Patents

Literature

190 results about "Potassium oleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

POTASSIUM OLEATE is a brown solid or clear to amber liquid with a soapy odor. Sinks and mixes slowly with water. (USCG, 1999)

Efficient laundry detergent and preparation method thereof

ActiveCN107955743AKeep activeEfficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPotassiumLinear alkylbenzene

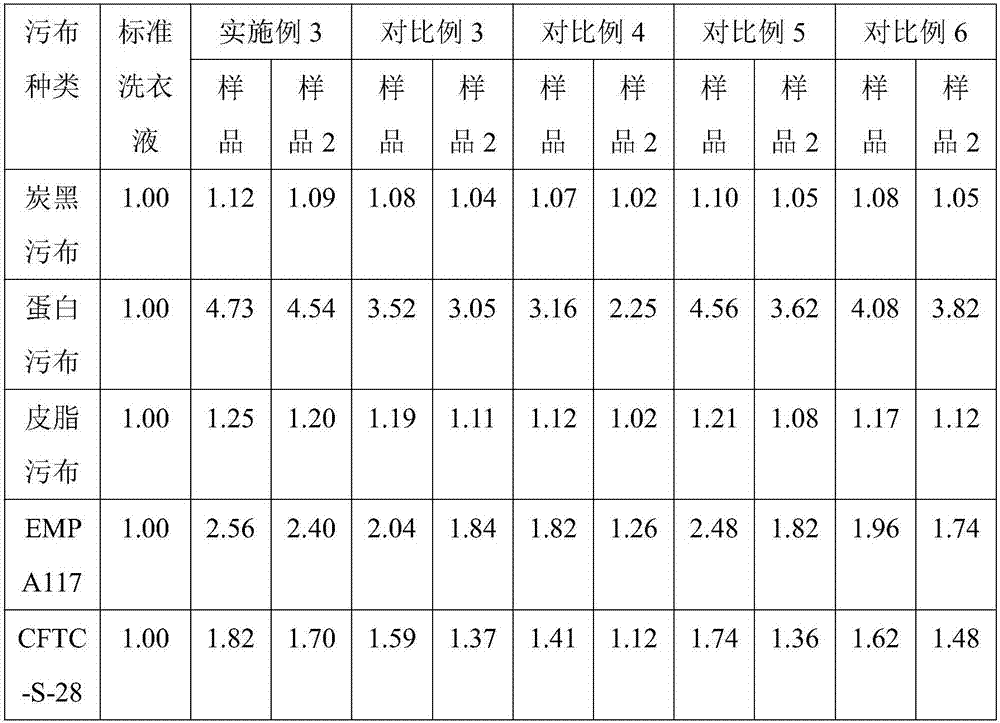

The invention belongs to the field of daily chemical products, and particularly relates to an efficient laundry detergent and a preparation method thereof. The efficient laundry detergent comprises, in weight percent, 5-20% of sodium ethoxylated alkyl sulfate with the mass concentration of 70%, 3-15% of linear alkyl benzene sulfonic acid, 3-6% of fatty alcohol-polyoxyethylene ether, 3-8% of cocamidopropyl betaine with the mass concentration of 35%, 3-10% of potassium laurate water solution with the mass concentration of 17%, 3-10% of potassium oleate water solution with the mass concentrationof 5%, 1-10% of sodium hydroxide, 0.1-2% of compound enzyme, 0.05-0.2% of preservative, 0.1-0.5% of ethylene diamine tetraacetic acid, 0.05-0.5% of citric acid, 0.5-3% of sodium chloride, 0.15-0.5% ofessence and the balance deionized water. The efficient laundry detergent is high in antibacterial and stain removal ability and environmentally friendly and has fewer bubbles, and energy, time and water are saved.

Owner:WALCH GUANGZHOU COMMODITY

Antibacterial natural latex product based on quaternary ammonium salt antibacterial agent and preparation technology of antibacterial natural latex product

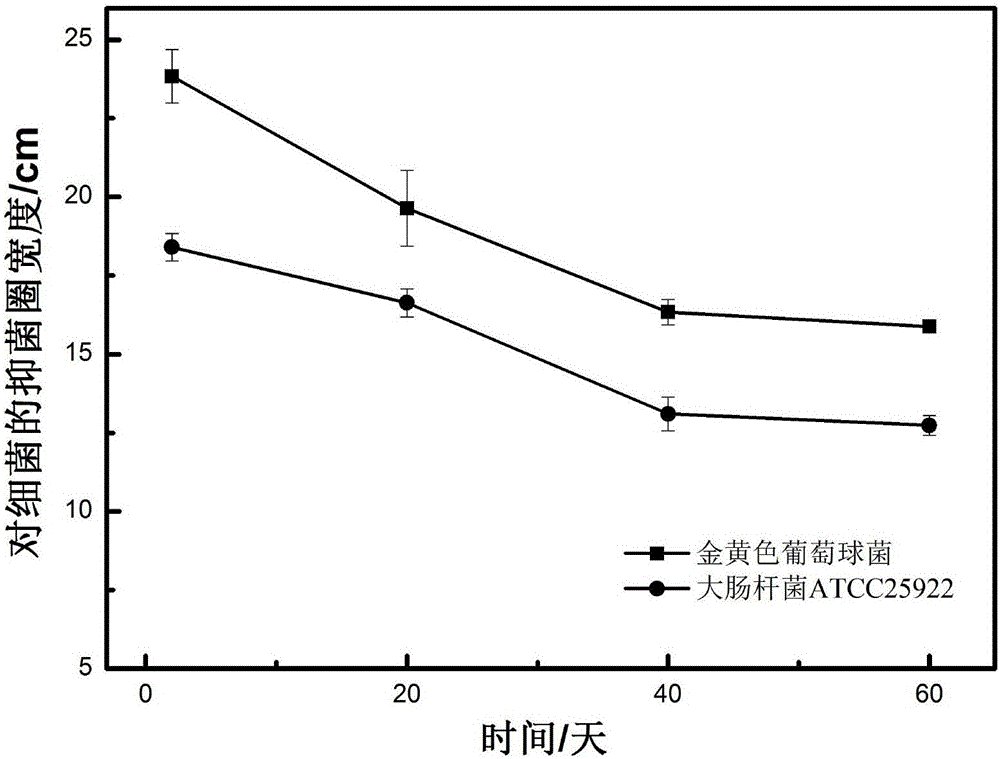

The invention discloses an antibacterial natural latex product based on a quaternary ammonium salt antibacterial agent and a preparation technology of the antibacterial natural latex product, and belongs to the technical field of latex materials. The antibacterial natural latex product is prepared from the following components by weight: 90 to 100 parts of natural latex, 1 to 9 parts of sulfur, 1 to 5 parts of a vulcanization accelerator, 1.5 to 2 parts of an anti-aging agent, 1 to 6 parts of zinc oxide, 0.5 to 2 parts of sodium fluosilicate, 1 to 3 parts of potassium castorate, 0.1 to 2 parts of potassium oleate, 0.5 to 1 part of potassium permanganate and 0.1 to 3 parts of the quaternary ammonium salt antibacterial agent. The antibacterial natural latex product is based on the antibacterial characteristic of a low-concentration quaternary ammonium salt compound. The adopted quaternary ammonium salt compound has the advantage of stable performance, and the compound is tightly combined with latex polymer molecules and cannot permeate the skin of people or an animal by changing the physicochemical property of material surface. The latex product prepared in the invention has the advantages of high antibacterial property, hygiene, high practicability and the like, and has a broad market prospect.

Owner:江苏金世缘乳胶制品股份有限公司 +1

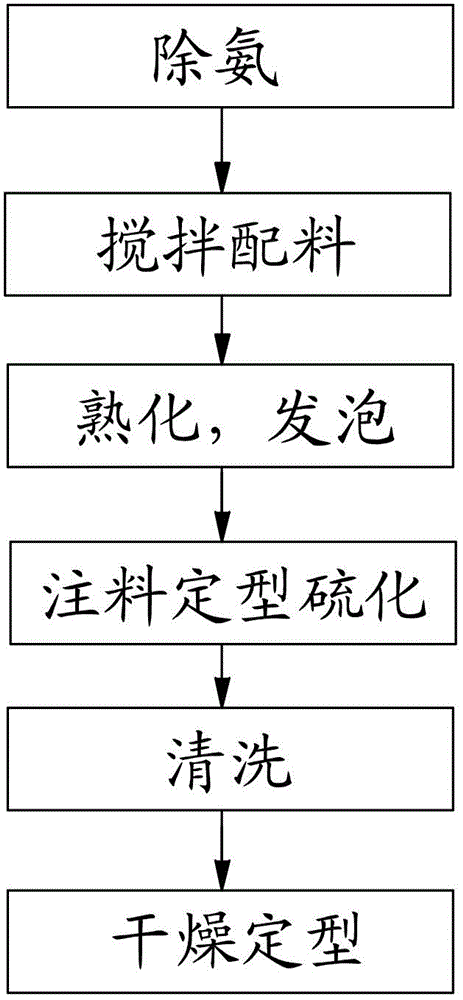

Process for producing aqueous PU foam gloves

InactiveCN101828780AAvoid stimulationProtect your healthFibre treatmentGlovesFoaming agentWarm water

The invention discloses a process for producing aqueous PU foam gloves, which comprises: impregnating knitted gloves in a resin, wherein the resin comprises 70 to 80 percent of PU resin and 20 to 30 percent of butadiene-acrylonitrile rubber, and based on the mixed volume of the PU resin and the butadiene-acrylonitrile rubber, also comprises 0.5 to2 percent of foaming agent, 0.5 to 2 percent of sodium dodecylsulphonate, 1 to 5 percent of potassium oleate, 1 to 5 percent of thickener and 5 to 20 percent of foam stabilizer, and the resin is foamed mechanically; before impregnating the knitted gloves with the resin, impregnating the knitted gloves with a coagulator to perform pulp spray and homogenate treatment; after impregnating the knitted gloves with the resin, impregnating the knitted gloves with a curing agent to perform pulp spray and homogenate treatment; drying the knitted gloves impregnated with the resin; and washing the knitted gloves impregnated with the resin with water by first soaking the knitted gloves in warm water for 1 to 30 minutes and then rinsing the knitted gloves with warm water for 1 to 30 minutes. The invention also discloses the aqueous PU foam gloves produced by the process for producing the aqueous PU foam gloves and a resin for use in the process for producing the aqueous PU foam gloves.

Owner:沙晓林

Negative ion bamboo charcoal latex foamed material and preparation method thereof

The invention discloses a negative ion bamboo charcoal latex foamed material and a preparation method thereof. The foamed material comprises 10 to 15 wt% of natural latex, 60 to 70% of synthetic latex, 1 to 5 wt% of vegetable oleic acid potassium salt, 0 to 2% of castor oil potassium salt, 1 to 5% of aluminum hydroxide, 3 to 5 wt% of sulphur, 5 to 10 wt% of negative ion powder and 1 to 5 wt% of bamboo charcoal powder. According to the invention, a solid foamed material is formed through a foaming process and can be used as a support; since bamboo charcoal powder, negative ion powder, natural latex and synthetic latex are stirred and foamed at the same time, it is guaranteed that all the components undergo a same foaming procedure, so better uniformity and stability are realized; moreover, the foamed material can be poured on a planar conveyer belt except pouring into a die, so a finished product is not restricted by the size and shape of the die, thereby improving production efficiency and substantially reducing cost.

