Graphene modified natural latex material as well as preparation method and application thereof

A technology of graphene modification and natural latex, which is applied in the field of latex products. It can solve the problems of further improvement of antibacterial performance, unfavorable graphene dispersion, latex failure, etc., and achieve the effect of enhanced strength and antibacterial effect, strength improvement, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

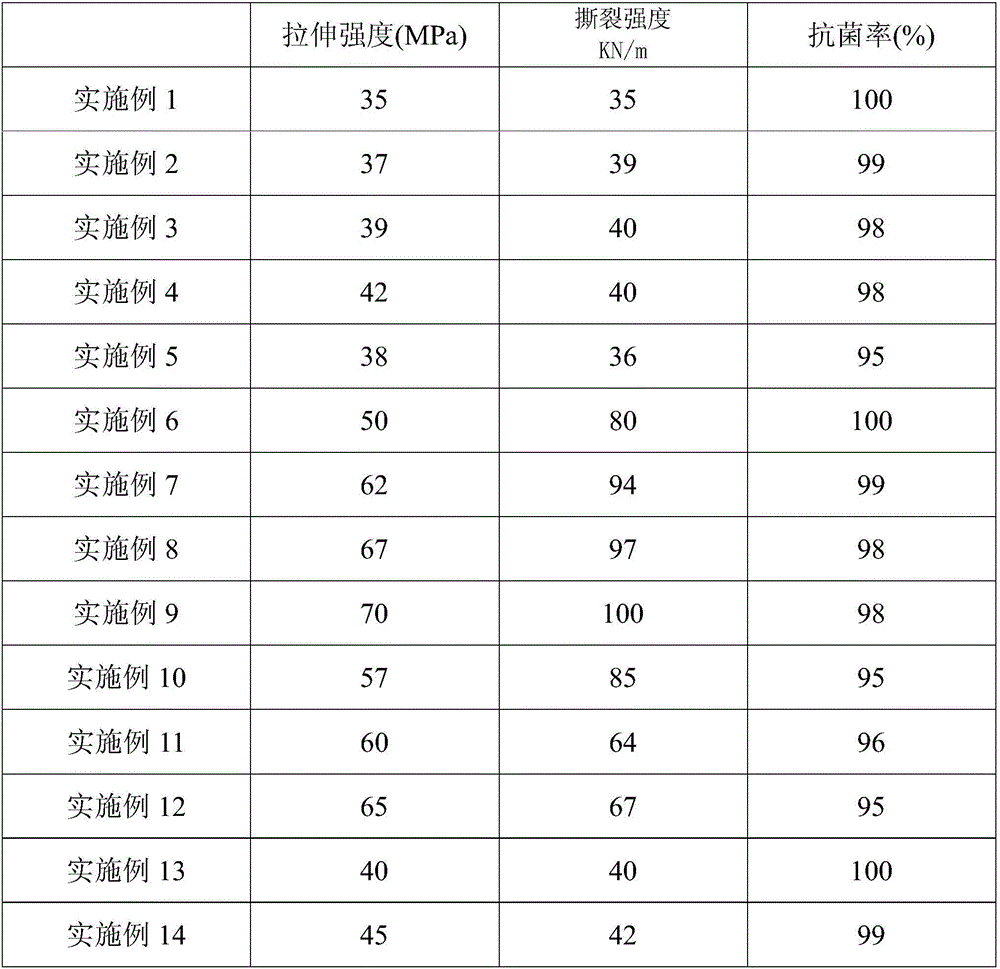

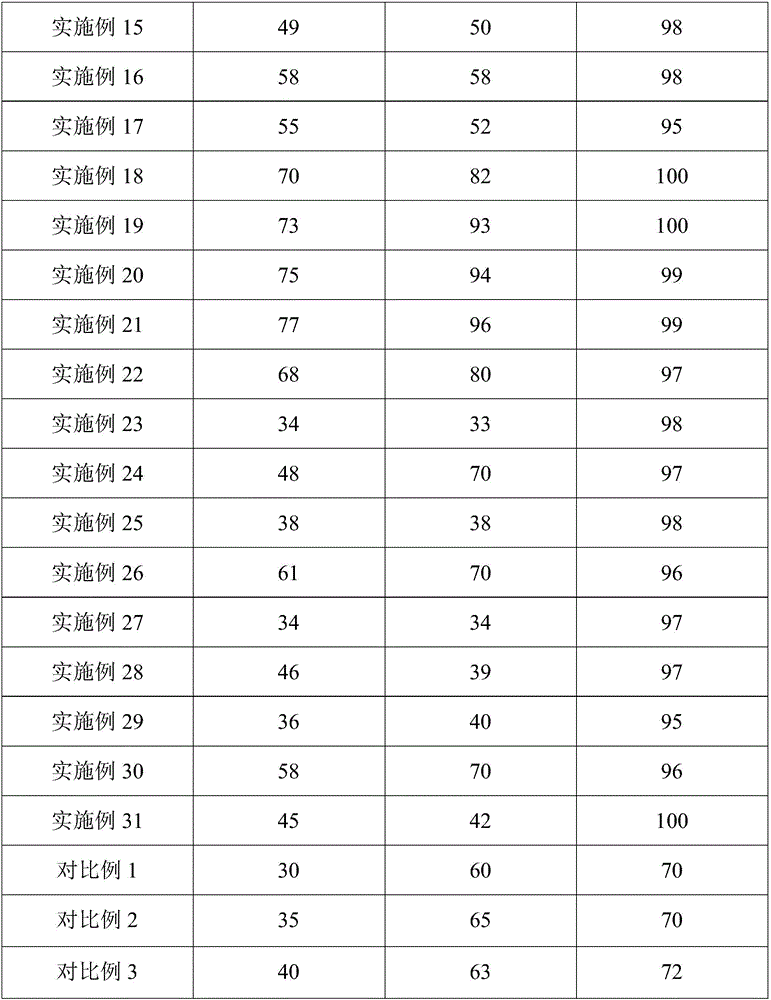

Examples

Embodiment 1

[0082] In the present embodiment, the graphene modified natural latex material is prepared by the following method, which specifically includes the following steps:

[0083] (1) biomass graphene is mixed with the vulcanizing agent needed for producing natural latex products, and the weight of natural latex is 100%, and the consumption of described biomass graphene is 3%, and the amount of described biomass graphene The particle size distribution is D100≤10 μm, the vulcanizing agent includes sulfur, vulcanization accelerator M, vulcanization dispersant, oleic acid and water, the amount of vulcanizing agent is 8%, and the mixture is obtained by grinding for 48 hours;

[0084] (2) the mixed material that step (1) obtains and setting agent (taking the weight of natural latex as 100%, consumption is 5%), accelerator (taking the weight of natural latex as 100%, consumption is 5%) Mix with whipping agent (100% by the weight of natural latex, consumption is 3%) with natural latex, obt...

Embodiment 2

[0086] In the present embodiment, the graphene modified natural latex material is prepared by the following method, which specifically includes the following steps:

