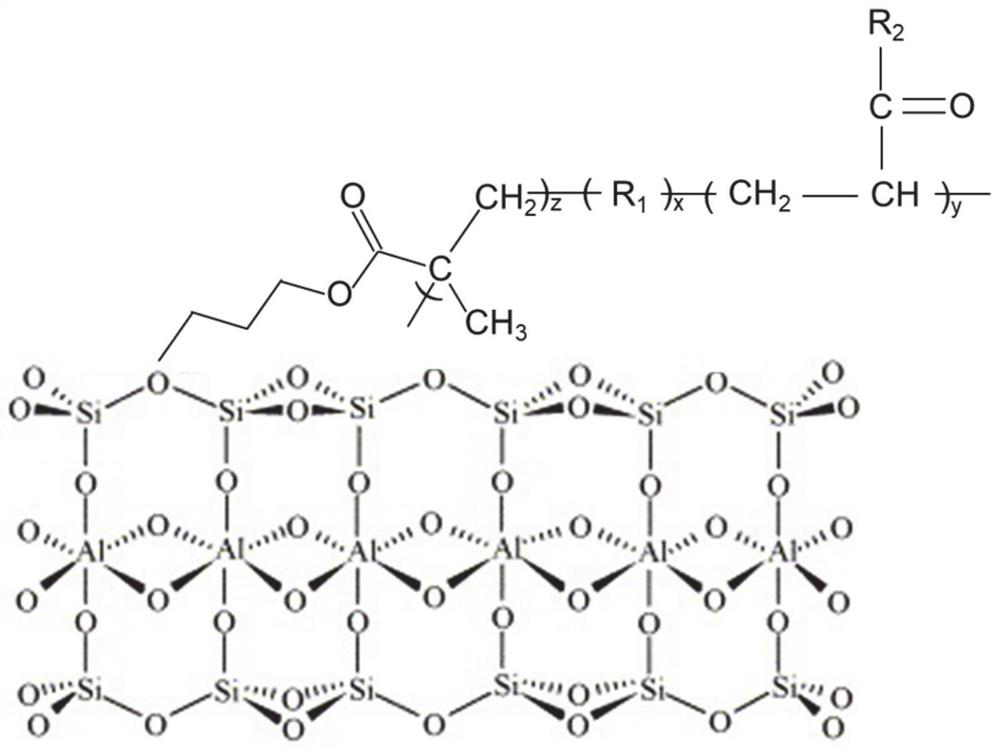

Organic-inorganic hybrid nano material as well as preparation method and application thereof

A nanomaterial and organic technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of unsuitable industrial production and application promotion, complex preparation process, etc., and achieve industrial production and application promotion, preparation technology suitable for Simple and easy to scale up production results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