Owner:孙隽毅

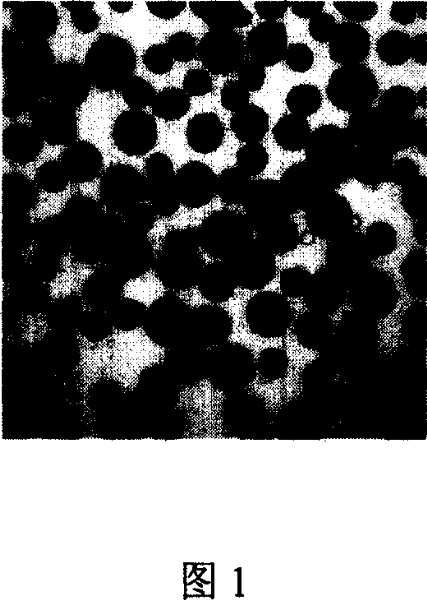

Low content nitrile cross-linked powdery acrylonitrile butadiene preparation method

The invention discloses a manufacturing method of cross linking powder butadiene acrylonitrile rubber with low acrylonitrile content, which is characterized by the following: adopting aliphatic potassium or sodium and potassium or sodium oleate as compound emulsifier to produce butadiene acrylonitrile rubber slurry through polymerization emulsion with 20-20 percent combination acrylic nitrile content; using 8-10 pH value saturated NaCl solution as coagulant, polymer resin emulsion-inorganic separant (lightweight CaCO3)-organic separant(potassium oleate)as composite separant to proceed agglomeration separation powdered reaction for butadiene acrylonitrile rubber slurry at 30-65 deg.c. The invention is easy to operate to produce stable index product, which satisfies the appliance need of resin and abrasion material.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing super-hole fibrin microsphere protein absorbing medium

InactiveCN101036876AEvenly distributedImprove stabilityOther chemical processesPeptide preparation methodsCelluloseMicrosphere

The present invention discloses a preparation method for superporous cellulose microglobulin adsorption medium, which belongs to the preparation technology of cellulose gel medium of bioseparation engineering field. The method comprises the steps of: dispersing calcium carbonate particles to the cellulose viscose to form composite water phase; putting the viscose into the transformer oil and adding composite emulsifier potassium oleate and Span 60 and then executing agitating and emulsification; heating and curing to form particles; adding ethylene glycol diglycidyl ether and epichlorohydrin to execute double crosslinking reaction under alkaline condition; removing the calcium carbonate particles by using muriate acid and then using sodium borohydride to reducing so as to prepare superporous cellulose microglobulin adsorption medium. The medium not only maintains the advantages of the quondam cellulose gel medium but also increases a plurality of superporous, so that the resistance to pressure, the mass transfer rate and the dynamic adsorption capacity of the medium are all obviously improved, thereby, the novel superporous cellulose microglobulin adsorption medium has wide application prospect.

Owner:TIANJIN UNIV

Latex foam product and preparation method thereof

The invention relates to a latex foam product and a preparation method thereof. The raw material of the latex foam product contains the following ingredients in percentage by weight: 15-25% of synthetic rubber, 60-70% of natural rubber, 1-3% of potassium oleate, 0.8-2% of castor oil, 0.1-10% of paraffin wax and 6-7.5% of rubber vulcanization accelerator. The latex foam product is prepared through steps of material preparing, foaming, material casting, digesting, drawing die, dehydrating and stoving, and the like.

