Negative ion bamboo charcoal latex foamed material and preparation method thereof

A technology of foaming material and negative ions, applied in the field of negative ion bamboo charcoal latex foaming material and preparation thereof, can solve problems such as poor uniformity, unstable structure and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

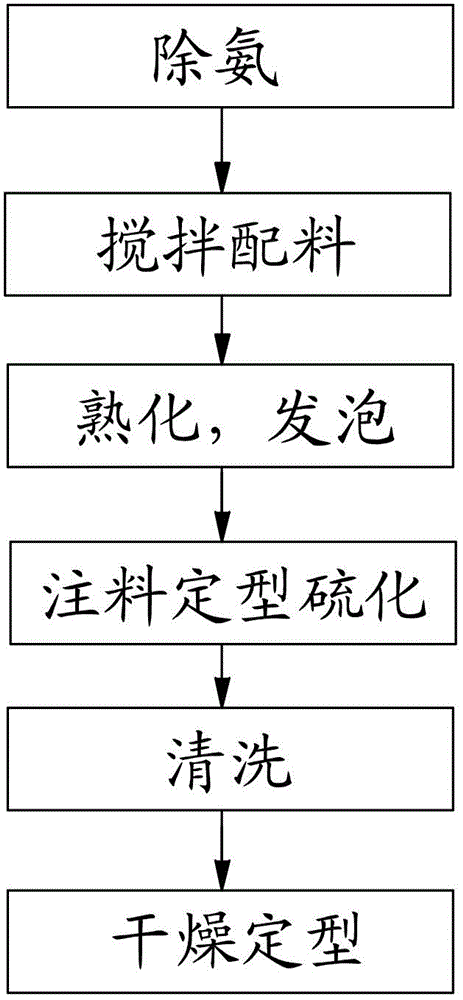

Method used

Image

Examples

Embodiment Construction

[0030]

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

[0032] A kind of negative ion bamboo charcoal latex foaming material that the present invention relates to comprises the following components:

[0033] Natural latex, 10-15wt%;

[0034] Synthetic latex, 60-70wt%;

[0035] Potassium vegetable oleate, 1-5wt%;

[0036] Potassium castor oil, 0-2wt%;

[0037] Aluminum hydroxide, 1-5wt%;

[0038] Sulfur, 3-5wt%;

[0039] Negative ion powder, 5-10wt%;

[0040] Bamboo charcoal powder, 1-5wt%.

[0041] Wherein, the synthetic latex is preferably styrene-butadiene copolymerized rubber latex, referred to as styrene-butadiene latex.

[0042] Natural latex is especially suitable for the main body of this material due to its natural excellent characteristics; for natural latex, if its component is less than 10%, it will not be able to exert its natural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com