Patents

Literature

44results about How to "Has anti-corrosion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel corrosion and scale inhibitor, and preparation method and application thereof

InactiveCN108623020AGood synergyLong stable periodSpecific water treatment objectivesScale removal and water softeningComposite filmPhosphate

The invention discloses a novel corrosion and scale inhibitor. The novel corrosion and scale inhibitor comprises the following components in percentages by weight: 15-20% of an organic phosphonate, 10-15% of acrylic acid or an acrylic acid copolymer, 3-5% of a phosphate, 10-20% of an organic acid, 4-8% of an inorganic base, 1-3% of an azole derivative and the balance of deionized water. The corrosion and scale inhibitor can form a mesh composite film on a metal surface. The novel corrosion and scale inhibitor can form a layer of mesh composite film on the metal surface, and the mesh compositefilm has a remarkable dirt repelling effect and the corrosion and scale inhibitor is suitable for treatment of circulating cooling water with high alkalinity, high hardness and high content of chloride ions.

Owner:XIAN JINGDA CHEM

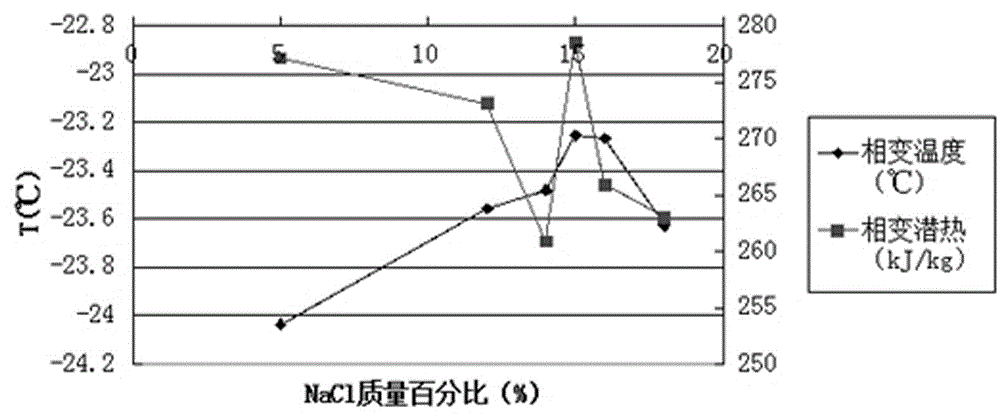

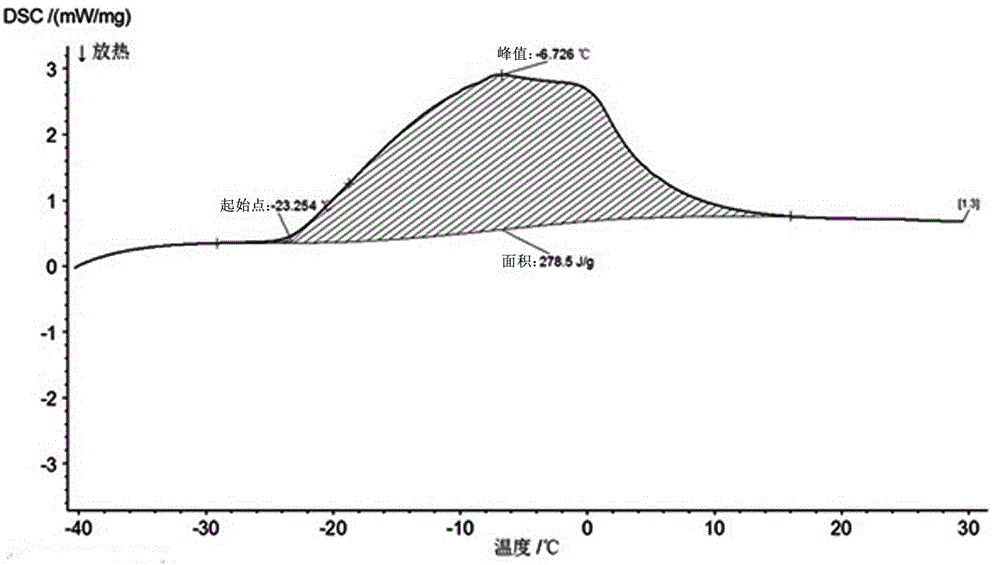

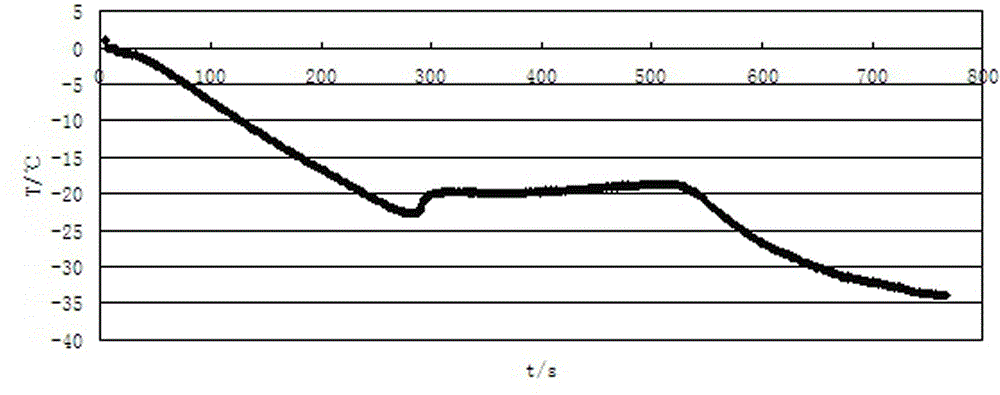

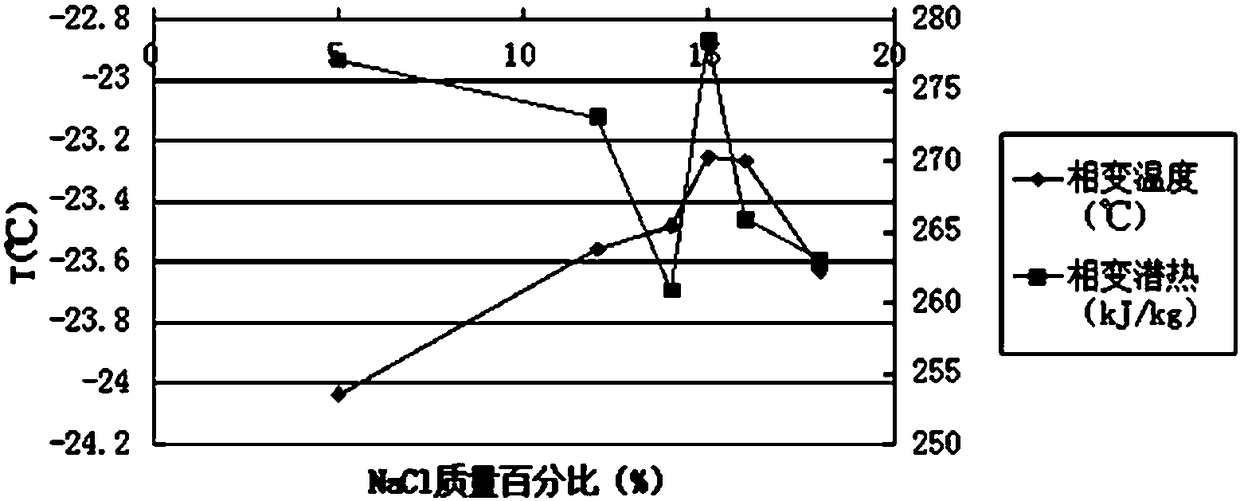

Low-temperature phase change cold storage material and production method thereof

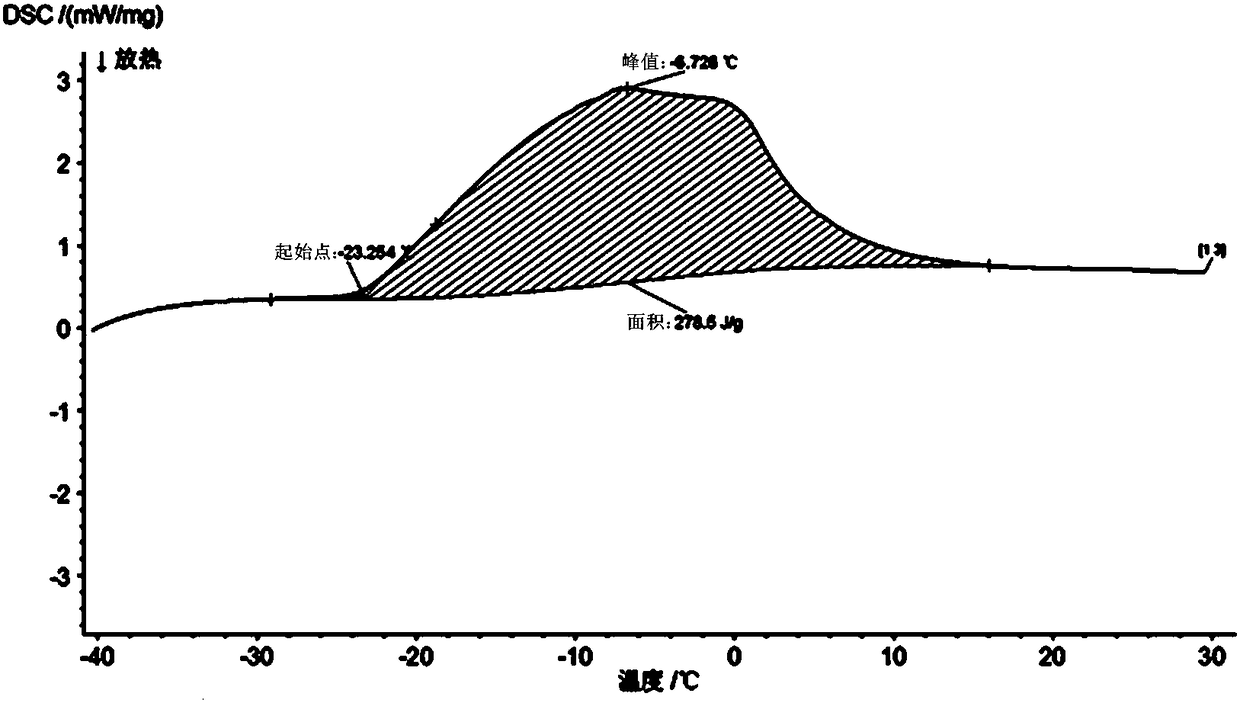

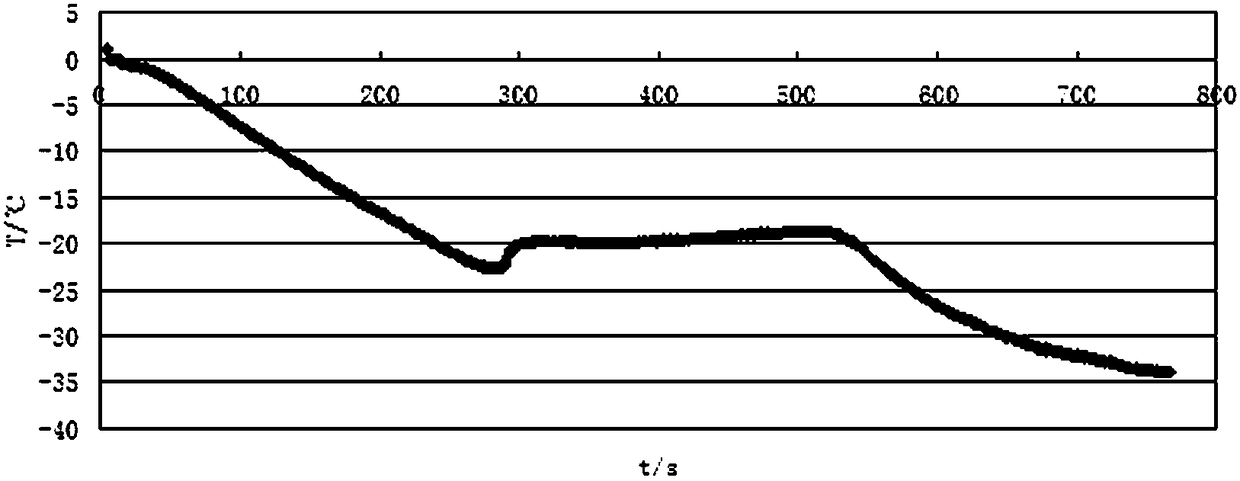

ActiveCN104830283AImprove thermal conductivityHigh latent heat of phase changeHeat-exchange elementsPotassium nitrateTO-18

The invention discloses a low-temperature phase change cold storage material and a production method thereof. The low-temperature phase change cold storage material is made from, by weight, 5% to 18% of sodium chloride, 4% to 17% of potassium nitrate, 74% of water, 1% of sodium tetraborate, 1% of sodium benzoate, and 2% of polyvinyl alcohol. The phase change temperature of the low-temperature phase change cold storage material is -20 DEG C to -25 DEG C; the low-temperature phase change cold storage material is suitable for cold-storage transportation of frozen foods, cold storage density per unit mass is high, and latent heat of phase change is above 260kJ / kg. The low-temperature phase change cold storage material has the advantages that the matching of ingredients is simple, the range of sources is wide, and the preparing method is easy to operate and suitable for industrial popularization.