Owner:东莞市铨兴乳胶制品有限公司

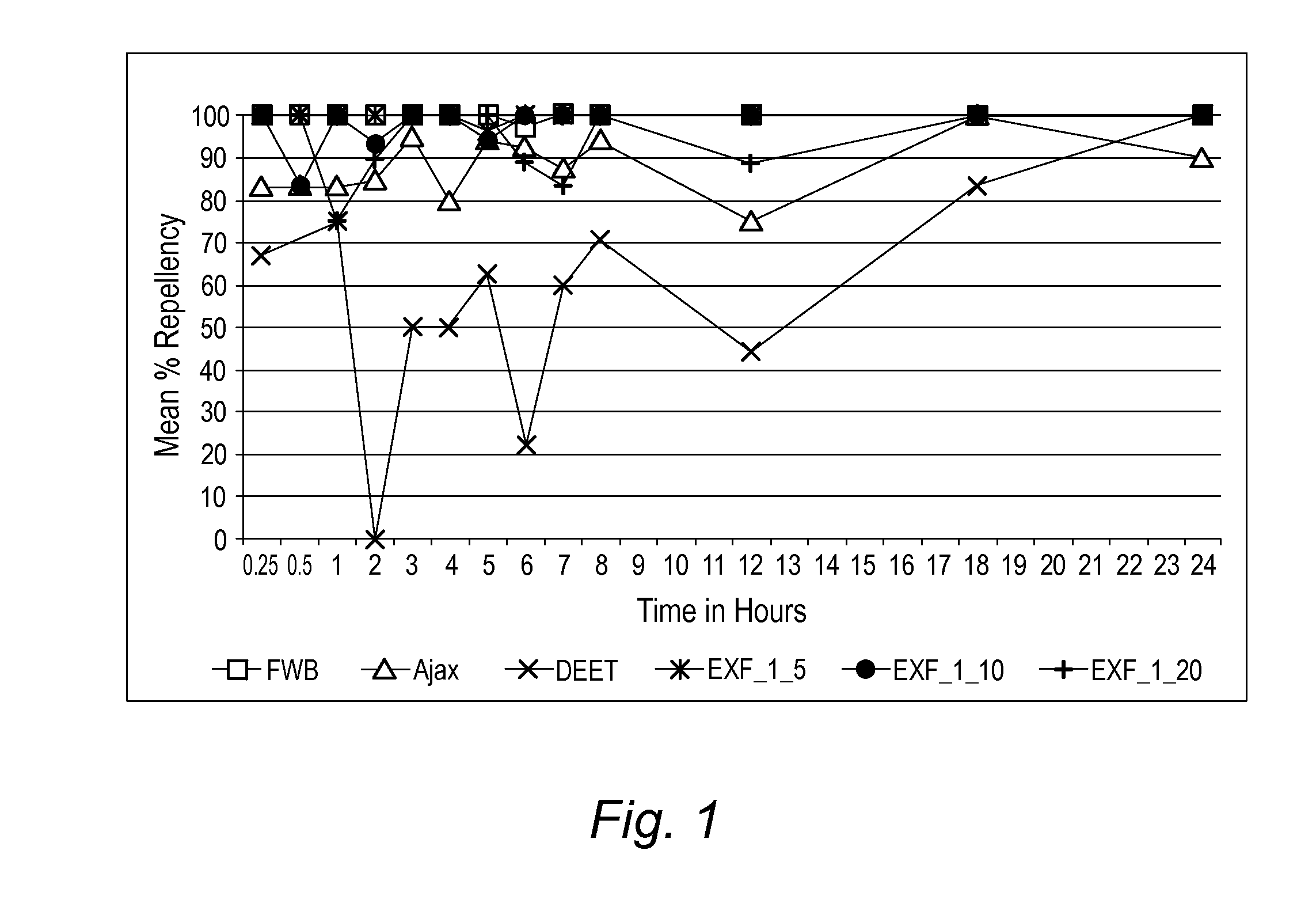

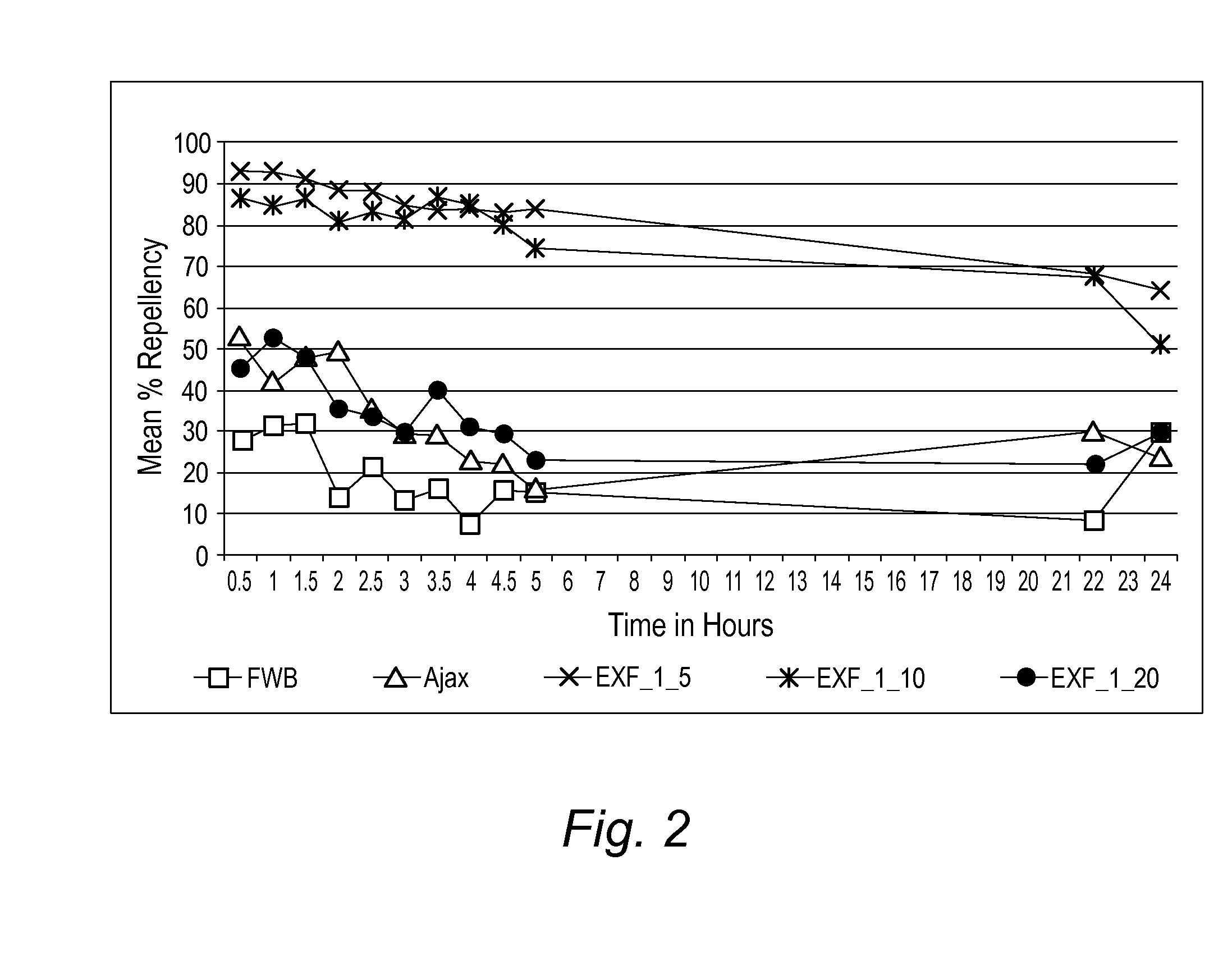

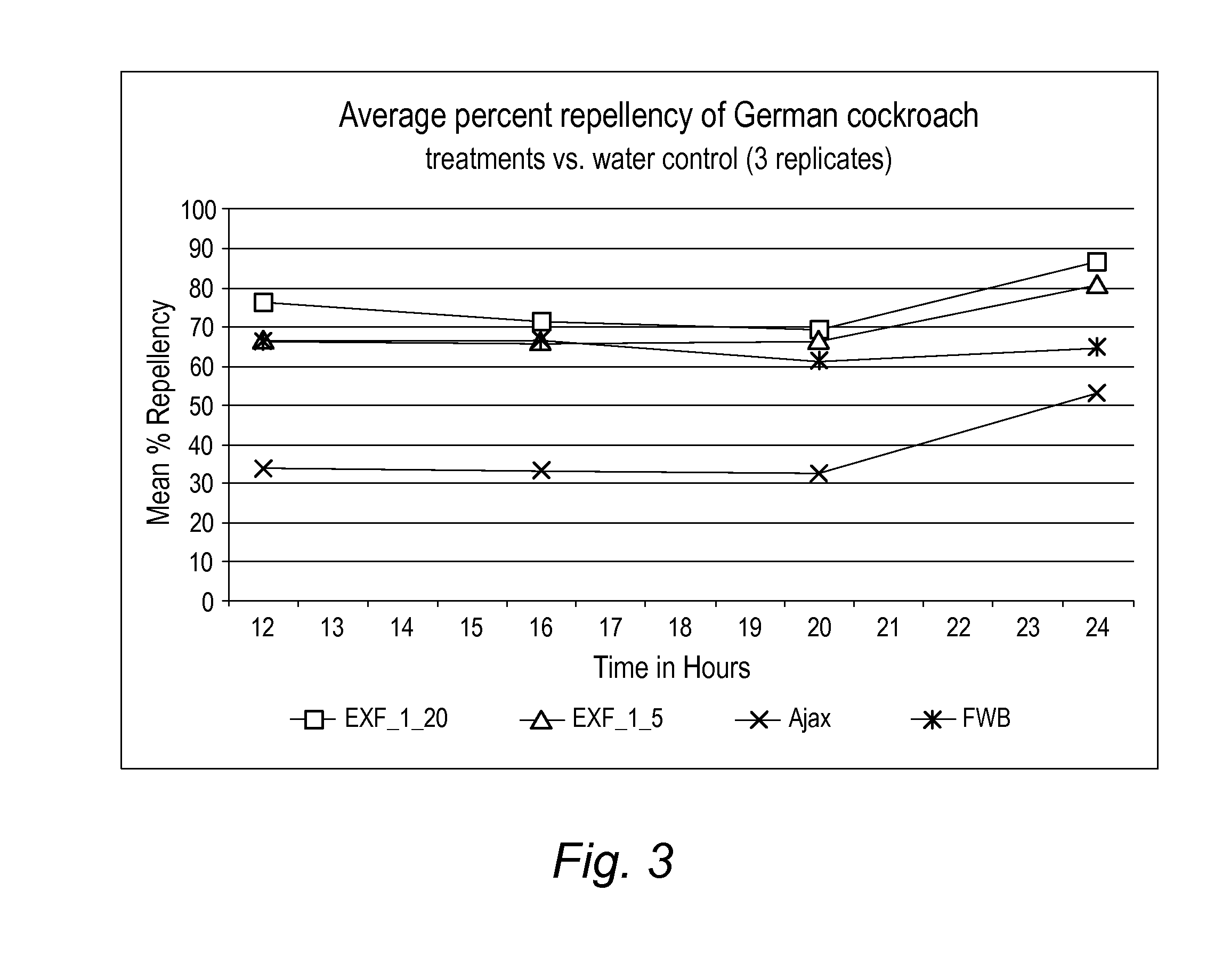

Insect repellent surface composition

Embodiments of the invention relate to a pest-control composition comprising at least one active ingredient and at least two other ingredients; wherein the at least one active ingredient is selected from the group consisting of geraniol, nootketone, amyl cinnamaldehyde, catnip, wintergreen, carvacrol, d-limonene, orange oil, lauric acid, alpha pinene, mint, cornmint oil, lemon oil, eucalyptus, eugenol, peppermint, lemongrass oil, and terpenes; and wherein the at least two other ingredients are selected from the group consisting of 2-propanol, alcohol, ethanol, monobutyl ether, ethylene glycol, terpenes, ethoxylated alcohol, dodecanol, ammonia, soap, lauryl polyglucose, polyethylene glycol, sodium lauryl sulfate, sodium olefin sulfonate, cocamidapropyl betaine, alkylbenzene sulfonate, polyoxyethelene alkylphenol sulfate, sodium dodecyl benzene sulfonate, sodium sterate, potassium sterate, potassium myristate, tomadol, polyglyceryl sterate, glycol monosterate, potassium oleate, polyglyceryl oleate, tween, polymers, acrylic polymers, ethyl cellulous, carboxymethyl cellulose, sodium hydroxide, ammonium hydroxide, polyacrylate polymer, polyvinyl pyrolidane, lauric diethanolamine, dimethyldodecylamine oxide, aspartic acid tetrasodium salt, and sodium citrate.

Owner:ENVANCE TECH LLC

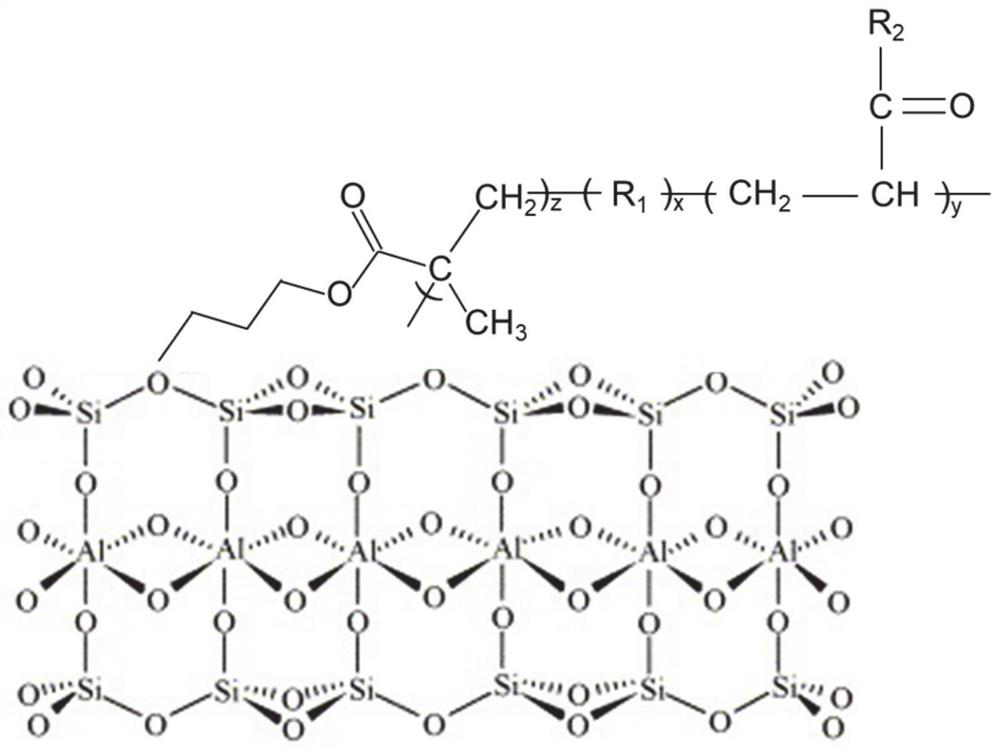

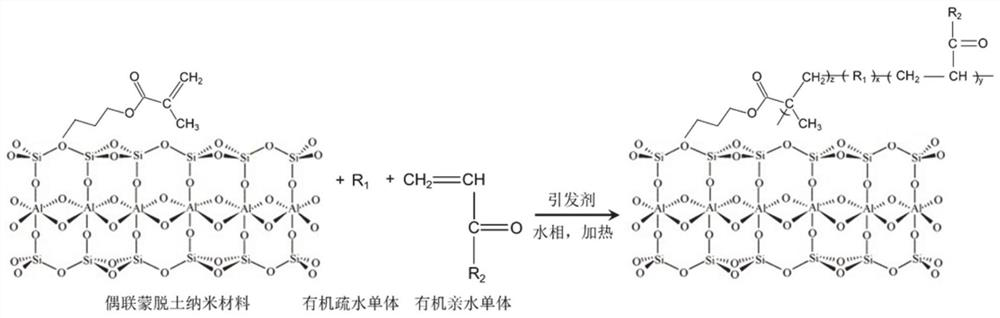

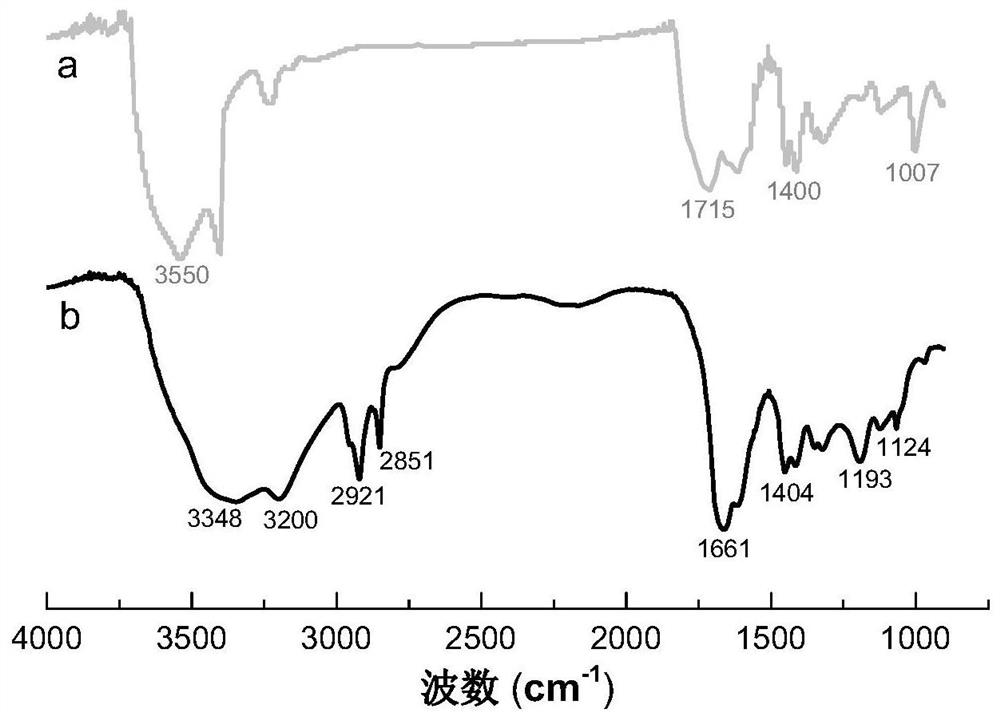

Organic-inorganic hybrid nano material as well as preparation method and application thereof

ActiveCN111995722AImprove dispersion stabilityGood temperature and salt resistanceDrilling compositionHydrophilic monomerStructural unit

The invention discloses an organic-inorganic hybrid nano material. The organic-inorganic hybrid nano material is composed of structural units represented by a formula i, a formula ii and a formula iiishown in the specification. The invention also discloses a preparation method of the organic-inorganic hybrid nano material. The emthod comprises the following steps: stirring and heating an aqueoussolution containing the coupled montmorillonite nano material, organic hydrophobic monomer and organic hydrophilic monomer raw materials, adding an initiator, and carrying out free radical polymerization reaction to obtain the organic-inorganic hybrid nano material. The organic hydrophobic monomer is selected from at least one of sodium alpha-olefin sulfonate, sodium oleate, potassium oleate and sodium linoleate; and the organic hydrophilic monomer is selected from at least one of acrylamide and acrylic acid. The preparation method is simple in process, wide in raw material source and suitablefor industrial production, application and popularization. The organic-inorganic hybrid nano material is used as a water-soluble nano viscosity reducer and has an obvious viscosity reduction effect.

