinc oxide and a coagulant into a foaming device, and foaming to prepare a material A; preparing a latex solution containing magnet powder, then adding the latex solution, zinc oxide and the coagulant into the foaming device, and foaming to prepare a material B; preparing a latex solution containing far infrared ceramic powder, then adding the latex solution, zinc oxide and the coagulant into the foaming device, and foaming to prepare a material C; preparing a latex solution containing ochre powder, then adding the latex solution, zinc oxide and the coagulant into the foaming device, and foaming to prepare a material D; arranging the materials A, B, C and D into the four corners of a mold; and arranging the mold into a steaming box, and steaming. The latex mattress produced by the production process is the same as the purely natural latex product, and due to the reasonable addition of the ochre powder, the far infrared ceramic powder, the magnet powder and the negative ion powder, the latex mattress has the health care effects of capability of suppressing hyperactive liver for calming endogenous wind, far infrared emission, magnet therapy and negative ions.

Owner:佛山市旗盛海绵有限公司

Method for modifying natural latex by aqueous polyurethane

Owner:QINGDAO WINCHANCE TECH

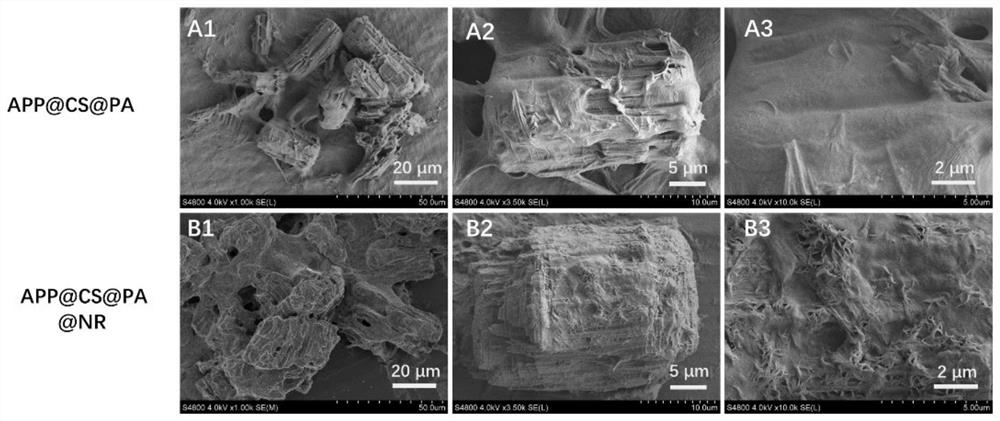

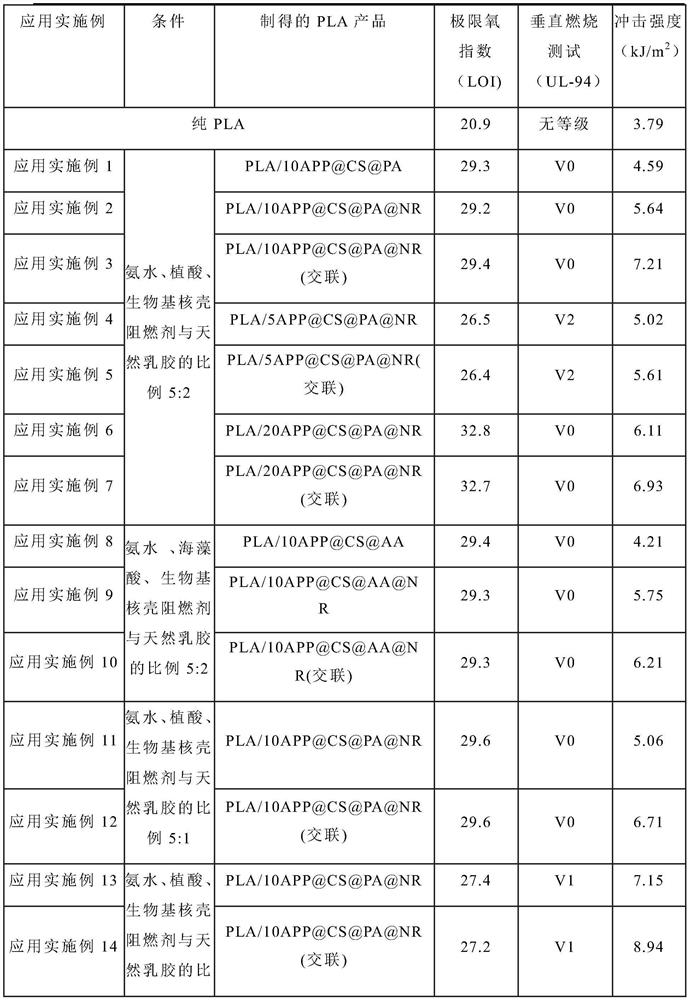

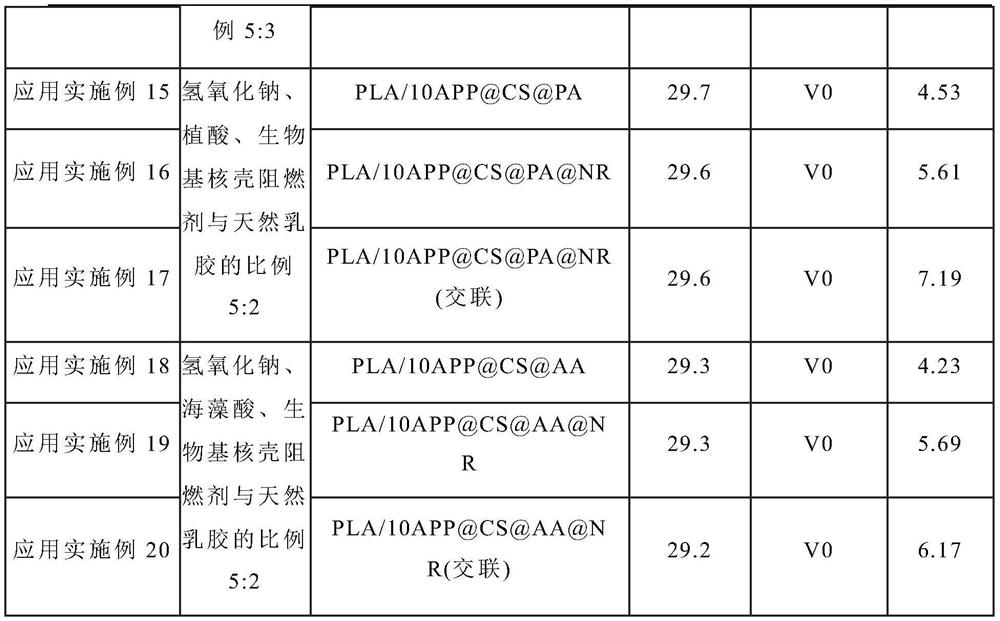

Bio-based intumescent flame retardant with dual functions of flame retardance and toughening as well as preparation method and application of bio-based intumescent flame retardant

The invention relates to a bio-based intumescent flame retardant with dual functions of flame retardance and toughening and a preparation method of the bio-based intumescent flame retardant, and belongs to the technical field of flame retardance. The flame retardant comprises a bio-based core-shell flame retardant and natural latex coating the outer surface of the bio-based core-shell flame retardant, the bio-based core-shell flame retardant takes ammonium polyphosphate as a core, and the outer layer of the core sequentially comprises a first shell chitosan layer and a second shell bio-based acid layer. The bio-based intumescent flame retardant disclosed by the invention integrates flame retardance and toughening, and meanwhile, has relatively good flame retardance and toughening property;most of the raw materials come from biomass resources and return to nature after being degraded; non-biomass resource ammonium polyphosphate is degraded into a fertilizer, the preparation process iseasy to process, an organic solvent is not needed, and the fertilizer is non-toxic and pollution-free; and the bio-based intumescent flame retardant disclosed by the invention is added into bio-basedpolyester, especially polylactic acid, so that the impact property of PLA is greatly improved while the flame retardance is ensured.

Owner:浙大宁波理工学院

Degradable highly-elastic sponge and preparation technology thereof

The invention relates to degradable highly-elastic sponge and a preparation technology thereof. The degradable highly-elastic sponge and the preparation technology thereof have the advantages that thedegradable highly-elastic sponge is made of green, natural and healthy materials according to the environment-friendly preparation technology, harmless to human bodies and capable of avoiding resource waste and environment pollution, and its mechanical properties including rebound resilience and compression set value are in compliance with the international standards; through adoption of recyclable pineapple fibers, resource waste is reduced and physical properties of low-density sponge with natural latex matrixes are improved to comply with the international standards; sodium alcohol ether sulphate and sodium lauryl sulfate which serve as foaming agents substitute for traditional pollutional ones to further avoid pollution; the high-performance low-density sponge with the excellent mechanical properties can be produced at a low preparation cost; the preparation technology is safe, simple and environment friendly.

