Method for preparing Nano cube of hematite

A nano-cube and hematite technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problem of poor shape and size uniformity of nanoparticles, agglomeration of hematite nanoparticles, complex process, etc. problems, to achieve the effects of easy control of the reaction process, uniform shape and particle size, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to the molar ratio of sodium oleate and iron ion number 3:1, 1.6g (5.1mmol) sodium oleate, 0.48g (1.7mmol) ferric chloride hexahydrate, 1mL oleic acid and 10mL ethanol were added to the The volume of 16mL aqueous solution is 30mL polytetrafluoroethylene reactor, stir magnetically at 400rpm for one hour, the solution is divided into two uniform phases: the upper layer is reddish brown, and the lower layer is colorless; after sealing the reactor, place it in an oven at 180°C Stand at constant temperature for 8 hours. The obtained synthetic solution was cooled to room temperature, and 0.12 g of solid was obtained after centrifugation. After the solid was washed with ethanol, it was dispersed in 10 mL of cyclohexane. 10 mL of ethanol was added to precipitate a solid product.

[0022] During the synthesis process, the prepared reaction solution is stirred and divided into two uniform phases. After detection, the reddish brown on the upper layer is the oleic acid s...

Embodiment 2

[0029] According to the molar ratio of potassium oleate and iron ion number 2:1, 1.5g (4.8mmol) potassium oleate, 0.48g (2.4mmol) ferric dichloride tetrahydrate, 2mL oleic acid and 8mL ethanol were added to the The volume of 16mL aqueous solution is 30mL polytetrafluoroethylene reaction kettle, magnetically stirred at 500rpm for two hours, the solution is divided into reddish-brown upper layer and colorless uniform two-phase lower layer; the reaction kettle is sealed and placed in an oven at 220°C to keep the temperature static Placed for 8 hours; the resulting synthetic solution was cooled to room temperature, centrifuged to obtain 0.14g solid, washed with ethanol, dispersed in 20mL of hexane, centrifuged again to separate the solid precipitate, and obtained red hexane Add 20 mL of ethanol to the alkane colloidal solution, and the solid product is precipitated.

[0030] The characterization method is the same as in Example 1.

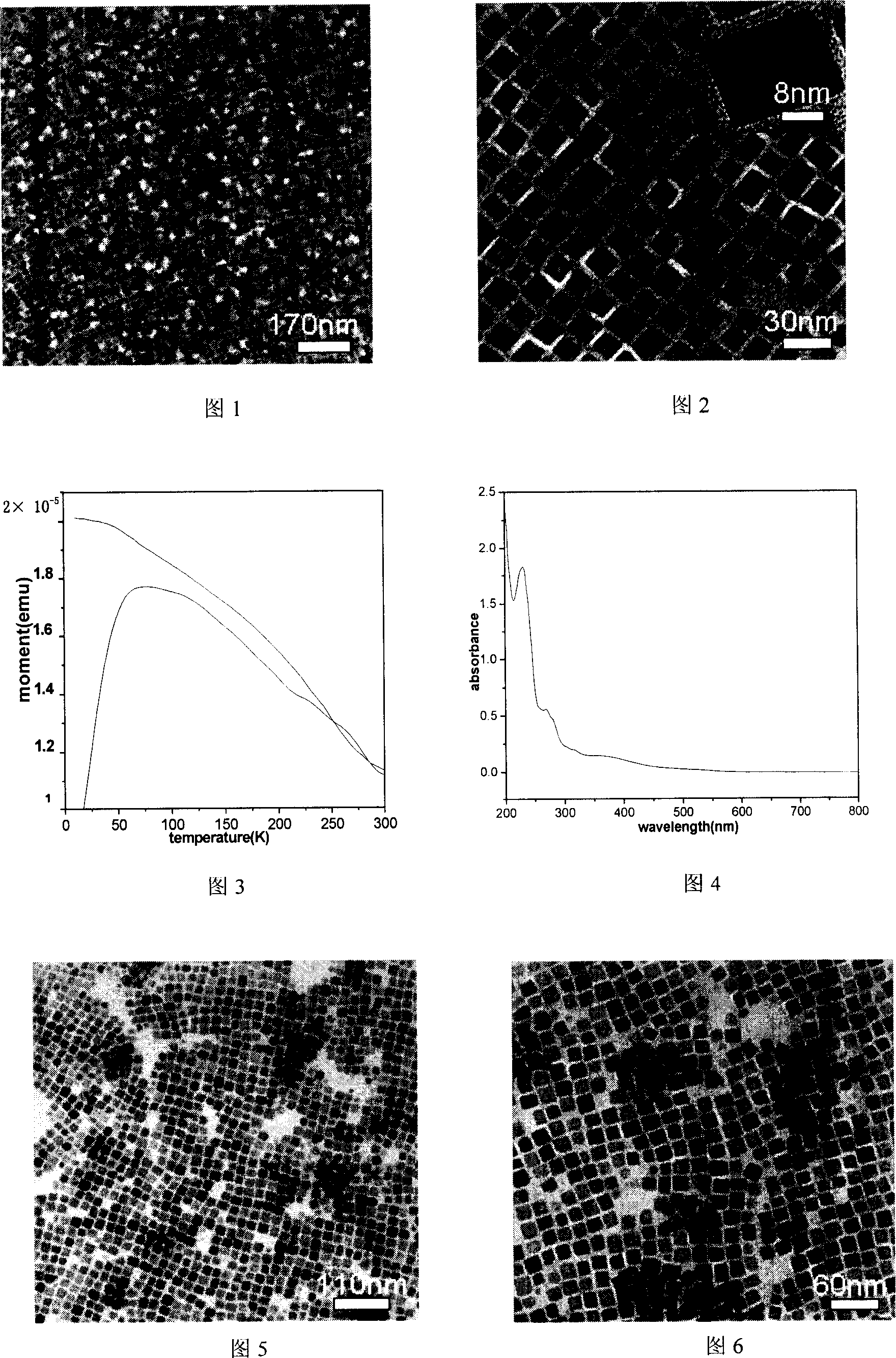

[0031] Figure 5 shows the transmission electron...

Embodiment 3

[0033]According to the molar ratio of sodium oleate and iron ion number 4:1, sequentially add the mixed solution of 0.97g (3.2mmol) sodium oleate, 0.32g (0.8mmol) ferric nitrate nonahydrate, 5mL oleic acid and 4mL ethanol to the container. There is 16mL of aqueous solution in a 30mL polytetrafluoroethylene reactor, magnetically stirred at 200rpm for two hours, until the solution is divided into two uniform phases, the reactor is sealed, and placed in an oven at 180°C for 8 hours at a constant temperature. The resulting synthetic solution was cooled to room temperature, and 0.09 g of solid was obtained after centrifugation. After the solid was washed with ethanol, it was dispersed in 2 mL of chloroform, and after the solid precipitate was separated by centrifugation, 2 mL of the obtained red chloroform colloidal solution was added. ethanol, the solid product precipitated out. The representation method is the same as above.

[0034] Figure 6 shows the transmission electron micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com