Owner:NINGBO FENGCHENG ADVANCED ENERGY MATERIALS RES INST CO LTD

Preparation method for small grainsize polybutadiene latex

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

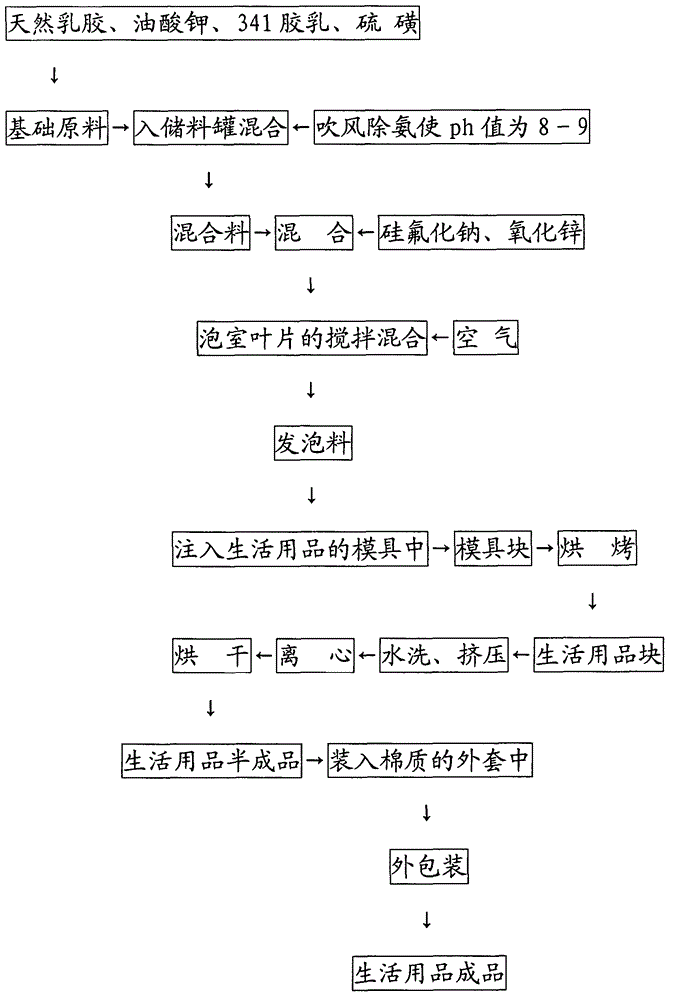

Method for manufacturing articles for daily use

The invention discloses a method for manufacturing articles for daily use and relates to the technical field of articles for daily use. The method comprises the following steps: by employing the daily article formula key technology, taking natural emulsion, potassium oleate, 341 latex and sulfur as basic raw materials, mixing and blowing air to make the pH value be 8-9, manufacturing a mixture, adding sodium silicofluoride and zinc oxide into a foaming chamber, pressing air, stirring and mixing to manufacture a foamed material to be injected into a daily article mold to manufacture a mold block, baking and manufacturing a daily article block, performing mold stripping, washing, extruding, centrifuging, drying and dehumidifying, manufacturing a daily article semi-finished product and packaging in a cover for performing external packing, and manufacturing the daily article finished product. The method is used for manufacturing pillows, mattresses, sofa cushions, chair cushions, backrests, automobile cushions, automobile neck-pillows and the like. The product is simple in process, high in quality and low in cost and contributes to popularization.

Owner:黄俊彬

Anti-rust oil having high resistance to damp-heat

InactiveCN103980994AExcellent heat and humidity resistanceImprove water resistanceAdditivesHigh resistancePotassium

The invention discloses anti-rust oil having high resistance to damp-heat. The anti-rust oil having high resistance to damp-heat comprises, by weight, 62-70 parts of light diesel fuel 0#, 2-3 parts of polyoxyethylene abietate, 1-2 parts of ammonium molybdate, 4-6 parts of acetylated lanolin, 1-2 parts of dodecanamine, 0.3-1 part of alkenyl succinic acid, 0.2-1 part of potassium dodecylbenzosulfonate, 0.2-0.3 parts of tetrahydrofurfuryl alcohol, 3-5 parts of phthalic acid ester, 2-3 parts of potassium oleate, 1-2 parts of methylbenzotriazole and 10-14 parts of a film-forming assistant. The anti-rust oil has good resistance to damp-heat, water and salt mist, has lasting workpiece protection effects and has good weatherability. The used film-forming assistant can effectively improve anti-rust oil stability.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

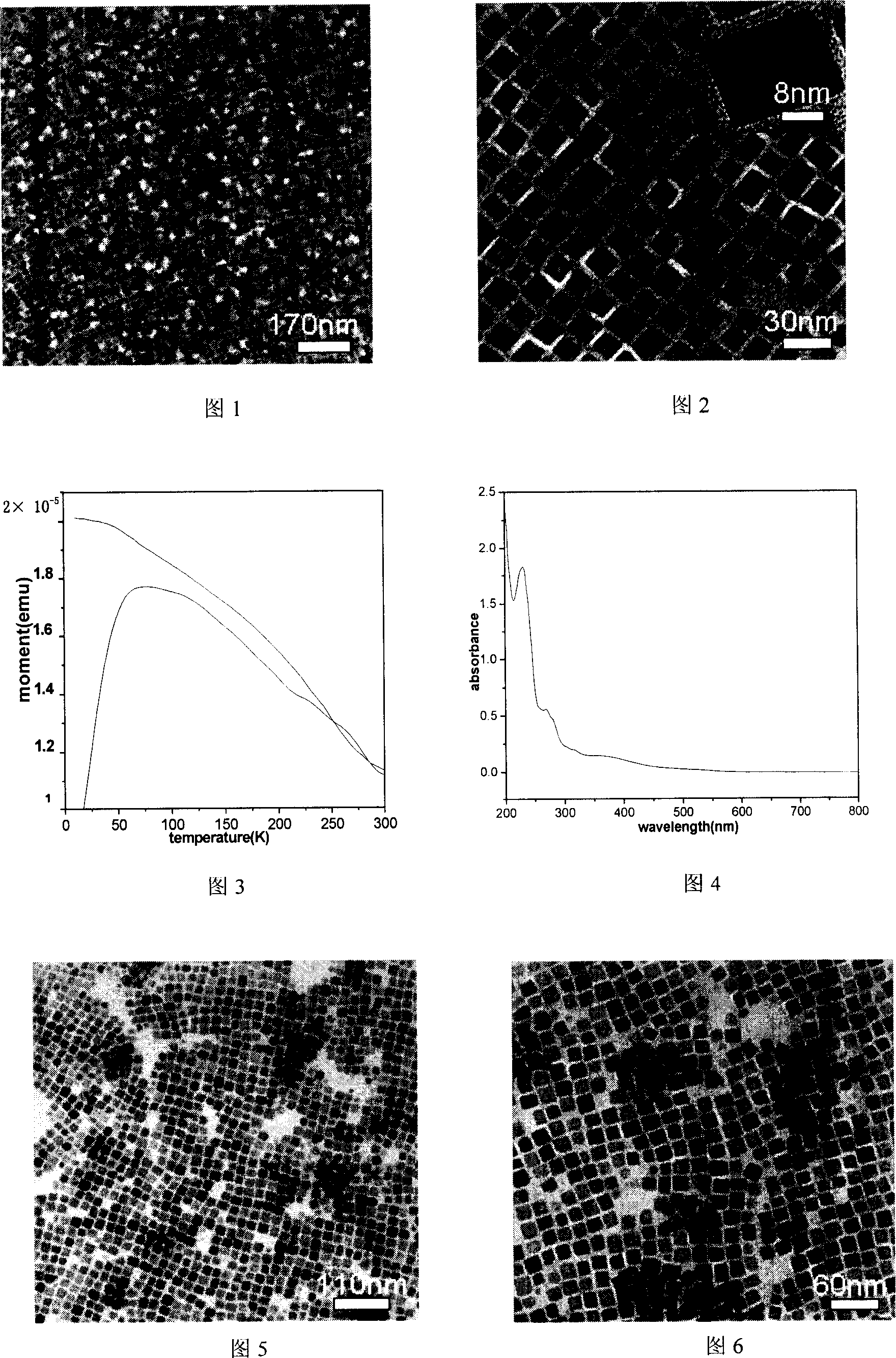

Method for preparing Nano cube of hematite

InactiveCN101003388AUniform particle sizeUniform shapeFerric oxidesMagnetic storageSuperparamagnetism

This invention discloses a method for preparing hematite nanocubes. The method comprises: (1) adding soluble inorganic ferric salt 0.8-2.4 mmol, potassium oleate or sodium oleate 2-4 mol times of ferric ions, ethanol 4-10 mL and oleic acid 1-5 mL into water 16 mL, stirring to uniformly demix, and placing in a sealed container; (2) standing at 160-220 deg.C for more than 8 h; (3) centrifuging to separate the solid precipitate, washing with ethanol, drying, and dispersing in alkane solvent; (4) centrifuging to separate the solid precipitate, adding ethanol into the obtained red alkane colloidal solution to precipitate aggregates of hematite nanocubes with average side length of 14-17 nm. The method has such advantages as easy operation, easy control, mild conditions and no pollution. The obtained hematite nanocubes have good monodispersity, uniform particle sizes, and regular and uniform morphology. The hematite nanocubes exhibit superparamagnetism at normal temperature, and can be used in magnetic storage and medical fields.