Owner:SHANGHAI MARITIME UNIVERSITY

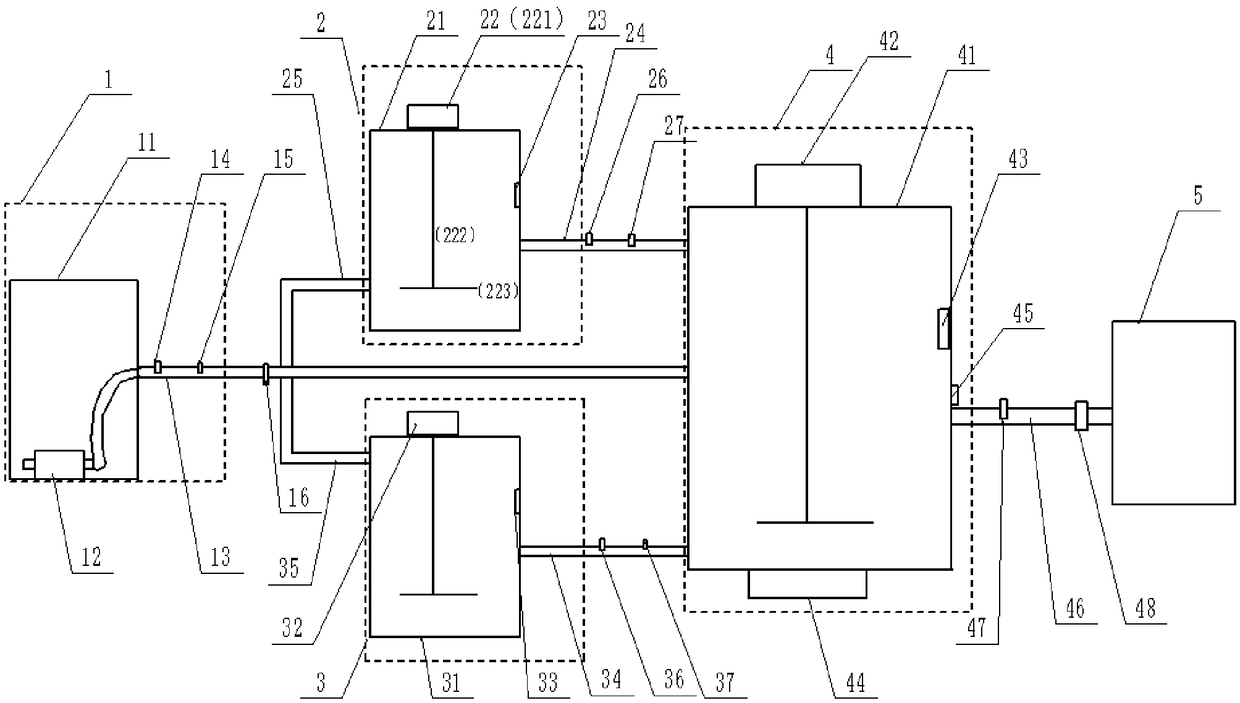

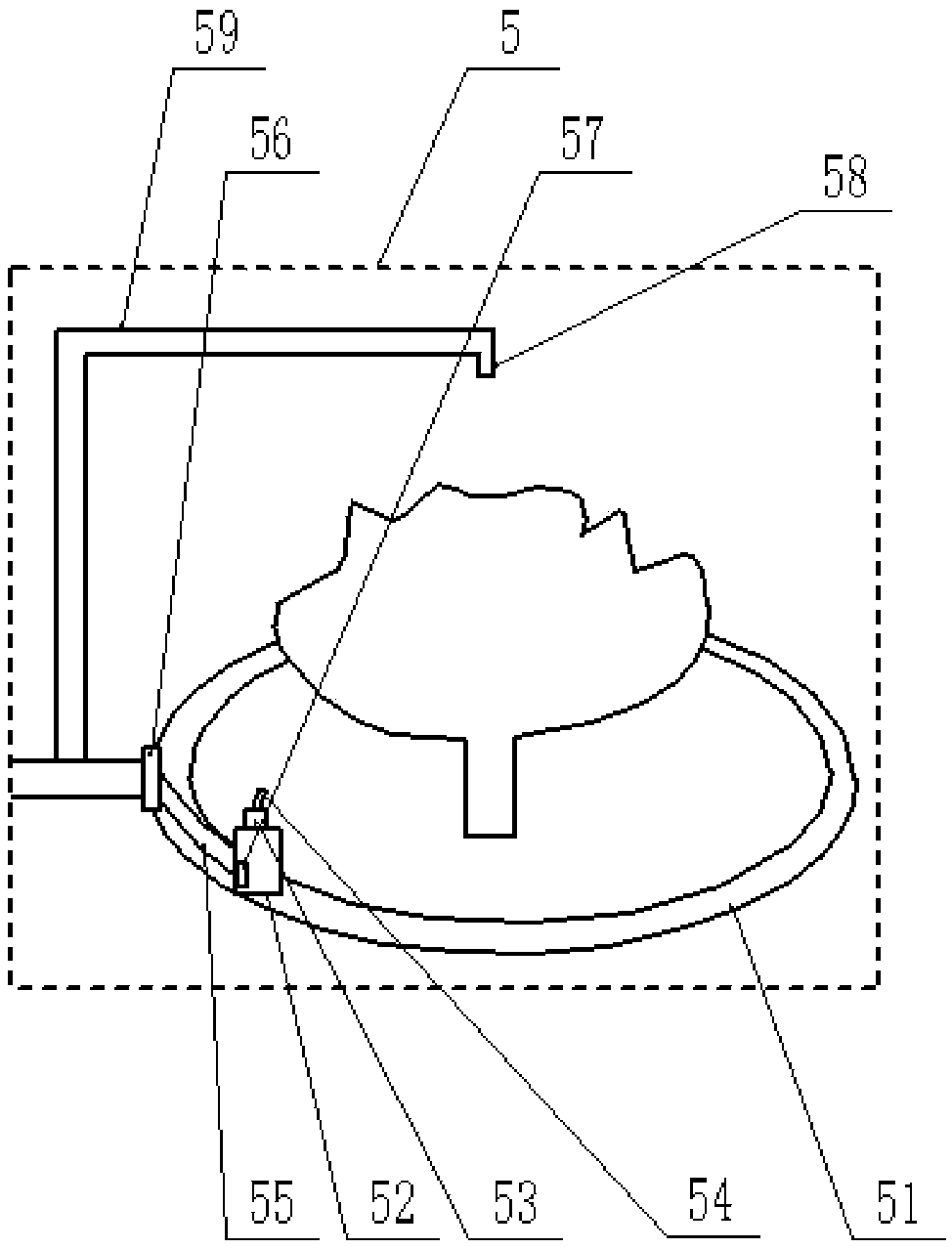

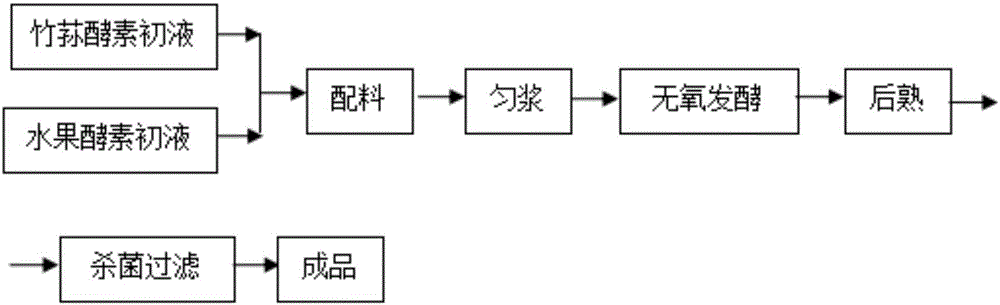

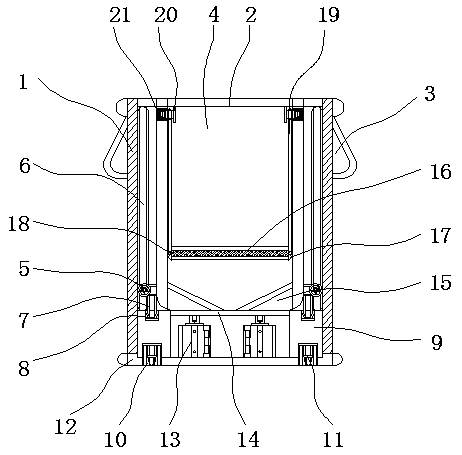

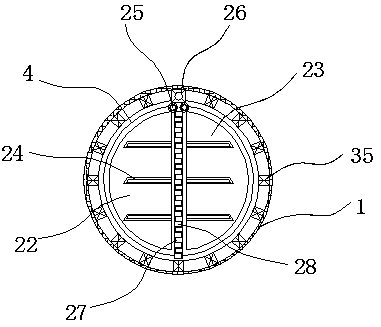

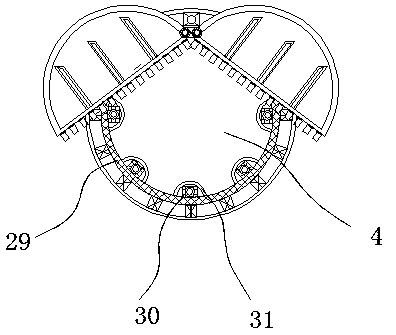

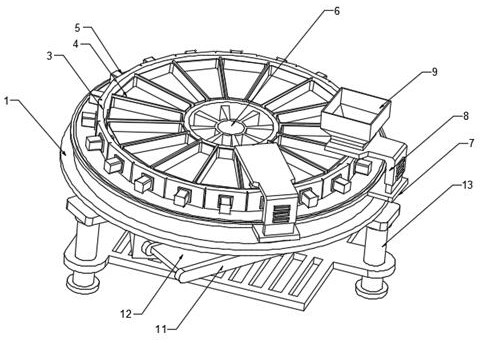

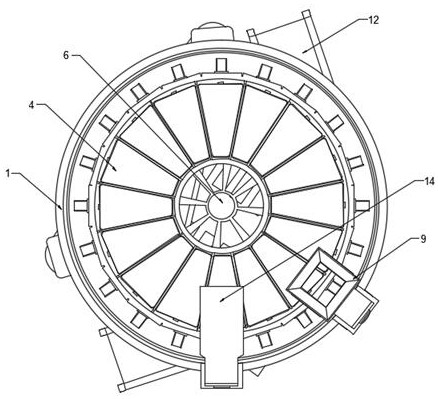

Orchard water-fertilizer-pesticide automatic integrated system

InactiveCN109122215AImprove spray uniformity and spray efficiencyImprove uniformity and spray efficiencyClimate change adaptationWatering devicesFertilizerPesticide

The invention discloses an orchard water-fertilizer-pesticide automatic integrated system, and belongs to the technical field of fruit tree irrigation equipment. The orchard water-fertilizer-pesticideautomatic integrated system comprises an irrigation system, a fertilizing system, a pesticide spraying system, a mixing system and a control system; the fertilizing system and the pesticide sprayingsystem are both connected with the irrigation system; the irrigation system, the fertilizing system and the pesticide spraying system are all connected with one side of the mixing system; the orchardwater-fertilizer-pesticide automatic integrated system is characterized by further comprising a sprinkling system; the sprinkling system is connected with the other side of the mixing system; and theirrigation system, the fertilizing system, the pesticide spraying system, the mixing system and the sprinkling system are all connected with the control system. According to the invention, integratedsprinkling of water, fertilizers and pesticides is realized, sprinkling uniformity and sprinkling efficiency are improved, and timeliness of operation is improved.