Owner:德清舒华泡沫座椅有限公司

Environmental protection type aqueous release film

InactiveCN104961902AHigh tensile strengthDecontaminationNatural rubber coatingsPolyurea/polyurethane coatingsEmulsionPolyvinyl alcohol

The present invention provides an environmental protection type aqueous release film, which comprises a thin film layer and a release layer positioned on the thin film layer, wherein the release layer comprises, by weight, 35-45 parts of an aqueous polyethylene wax emulsion, 45-55 parts of an aqueous polyurethane emulsion, 20-30 parts of an aqueous modified polyvinyl alcohol solution, 5-10 parts of natural latex, 3-5 parts of a silane coupling agent, 0.3-0.5 part of a defoamer, and 0.3-0.5 part of a thickener, and the aqueous modified polyvinyl alcohol solution comprises, by weight, 100 parts of polyvinyl alcohol, 700-800 parts of deionized water, and 30-50 parts of modified calcium carbonate. The release film of the present invention is the aqueous environmental protection type release film, has characteristics of good peel strength and good stretching strength, and is the release film having the good comprehensive performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

Method for preparing nano montmorillonite modified natural emulsion medical product

InactiveCN1821289AImprove aging resistanceImprove tensile propertiesMale contraceptivesDiagnosticsPolymer scienceMedical product

The present invention discloses the preparation process of nanometer montmorillonite modified natural latex for medical product. Montmorillonite, which may be natural montmorillonite mineral, nanometer montmorillonite, organic montmorillonite treated with C12-C18 alkyl trimethyl ammonium chloride or ammonium bromide or nanometer montmorillonite through mechanical and chemical grinding, is added into natural rubber latex in the sulfurizing or cooperating stage, and through the subsequent dispersion, pressurizing or dipping, washing, filtering and sulfurizing drying, the modified product is obtained. The present invention has simple technological process, and the prepared medical product has excellent ageing resistance, high tensile and breaking strength, and good microbe permeation resistance.

Owner:JINAN UNIVERSITY

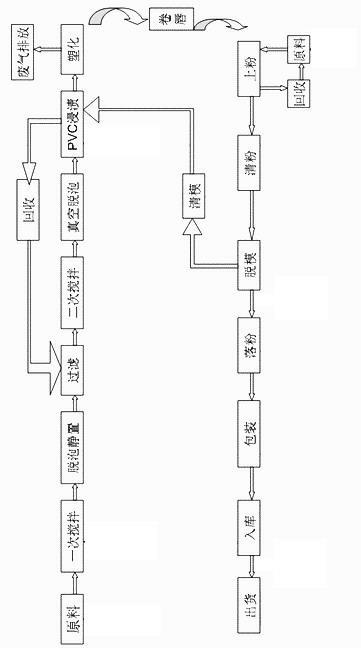

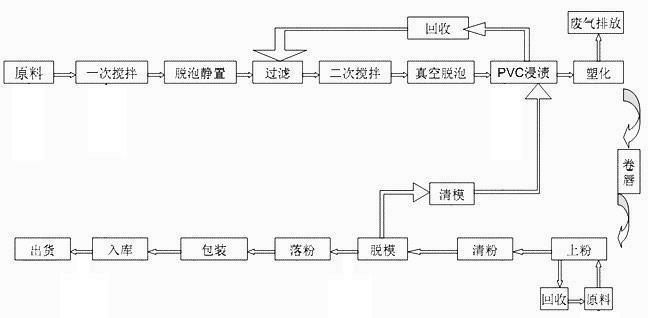

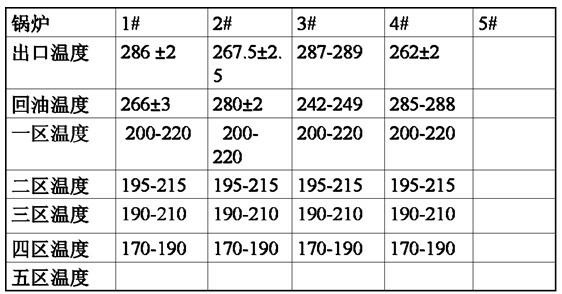

Nutritional skin-care skin-moisturizing powder-containing polyvinyl chloride (PVC) glove and manufacturing method thereof

The invention discloses a manufacturing method of a nutritional skin-care skin-moisturizing powder-containing polyvinyl chloride (PVC) glove, which comprises the following steps: preparing materials, filtering, defoaming under vacuum, immersing, dropping, plasticizing, cooling, rolling edge, preparing powder, adhering powder and demoulding. The method is characterized in that: collagen and vitamin E are added during material preparation; and submicron wall-broken powder of pearl powder, dandelion, witch hazel, aloe, peach blossom and pear blossom is added into corn starch in a powder adhering process. The glove has the advantages of overcoming the drawbacks of the conventional PVC gloves, integrating sanitation, environment protection, safety, nutrition, skin care and skin moisturizing, offering comfortable wear and flexible use experience, avoiding any natural latex components and avoiding causing allergic reaction, along with good nutritional skin-care and skin-moisturizing functions.

Owner:辽宁尚威医疗用品有限公司

Photo-thermal conversion polymer solar energy absorbing material as well as preparation method and application thereof

PendingCN111892742AExcellent thermal positioning insulation performanceIncrease elasticitySolar heating energyGeneral water supply conservationPolymer scienceLatex rubber

