Waterborne heat-reflection colorful paint

A technology of colorful coatings and heat-reflecting pigments, applied in the field of coatings, can solve the problems of attenuation of heat insulation effect of reflective heat-insulating coatings, poor water resistance, poor pollution resistance, rare reflective heat-insulating coatings, etc., to achieve enhanced compactness and resistance to ion penetration Excellent durability, weather resistance and water resistance, beautiful color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

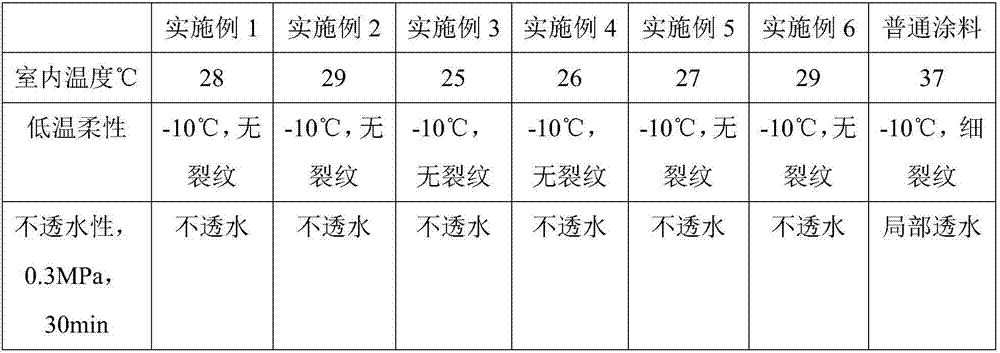

Examples

Embodiment 1

[0024] The present embodiment water-based heat-reflective colorful coating comprises the raw material of following weight portion: 30 parts of water-based polyurethane emulsions, 10 parts of nano-zinc oxides, 5 parts of rheology additives, 12 parts of heat-reflective pigments, 2 parts of additives; Wherein, heat-reflective pigments are Natural pigments, natural pigments are cinnabar, red clay, realgar and malachite green mixed according to the mass ratio of 1:1.2:1:0.7; the particle size of nano-zinc oxide is 10-20μm; the rheology additive is made of modified urea solution, poly The acrylate and polyurethane thickeners are composed according to the mass ratio of 0.7:1:0.8; the additives are thickeners, solvents, and fungicides.

Embodiment 2

[0026] The present embodiment water-based heat-reflective colorful paint comprises the following raw materials in parts by weight: 45 parts of water-based polyurethane emulsion, 20 parts of nano-zinc oxide, 10 parts of rheological additives, 18 parts of heat-reflecting pigments, and 9 parts of additives; wherein, the heat-reflecting pigments are Bio-pigments, bio-pigments are made of carmine and natural fish scale powder according to the mass ratio of 1.2:1.5; the particle size of nano-zinc oxide is 20μm; the rheology additive is made of modified urea solution, polyacrylate and polyurethane. The thickener is composed according to the mass ratio of 0.7:1:0.8; the additive is a mixture of thickener, dispersant, defoamer, solvent, and fungicide.

Embodiment 3

[0028] The present embodiment water-based heat-reflective colorful coating comprises the raw material of following weight portion: 38 parts of water-based polyurethane emulsions, 15 parts of nano-zinc oxides, 8 parts of rheology additives, 15 parts of heat-reflective pigments, 5.5 parts of additives; Wherein, heat-reflective pigments are Natural pigments, natural pigments are cinnabar, red clay, realgar, and malachite green mixed according to the mass ratio of 1:1.2:1:0.7; the particle size of nano-zinc oxide is 15μm; the rheology additive is made of modified urea solution, polyacrylate It is composed of polyurethane thickener according to the mass ratio of 0.7:1:0.8; the additive is mixed with dispersant, defoamer, solvent and fungicide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com