Owner:UNIV OF SCI & TECH OF CHINA

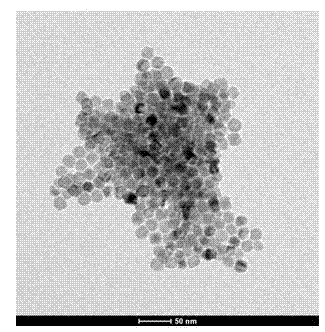

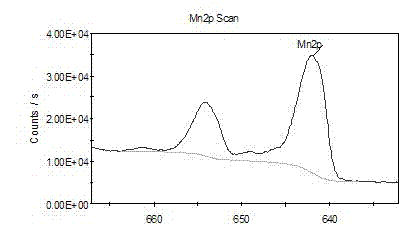

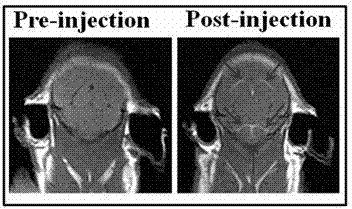

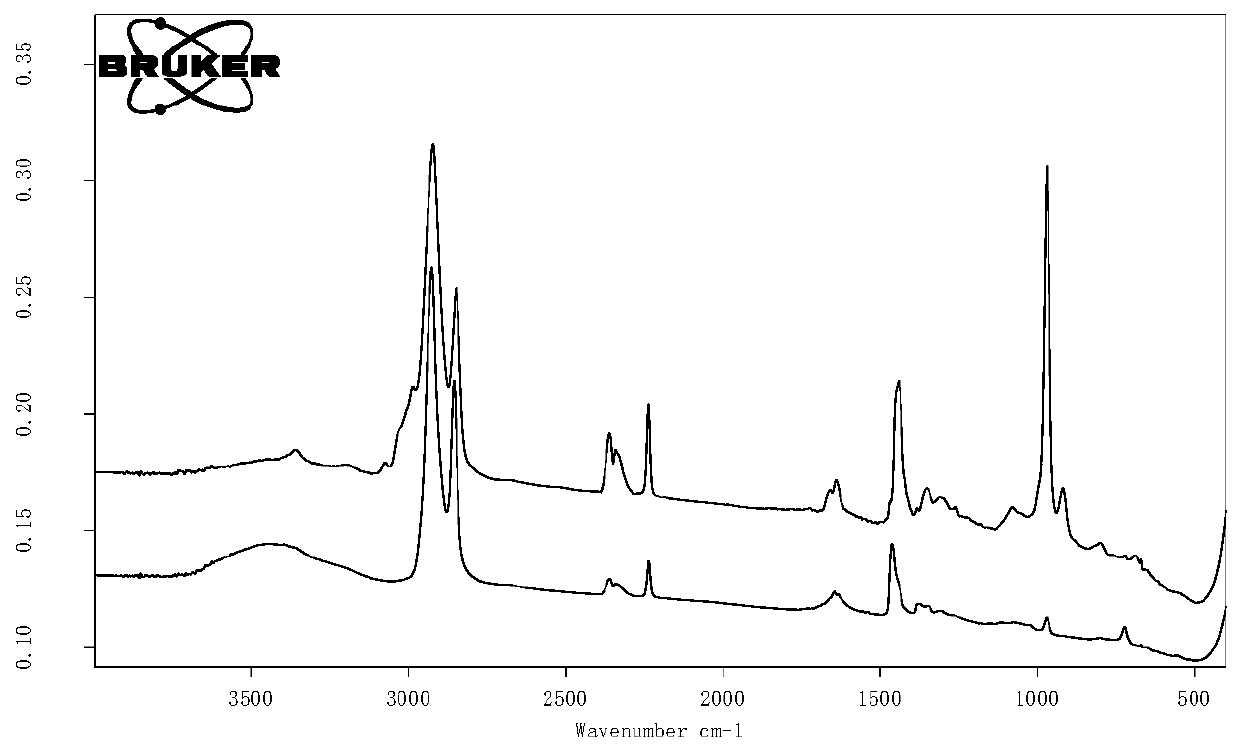

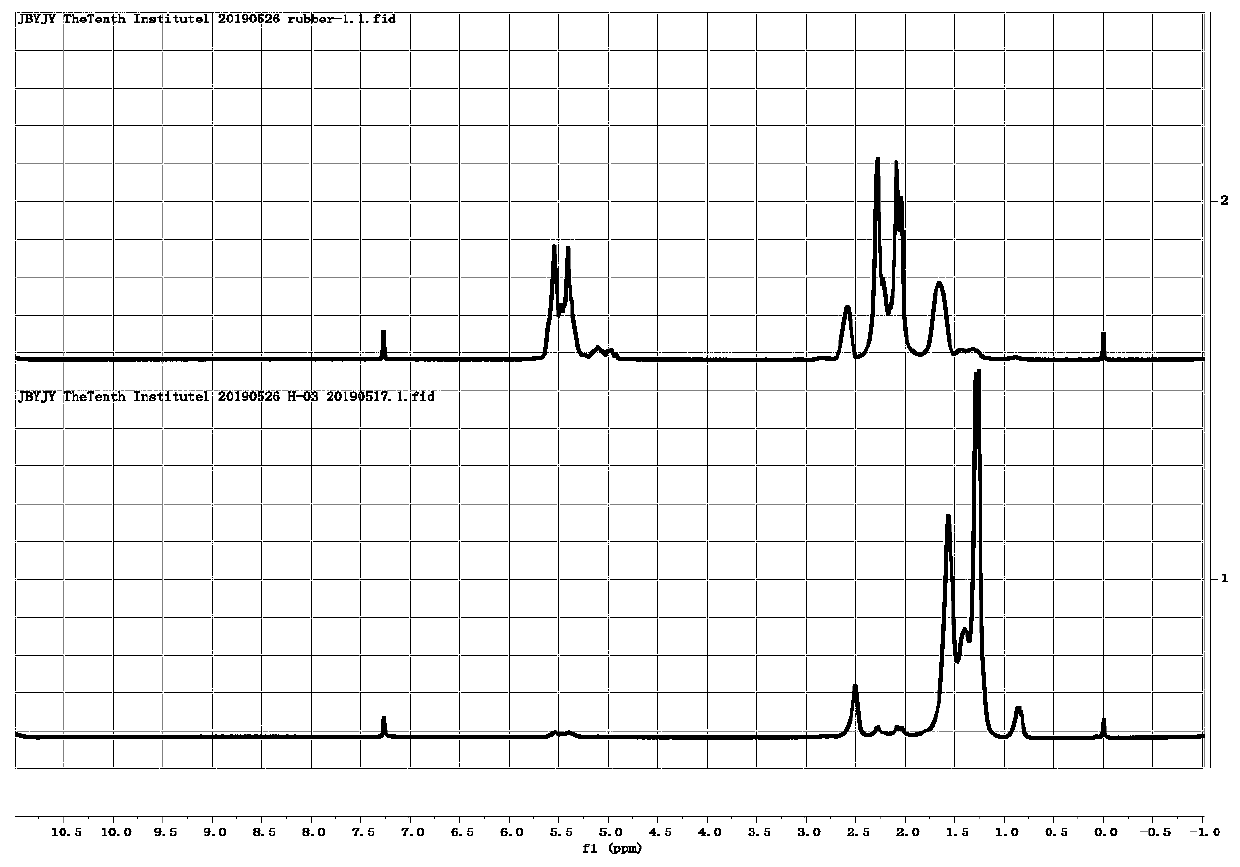

Method for manufacturing KMnF<3> nuclear magnetic resonance imaging contrast agents

InactiveCN103203030AGood biocompatibilityNo immune effectsNMR/MRI constrast preparationsAnhydrous ethanolNMR - Nuclear magnetic resonance

The invention discloses a method for manufacturing KMnF<3> nuclear magnetic resonance imaging contrast agents. The method includes accurately weighing corresponding raw materials including KF.2H<2>O and MnCl<2>.4H<2>O according to a molar ratio of 3:1; adding a proper quantity of potassium oleate into the raw materials; dissolving the raw materials and the potassium oleate into anhydrous ethanol; and uniformly stirring the anhydrous ethanol with the raw materials and the potassium oleate to obtain a mixture, then adding the mixture into a sealed reaction container, and heating the mixture at the temperature of 160 DEG C for 24 hours to obtain KMnF<3> spherical particles with particle sizes of 15nm. The KMnF<3> spherical particles are uniform in particle size distribution. The method has the advantages that nanometer crystals manufactured by the method are low in cell toxicity and high in biocompatibility after being modified, the contrast agents are high in relaxation efficiency (of 23.15mM.S<-1>) and low in r2 / r1 ratio (of 3.23), and can be used for contrast-enhanced imaging for brains of mice as shown by primary animal nuclear magnetic resonance imaging experiments by the aid of colloidal solution manufactured by the KMnF<3> nuclear magnetic resonance imaging contrast agents; and the in-vivo retaining time of the KMnF<3> nuclear magnetic resonance imaging contrast agents is proper, and the KMnF<3> nuclear magnetic resonance imaging contrast agents can be used as novel medical nuclear magnetic resonance contrast agents.

Owner:NANCHANG UNIV

Waterproof concrete compacting agent and preparation method thereof

The invention discloses a waterproof concrete compacting agent and a preparation method thereof. The compacting agent consists of the following raw material components in percentage by weight: 10 to 13 percent of potassium hydroxide, 0.5 to 1 percent of volcanic ash, 0.5 to 1 percent of potassium oleate, 10 to 12 percent of sulfur, 0.5 to 1 percent of glycerol, 3 to 5 percent of triethanolamine, 0.5 to 1 percent of citric acid, 0.5 to 1.5 percent of ferric oxide, 0.5 to 1 percent of sodium fluosilicate, and the balance of water. Chemical crystal or colloid generated by chemical reaction of components in the compacting agent and silicon, calcium, sodium, magnesium and the like in cement can effectively prevent permeation of water molecules and effectively control cracking. The compacting agent contains extremely low harmful substances, particularly has extremely low chlorine ion content and ammonia content, reduces damage to steel bars and concrete, and is beneficial to environmental protection.

Owner:北京龙阳伟业科技股份有限公司

Hard polyurethane foam plastic specially adapted for pipe insulation layer

The invention discloses a hard polyurethane foam plastic in the insulating pipe layer, which is characterized by the following: adopting plural polyether, catalyst, foam stabilizer, distill water and foamer to form component A; using polymethylene polyphenyl polyisocyanates as raw material B; selecting triethanolamine, N, N-dimethyl cyclohexylamine, 2, 4, 6-tri (dimethylamine methyl) phenol and potassium oleate as catalyst; blending component A and B evenly; stirring; pouring the mass into mould; foaming; solidifying; obtaining the product with stable size for SY / T0415-96 standard.

Owner:SICHUAN NORMAL UNIVERSITY

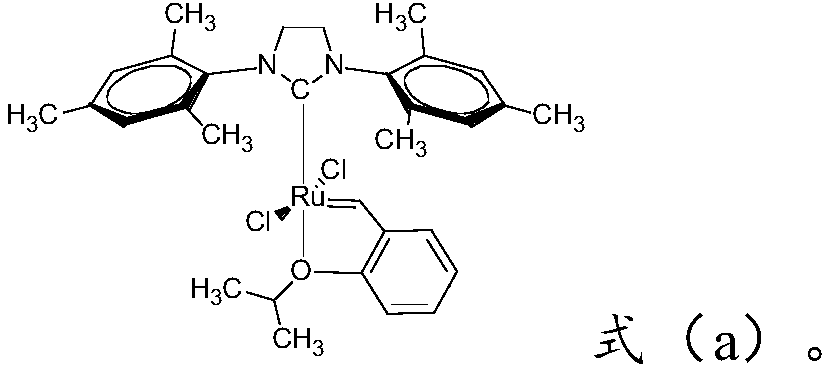

Method for producing hydrogenated copolymer through hydrogenation of conjugated diene

ActiveCN110627928AEfficient realization of selective hydrogenation reactionReduce dosageHydrogenation reactionHydrogen pressure

The invention provides a method for producing a hydrogenated copolymer through hydrogenation of conjugated diene. The method for producing the hydrogenated copolymer through hydrogenation of the conjugated diene comprises the following steps: (1) mixing part of conjugated diene latex and a Hoveyda-Grubbs II catalyst to obtain a mixture A; (2) mixing the rest of conjugated diene latex, the mixtureA and assistants to obtain a mixture B, wherein the assistants are potassium oleate and / or sodium oleate; (3) introducing hydrogen into the mixture B for stirring and degassing treatment, and then conducting stirring treatment continuously to obtain a mixture C; and (4) heating the mixture C, and improving hydrogen pressure for a hydrogenation reaction to obtain the hydrogenated copolymer. According to the method for producing the hydrogenated copolymer through hydrogenation of the conjugated diene, through a mixing mode where the conjugated diene latex and the Hoveyda-Grubbs II catalyst are added in batches, introduction of the specific assistants, and a treatment method where the hydrogen is adopted for degassing treatment in advance, and stirring is conducted after degassing treatment is conducted, the selective hydrogenation reaction of the conjugated diene can be efficiently achieved without solvents to obtain a product with a high hydrogenation degree.