Owner:靖西海越农业有限公司

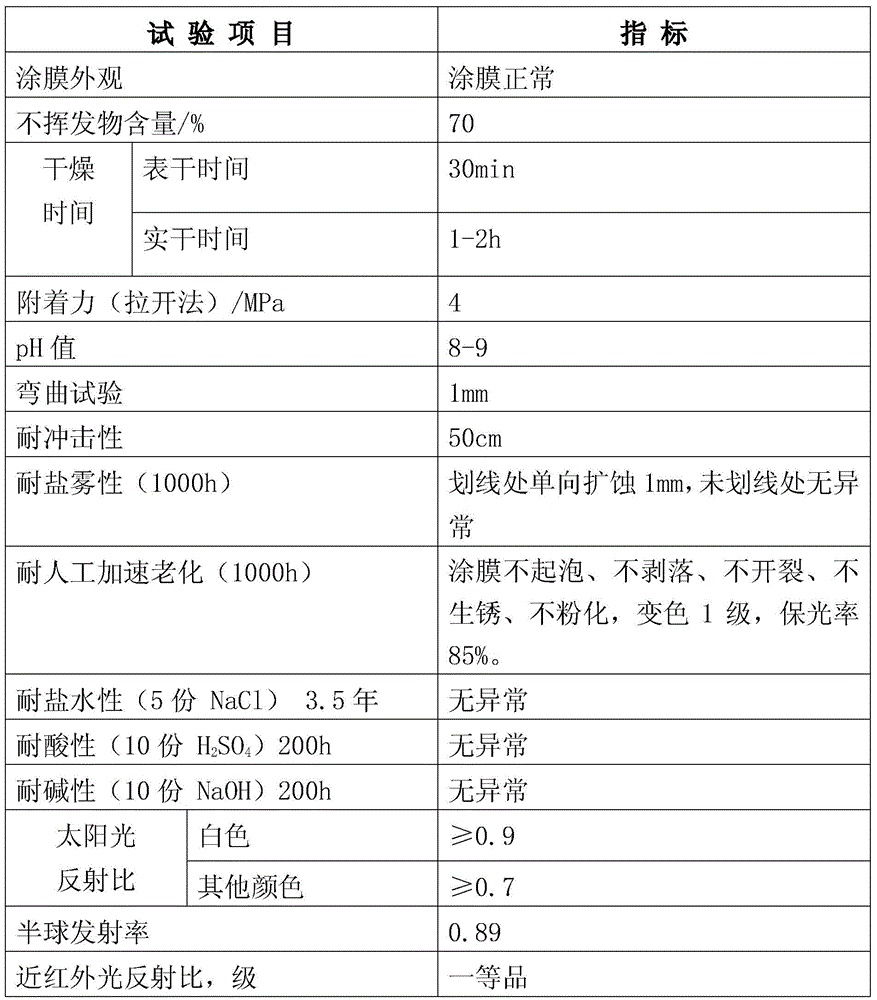

Heat-reflection thermal insulation anti-corrosion coating and preparation method thereof

InactiveCN105602329AGood thermal stabilityLow priceAnti-corrosive paintsReflecting/signal paintsThermal insulationZinc

