Method for manufacturing articles for daily use

A technology for daily necessities and a production method, applied in the field of daily necessities, can solve the problems of no skin texture, rigid and soft texture, insufficient elasticity, etc., and achieve the effects of stable and reliable effect, simple production method and convenient production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

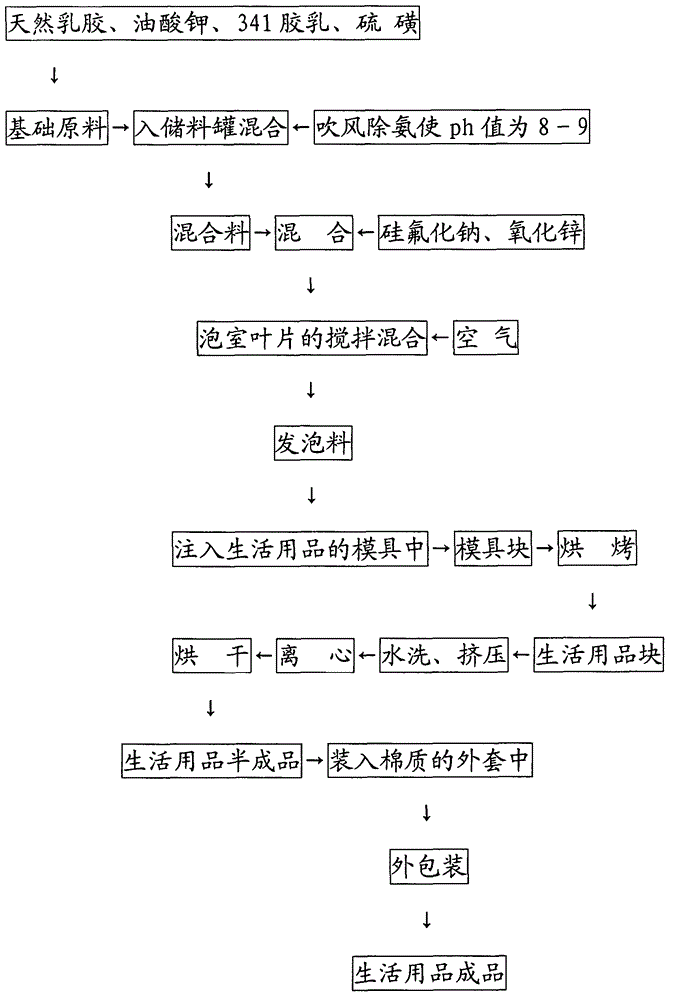

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0022] A method for making daily necessities:

[0023] 1. Preparation of mixture: 100 parts by weight of natural latex, 1 part by weight of potassium oleate as a foam stabilizer, 5-20 parts by weight of 341 latex as a cell modifier, and 2.5 parts by weight of sulfur as a crosslinking agent As the basic raw material, the basic raw material is put into the storage tank and mixed, and the ammonia is removed by blowing during the mixing process so that the pH value is 8-9, and the purpose of controlling the ammonia content is achieved by controlling the pH value, and the mixture is prepared. stand-by;

[0024] 2. Preparation of foaming material: the mixture, 1 part by weight of sodium silicofluoride as a gelling agent, and 5 parts by weight of zinc oxide as an active agent are pumped into the foaming chamber of the foaming machine...

specific Embodiment approach 2

[0031] Carry out by specific embodiment one, just: to described natural latex, potassium oleate as foam stabilizer, 341 latex as cell improving agent, sodium silicofluoride as gelling agent, oxidation as active agent Zinc and sulfur as a cross-linking agent were carried out at a reduction of 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30 times, and were also enlarged by 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, and 30 times have been implemented, and all have received expected good results. The present invention has a solid foundation for small-scale experiments, laboratory experiments, enlarged experiments, and productive experiments, as well as a solid foundation for theoretical guidance and operability for production and application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com