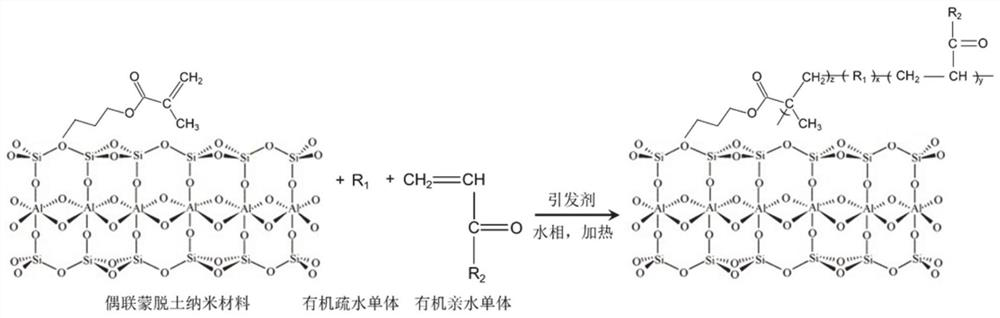

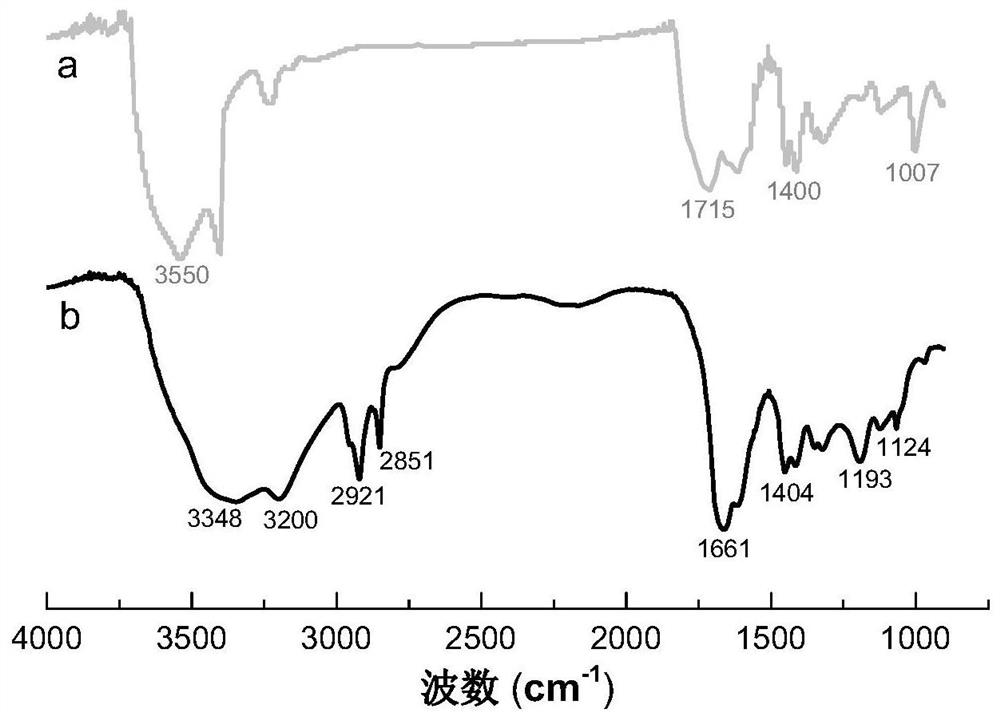

Method used

Image

Examples

Embodiment approach

[0065] The apparent viscosity of the system was measured with a DV2TLV viscometer produced by Brookfield, and the test temperature was 50°C. According to an embodiment of the present application, the experimental procedure is as follows:

[0066] Step (1): add the purchased industrial-grade coupled montmorillonite nanomaterials, organic hydrophilic monomers, and organic hydrophobic monomers into a round-bottomed flask, add an appropriate amount of water, stir and dissolve, and pass nitrogen to remove oxygen;

[0067] Step (2): adding the initiator into the beaker, adding an appropriate amount of water, stirring and dissolving, and deoxidizing with nitrogen;

[0068] Step (3): the round-bottomed flask in (1) is placed in an oil bath, mechanically stirred and heated;

[0069] Step (4): add the solution in step (2) into the dropping funnel on the round-bottomed flask in step (3), and drop the solution in step (2) into the round-bottomed flask in step (3), After heating and reac...

Embodiment 11

[0093] Example 1 Preparation of 1# hybrid nanomaterials

[0094] Put 5.00 g of coupled montmorillonite nanomaterials, 2.50 g of sodium α-alkenyl sulfonate and 2.50 g of acrylamide (the mass ratio of the two is 1:1) into a round-bottomed flask, add 80 g of water, and stir to mix. Evenly, introduce nitrogen to remove oxygen for 30min, then place in oil bath pot, stir mechanically at 300rpm, and heat to 50°C to obtain mixed solution I; add 0.025g potassium persulfate into the beaker, add 10g water, stir to dissolve, pass into Deoxygenate with nitrogen for 20 minutes to obtain mixed solution II; add mixed solution II to the dropping funnel on the round-bottomed flask, adjust the dropping rate, add dropwise time for 10 minutes, heat to 80°C, and react for 5 hours. The organic-inorganic hybrid nanomaterial was obtained, which was recorded as sample 1#.

Embodiment 22

[0095] Example 2 Preparation of 2# hybrid nanomaterials

[0096] Put 0.10g of coupled montmorillonite nanomaterials, 4.95g of sodium α-alkenyl sulfonate and 4.95g of acrylamide (the mass ratio of the two is 1:1) into a round-bottomed flask, add 80g of water, and stir to mix. Evenly, introduce nitrogen to deoxygenate for 30min, then place in an oil bath pot, stir mechanically at 300rpm, heat to 50°C to obtain mixed solution I; add 0.05g potassium persulfate into a beaker, add 10g water, stir to dissolve, and pass Deoxygenate with nitrogen for 20 minutes to obtain mixed solution II; add mixed solution II to the dropping funnel on the round-bottomed flask, adjust the dropping rate, add dropwise time for 10 minutes, heat to 80°C, and react for 5 hours. The organic-inorganic hybrid nanomaterial is obtained, which is recorded as sample 2#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com