[0087] (1) biomass graphene is mixed with the accelerator required for producing natural latex products, and the weight of natural latex is 100%, and the consumption of described biomass graphene is 2%, and the amount of described biomass graphene The particle size distribution is D100≤10 μm, the accelerator includes zinc oxide, oleic acid and water, the amount of the accelerator is 8%, and the mixture is obtained by grinding for 36 hours;

[0088] (2) the mixed material that step (1) obtains and vulcanizing agent (taking the weight of natural latex as 100%, consumption is 5%), setting agent (taking the weight of natural latex as 100%, consumption is 8%) Mix with whipping agent (100% by the weight of natural latex, consumption is 5%) with natural latex, obtain described graphene modified natural latex material, w...

Embodiment 3

[0090] In the present embodiment, the graphene modified natural latex material is prepared by the following method, which specifically includes the following steps:

[0091] (1) biomass graphene is mixed with the required sizing agent for producing natural latex products, and the weight of natural latex is 100%, and the consumption of described biomass graphene is 2%, and the amount of described biomass graphene The particle size distribution is D100≤10 μm, and the setting agent includes sodium fluorosilicate, bentonite (bentonite can be dispersed into a gelled state and a suspended state in an aqueous medium, and this medium solution has certain viscosity, thixotropy and lubricating properties. property), oleic acid and water, the consumption of setting agent is 6%, grinds 24 hours, obtains mixed material;

[0092] (2) the mixed material that step (1) obtains and vulcanizing agent (taking the weight of natural latex as 100%, consumption is 4%), accelerator (taking the weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com