Operation method of a multifunctional mixer for water conservancy and hydropower engineering

A technology of water conservancy, hydropower, and operation methods, which is applied in the direction of cement mixing devices, chemical instruments and methods, control devices, etc., can solve the problems of inconvenient water addition, residue of agitator, and affecting the quality of mixing, so as to achieve convenient water addition, easy cleaning, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

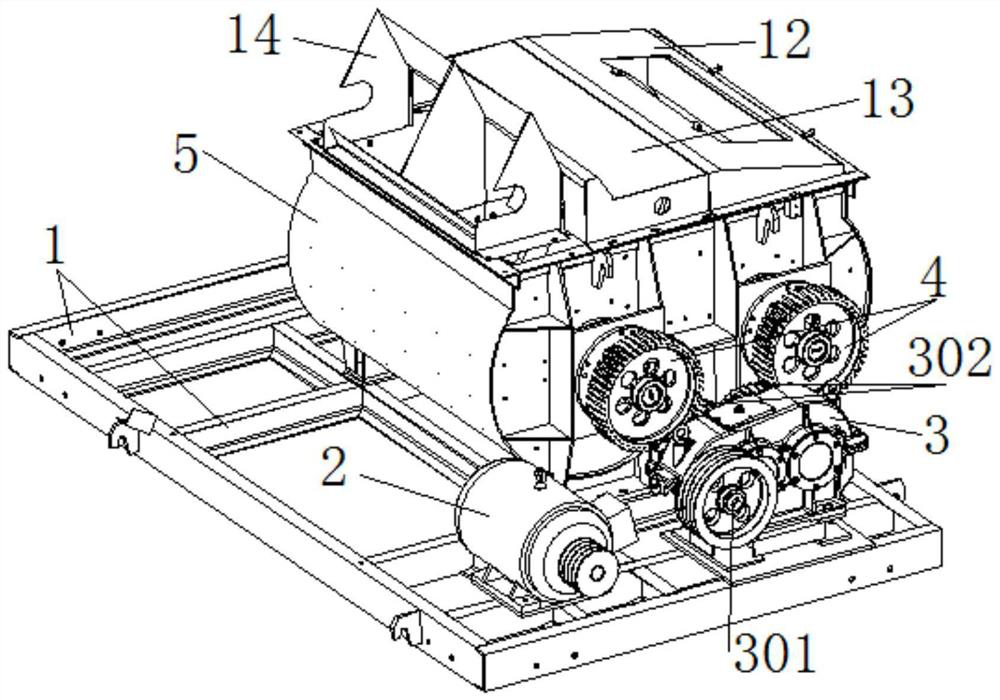

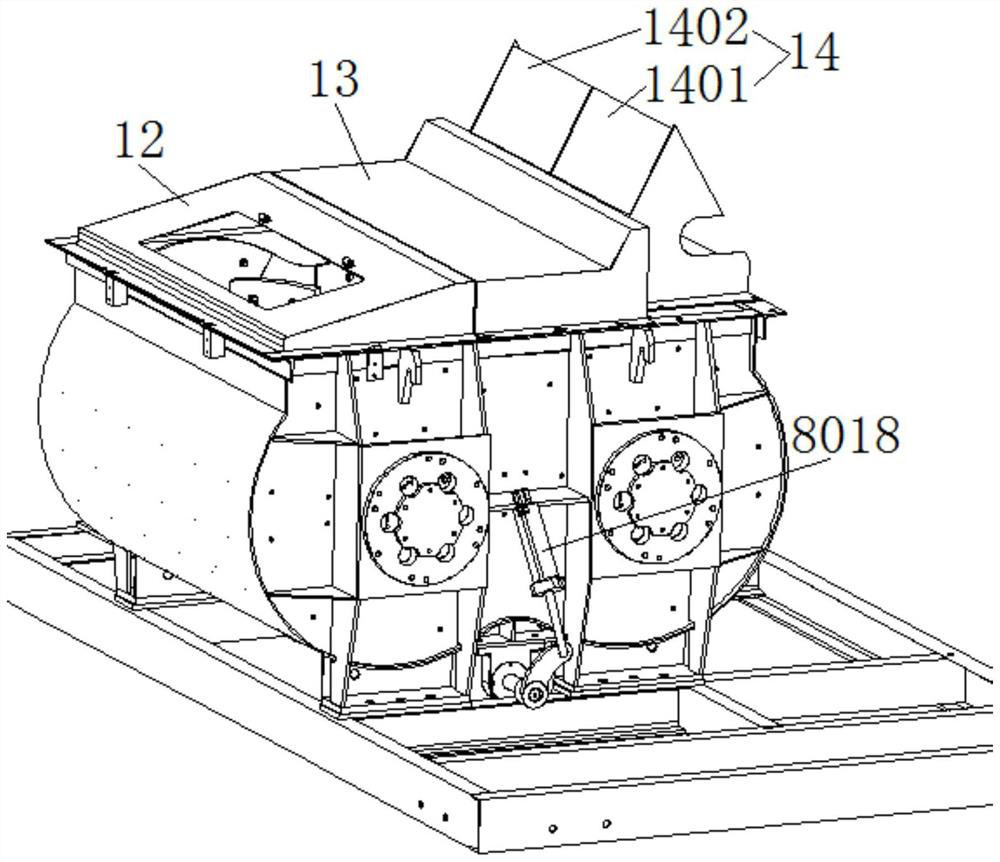

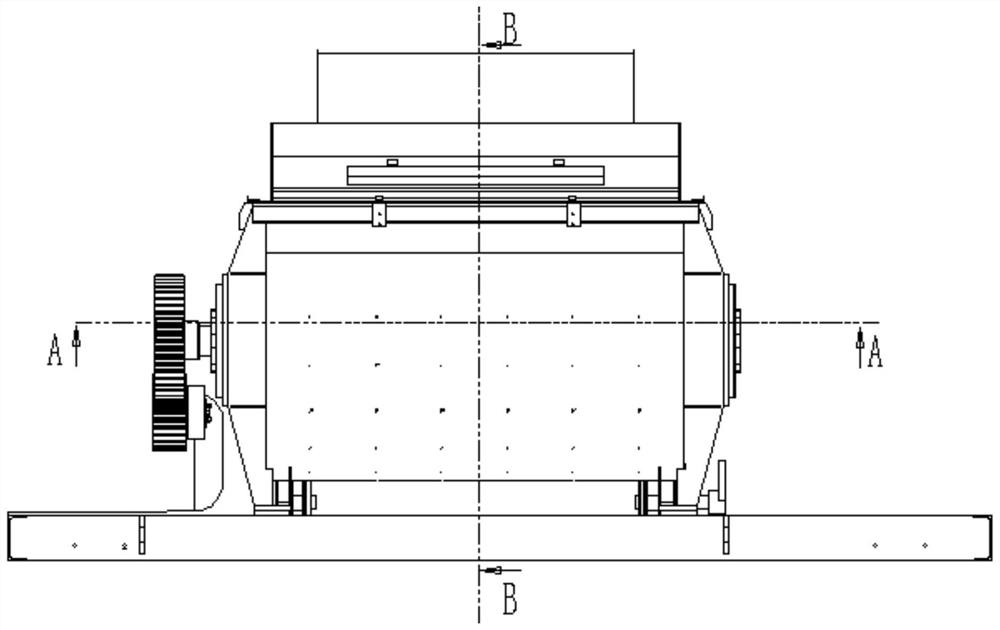

[0071] A multifunctional mixer for water conservancy and hydropower engineering, comprising a base 1 in a frame structure, a servo motor 2 and a reducer 3 are mounted on the outer bolts of the base 1, the output shaft of the servo motor 2 and the input shaft 301 of the reducer 3 pass through a belt 15 drive connections. The two output shafts 302 of the reducer 3 are connected to the two driving wheels 4 through gear meshing transmission.

[0072] The upper part of the base 1 is bolted with a stirring shell 5 , and a vertical partition plate 501 is arranged in the middle of the stirring shell 5 , and the partition plate 501 divides the stirring shell 5 into a left and right double cavity structure.

[0073] The left and right sides of the stirring housing 5 are respectively provided with penetrating mounting holes, and bearing seats I7 are mounted on the mounting holes. A stirring assembly 6 is installed between the two bearing seats I7 corresponding to the left and right.

...

Embodiment 2