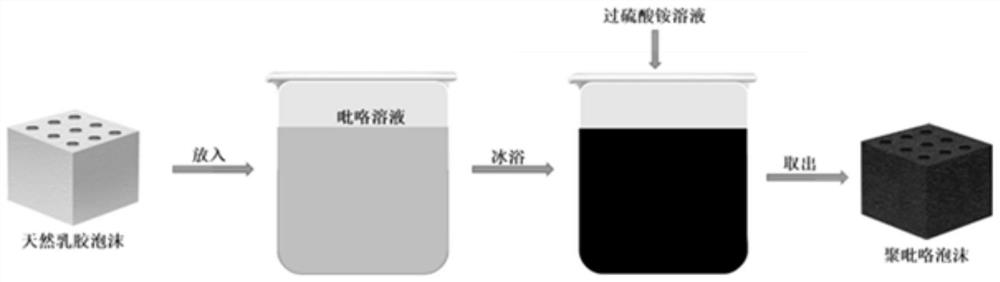

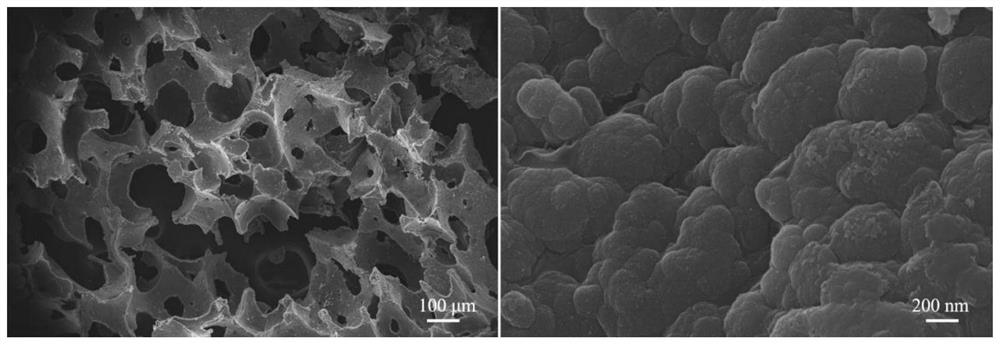

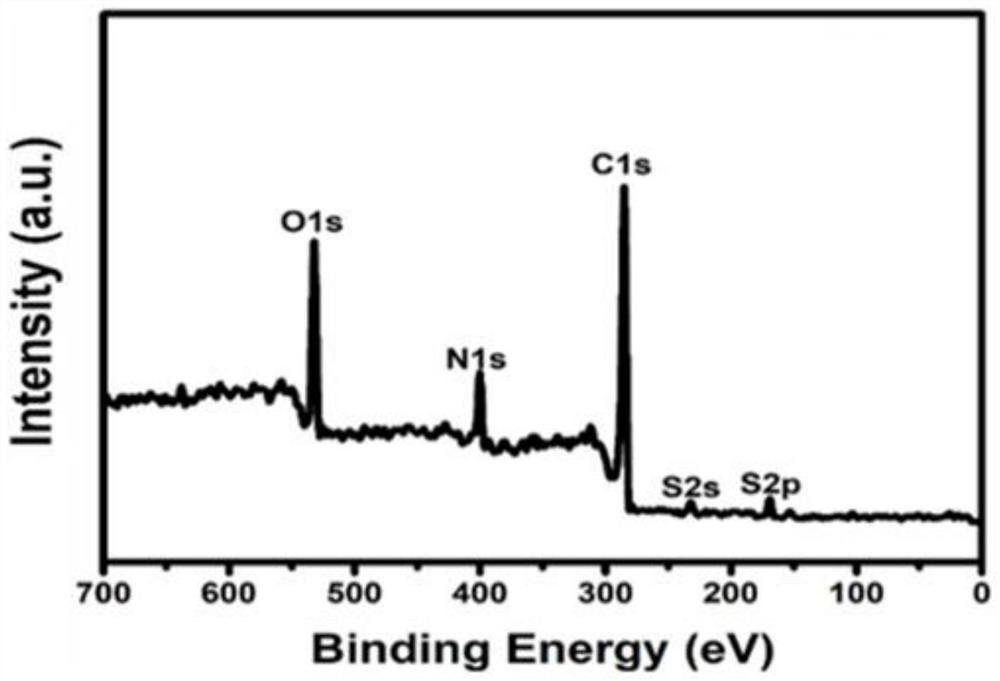

The invention belongs to the technical field of nano composite materials, and relates to a photo-thermal conversion polymer solar absorbing material as well as a preparation method and application thereof. The method comprises the following steps of: 1) obtaining a clean and dry natural latex foam material; and 2) soaking the natural latex foam in the step 1) in a pyrrole solution, dropwise addingan ammonium persulfate solution into the pyrrole solution under an ice bath condition, and carrying out full reaction until the solution and the natural latex foam become black, thereby obtaining thephoto-thermal conversion polymer solar absorbing material. The obtained absorbing material is placed in water, and solar water evaporation can be carried out under illumination.

Owner:HUBEI UNIV

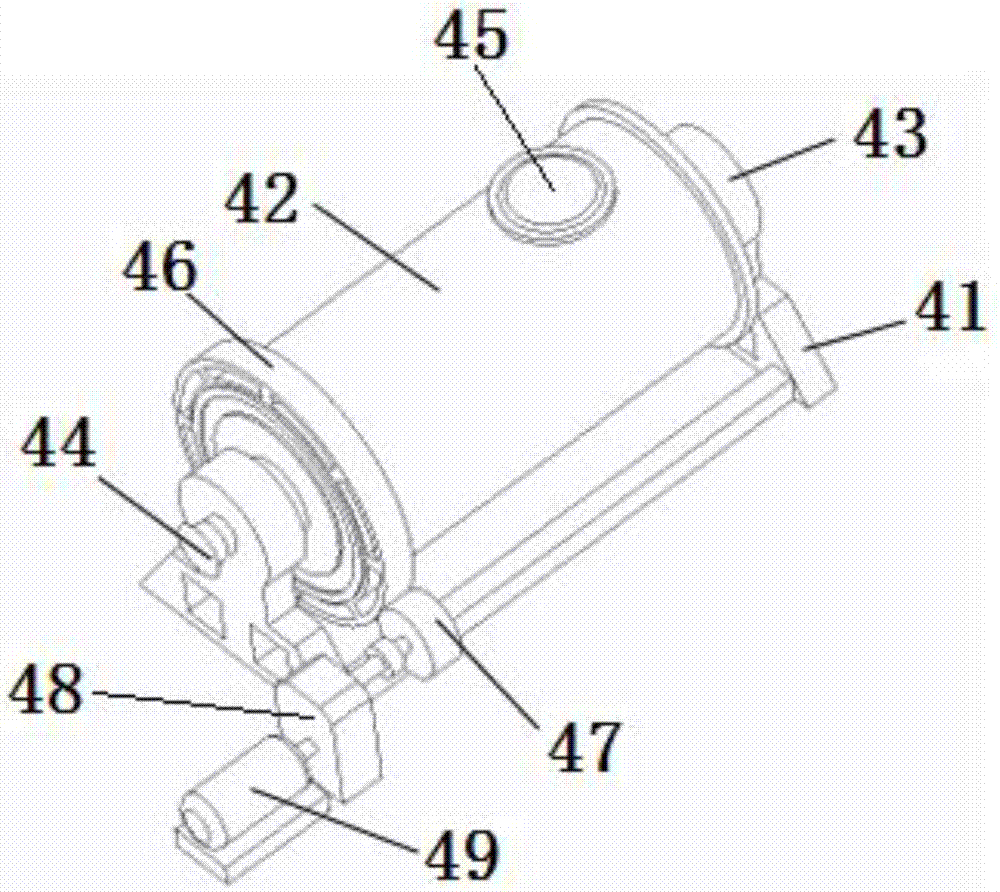

Packing emulsion atomization drying continuous production equipment

ActiveCN107325305AQuality improvementImprove performanceDrying solid materials with heatChemical industryMasterbatchEmulsion

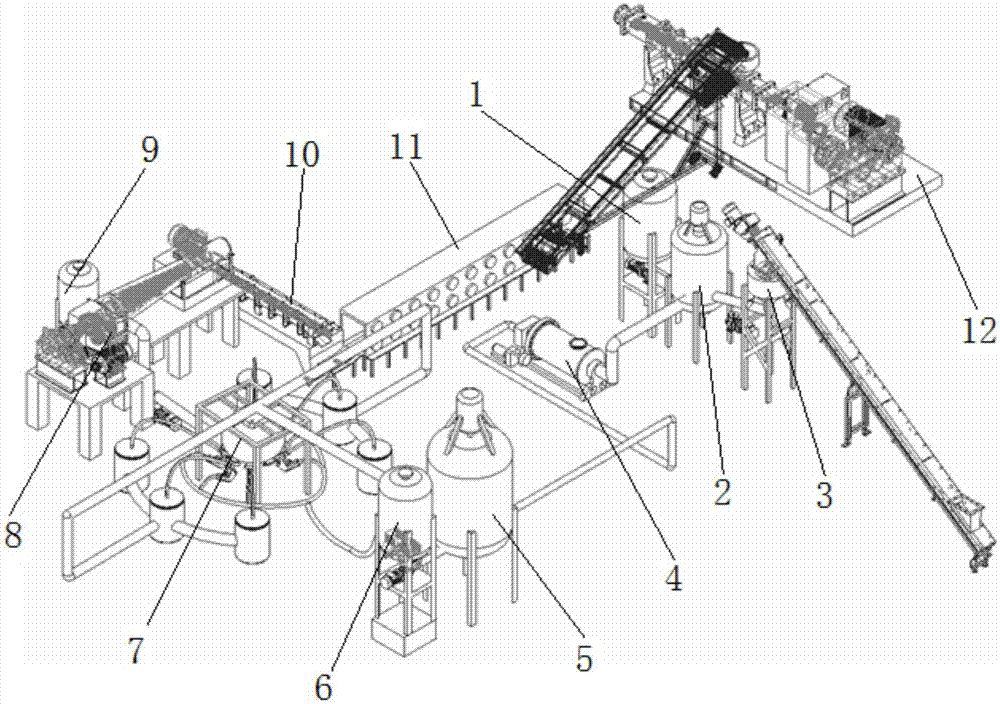

The invention belongs to the technical field of rubber wet-method mixing equipment, and relates to packing emulsion atomization drying continuous production equipment which comprises a main structure, wherein the main structure comprises a first water storage tank, a stirring tank, a conveying weighing device, a continuous liquid-phase grinding machine, a packing latex stirring tank, a pretreatment latex tank, a high-pressure atomization ejection device, a roller scraper device, a second water storage tank, a secondary double-screw dehydration device, a drying device and a double-rotor continuous mixing machine, wherein the continuous liquid-phase grinding machine is used for grinding and crushing an aqueous packing dispersion; the high-pressure atomization ejection device is used for performing high-pressure atomization ejection on packing emulsion-natural latex slurry; the secondary double-screw dehydration device is used for performing drying, primary dehydration and secondary dehydration on packing-natural latex slurry, and masterbatch pieces are extruded by using a molding machine; the masterbatch pieces are conveyed into the drying device; and masterbatch and a complexing agent are continuously and quantitatively adding into rubber by using the double-rotor continuous mixing machine, continuous mixing is carried out, and mixed rubber is extruded out.

Owner:QINGDAO UNIV OF SCI & TECH

Alkylated glass mold for producing waterborne polyurethane condoms and waterborne polyurethane condom production method

InactiveCN106541529AMature production processLow costDomestic articlesCoatingsEmulsionSurface modification

The invention discloses an alkylated glass mold for producing waterborne polyurethane condoms. The alkylated glass mold is obtained by conducting alkylating treatment on the surface of a glass mold by adopting an alkylating agent. A method for producing waterborne polyurethane condoms by utilizing the alkylated glass mold comprises the steps that 1, a surface tension regulating agent is added to a waterborne polyurethane emulsion to regulate the surface tension of the waterborne polyurethane emulsion to reach 25-35 mN / m; 2, the alkylated glass mold is immersed into the waterborne polyurethane emulsion in the step 1 and then is taken out, and drying, edge curling and mold release are performed to obtain the waterborne polyurethane condoms. An existing mature glass mold for natural latex condoms can be directly adopted to perform surface modification, the glass mold is low in cost, surface alkylating operation is simple, a coating is durable, and mold release and edge curling of the alkylated glass surface become easy after glue film drying. It is proved through practice that industrialized production of the waterborne polyurethane condoms can be achieved, and the process is stable.