Owner:SHENGYA TECH DALIAN

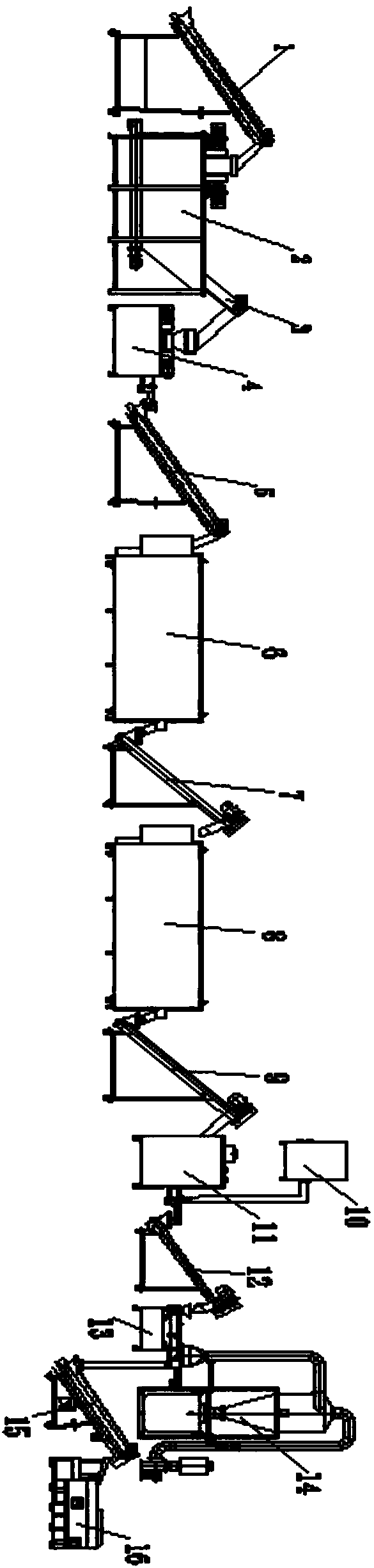

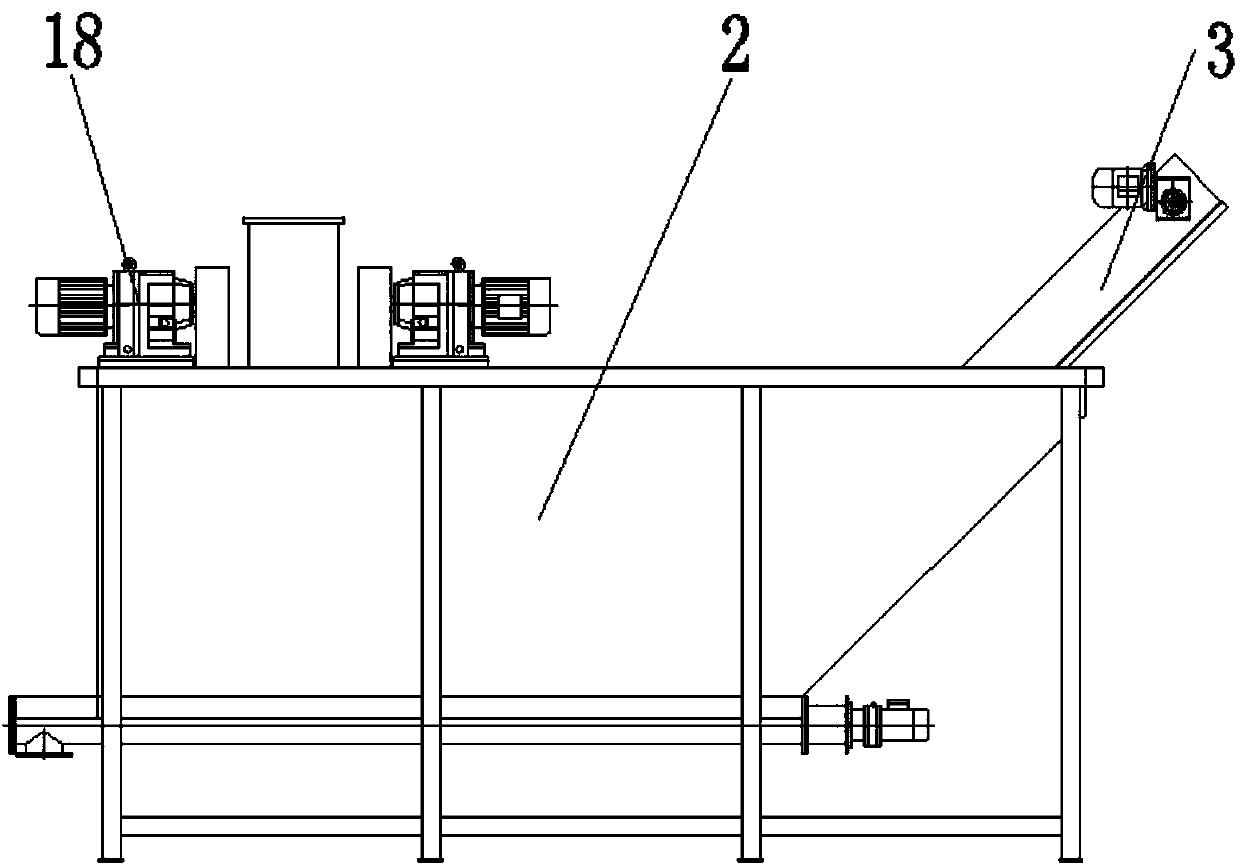

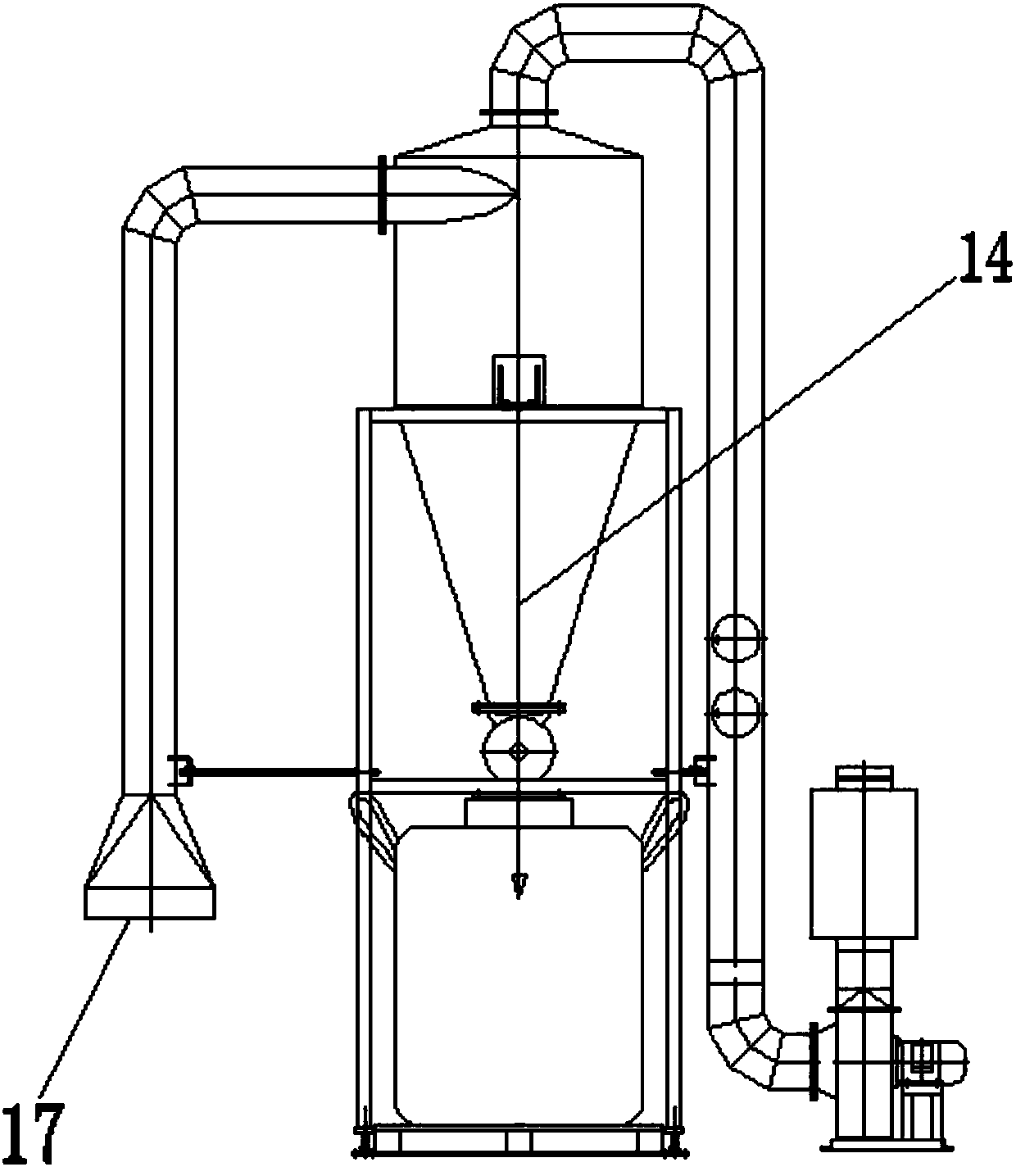

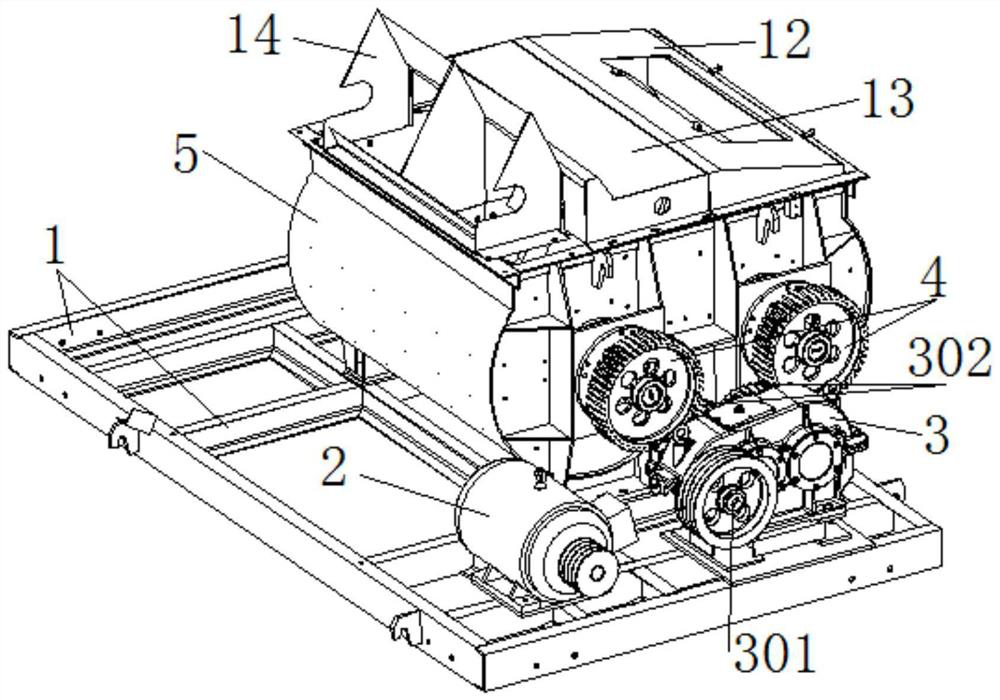

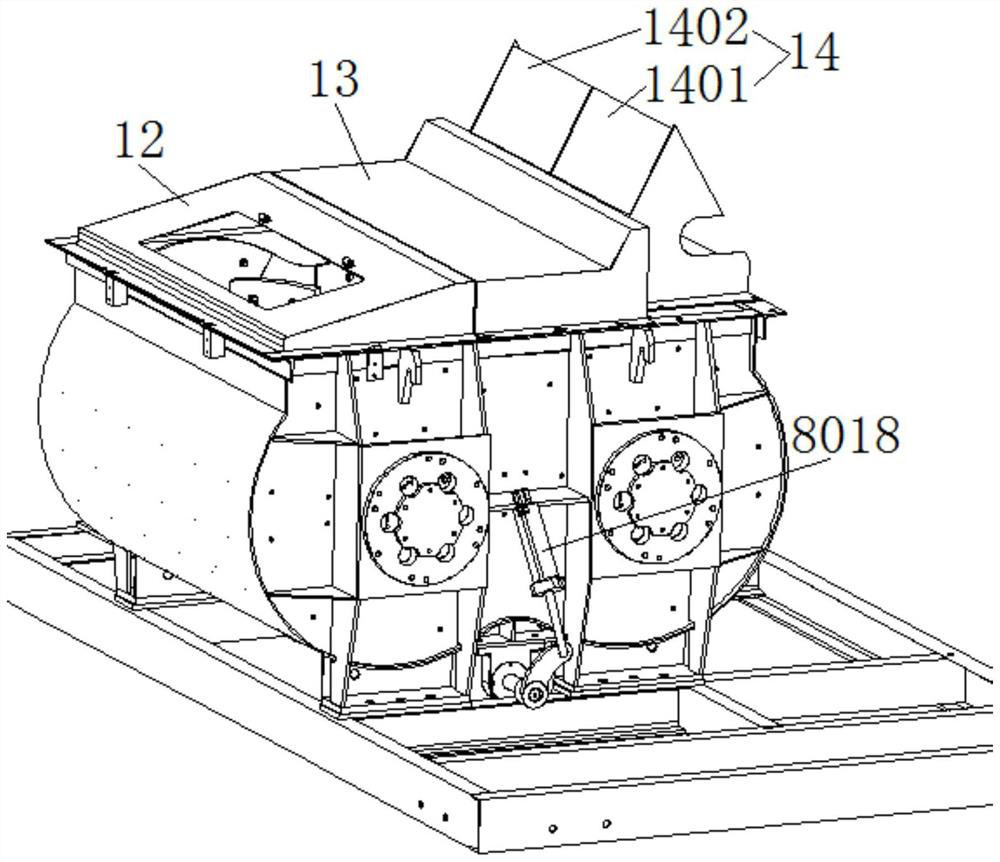

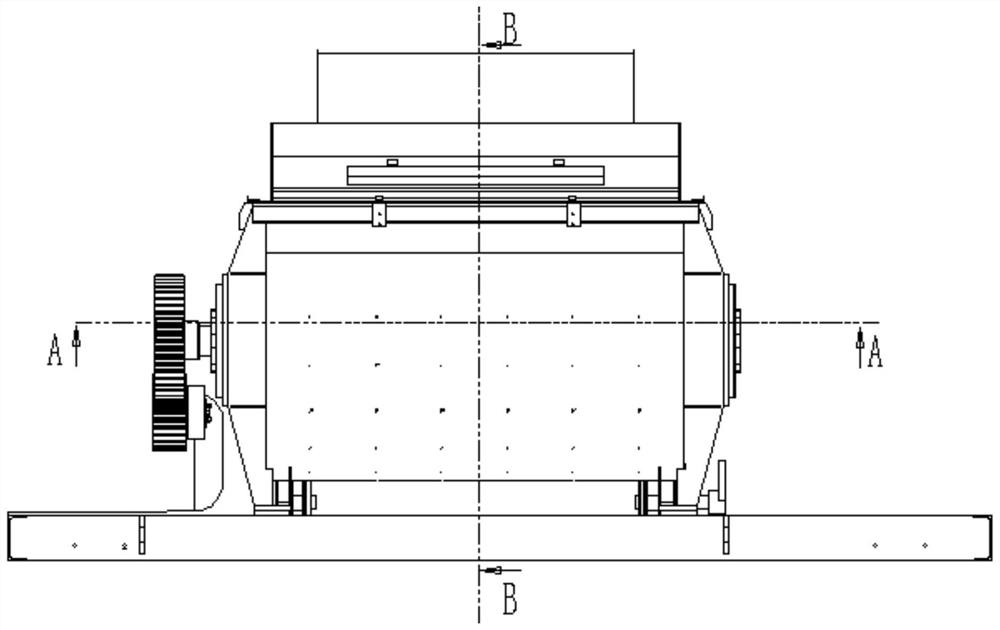

Recovery and shredding processing equipment for waste lithium battery and processing technology thereof

The invention relates to the technical field of waste lithium battery recovery, and discloses recovery and shredding processing equipment for the waste lithium battery and the processing technology thereof. The recovery and shredding processing equipment for the waste lithium battery comprises a physical decomposition device, a second double-shaft shredding machine and a tunnel type hot air circulating drying oven, a crusher, a vibration screening machine, a cyclone separator positioned below the vibration screening machine, and a closed conveyor; the physical decomposition device communicateswith the second double-shaft shredding machine through a screw conveyer in a transmission mode, the second double-shaft shredding machine communicates with the tunnel type hot air circulating dryingoven in a transmission mode, and the tunnel type hot air circulating drying oven communicates with the crusher in a transmission mode; and the crusher communicates with the vibration screening machinein a transmission mode, the vibration screening machine communicates with the cyclone separator in a transmission mode, and the cyclone separator communicates with the closed conveyor in a transmission mode. According to the recovery and shredding processing equipment for the waste lithium battery, the safe crushing and decomposition of the lithium batteries can be achieved; and moreover, the waste lithium batteries can be produced and handled in a large scale, and the process of handling and recovering the waste lithium batteries can be extremely environment-friendly.

Owner:广州市滨一塑料机械设备有限公司

Process for preparing canned sweet potato

InactiveCN104431870AGreat tasteEasy to operateFruit and vegetables preservationFood preparationTinningVitamin C

The invention discloses a process for preparing a canned sweet potato, and relates to the technical field of can processing. The process sequentially comprises the following steps: peeling; chopping; rinsing; blanching; tinning; injecting a cooking liquor; sealing in vacuum; sterilizing; and cooling. The process is characterized in that the blanching comprises the following sub-steps: putting chopped sweet potatoes into a mixed solution containing 0.1%-0.2% of calcium chloride and 6%-8% of sulphurous acid, soaking for 8-10 minutes, and cleaning and rinsing with clean water, wherein the temperature of water for blanching is set to be 70-90 DEG C and the lasting time is 8-10 minutes; the step of injecting the cooking liquor comprises the following sub-steps: heating the cooking liquor containing 0.6% of table salt, 1% of white sugar, 0.2% of vitamin C and 0.03-0.04% of citric acid until boiling, cooling the cooking liquor to 80-90 DEG C, and then injecting the cooled cooking liquor into a tank, wherein the weight of the cooking liquor is not less than 50% of that in the tank. The process is convenient to operate; processed bamboo shoots are good in mouthfeel, good in taste, convenient to process and store for a long period of time, not easy in changing of color or going bad, and good in quality.

Owner:GUANGDE XIANGYANG ECOLOGY FOOD

Water-based type soldering flux cleaning agent and preparation method thereof

InactiveCN108130208AEasy to cleanFast cleaningInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsWater basedSlag

The invention relates to the technical field of cleaning agents, in particular to a water-based type soldering flux cleaning agent and a preparation method thereof. The water-based type soldering fluxcleaning agent is prepared from the following raw materials in parts by weight: 20 to 40 parts of fatty amine, 20 to 40 parts of glycol ether, 5 to 15 parts of non-ionic surface active agent, and 10to 30 parts of deionized water. The water-based type soldering flux cleaning agent provided by the invention is a water-based type cleaning agent, does not contain a fluoro-carbon solvent and a halogenated hydrocarbon solvent harmful to a human body so as not to hurt human health, is convenient to use, safe, environmentally-friendly, non-toxic and economical, and simple in use method, can be usedfor soaking or ultrasonically cleaning, and is capable of remarkably improving the cleaning work efficiency of parts. The water-based type soldering flux cleaning agent provided by the invention has ahigher cleaning effect on a soldering flux, and can be used for cleaning the soldering flux and welding slags on workpieces; electronic parts treated through the cleaning agent are clean in surface,and can be directly assembled or packaged after being subjected to water rinsing and air drying.

Owner:东莞市亿洁优实电子科技有限公司

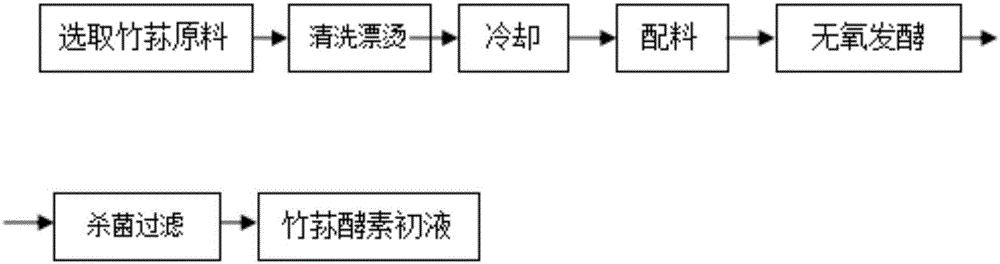

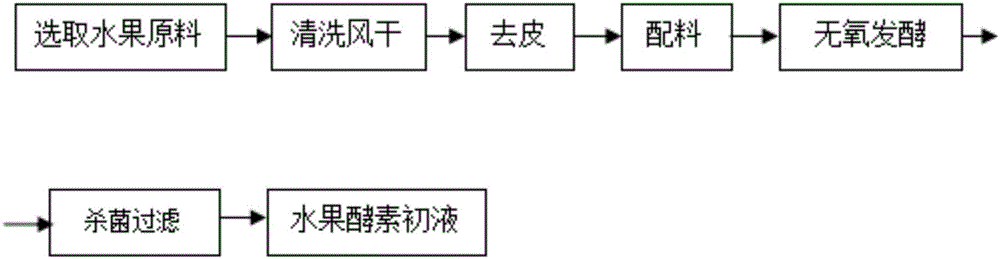

Bamboo fungus and tropical fruit complex active ferment and preparation method thereof

ActiveCN106307503ASweet and sour tastePlay a role in acid regulationYeast food ingredientsLactobacillusAdditive ingredientDigestion

The invention provides a preparation method of a bamboo fungus and tropical fruit complex active ferment. The preparation method comprises the following steps of: (1) preparing bamboo fungus ferment primary liquid; (2) preparing tropical fruit ferment primary liquid; and (3) preparing complex active ferment. The ferment produced by adopting the method has higher activity and can be stored at normal temperature; by adopting tropical fruits, the heavy mushroom aroma can be covered by fruit aroma, the mouthfeeling is sweet and sour and palatable. The bamboo fungus and tropical fruit complex active ferment plays a role in helping the digestion, absorption, metabolism and the like of human bodies on nutritional ingredients.

Owner:海南省农垦科学院集团有限公司 +1

Anti-corrosion paint for intelligent house

InactiveCN103642388ASimple production processLow costAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolymer science

The invention relates to an anti-corrosion paint for an intelligent house. The anti-corrosion paint is characterized in that the anti-corrosion paint comprises the following components in percentage by weight: 18%-25% of oil material, 3%-10% of resin, 3%-6% of pigments, 5%-8% of solvent, 2.5-4.5% of auxiliary materials, and the balance of water, wherein the oil material comprises including drying oil and semi-drying oil and is one of main film-forming substances; the resin comprises epoxy resin, acrylic resin and polyurethane at the mass ratio of the epoxy resin to the acrylic resin to the polyurethane of (3-4): (7-8): (3-5); the pigments comprise a coloring pigment, an extender pigment and an anti-rust pigment and are used for the film-forming substances; the auxiliary materials comprise a stabilizer, an anti-aging agent and an anti-freezing agent in the mass ratio of 3: 2: 5.