Owner:SHANDONG JINGBO PETROCHEM +2

Bacteriostatic linen fiber softener

InactiveCN102877294APromote degradationBiodegradability is superior to dialkyl quaternary ammonium saltsBiochemical fibre treatmentVegetal fibresFiberAlkalinity

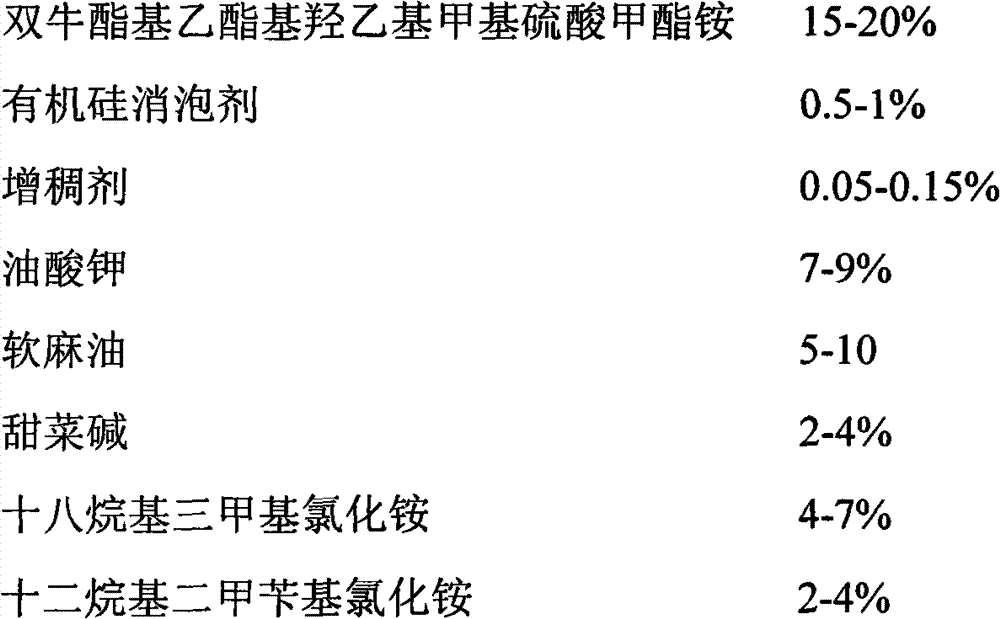

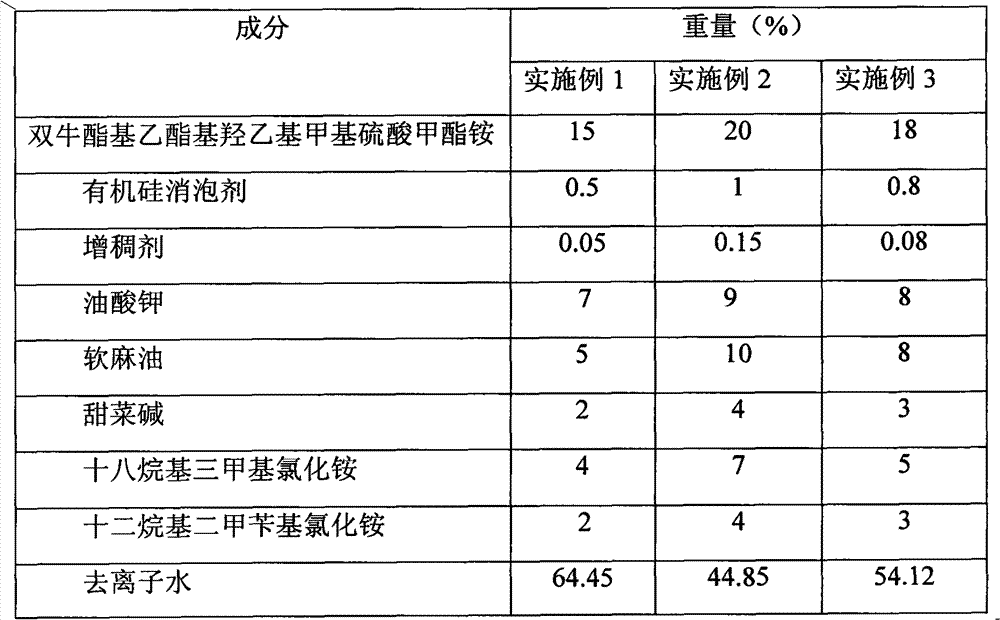

The invention relates to a bacteriostatic linen fiber softener, which comprises the following ingredients in percentage by weight: 15 to 20 percent of bitallow ethoxycarbonyl ethoxyl methyl sulfate, 0.5 to 1 percent of organosilicone defoamer, 0.05 to 0.15 percent of thickening agent, 7 to 9 percent of potassium oleate, 5 to 10 percent of linen softening oil, 2 to 4 percent of glycine betaine, 4 to 7 percent of octadecyl trimethyl ammonium chloride, 2 to 4 percent of dodecyl dimethyl benzyl ammonium chloride and the balance of deionized water, wherein 1 to 2 weight percent of marine biological rhzomorph and 0.3 to 0.5 weight percent of bacitracin can also be added into the softener. The clothes softener has high softness and antistatic property. By the clothes softener, clothes are soft and comfortable; and the clothes softener is faintly acidic, so that alkalinity in a detergent can be neutralized, and the clothes are close to the PH values of human bodies. The bacteriostatic linen fiber softener has high killing effect on common microbes and particularly pathogenic bacteria.

Owner:QINGDAO SANDING SANITARY PROD

Chemical coating method for modifying surface of magnesium hydroxide whisker material

InactiveCN101165105ACreation purpose realizationGood modification effectPigment treatment with non-polymer organic compoundsSodium stearatePhysical chemistry

The chemical coating process for surface modifying magnesium hydroxide crystal whisker material includes the following main steps: preparing materials, adding modifier, stirring to mix, filtering and drying, and packing. It features the modifier of potassium oleate C17H33COOK or sodium stearate C17H35COONa in the amount of 1.2-5.0 wt% of magnesium hydroxide crystal whisker, the concentration of the magnesium hydroxide crystal whisker suspension of 2.0-5.0 wt%, the stirring rate of 450-900 rpm, the mixing temperature of 75-90 deg.c and the mixing time of 20-60 min. The process has excellent modification effect and activating index of magnesium hydroxide crystal whisker up to 95 %, and is simple, low in cost, energy saving and environment friendly.

Owner:SHENYANG LIGONG UNIV

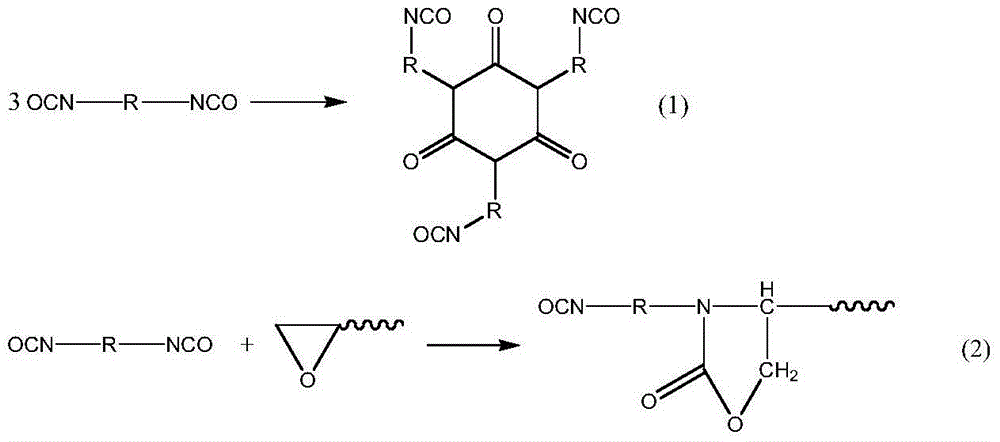

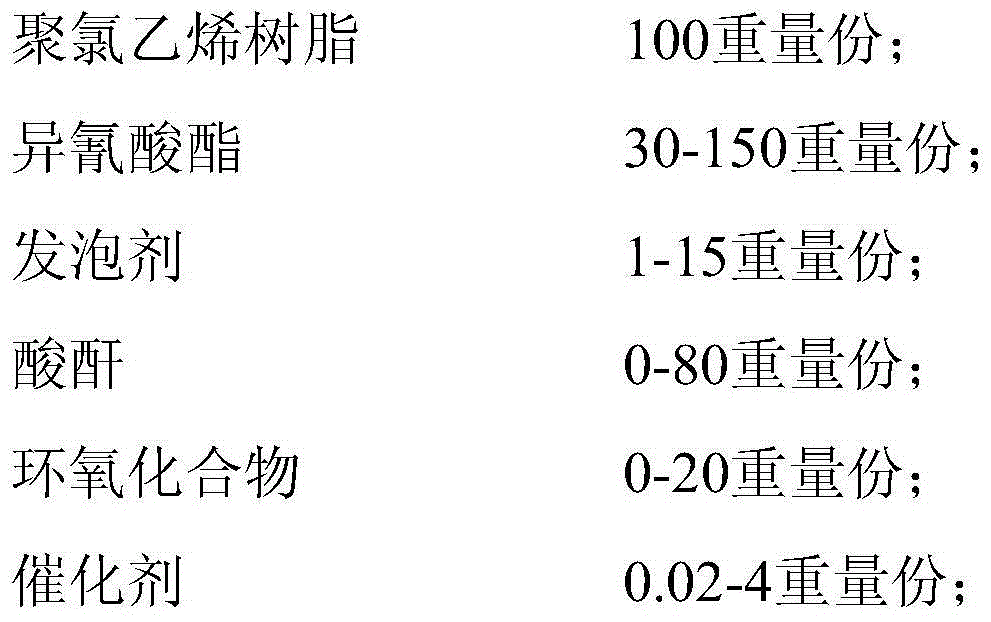

Crosslinking polyvinyl chloride foam and preparation method thereof

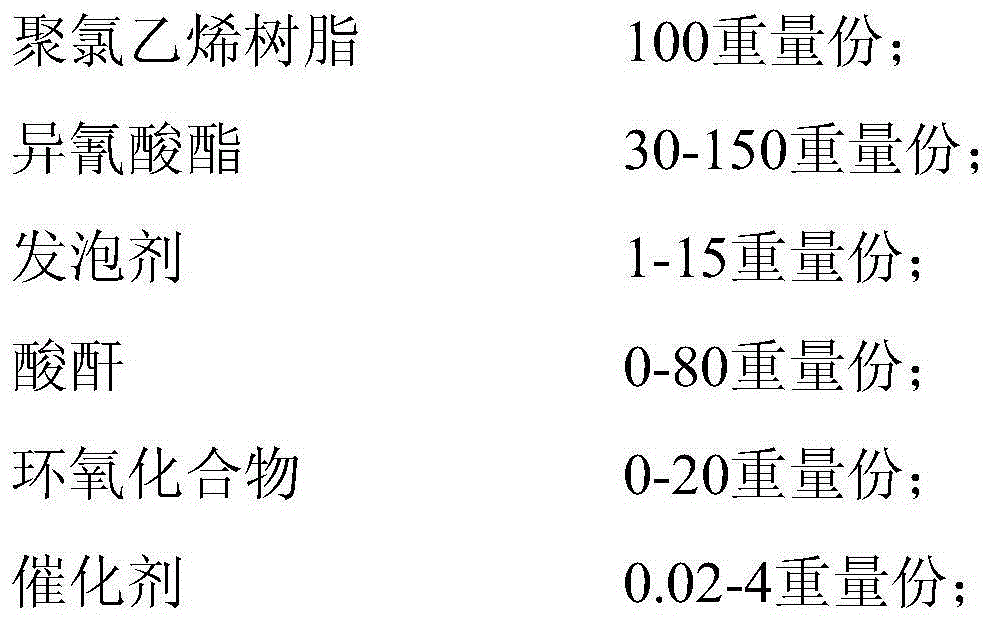

The invention discloses crosslinking polyvinyl chloride foam and a preparation method thereof, and belongs to the technical field of foamed materials. The problem of long time consumption of preparation of a crosslinking polyvinyl chloride foamed material in the prior art is solved, so that the quality and heat-resistant performance of the foamed material can be improved. The crosslinking polyvinyl chloride foam comprises the components in parts by weight: 100 parts of PVC resins, 30-150 parts of isocyanate, 1-15 parts of foaming agents, 0-80 parts of anhydride, 0-20 parts of epoxy compounds and 0.02-4 parts of catalysts, wherein the catalyst is one or more of N',N'',N'''-tri(dimethyl aminopropyl) symmetrical hexahydro-triazine, N-(alpha-ethoxyl) dimethylenimine, indole, sodium caprylate, isocaprylic acid, potassium oleate and potassium stearate. The foamed material is high in quality and heat-resistant performance, and high in production efficiency.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Cleaning agent

InactiveCN103194337AHas anti-corrosion effectEasy to cleanSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsPotassium oleate

The invention discloses a cleaning agent. The cleaning agent comprises the following materials in percentage by weight: 1 to 6% of potassium silicate, 2 to 7% of tripoly-sodium silicate, 1 to 5% of sodium carbonate, 0.5 to 3% of potassium oleate, 0.5 to 3% of alkaryl polyether, 0.5 to 3% of sodium gluconate, 0.5 to 3% of tetrasodium ethylenediamine tetraacetate, 0.5 to 3% of an antifoaming agent, 0.5 to 3% of a corrosion inhibitor, and the balance of water. According to the mode mentioned above, the cleaning agent provided by the invention has the formula adopting components without smell and toxicity, the residual scaling powder and the residual rosin can be permanently decomposed and fallen, the residual greasy dirt can be removed and dissolved, and the foam can be effectively removed; and the cleaning agent has the corrosion protection effect, is remarkable in the cleaning effect and is durable, and is an environment-friendly cleaning agent with reasonable price and high cost performance.