Owner:LANZHOU KETIAN HEALTH TECH CO LTD

Polycarbonate release film

InactiveCN104945875AImprove water resistanceGood solvent resistancePolymer sciencePolyethylene glycol

The present invention provides a polycarbonate release film, wherein the thin film layer comprises, by weight, 100 parts of PC, 10-15 parts of PTFE powder, 10-20 parts of TPX, 5-10 parts of nanometer silica, 3-5 parts of 3-aminopropyltriethoxysilane, 10-16 parts of butyl acrylate, 15-20 parts of methyl methacrylate, 1-2 parts of octadecyl methylacrylate, 10-20 parts of polyethylene glycol, 5-10 parts of natural latex, 0.3-0.5 part of a defoamer, and 0.3-0.5 part of a thickener. According to the present invention, the thin film layer of the release film uses the PC, the PTFE and the TPX as the compounding components and is added with the nanometer silica, and the prepared release film has characteristics of excellent peel strength, excellent water resistance, excellent mechanical property, excellent solvent resistance, excellent high temperature performance and excellent chemical resistance, and provides wide application range compared with the conventional release film.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

OPP release film

InactiveCN104945731AGood weather resistanceHigh tensile strengthSynthetic resin layered productsPolymer sciencePolyvinyl alcohol

The present invention provides an OPP release film, wherein the thin film layer comprises the following components: OPP, OPP weathering resistance masterbatch, nanometer silica, 3-aminopropyltriethoxysilane, butyl acrylate, methyl methacrylate 15, octadecyl methylacrylate, polyethylene glycol, ethanol, deionized water, natural latex, a defoamer and a thickening agent, the release layer comprises the following components: an aqueous polyvinyl acetate emulsion, an aqueous polyurethane emulsion, an aqueous modified polyvinyl alcohol solution, natural latex, 3-aminopropyltriethoxysilane, a defoamer and a thickening agent, and the aqueous modified polyvinyl alcohol solution comprises polyvinyl alcohol, deionized water, and modified calcium carbonate. The release film of the present invention has characteristics of good peel strength, good mechanical property, and good weather resistance, and is the release film having the good comprehensive performance.

Owner:JIXIANGBAO TAICANG RELEASE MATERIAL TECH CO LTD

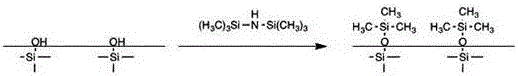

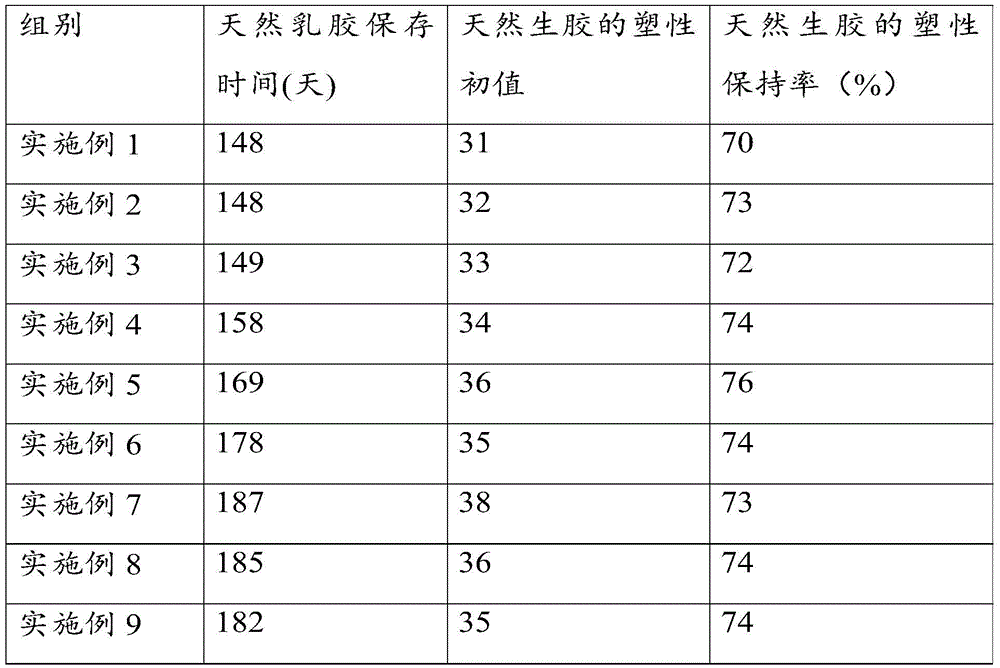

Natural latex preserving method and prepared latex product

The invention relates to the technical field of natural latex, and in particular, relates to a natural latex preserving method and a prepared latex product. The natural latex preserving method comprises that bamboo charcoal is added in natural latex for preservation. The natural latex preserving method provided by the invention adopts the bamboo charcoal for preserving the natural latex, so that an ammonia stabilizer cannot be added in the natural latex or can be added with a little amount, no ammonia or low ammonia preservation is implemented, the preserved natural latex has relatively small pungent odor or even has no pungent odor, and moreover, the preservation shelf life is not affected. The latex product provided by the invention has antibacterial and bacteriostasis functions, and has small pungent odor and long preservation shelf life. In addition, the latex product provided by the invention also has a far infrared function, and can promote microcirculation of a human body; and moreover, the latex product has excellent mechanical properties, adsorption function and moisture absorption and sweat releasing functions, has excellent application performance, and is beneficial for wide application of the natural latex.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

