Preparation method of graphene complex latex sponge

A graphene composite, latex sponge technology, applied in the field of latex sponge preparation, can solve the problems of single product function, easy aging, low mechanical properties, etc., and achieve the effects of simple production process, not easy to aging, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through specific implementation, but not limited thereto.

[0015] 1. Preparation of graphene modifier:

[0016] Take 25-30 kg of water, 40-50 kg of sulfuric acid, 25-30 kg of potassium permanganate, 10-15 kg of graphite powder, and 0.5-8 kg of sodium octadecylsulfonate.

[0017] Preparation:

[0018] (1) The graphite powder was oxidized by the Hummer method to prepare graphene oxide.

[0019] (2) Stir graphene oxide, sodium octadecylsulfonate and water at 20-30° C. under ultrasonic conditions for 0.5-5 hours to prepare a graphene oxide aqueous solution.

[0020] (3) Freeze-dry the graphene oxide aqueous solution at -20~-50°C to obtain the graphene modifier.

[0021] Performance investigation of graphene modifier:

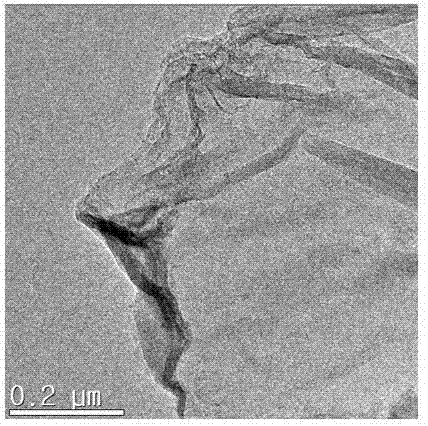

[0022] (1) Transmission electron micrographs of graphene modifiers such as figure 1 Shown: the graphene in the improver is a flake carbon material with a diameter of about 0.5 μm.

[0023] (2) Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com