[0090] On the basis of Example 1, the outer surfaces of the anti-corrosion plate A9, the anti-corrosion plate B10 and the anti-corrosion plate C11 are uniformly coated with anti-corrosion paint.

[0091] The anti-corrosion coating comprises the following weight components: 10 parts of epoxy resin, 5 parts of polytetrafluoroethylene, 10 parts of basalt fiber trifluorochlorochrysanthemum modified hyperbranched polyborosilazane containing benzene ring, and hydroxy group-containing fragrance 5 parts of soybean ketone resin, 1 part of 2-mercaptobenzothiazole, 1 part of acrylic acid, 3 parts of calcium carbonate, 30 parts of vinyl urethane, 40 parts of 4,6-tribromophenyl ester, 1 part of initiator, curing agent 6 parts, 1 part of dispersant, 1 part of film-forming aid.

Embodiment 3

[0093] On the basis of Example 1, the outer surfaces of the anti-corrosion plate A9, the anti-corrosion plate B10 and the anti-corrosion plate C11 are uniformly coated with anti-corrosion paint.

[0094] The anti-corrosion coating includes the following weight components: 30 parts of epoxy resin, 10 parts of polytetrafluoroethylene, 20 parts of basalt fiber trifluorochlorochrysanthemic acid-modified hyperbranched polyborosilazane containing benzene ring, and hydroxy group-containing fragrance 20 parts of soybean ketone resin, 5 parts of 2-mercaptobenzothiazole, 5 parts of acrylic acid, 10 parts of calcium carbonate, 45 parts of vinyl polyurethane, 50 parts of 4,6-tribromophenyl ester, 3 parts of initiator, curing agent 12 parts, 5 parts of dispersant, 5 parts of film-forming aids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com