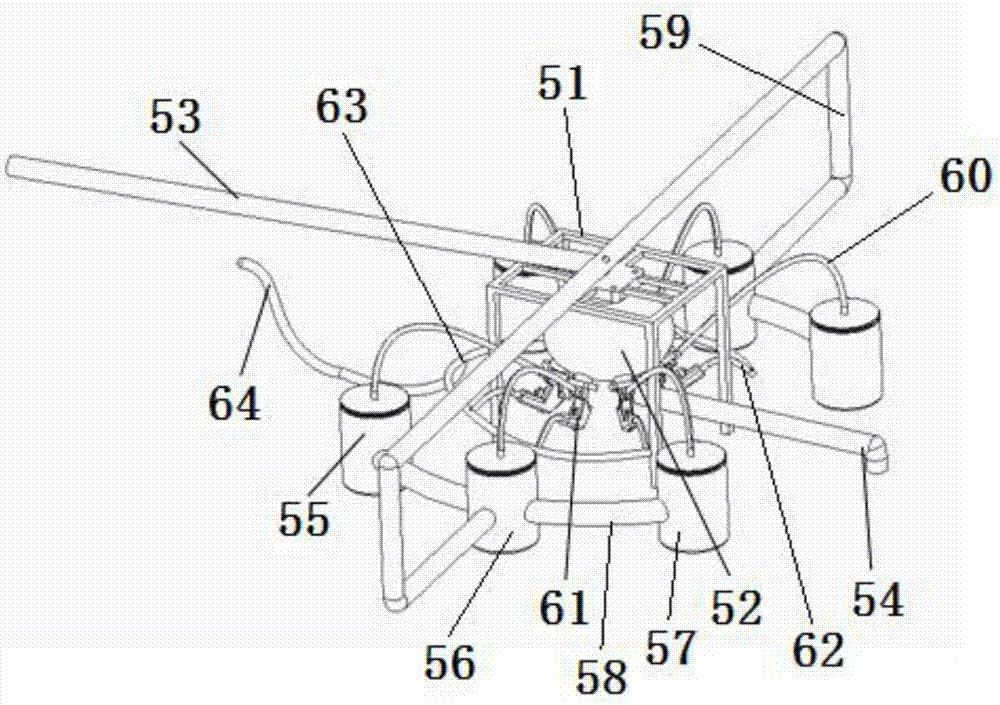

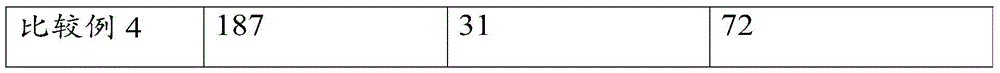

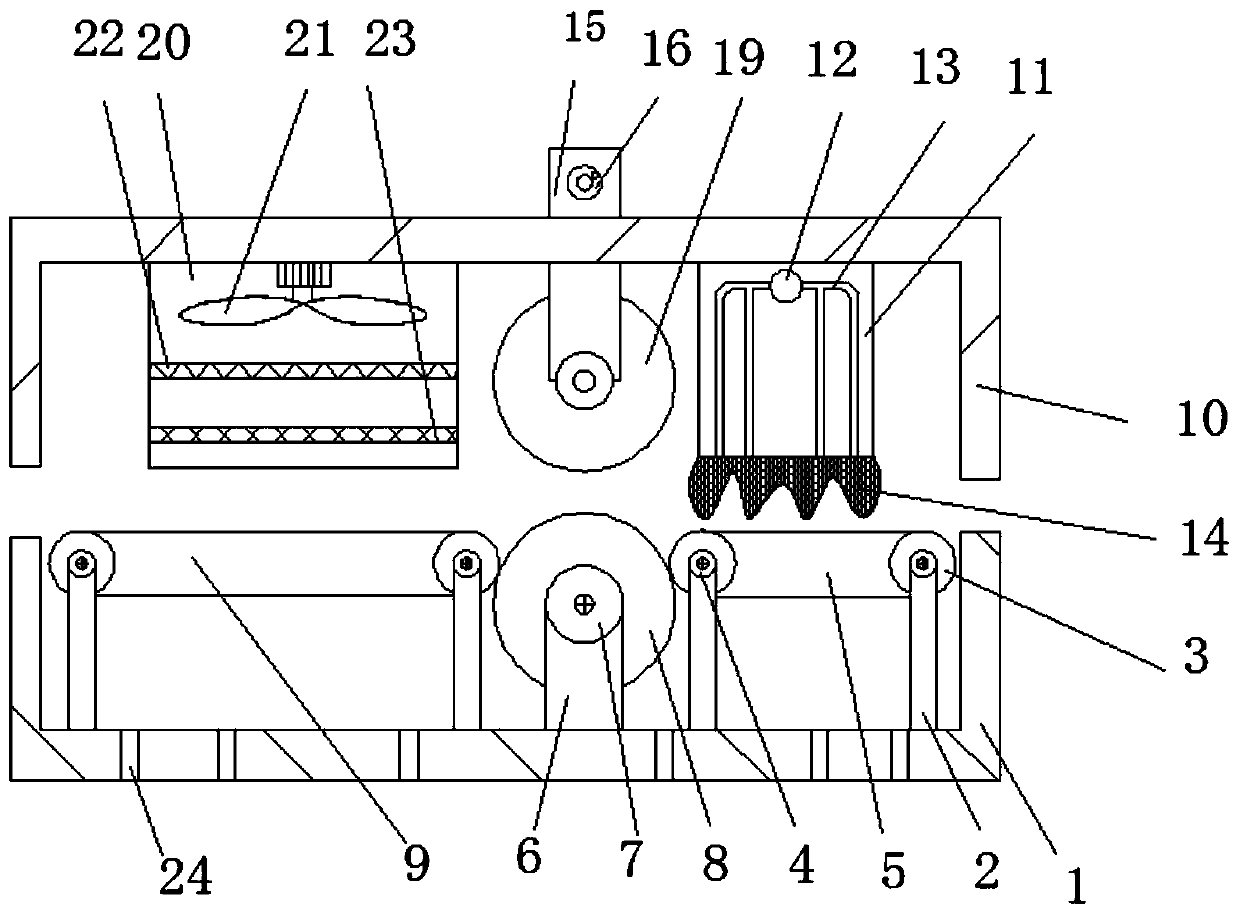

Large-batch natural emulsion mattress cleaning equipment

InactiveCN110479661AHas a cleaning effectRealize the cleaning functionDrying gas arrangementsCleaning using toolsEmulsionAssembly line

The invention relates to the field of mattress correlation techniques, and discloses assembly line type natural emulsion mattress cleaning equipment. The assembly line type natural emulsion mattress cleaning equipment comprises a lower base, and a supporting seat is fixedly connected in the lower base. The top end of the supporting seat is movably connected with rolling wheels. According to the assembly line type natural emulsion mattress cleaning equipment, a mattress enters the equipment from a first conveying belt, cleaning cloth is arranged above the first conveying belt, and the cleaningcloth can be kept wet all the time through a water dividing pipe in a water pipe cavity and has a cleaning effect. After the mattress is cleaned by the cleaning cloth, water in the mattress can be squeezed out through the cooperation of an upper squeezing wheel and a lower squeezing wheel, then the mattress enters a second conveying belt, and a drying chamber is arranged above the second conveyingbelt. Under pushing of an exhaust fan, air is heated by two heating screens and reaches the mattress to dry the mattress. After drying is completed, the mattress is discharged out of the equipment accordingly, the equipment successfully achieves an assembly line type cleaning function, and the natural emulsion mattress can be efficiently cleaned in large batch.

Owner:杭州盟韵科技有限公司

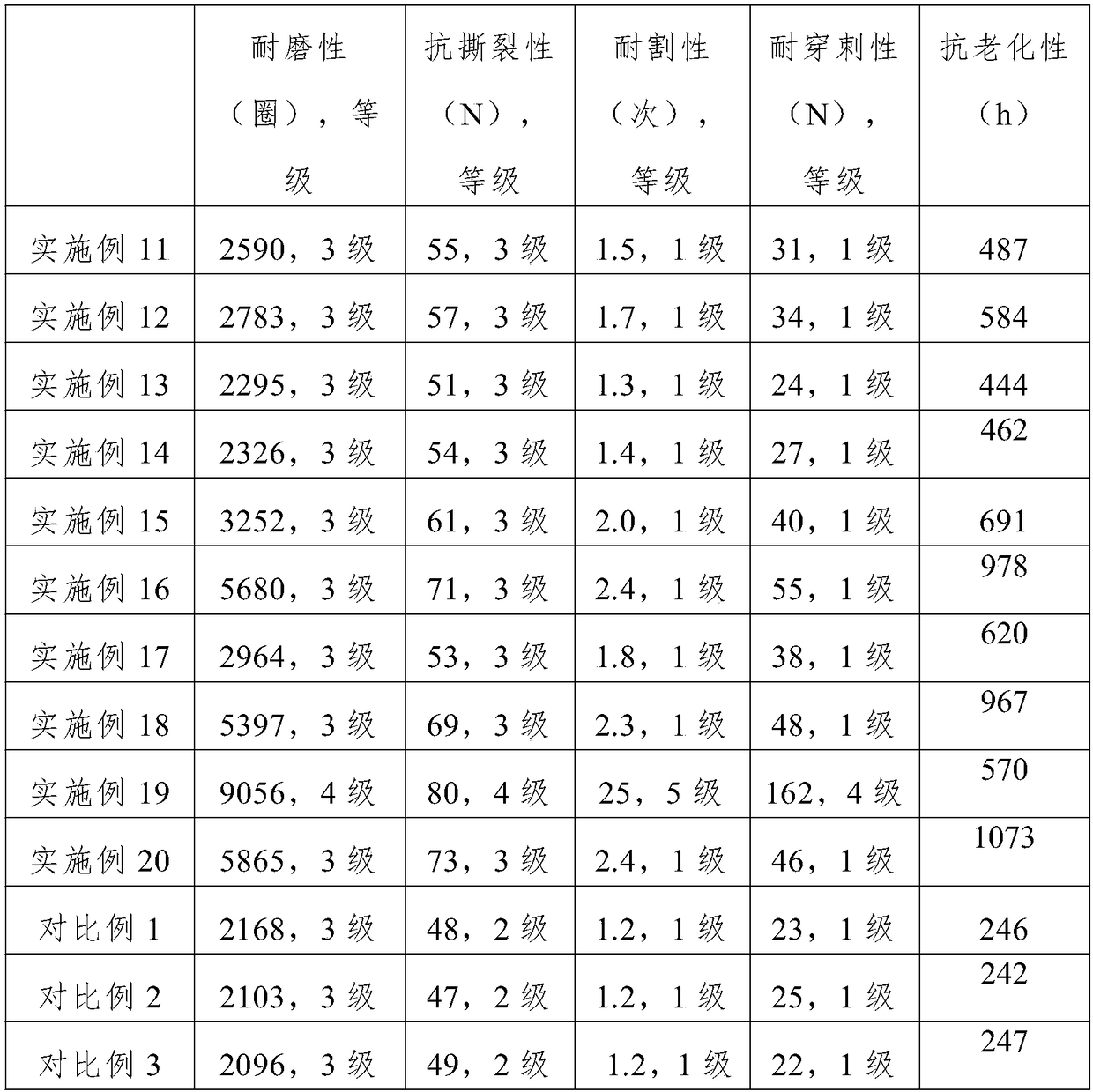

Preparation method of high wear-resistant compounded latex gloves

The invention provides a preparation method of a pair of high wear-resistant compounded latex gloves, and relates to the technical field of preparation technologies of gloves. The method comprises the following steps: S1, evenly mixing natural latex, butadiene-acrylonitrile latex, styrene-butadiene latex, potassium hydroxide, casein, sulfur, an accelerant BZ, zinc oxide, an antioxidant, paraffin and black pigment according to a weight ratio to obtain compounded latex; S2, adding hydroxyethyl cellulose into the obtained latex; S3, sleeving the palm of an inner container of each glove on a mold, preheating, immersing in an anti-seepage agent and then air-drying, and immersing in the compounded latex to form a rubber coating; S4, after the rubber coating is air-dried, carrying out anti-slip treatment on the surface of the rubber coating, drying in an oven and then immersing in clean water; S5, placing the inner containers, treated in step S4, of the gloves in the oven, drying and vulcanizing, and carrying out demoulding treatment to obtain the glove product. The compounded latex gloves prepared by the method provided by the invention are good in softness and long in service life.