Owner:NINGBO DEEPBLUE SMARTHOUSE

Packing bag coating and preparation method thereof

InactiveCN105315798AAntiseptic and insecticidalHas anti-corrosion effectAntifouling/underwater paintsRosin coatingsFiberCellulose

The invention discloses a packing bag coating and a preparation method thereof. The packing bag coating comprises the following raw materials by weight: 1 to 2 parts of tung oil, 1 to 2 part of tung oil anhydride, 0.3 to 0.5 part of a silane coupling agent, 20 to 40 parts of calcium carbonate, 15 to 25 parts of polypropylene, 10 to 20 parts of permethrin, 5 to 10 parts of cellulose base fiber, 5 to 10 parts of alanine, 3 to 7 parts of talcum powder, 2 to 5 parts of nano titanium dioxide, 1 to 2 parts of isobutyl methacrylate, and 5 to 7 parts of rosin resin. The preparation method comprises the steps of grinding, modifying, stirring and drying. After being treated with the packing bag coating, the surface of a material is excellent in lipophilic-hydrophobic property; moreover, rosin resin has a forming and enveloping function, and permethrin has corrosion-resistant and insect-killing functions, so that the coating is resistant to corrosion.

Owner:桐城市人和包装有限公司

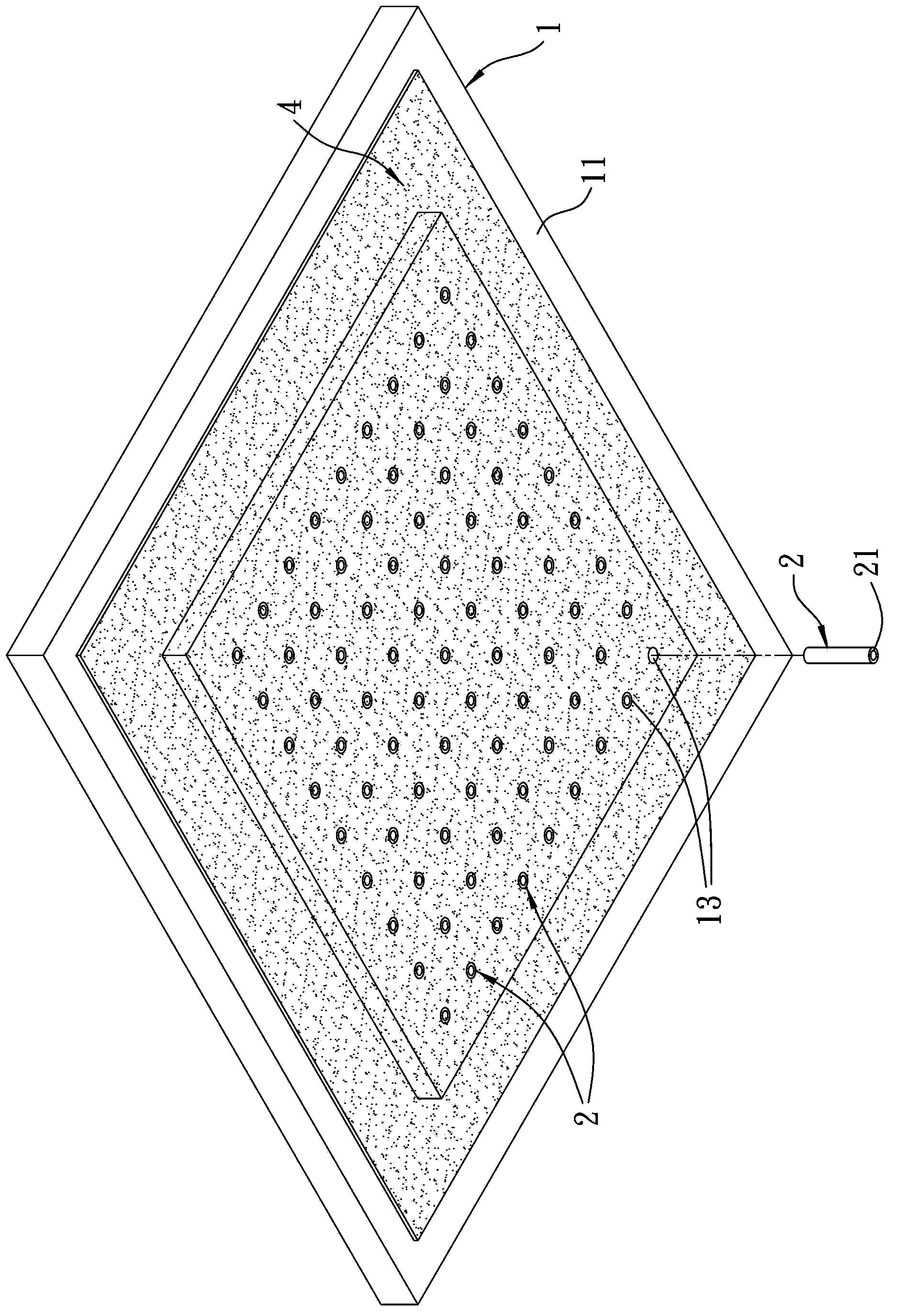

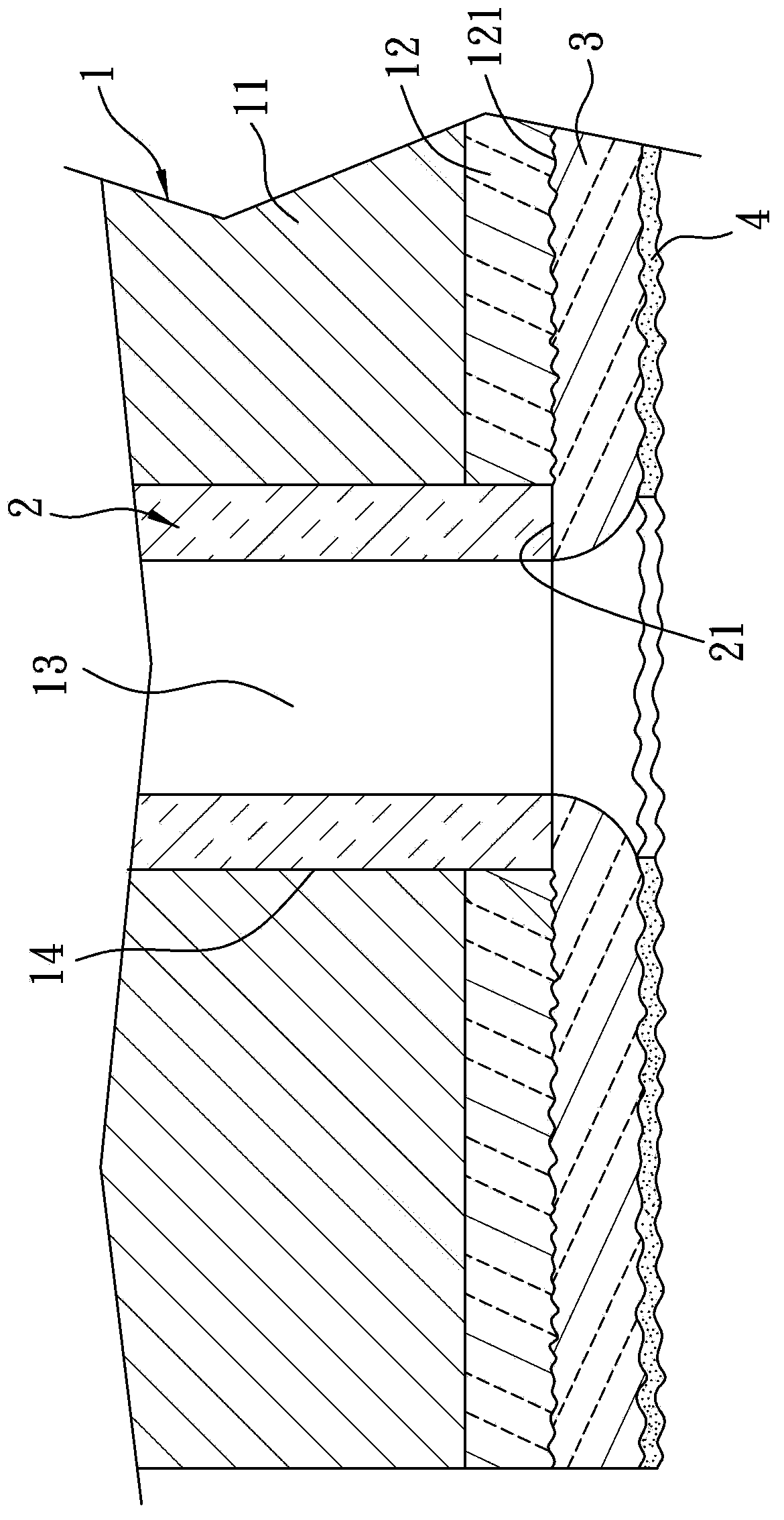

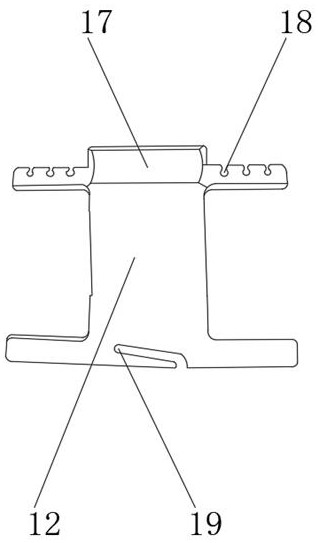

Top electrode of reaction tank device for etching equipment

The invention discloses a top electrode of a reaction tank device for etching equipment. The top electrode comprises an electrode plate and a ceramic spray film. The electrode plate comprises a body layer, a buffer layer arranged on the body layer, and multiple vent holes which penetrate through the body layer and the buffer layer. The difference of thermal expansion coefficients of the body layer and the ceramic spray film is buffered through the buffer layer, and high binding force exists between the buffer layer and the ceramic spray film, so the buffer layer and the ceramic spray film can be tightly bound and difficultly drop. Meanwhile, the buffer layer and the ceramic spray film have good anti-corrosion effects so as to provide dual protection for the body layer, so that the electrode plate can be repeatedly used, and the equipment cost can be reduced.

Owner:CHOU YEH INVESTMENT CO LTD

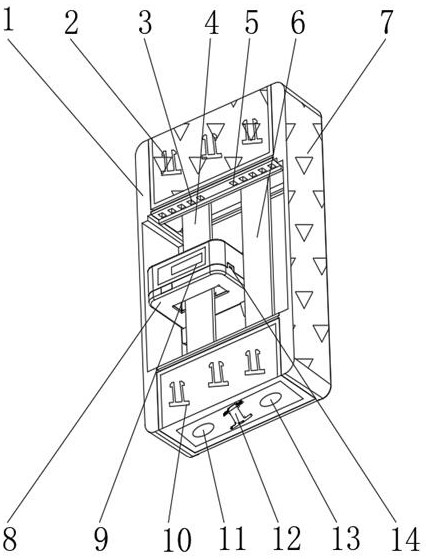

Manufacturing method for epoxy resin filling type pre-stress steel strand

ActiveCN108004816AImprove corrosion resistanceHas anti-corrosion effectRope making machinesAnti-corrosive paintsEpoxySpray coating

The invention discloses a manufacturing method for an epoxy resin filling type pre-stress steel strand, and belongs to the technical field of steel strand manufacturing. The method comprises: using aniline as a raw material, emulsifying the aniline at normal temperature, to initiate polymerization to obtain a polyaniline emulsion, spraying an epoxy spraying coating to a bright steel wire through electrostatic spraying, to obtain an epoxy steel strand wire, immediately spraying imvite powders on the epoxy steel strand wire, twisting and stretching repeatedly to form a frosted epoxy steel strandwire, and demagnetizing, solidifying and drying, and cooling to obtain the epoxy resin filling type pre-stress steel strand. An epoxy resin coating has certain anti-corrosion effect. Once an outer layer has defects, corrosion would occur. Because of an inductive coupling effect of the polyaniline, the steel strand has good anti-corrosion property. The epoxy spraying coating is sprayed to the surface of the steel strand through electrostatic spraying, and electrons on the surface of the steel strand wire are obtained. A layer of oxidized metal film is added to the surface of the pre-stress steel strand, so as to improve corrosion resistance of the pre-stress steel strand. The method is wide in application prospect.