Owner:SUZHOU RUINAIJIE ELECTRONICS SCI & TECH NEW MATERIAL

Hard polyurethane foam plastic

The invention discloses a hard polyurethane foam plastic, which is characterized by the following: adopting complex polyether, catalyst, foamer, distill water and foamer as raw material A; using polymethylene polyphenyl polyisocyanates as raw material B; blending micromolecular hydroxy compound, tertiary amine catalyst and potassium oleate as catalyst; blending each component of raw material A evenly with component B; pouring the mass into mould; foaming; solidifying; obtaining the product with little toxicity and good environment-protective property.

Owner:SICHUAN NORMAL UNIVERSITY

Antibacterial softener

Owner:QINGDAO SANDING SANITARY PROD

Corrosion-resistant medical equipment disinfectant

InactiveCN104824050AImprove corrosion resistanceEffective protectionBiocideDisinfectantsSodium acetateMedical equipment

The invention discloses a corrosion-resistant medical equipment disinfectant which is prepared from the following raw materials in parts by weight: 5-8 parts of radix clematidis, 3-6 parts of schefflera arboricola, 4-5 parts of folium artemisiae argyi, 10-20 parts of nitrilotriacetic acid sodium salt, 2-4 parts of potassium oleate, 1.2-2.3 parts of sodium perborate, 2-4 parts of monosaccharide, 5-6 parts of a mine extract liquid, 13-16 parts of ethanol, 12-26 parts of sodium dichloro isocyanurate, 4-8 parts of mock-strawberry, 6-8 parts of myrrh and 12-24 parts of glycerinum. The corrosion-resistant medical equipment disinfectant disclosed by the invention has the beneficial effects of high corrosion resistance, long-lasting disinfecting capability, no poison and no pollution; and equipment can be effectively protected.