Owner:WONDERGRIP CHINA CO LTD

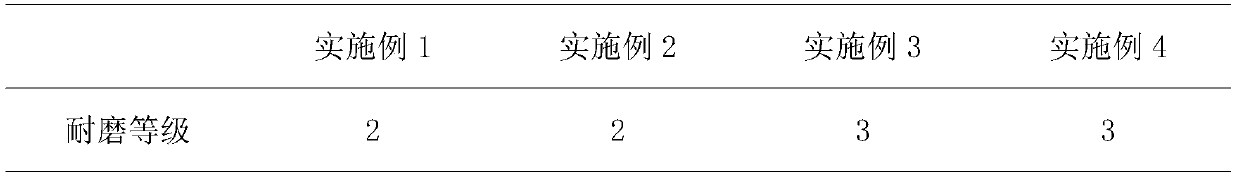

Natural emulsion composite slurry and preparation method thereof, protection gloves and preparation method thereof

ActiveCN108299689ASave materialReduce manufacturing costGlovesDomestic articlesEmulsionPolypropylene glycol

The invention relates to natural emulsion composite slurry. The natural emulsion composite slurry is prepared from natural emulsion and a heat sensitizing agent, wherein the natural emulsion is subjected to pre-sulfurization, and the heat sensitizing agent is diluted by cold water and is a composition comprising one or more of polyvinylmethyl ether, polyether polyformaldehyde dimethyl acetal and polypropylene glycol. The invention further relates to natural emulsion thermosensitive embossed protection gloves prepared from the natural emulsion composite slurry. The natural emulsion composite slurry can not only prevent the gloves from glue penetration during impregnation, avoid damage to the human body, save energy and protect the environment but also prevent liquid from entering the gloves, so that the prepared gloves are soft in texture, light, sensitive and good in breathability, people does not easily feel tired when wearing the gloves for a long time, and therefore the prepared gloves are particularly suitable for mechanical operation; besides, the prepared gloves can have good composite performance of abrasion resistance, cutting resistance, tearing resistance, stabbing resistance, aging resistance and the like, so that influence on the latter aging resistance performance of glove products and blooming are avoided.

Owner:SHANDONG XINGYU GLOVES

Seven-needle pure cotton white latex coated gloves and manufacturing technology thereof

InactiveCN103519439AImprove breathabilitySoft textureGlovesProtective garmentPolymer scienceAdhesive

The invention relates to seven-needle pure cotton white latex coated gloves and a manufacturing technology thereof. The manufacturing method of the gloves comprises the steps of material preparation, latex mixing, impregnation and drying, wherein during material preparation, a glove blank is a seven-needle pure cotton glove blank, casein serves as the thickening agent, and the amount of the casein is 5%o of mass fraction of natural latex; during latex mixing, the natural latex and the thickening agent are added into a liquid mixing and stirring device in proportion, and stirring is carried out at a controlled speed to obtain impregnation adhesive; during impregnation, the glove blank is placed into a hand mold in a sleeved mode and then is dipped into the impregnation adhesive for 1-2s, the dipping depth is 3.5+ / -0.5cm from the thumb tip, and adhesive uniformization is carried out twice. Due to the fact that the glove blank is woven with pure cotton thread, the gloves manufactured with the method have the advantages of being free of static electricity, durable, free of pilling after friction, and good in air permeability. The surface coated with the natural latex can prevent liquid from entering the gloves, the texture is soft, light, sensitive, and good in air permeability, and fatigue can not occur easily after long-term wearing.

Owner:SHANDONG XINGYU GLOVES

Anionic latex product and processing process therefor

An anionic latex product and a processing process therefor. The invention provides the anionic latex product, which is soft in touch and rich in resilience and has antibacterial characteristic, and the processing process therefor. The anionic latex product contains the following ingredients in parts by weight: 80-100 parts of natural latex, 2-5 parts of anion powder, 0.1-3 parts of quaternary ammonium salt antibacterial agent, 1-5 parts of sulfur, 1-5 parts of vulcanization accelerator, 1-6 parts of zinc oxide, 0.1-0.3 part of potassium pyrophosphate, 1-4 parts of sodium stearate and 0.1-2 parts of potassium ricinoleate. The latex product provided by the invention contains the anion powder, and anions have an extremely high degermation action, guarantees air cleanness and can also be used for improving allergic constitution, promoting the synthesis and storage of vitamins of human bodies and improving quality of sleep; and meanwhile, the latex product contains the quaternary ammonium salt antibacterial agent, and the quaternary ammonium salt antibacterial agent is grafted to a latex high polymer, so that antibacterial natural latex products with low toxicity, long antibacterial time and light environmental pollution can be prepared. The latex product provided by the invention is antibacterial, practical, sanitary and reliable.

Owner:江苏金世缘乳胶制品股份有限公司 +1

Preparation technology of vibration isolation gloves

The invention relates to the preparation technology of vibration isolation gloves. The preparation technology of the vibration isolation gloves is characterized by comprising the steps of sequentially going through the procedure of material preparation, the procedure of foam rubber preparation, the procedure of dotting and the procedure of drying, wherein the procedure of rubber soaking preparation after the procedure of foam rubber preparation is further included, and the procedure of rubber soaking and the procedure of re-drying are further included after the the procedure of drying. In the procedure of material preparation, raw materials comprise natural emulsion, foaming agents, thickening agents and waterborne PU resin. According to procedure of dotting, foam rubber is used for frictioning for about 10 seconds. According to the procedure of rubber soaking, the rubber is soaked in the rubber soaking glue for about 1-2 seconds. The rubber is made to be even for 5 times. The manufactured vibration isolation gloves have buffer performance, is capable of effectively reducing vibration to hands, strong in holding power, soft, light, sensitive, good in breathability, and incapable of enabling a user to feel fatigue after being worn for a long time.

Owner:SHANDONG XINGYU GLOVES

Composition for latex pad, producing method thereof, and the latex pads made therefrom

ActiveUS20150084223A1Addition is acceleratedStir wellAntifouling/underwater paintsPaints with biocidesActivated carbonPolymer science

The present invention relates to a composition for preparation of latex pads, comprising natural latex, artificial latex, sliver nanoparticles, zinc oxide nanoparticles, and active carbon mixed in a specified proportion. The present invention also provides a method for manufacturing latex pads from the composition.