Owner:贵州水钢金属科技有限公司

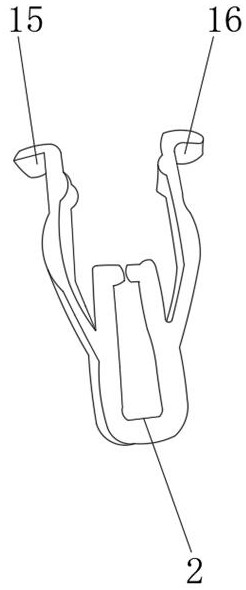

Electric energy meter with positioning function

InactiveCN111624381AQuick installationImprove work efficiencyTime integral measurementMechanical engineeringElectric energy

The invention discloses an electric energy meter with a positioning function. A heat dissipation anticorrosion coating is fixedly connected on the outer surface of the periphery of the electric energymeter body. A first double-insurance fixing buckle and a second double-insurance fixing buckle are fixedly connected on the outer surface of the front end of the electric energy meter body. A first buckle is fixedly connected to the outer surface of one side of the first double-insurance fixing buckle, a second buckle is fixedly connected to the outer surface of the other side of the first double-insurance fixing buckle, and the second double-insurance fixing buckle is located on one side of the first double-insurance fixing buckle. According to the electric energy meter with the positioningfunction, the double-insurance fixing buckles, the reel and the heat dissipation anticorrosive coating are arranged so that the electric energy meter can be conveniently and quickly mounted, the working efficiency is improved, lines can be more conveniently arranged, danger caused by line disorder is prevented, damage to the electric energy meter due to high temperature can be prevented, the service life of the electric energy meter is prolonged, and a better use prospect is brought.

Owner:宁波泰丰源电气有限公司

Environmental protection maintenance oil for root carving of wooden handicrafts, and preparation method thereof

The invention discloses an environmental protection maintenance oil for the root carving of wooden handicrafts, and a preparation method thereof, wherein the environmental protection maintenance oil is prepared from the following components by weight: 40-50 parts of sunflower seed oil, 20-30 parts of linseed oil, 4-8 parts of beeswax, 2-6 parts of mutton tallow, and 20-30 parts of D-limonene oil.The preparation method comprises: adding sunflower seed oil and linseed oil to a reaction pot, and refining to obtain refined vegetable oil a; after the refined vegetable oil a is cooled to a temperature of 70-100 DEG C, adding beeswax and mutton tallow, and polymerizing to prepare refined vegetable oil b; and dispersing the refined vegetable oil b for 4-30 min by using a homogenizing dispersion machine while adding D-limonene oil to prepare the environmental protection maintenance oil. The environmental protection maintenance oil of the present invention has advantages of environmental protection, harmlessness to the human body and the like.

Owner:安徽新碳实业有限公司

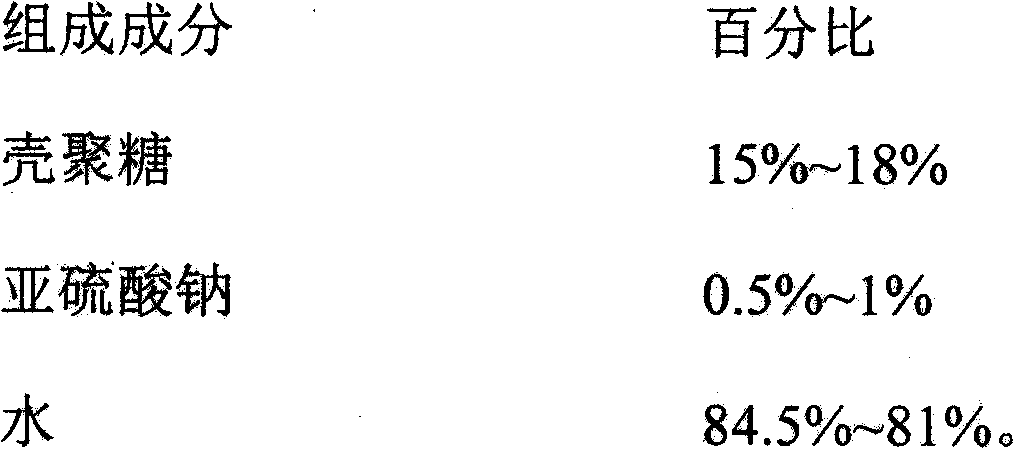

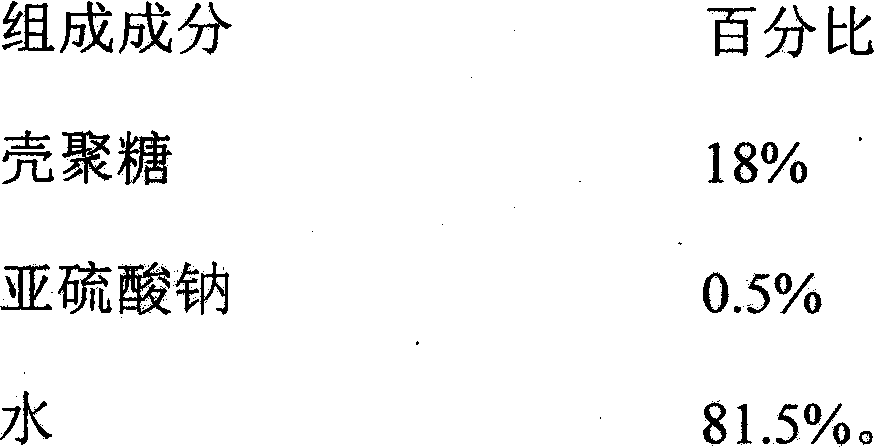

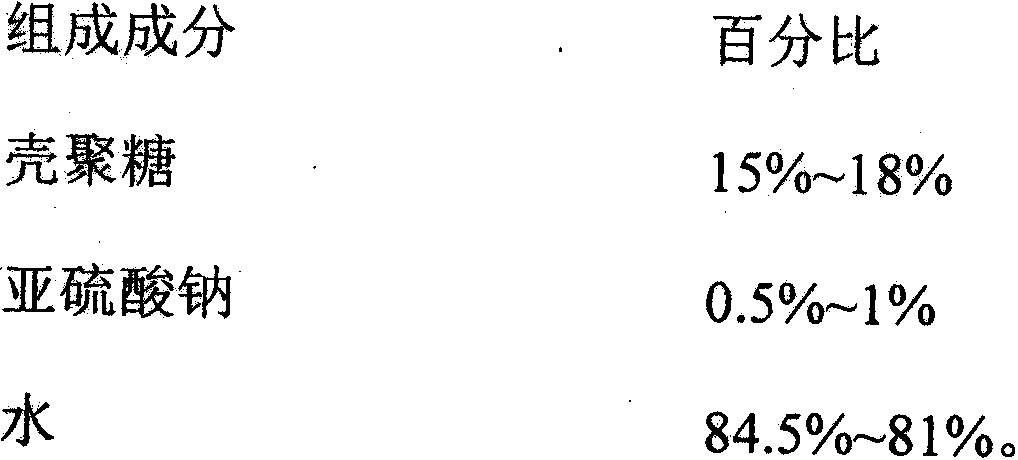

Egg preservative free from toxic and side effect

InactiveCN103988889AHas anti-corrosion effectCause some damagesEggs preservation by coatingPreservative freeEggshell

The invention discloses an egg preservative free from toxic and side effect. The egg preservative, which is smeared on surface of eggshell, plays the role of preventing corrosion and mould and is free from toxic and side effect. A technical scheme is realized by the follows: the egg preservative free from toxic and side effect is composed of the following components by weight percent: 15-18% of chitosan, 0.5-1% of sodium sulfite and 84.5-81% of water. The egg preservative disclosed by the invention has the beneficial effects that the adopted chitosan is one of internationally accepted novel and safe food preservatives; the sodium sulfite has an anticorrosion effect, and cannot harm a human body if a few amount of preservative is added.

Owner:南通天乐农业科技有限公司

Preparing method of polyaniline blended corrosion-prevention strippable paint

InactiveCN110172297AImprove high temperature resistanceImprove wear resistanceFireproof paintsAnti-corrosive paintsEpoxyIsolation effect

The invention discloses a preparing method of a polyaniline blended corrosion-prevention strippable paint, and belongs to the technical field of paints. A matrix can be coated with the polyaniline blended corrosion-prevention strippable paint through electrophoretic deposition. A high-density alumina film not only improves the high-temperature resistance of the strippable paint, but also improvesthe wear resistance and corrosion resistance of a coating. The strippable paint is a blended paint of polyaniline and epoxy resin; since the polyaniline has poor adhesion to the metal matrix, the epoxy resin serves as a blended film formation ingredient, and after the surface of the metal is coated with the paint, a reaction can be carried out between the paint and the metal; due to the inductivecoupling function of the polyaniline, a very thin oxidation film is formed on the surface of the metal, and the corrosion resistance is improved, so that the corrosion speed is lowered, and the polyaniline has good electrical conductivity and electrochemical activity; under metal protection, the polyaniline in this form not only has a certain mechanical isolation effect, but also has a certain catalytic deactivation effect, so that the coating has good corrosion resistance, and the application prospect is broad.

Owner:曾祥民

Automobile fuel combustion enhancing additive

InactiveCN106190367APromote combustionBurn completelyLiquid carbonaceous fuelsFuel additivesPhosphateAlkylphosphate

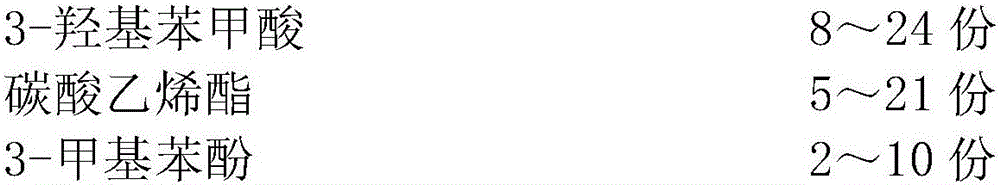

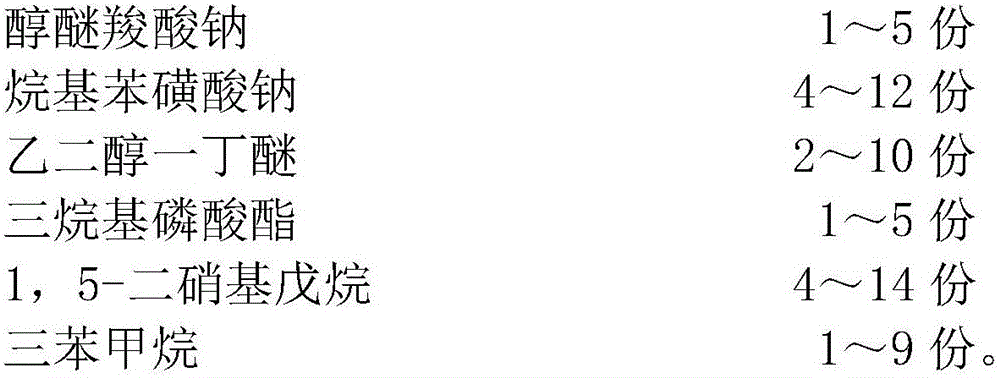

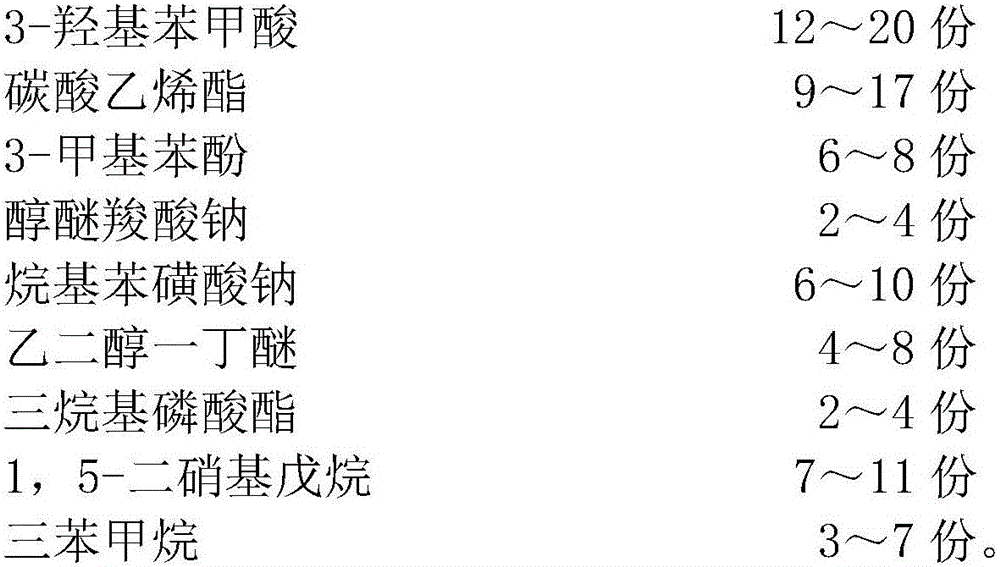

The invention relates to the technical field of fuel additives, in particular to an automobile fuel combustion enhancing additive. The additive is prepared from, by weight, 8-24 parts of 3-hydroxybenzoic acid, 5-21 parts of ethylene carbonate, 2-10 parts of 3-methylphenol, 1-5 parts of alcohol polyoxyethyleneether carboxylate, 1-7 parts of sodium alkyl benzene sulfonate, 2-10 parts of ehtylene glycol monobutyl ether, 1-5 parts of trialkyl phosphate, 4-14 parts of 1,5-binitro pentane and 1-9 parts of triphenylmethane. The additive has a remarkable smoke abatement and discharge function, the emission of harmful substances is reduced, gasoline is saved, and the combustion performance of automobile fuel is effectively improved.