Owner:青岛千帆高新技术有限公司

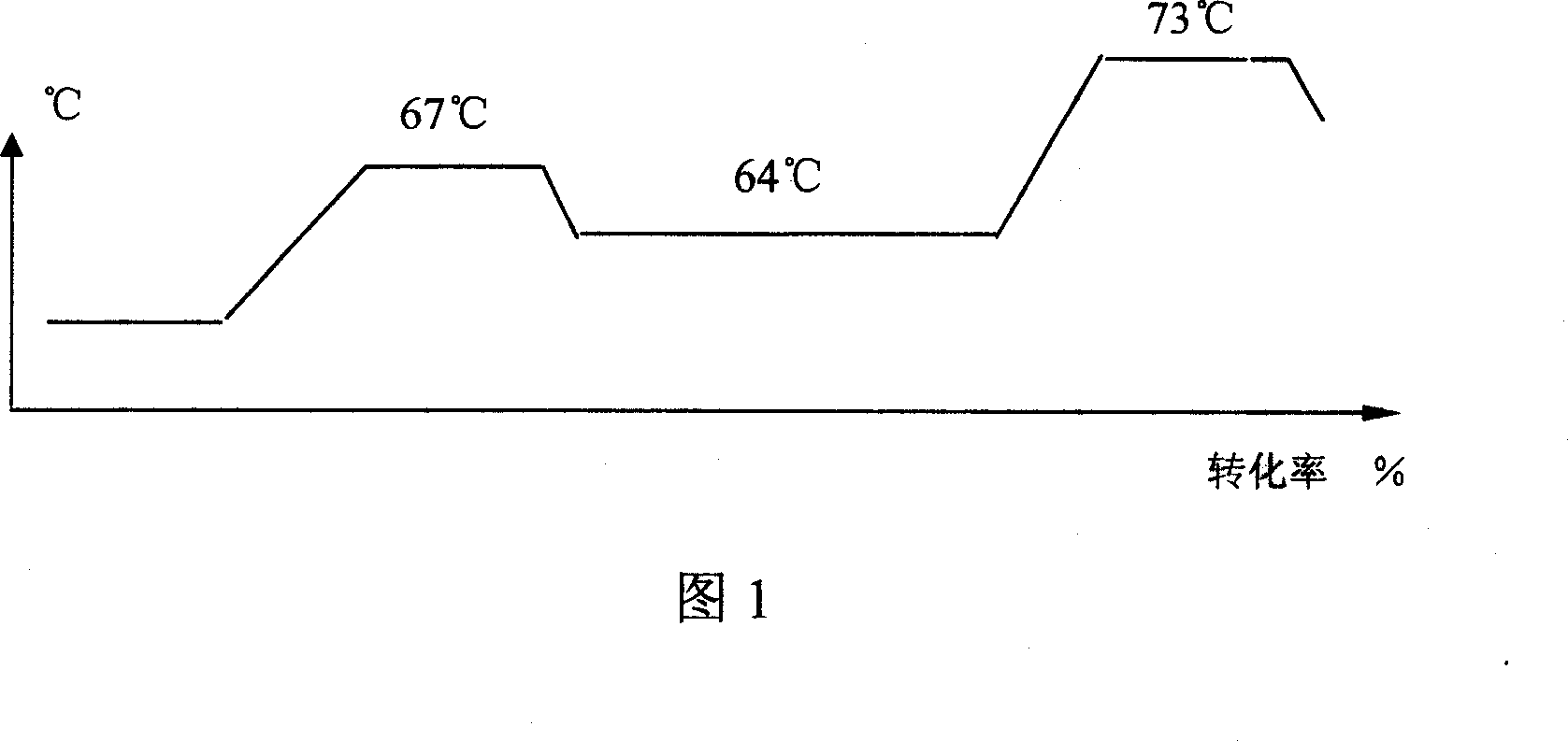

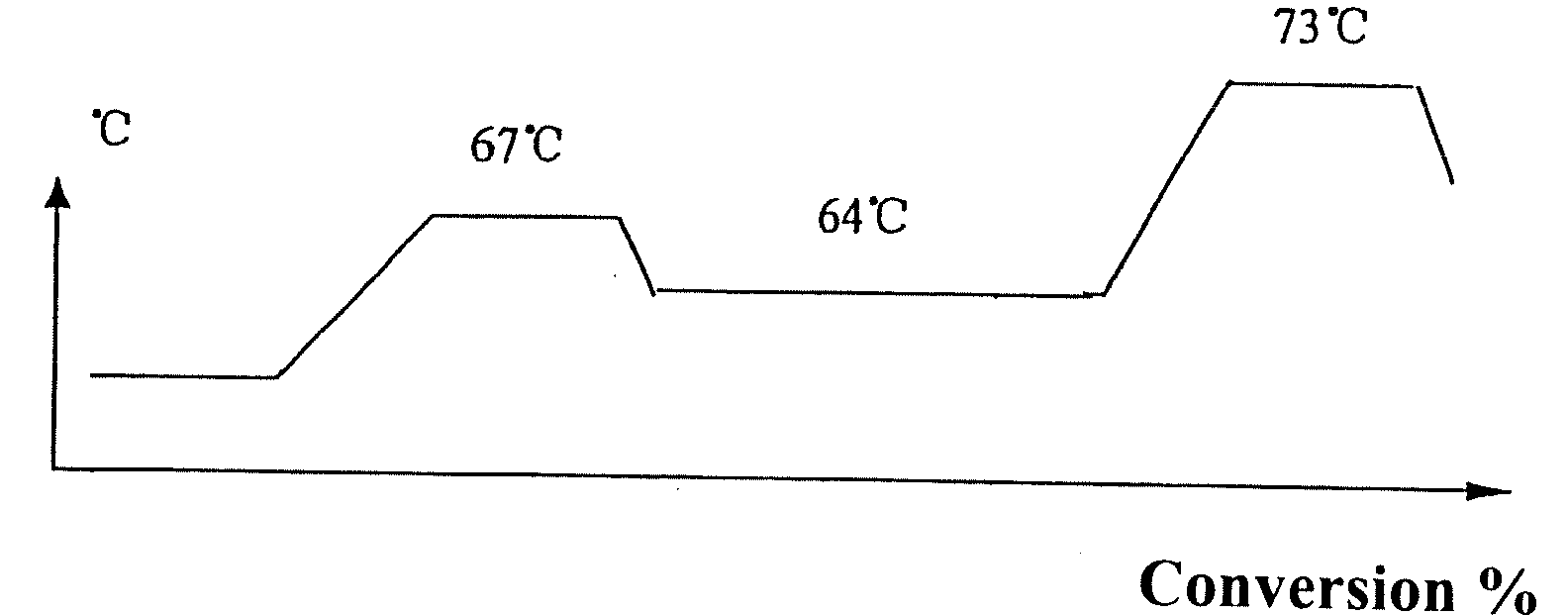

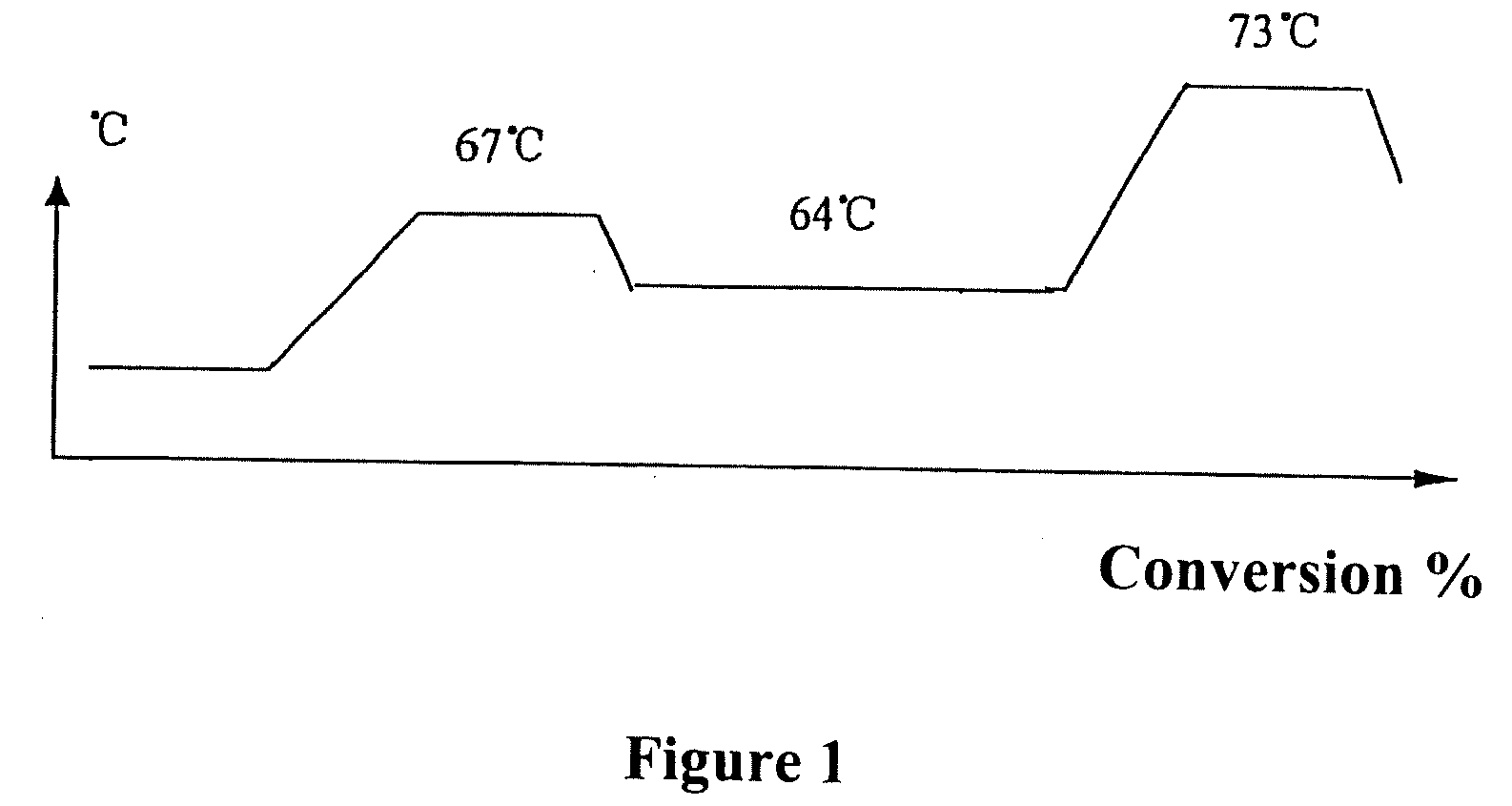

Preparation method of small particle sized polybutadiene latex used for the production of ABS

A preparation method of small particle-sized polybutadiene latex used for the production of ABS is disclosed, which includes putting components comprising 34.00-45.00% by weight of the butadiene, 0-6.0% by weight of the second monomer, 52.11-63.13% by weight of the desalinized water, 0.12-0.22% by weight of the mercaptan(TDM), 0.80-2.60% by weight of the emulsifiers composed of potassium abietate and potassium oleate, into the same polymerization reactor, then heating the mixture of the components and stirring the same at a temperature range of 60-75° C. The reaction lasts for 9-12 hours and the conversion is higher than 97%. The method has the advantages such as higher conversion, shorter reaction period and lower latex viscosity. During the first stage of the reaction, more heat is released by increasing the reaction rate. When the conversion reaches 40-80%, the heat release rate of intermediate stage is depressed by decreasing the reaction temperature. When the conversion is higher than 80%, the reaction temperature reaches the highest. Thus, severe heat release is avoided. Moreover, the butadiene polymerization can be controlled steadily and the reaction period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anion natural latex sheet and processing method thereof

InactiveCN105985541AImprove sterilization abilityEasy to synthesizeFlat articlesHuman bodyLife quality

The invention relates to an anion natural latex sheet and a processing method thereof, relates to the field of latex sheet manufacturing and provides the anion natural latex sheet which is antibacterial, high in elasticity, comfortable, environmentally friendly, soft and elastic and the processing method thereof. The anion natural latex sheet is characterized by being prepared from, by weight, 90-100 parts of natural latex, 3-8 parts of anion powder, 1-9 parts of sulfur, 1-5 parts of accelerant, 1-6 parts of zinc oxide and 0.1-2 parts of potassium oleate. The processing method includes the steps of weighing, mixing, vulcanization, shaping, forming and processing into a finished product. The anion natural latex sheet has the advantages of being high in elasticity, soft, comfortable and the like, and can effectively condition functions of a human body and improve living quality of people.

Owner:江苏金世缘乳胶制品股份有限公司

Efficient wiredrawing fluid capable of realizing surface metal rust prevention

InactiveCN103966004AImprove wear resistanceImprove antioxidant capacityLubricant compositionEnvironmental resistanceEngineering

The invention relates to a wiredrawing fluid, particularly to an efficient wire drawing fluid capable of realizing surface metal rust prevention. Thewiredrawing fluid is prepared from the raw materials in parts by weight as follows: 28-32 parts of trimethylolpropane oleate, 4-5 parts of emulsified silicon oil, 15-18 parts of pentaerythritol oleate, 2-3 parts of ascorbyl palmitate, 6-8 parts of potassium oleate, 5-6 parts of sodium dodecyl sulfate, 2-3 parts of chlorinated paraffin, 4-5 parts of inositol hexaphosphate, 4-5 parts of additives and 800-1000 parts of deionized water. According to thewiredrawing fluid, the trimethylolpropane oleate and the pentaerythritol oleate which are excellent in lubricating property, high in viscosity index, good in fire resistance and readily biodegradable are mixed to be used as base oil, and then the additives such as theinositol hexaphosphate, thechlorinated paraffin and the like are combined, so that the prepared wiredrawing fluid has the excellent abrasion resistance, the excellent oxidation resistance and the good corrosion and rust resistance, theoxidative blackening phenomenon of a metal surface is effectively improved, the wire smoothness is high, and thewiredrawing fluid is environment-friendly and efficient.

Owner:ANHUI JIUHUA KIMRUN COPPER IND

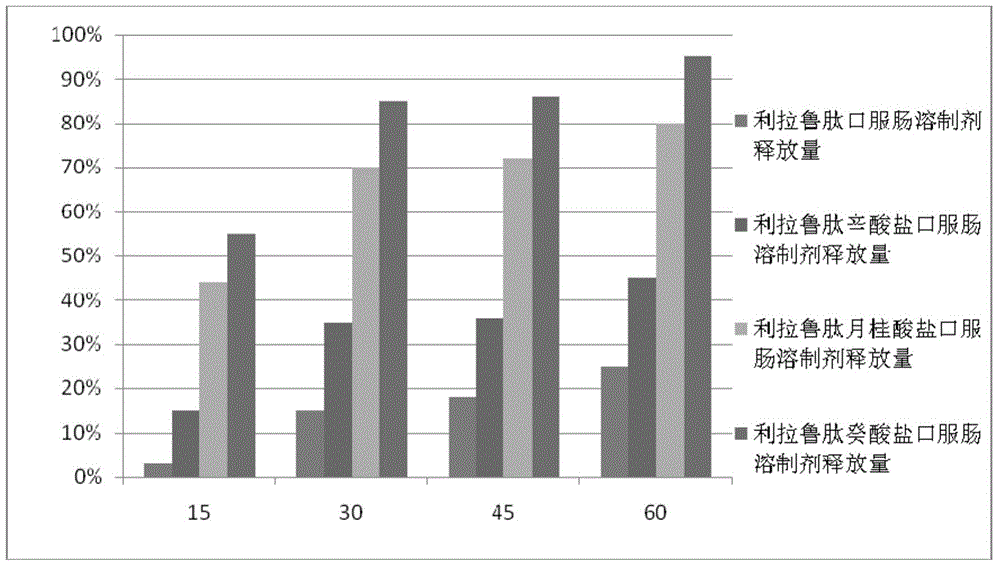

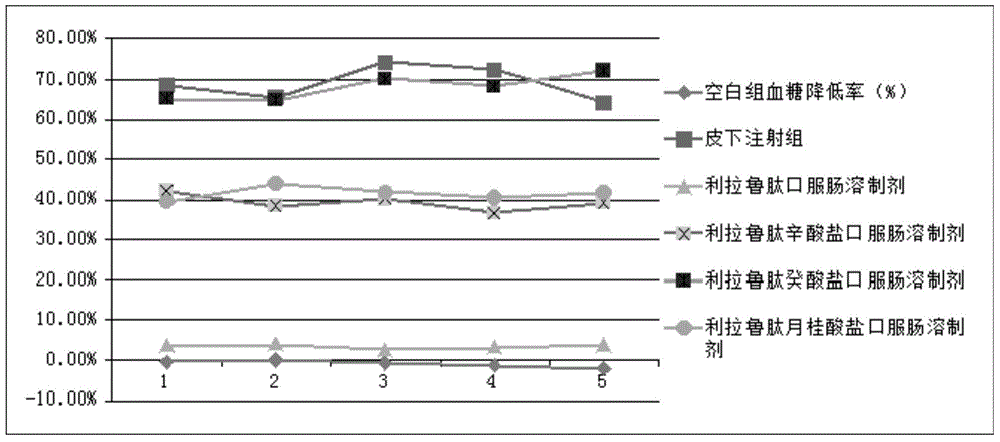

Intestinal absorption promoting liraglutide salt for preparing oral enteric-coated preparations

InactiveCN104998251AImprove bioavailabilityImprove stabilityPeptide/protein ingredientsMetabolism disorderPotassiumSodium octanoate

The invention discloses an intestinal absorption promoting liraglutide salt for preparing oral enteric-coated preparations, and belongs to the field of medicines. The liraglutide salt is selected from salts formed through reacting liraglutide with sodium caprate, potassium caprate, benzene sulfonic acid, sodium dodecyl benzene sulfonate, potassium dodecyl benzene sulfonate, sodium octanoate, potassium octanoate, sodium laurate, potassium laurate, sodium oleate and potassium oleate.

Owner:哈尔滨吉象隆生物技术有限公司

Multifunctional microemulsified gasoline and diesel combustion adjuvant

InactiveCN101348739AGood energy saving and environmental protection effectEffective heat increaseLiquid carbonaceous fuelsAdjuvantSoft water

The invention relates to amultifunctional micro-emulsified gasoline and diesel oil combustion-supporting agent which consists of additive soft water, C5-9 fatty alcohol, oleic acid, sodium hydroxide, isopropanolamine and potassium oleate. The multifunctional micro-emulsified gasoline and diesel oil combustion-supporting agent is characterized by comprising the following compositions in percentage by weight: 20 to 35 percent of the additive soft water, 20 to 30 percent of the C5-9 fatty alcohol, 40 to 50 percent of the oleic acid, 1 to 2 percent of the sodium hydroxide, 2 to 3 percent of the isopropanolamine and 1 to 2 percent of the potassium oleate. The compositions are fully stirred and mixed in a container to prepare the multifunctional micro-emulsified gasoline and diesel oil combustion-supporting agent which has the characteristics of high stability, wide applicability, energy conservation, environmental protection, non-corrosiveness, etc. at the normal temperature, the combustion-supporting agent and gasoline or diesel oil according to the weight rate of 15 to 85 percent are mixed to prepare a micro-emulsified gasoline or diesel oil composite fuel which has transparent appearance, good stability and high thermal efficiency and can be widely used in an internal combustion engine of gasoline and diesel oil as an environment-friendly fuel.

Owner:金相哲

Preparation method of graphene complex latex sponge

The invention relates to a preparation method of graphene complex latex sponge and belongs to the technical field of latex sponge preparation. The preparation method comprises the following steps: carrying out ultrasonic mixing on natural latex, a graphene improver, sulphur and water, and carrying out ultrasonic mixing on zinc oxide, diphenylguanidine, sodium fluosilicate and potassium oleate; remixing the two mixtures to obtain uniform emulsion, then carrying out physical foaming on the emulsion, then putting in a mould to be cured, and demoulding, so that the graphene complex latex sponge is obtained. The preparation method provided by the invention is simple and reasonable in production technology, the graphene improver is adopted in the production process, and excellent mechanical properties of graphene are utilized, so that mechanical properties of the sponge are enhanced, and the product has excellent stretchability and resilience and is difficult to be aged. The hardness of the product can reach 30-45KPa, the resilience reaches 90-95%, and the tensile strength reaches 150-200KPa.

Owner:YANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com