Owner:DER YOU ENTERPRISE

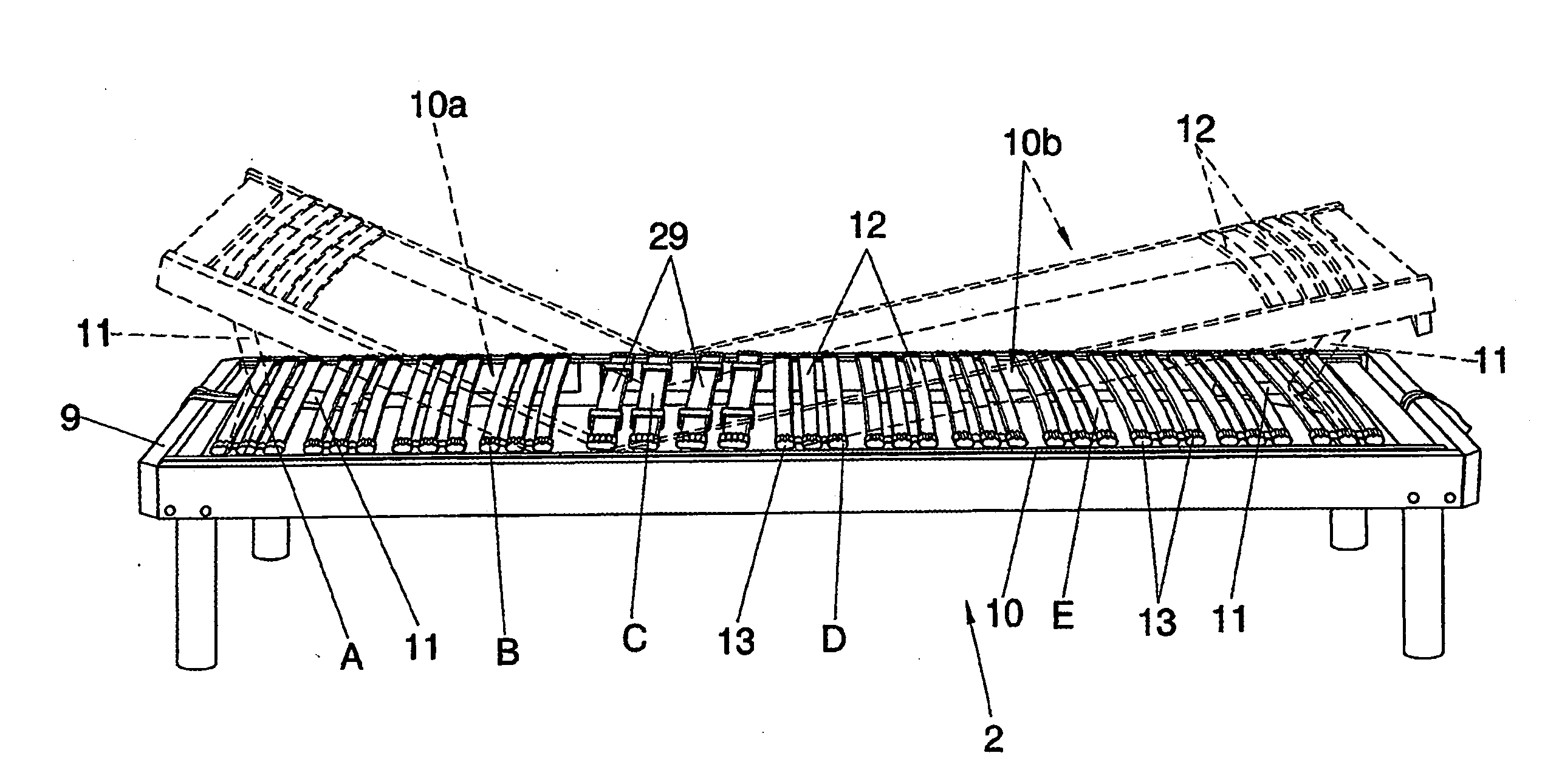

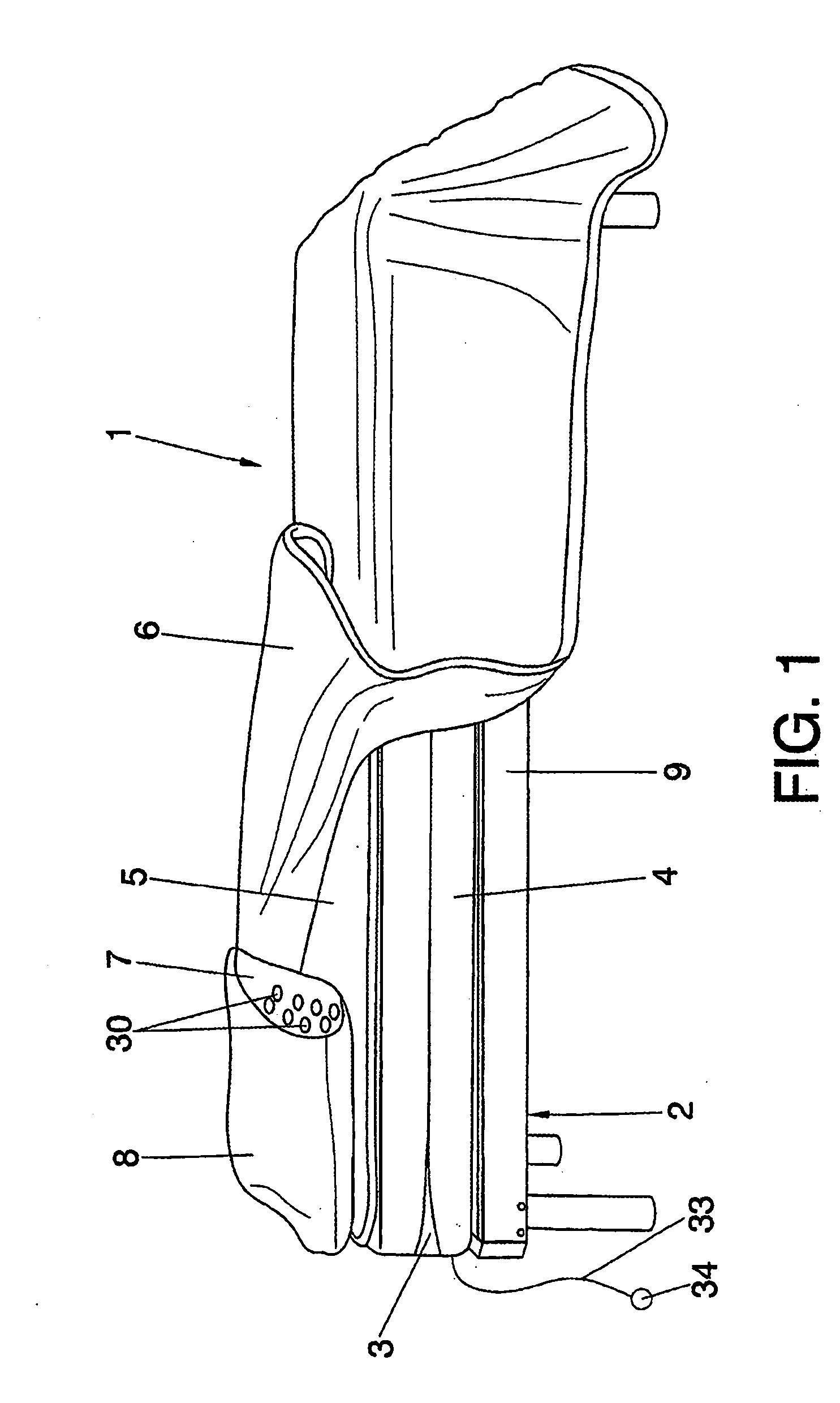

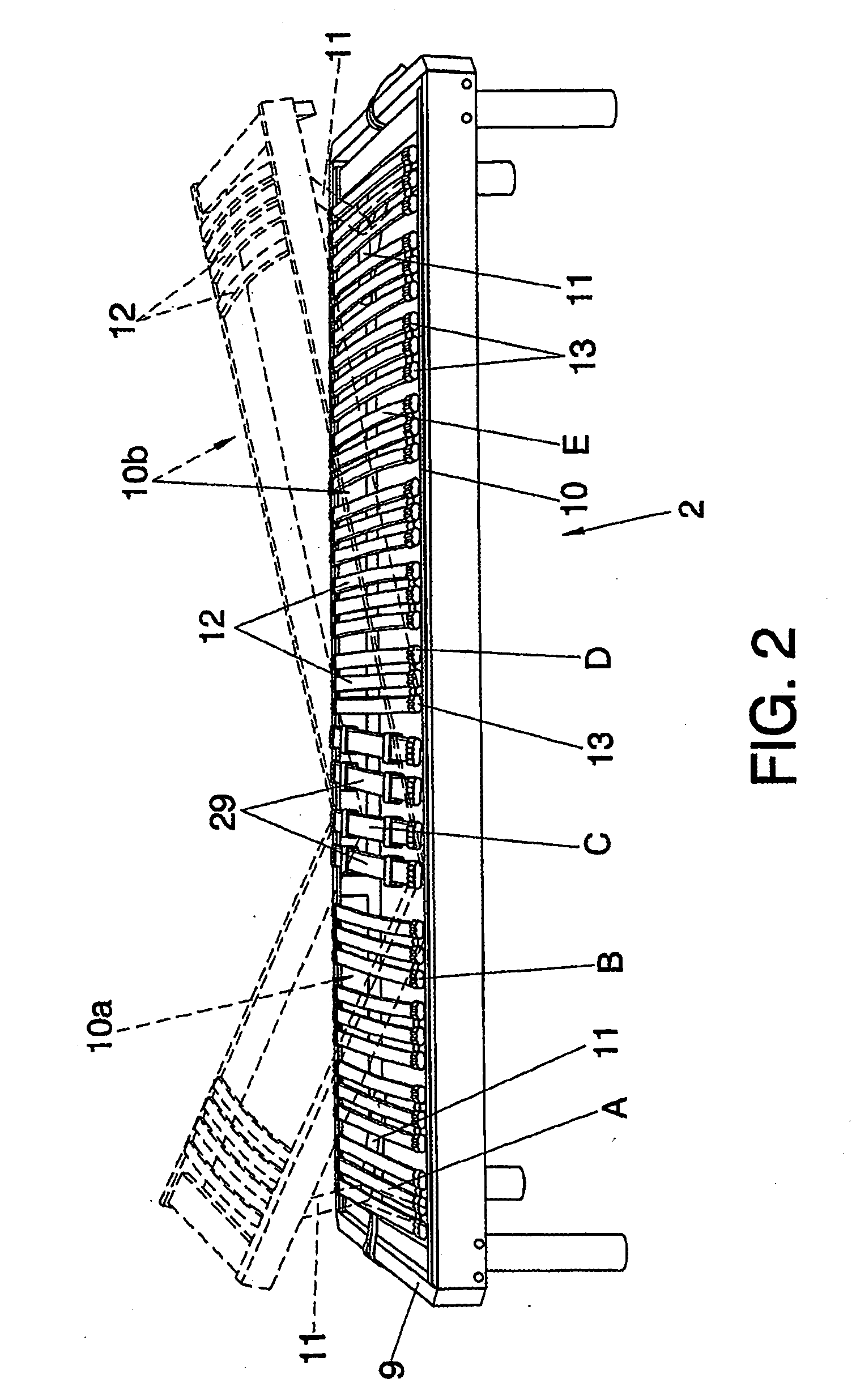

Therapeutic rest bed

Therapeutic rest bed, which comprises a bed base (2) of which the beechwood slats (12) are connected to the frame in movable groups of two or three slats, depending on the areas of the body to which they correspond, by means of pivot pieces (13), shock-absorbing supports (17), height-adjustable supports (22) and arm rests (29), a mattress (3) made from 100% natural latex with holes (30) and a sheet (31) of coconut fibre; a mattress cover (4) with an organic-carbon mesh (32) connected to a wire (33) acting as earth, a mattress topper (5) that has another organic-carbon mesh (35), a blanket (6) with a merino-wool cover (8) with a heat-regulating effect, and a pillow (7) also made from 100% natural latex.

Owner:BIOVITAL SORT

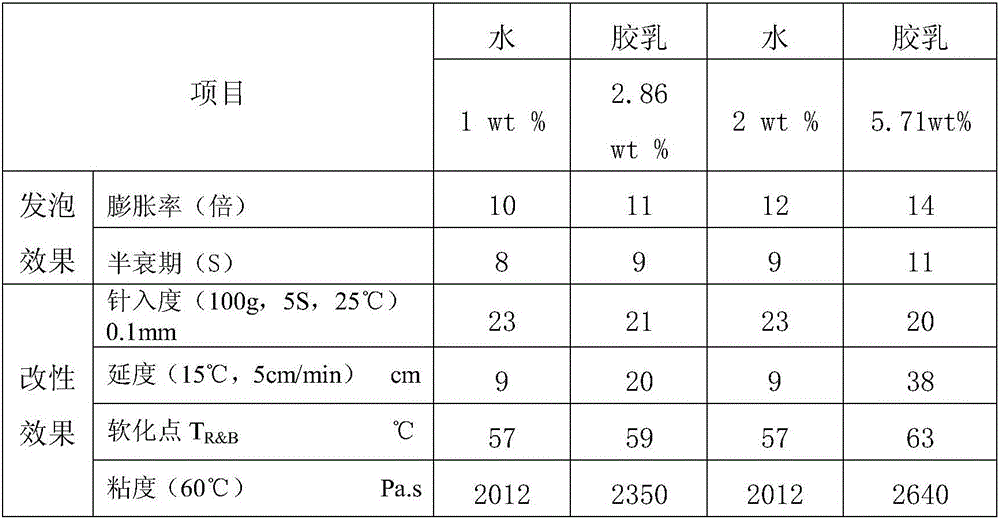

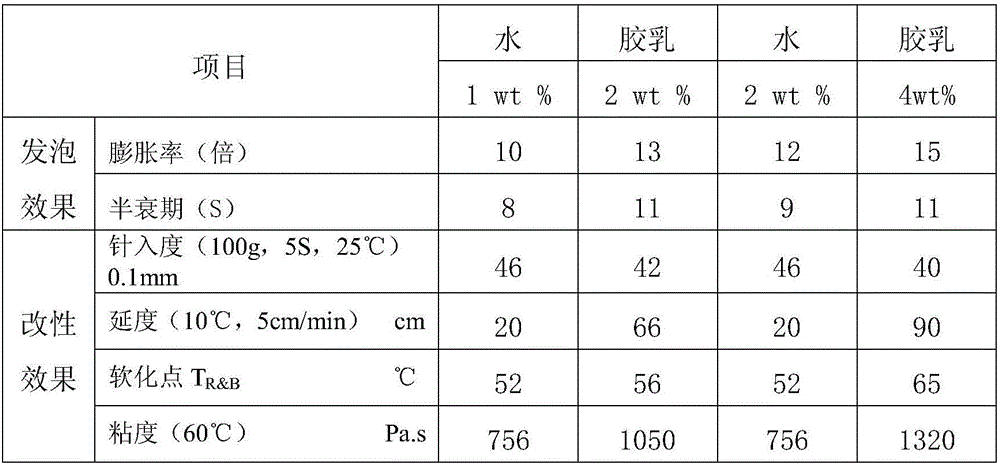

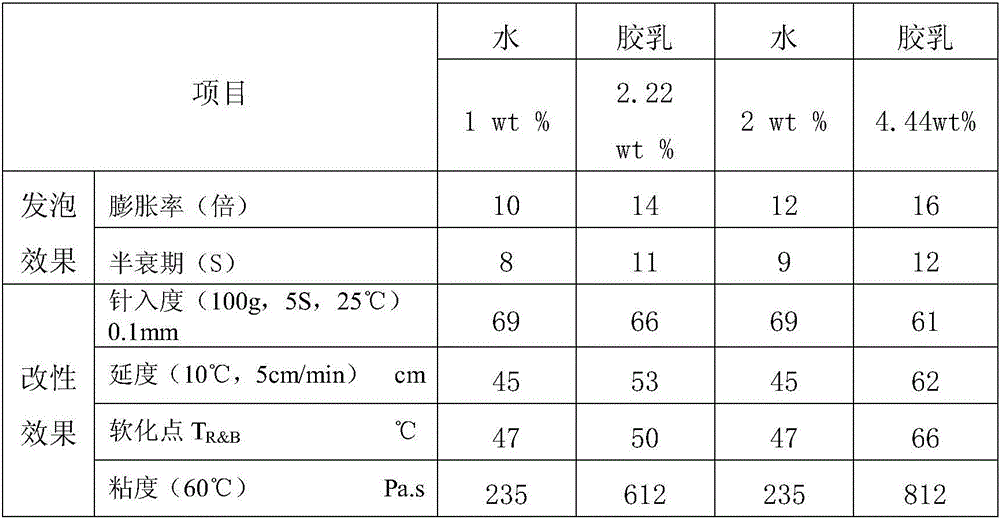

Asphalt foaming agent and preparation method thereof

InactiveCN106496677AHigh expansion rateExtended half-lifeClimate change adaptationBuilding insulationsFoaming agentPavement engineering

The invention relates to manufacturing of a foaming agent applied to foamed asphalt production for pavement engineering, as well as asphalt mixed material warm-mixing construction, asphalt pavement cold-regeneration and modified asphalt technologies, in particular to an asphalt foaming agent for foamed asphalt and modified asphalt, and a preparation method of the asphalt foaming agent. The components of the asphalt foaming agent are natural latex and industrial latex, wherein the mass ratio of the natural latex to the industrial latex is 100:0 to 0:100; and the solid content mass percent is 1 to 80 percent, preferably 30 to 80 percent. The