Owner:GUANGXI DONGQI ENERGY TECH CO LTD

Waterborne heat-reflection colorful paint

InactiveCN107880753ALow solar heat absorptionGood water resistance and weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsNano zinc oxideAbsorption rate

The invention provides waterborne heat-reflection colorful paint, and relates to the technical field of paint. The waterborne heat-reflection colorful paint is prepared with waterborne polyurethane emulsion, nano zinc oxide, rheological auxiliaries, heat-reflection pigments and additives. According to the waterborne heat-reflection colorful paint, by adopting base materials low in solar heat absorption rate and excellent in weather and water resistance, the weather and water resistance and heat reflection performance of the paint are effectively improved, the color of the paint is beautiful, and the color of an exterior wall of a building after coated with the paint is attractive.

Owner:GUANGDONG VALSPAR CHEM IND

Wall face tile cleaning agent and preparing method thereof

InactiveCN104004610AQuick clearWon't hurtSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsHydrogen fluorideBenzotriazole

The invention relates to a wall face tile cleaning agent and a preparing method thereof, and belongs to the technical field of cleaning agents for buildings. The wall face tile cleaning agent is low in price and good in cleaning effect. The wall face tile cleaning agent comprises, by mass, 17%-22% of hydrochloric acid, 2%-3% of hydrogen fluoride, 1%-2% of nonyl phenol polyoxyethylene ether, 0.1%-0.5% of benzotriazole and the balance water. The preparing method of the wall face tile cleaning agent comprises the steps that the hydrochloric acid, the hydrogen fluoride, the nonyl phenol polyoxyethylene ether and the benzotriazole are added in the water in sequence, stirring is carried out until all the raw materials are completely dissolved, and thus the wall face tile cleaning agent is obtained. Through experiments, dirt of wall face tiles can be fast cleaned out, the surfaces of the tiles cannot be damaged, the side effect is small, cost is low, and the cleaned tiles are still pure white as new after being placed for 15 days.

Owner:XIAMEN UNIV

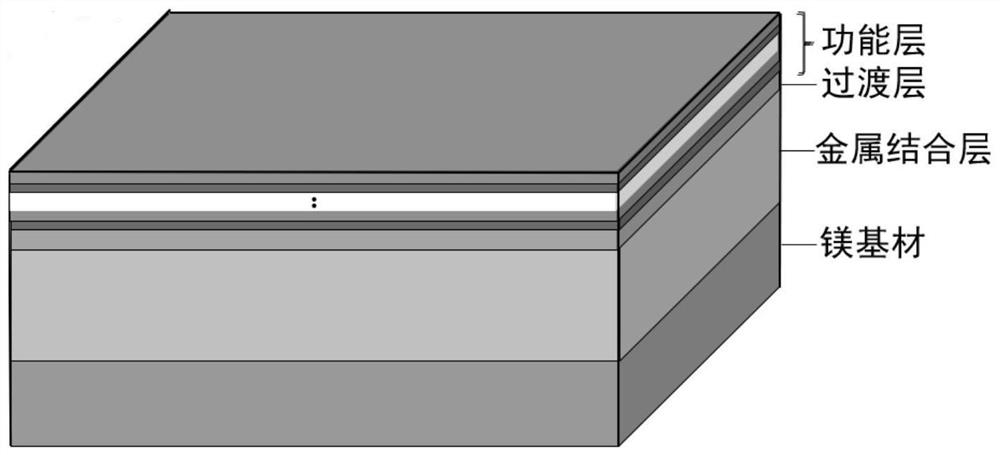

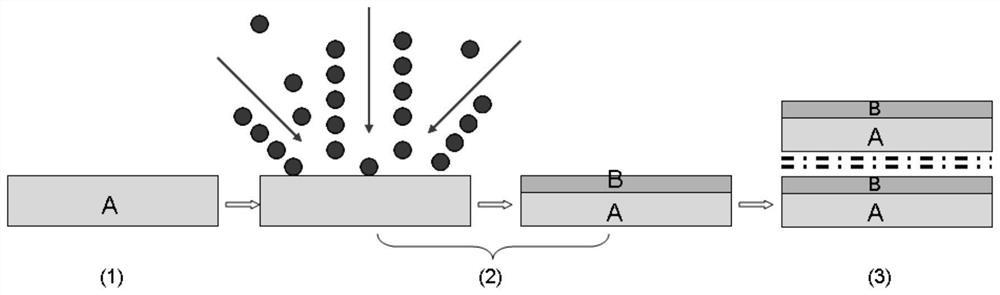

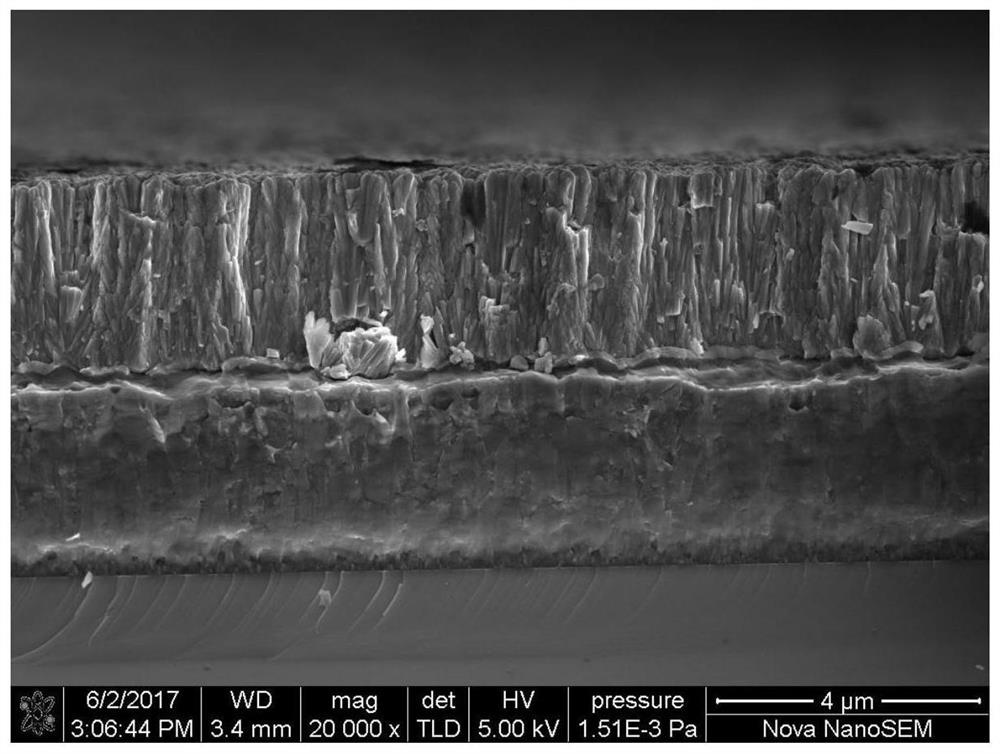

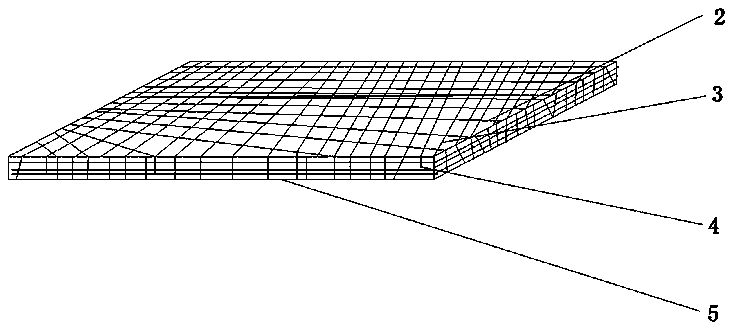

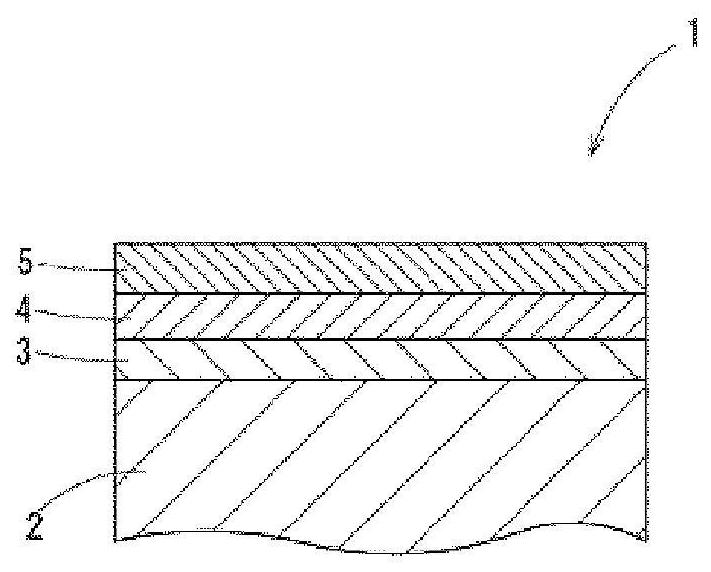

Magnesium alloy protective coating and preparation method thereof

PendingCN113667932AImprove corrosion resistanceImprove wear resistanceVacuum evaporation coatingSputtering coatingSoft layerWear resistance

The invention provides a magnesium alloy protective coating. The magnesium alloy protective coating comprises a magnesium base material, a metal bonding layer, a transition metal layer and a functional layer, all of which are sequentially stacked; and the functional layer is of a single-layer film structure or a multi-layer film structure, the single-layer film structure is a single-layer hard layer or a single-layer soft layer, the multi-layer film structure is formed by stacking multiple single-group sub-films, and each single-group sub-film is formed by stacking a single-layer hard sub-layer and a single-layer soft sub-layer. According to the long-acting, stable, corrosion-resistant and wear-resistant surface protective coating, the problem of magnesium alloy building formboard engineering practice is solved, and according to the relation between the microstructure of the protective coating and corrosion resistance and wear resistance of the coating, the invention further provides a preparation method of the long-acting, stable, corrosion-resistant and wear-resistant protective coating for the surface of a magnesium alloy building formboard.

Owner:CHONGQING UNIV

Low temperature phase change cold storage material and preparation method thereof

ActiveCN104830283BImprove thermal conductivityHigh latent heat of phase changeHeat-exchange elementsPotassium nitratePolyvinyl alcohol

The invention discloses a low-temperature phase change cold storage material and a production method thereof. The low-temperature phase change cold storage material is made from, by weight, 5% to 18% of sodium chloride, 4% to 17% of potassium nitrate, 74% of water, 1% of sodium tetraborate, 1% of sodium benzoate, and 2% of polyvinyl alcohol. The phase change temperature of the low-temperature phase change cold storage material is -20 DEG C to -25 DEG C; the low-temperature phase change cold storage material is suitable for cold-storage transportation of frozen foods, cold storage density per unit mass is high, and latent heat of phase change is above 260kJ / kg. The low-temperature phase change cold storage material has the advantages that the matching of ingredients is simple, the range of sources is wide, and the preparing method is easy to operate and suitable for industrial popularization.

Owner:SHANGHAI MARITIME UNIVERSITY

Intelligent garbage can for blind persons

InactiveCN109335406AImprove the protective effectAvoid breakageRefuse receptaclesEngineeringBlind persons

The invention discloses an intelligent garbage can for blind persons, and relates to the technical field of garbage cans. The intelligent garbage can comprises a shell and hydraulic air cylinders. A storage inner bin is arranged in the shell and is movably connected with the shell. The hydraulic air cylinders are arranged at the bottom end of the inner side of the shell. The inner wall of the shell and the lower surfaces of the hydraulic air cylinders are welded and fixed. An upper seal strip is bonded and fixed to the top of the shell, and a lower seal strip is mounted at the bottom of the shell. The intelligent garbage can has the advantages that according to the intelligent garbage can for the blind persons, through the intelligent arrangement for a steering engine, when the blind persons need to throw garbage, the blind persons send out commands, the garbage can automatically produce sounds under cooperation of the voice recognition technology, and the position of the garbage can can be locked; a voice recognition module is combined for recognizing the voice commands, and the steering engine is controlled to open a left cover plate and a right cover plate; and through the arrangement, the blind persons can conveniently find the position of the garbage can correctly, and meanwhile the work that the blind persons throw the garbage is also facilitated.