foaming agent provided by the invention not only can increase the expansion rate and the half-life period of asphalt foaming and improve the stability of the foamed asphalt, but also can obviously improve the high and low temperature properties of the asphalt and improve the character of the asphalt.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

Method for producing latex foamed product by using low-protein latex

PendingCN110982131AReduce allergies and other hazardsImprove foam stabilityPolymer scienceFoaming agent

The invention relates to the technical field of latex foamed products, in particular to a method for producing a latex foamed product by using low-protein latex. The natural latex foamed product is prepared from the following raw materials in parts by weight: 100 parts of latex, 2-5 parts of a vulcanizing agent, 0.5-6 parts of a foaming agent, 1-5 parts of a foam stabilizer, 0.5-1.5 parts of a gelatinizing agent, 3-5 parts of an active agent, 3-12 parts of an auxiliary agent and 1-15 parts of a filler. The natural latex in the preparation raw materials of the natural latex foamed product provided by the invention is low-protein natural latex, and has the characteristics of nature, environmental protection, no pollution, no toxicity, antianaphylaxis and the like. Proper amounts of the foamstabilizer and the active agent are added in the production and preparation process of the latex foamed product; meanwhile, the production process parameters are changed, so that the prepared latex foamed product has good foam stability, uniform foam pore size, regular and stable pore structure, few internal defects and the like, the prepared foamed product has good resilience, and the tensile strength, elongation at break, resilience rate and the like are remarkably improved.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com