Owner:DONGGUAN UNIV OF TECH

Radiator inner paint film and preparation method thereof

InactiveCN109161276AAvoid direct contactStrong adhesionAntifouling/underwater paintsPaints with biocidesALLYL SUCROSEPorous particle

The invention discloses a radiator inner paint film and a preparation method thereof. The inner paint film is formed through solidification after inner paint is coated, wherein the inner paint comprises the following raw materials in parts by weight: 30 to 70 parts of tung oil, 30 to 50 parts of lecithin, 100 to 300 parts of porous particles, 50 to 200 parts of shell powder, 100 to 300 parts of polyacrylic acid resin, 10 to 30 parts of dispersing agent and 20 to 70 parts of solidifying agent; the porous particles comprises core-shell particles, glass flakes and organosilicone resin; and the porous particles are particles which have a porous structure and are formed by filling the glass flakes with the core-shell particle and coating the glass flakes with the organosilicone resin. The innerpaint is solidified into the film to be attached to a radiator so as to avoid direct contact of circulating water and an aluminum alloy matrix; after compound use of the porous particles and other raw materials, the radiator inner paint film has anti-corrosion effect and high water resistance, is nonhazardous, has a certain antibacterial effect and has a strong adhesive force on the aluminum alloy matrix.

Owner:ZHEJIANG YANGMING IND & TRADE CO LTD

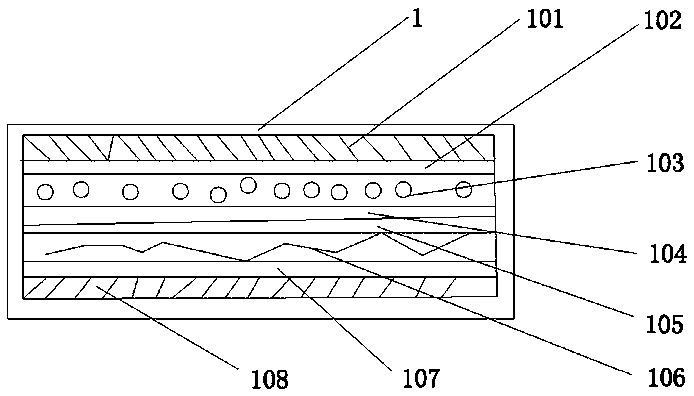

Anti-corrosive woolen fabric

InactiveCN107554025AImprove corrosion resistanceImprove tear resistanceSynthetic resin layered productsPolyesterTear resistance

The invention discloses an anti-corrosive woolen fabric, which comprises a woolen layer, wherein the lower surface of the woolen layer fits closely to a breathable woven mesh layer, and the lower surface of the breathable woven mesh layer fits tightly to a polypropylene layer; the lower surface of the polypropylene layer fits tightly to a breathable layer, and the lower surface of the breathable layer fits tightly to a polyester fiber; the lower surface of the polyester fiber fits tightly to a bamboo fiber. The anti-corrosive woolen fabric is provided with the polypropylene layer which is internally provided with an antibacterial agent, so that the fabric not only has good anti-corrosion properties, but also has good antibacterial properties; the polyester fiber and nylon fiber have anti-corrosive effects, and the polyester fiber and the nylon fiber fit closely to further increase the anti-corrosive properties of the fabric; the warp and weft closely fit, and are distributed in a 'cross-shape' shape, so that the tear resistance of the fabric is enhanced, but also the fabric has an anti-wrinkle effect.

Owner:JIANGSU SUNSHINE

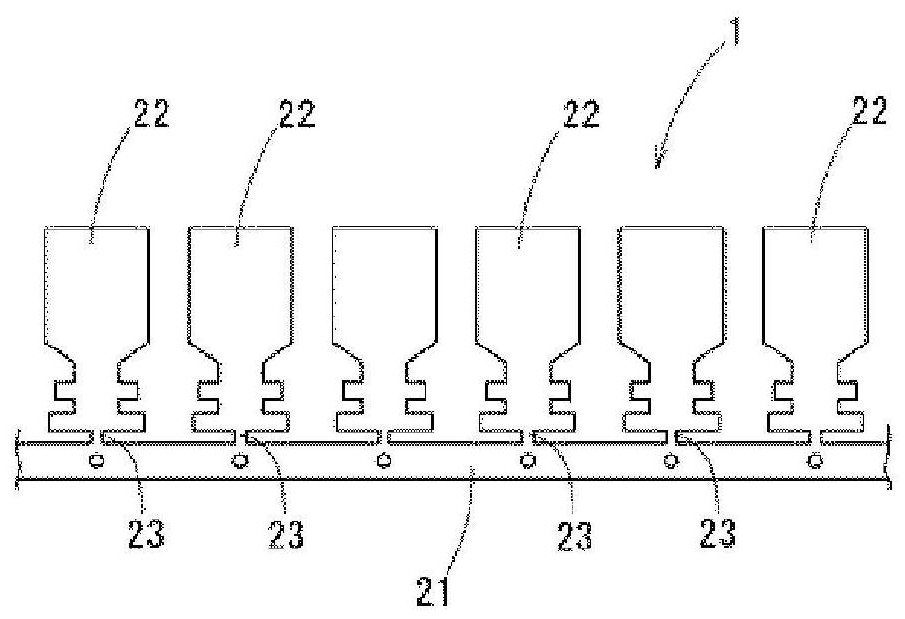

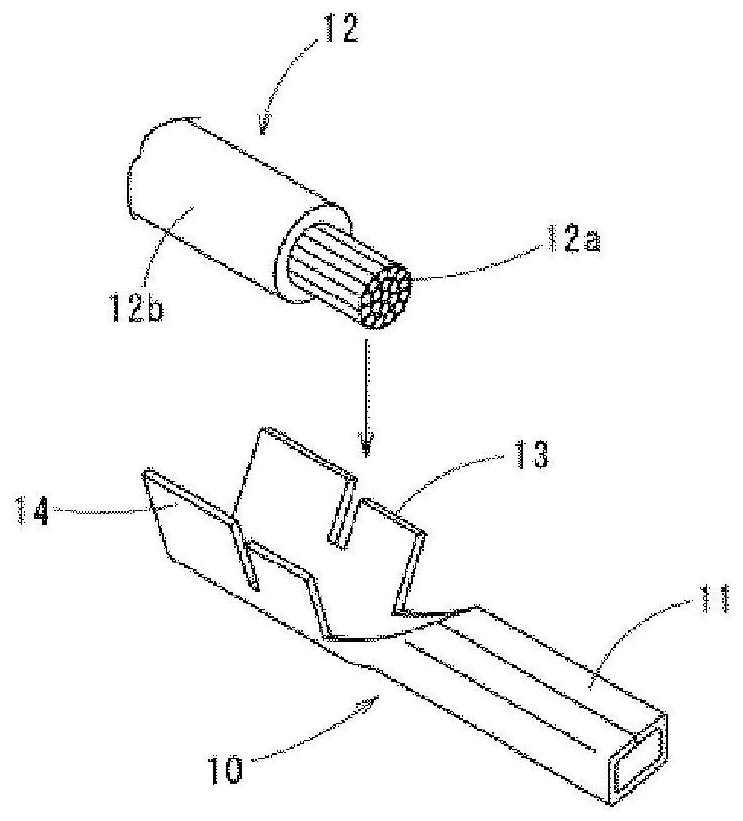

Tin-plated copper terminal material, terminal and wire end structure

ActiveCN110603349BHas anti-corrosion effectLower the resistance valueConductive materialCoupling contact membersTin platingZinc alloys

The present invention provides a tinned copper terminal material, a terminal made of the terminal material, and an electric wire end structure using the terminal. The tinned copper terminal material has: a base material, which is made of copper or a copper alloy; an intermediate zinc layer, formed on the base material and composed of a zinc alloy, and having a thickness of 0.10 μm or more and 5.00 μm or less; and a tin layer formed on the intermediate zinc layer and composed of tin or a tin alloy, and having a small-tilt grain boundary length The tin-plated copper terminal material effectively suppresses galvanic corrosion when the ratio to the total grain boundary length is 2% or more and 30% or less.

Owner:MITSUBISHI MATERIALS CORP

A kind of preparation method of anticorrosion aluminum profile

ActiveCN104195615BHas anti-corrosion effectImprove anti-corrosion performanceSurface reaction electrolytic coatingAnti-corrosive paintsChemical treatmentAnodizing

The invention relates to the field of preparation methods of aluminum profiles, and provides a method for preparing anti-corrosion aluminum profiles with good corrosion resistance, strong adhesion, no toxic substances, and no environmental pollution, including degreasing, washing, anodizing, spraying, and curing Surface chemical treatment is carried out after the anodic oxidation and before spraying. The specific process steps of the surface chemical treatment are: preparing a chemical treatment solution, and immersing the anodized aluminum profile workpiece in the chemical treatment solution for 3 to 5 minutes , drying to obtain an aluminum profile workpiece with a protective layer, and then spray a layer of anti-corrosion coating on the aluminum profile workpiece with a protective layer for 1.0-2.0 minutes, and the spray pressure is 0.05-0.07Mpa.

Owner:FUJIAN MINFA ALUMINUM

Crystallization method for aluminum fluoride production

PendingCN114011110AHigh crystallinityRealize solid-liquid separationSolution crystallizationAluminium fluoridesAluminum fluorideAluminium hydroxide

The invention belongs to the technical field of clean production, and particularly relates to a crystallization method for aluminum fluoride production. The method comprises the steps of S1, reacting fluosilicic acid and aluminum hydroxide in an anti-corrosion storage tank to generate aluminum fluoride-silica gel slurry; S2, conveying the generated aluminum fluoride-silica gel slurry to a belt filter through a filter pump, and separating an aluminum fluoride supersaturated solution from silica gel under the action of negative pressure pumping of a vacuum pump, wherein the aluminum fluoride supersaturated solution enters a crystallization tank to generate aluminum fluoride trihydrate crystals, and silica gel enters a cryolite-containing silica gel synthesis tank; S3, introducing 90 DEG C steam into the aluminum fluoride supersaturated solution filtered by the silica gel in the crystallization tank, and keeping for 4-6 hours to generate aluminum fluoride trihydrate crystals; and S4, putting the crystallized solid-liquid mixture on a tilting-pan filter, separating aluminum fluoride crystals from mother liquor under the negative pressure pumping action of the vacuum pump to obtain ointment, enabling the mother liquor to flow into a settling tank for settling, treating waste gas by using supernate, retaining precipitate crystals, scattering the crystallized ointment to enter, and drying a first-section semi-finished product of aluminum fluoride. The crystallization effect is good.

Owner:云南云天化氟化学有限公司

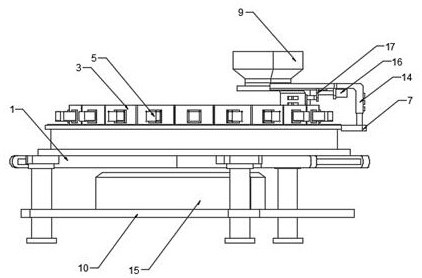

Operation method of a multifunctional mixer for water conservancy and hydropower engineering

ActiveCN112092187BStir to mix thoroughlyNot easy to residueDischarging apparatusCement mixing apparatusStructural engineeringMechanical engineering

Owner:杨忠刚

A kind of preparation method of nanoscale calcium carbonate for anti-corrosion coating

InactiveCN103555032BHas anti-corrosion effectGood lipophilic and hydrophobicAnti-corrosive paintsMethacrylateSlurry

The invention discloses a method for preparing nano calcium carbonate for anti corrosive paints, wherein the method comprises the following steps of: (1) adding a proper amount of water in light calcium carbonate, grinding the mixture into nano slurry, adding 1-2 parts of silane coupling agent KH580 under 40-50 DEC C, stirring for 30-50 min, then adding 0.3-0.5 parts of anti-oxidant 1076, and 1-2 parts of anti-oxidant BHT, stirring for 10-20min, filtrating, drying and grinding; (2) uniformly mixing 0.1-0.2 parts of ammonium molybdate, 1-2 parts of isobutyl methacrylate, 5-7 parts of rosin resin, and 10-15 parts of solvent, to obtain a modified liquid for standby application; and (3) adding the powder prepared in the step (1) into a high speed mixer, maintaining temperature at 70-80 DEG C, adding the modified liquid, drying after stirring for 20-30min, and grinding to form a nano powder.

Owner:ANHUI SHENGJIA COLOR PRINTING PACKING

Metallic paint with anti-corrosion effect

InactiveCN110551423ADissolution inhibitionTo achieve the purpose of anticorrosionFireproof paintsAnti-corrosive paintsEmulsionTitanium dioxide

The invention discloses metallic paint with an anti-corrosion effect. The metallic paint is prepared from the following materials in parts by weight: 15-20 parts of epoxy resin, 30-35 parts of cellulose ester, 15-20 parts of silicon dioxide emulsion, 7-11 parts of titanium dioxide, 2-4 parts of calcium carbonate, 5-8 parts of talcum powder, 10-15 parts of a deformer, 0.3-0.6 part of a leveling agent, 2-4 parts of a wetting agent, 20-30 parts of methylbenzene, 5-10 parts of an amphoteric compound and 4-8 parts of a chromate. According to the provided metallic paint with the anti-corrosion effect, the anti-corrosion effect of the metallic paint is effectively improved, the service life of the metallic paint is advantageously prolonged, the maintenance cost is lowered, preparation is easy, and industrial production is easy.

Owner:TIANJIN BAOLIJIE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com