Preparation method of nano SiO2 hybrid self-cleaning organic silicon resin

A self-cleaning, silicone technology, applied in the direction of coating, etc., can solve the problems of expensive fluorine-containing raw materials, low practical application value, and difficulty in engineering, and achieve excellent self-cleaning performance, low price, and easy film formation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

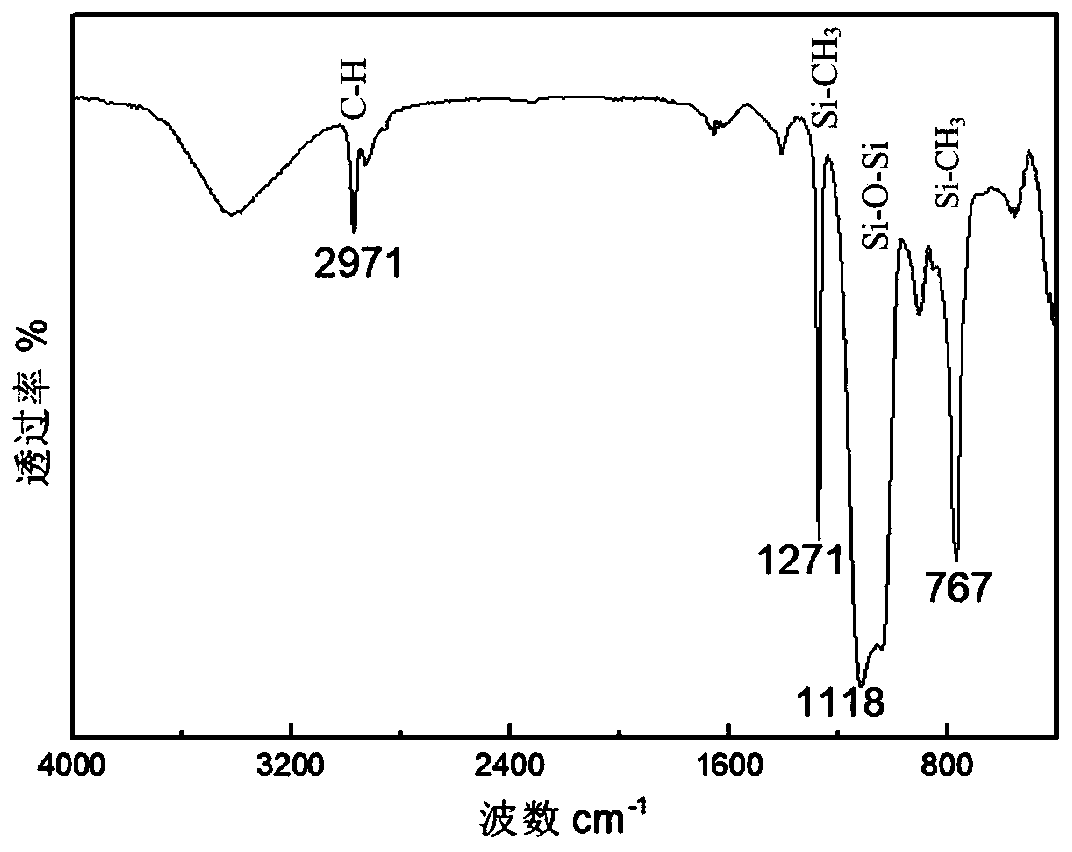

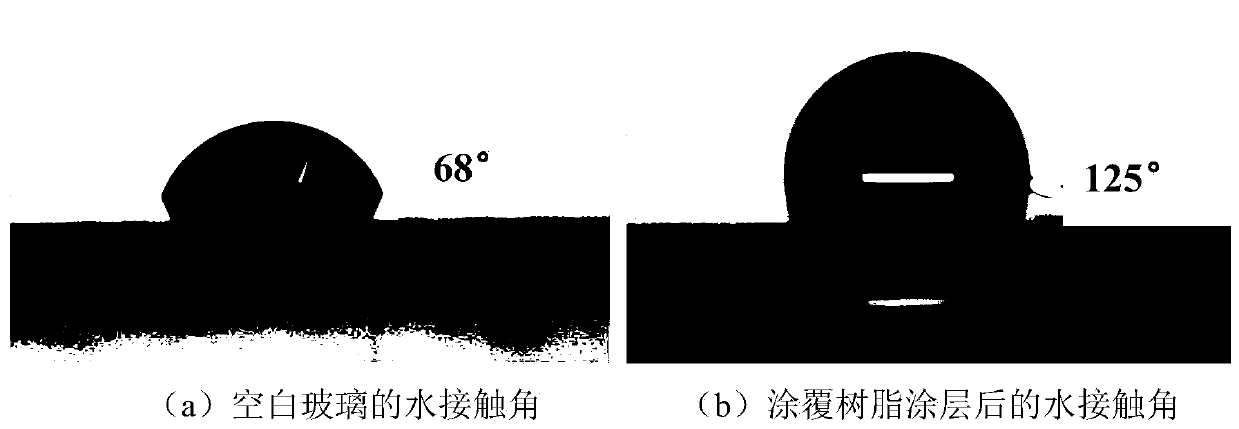

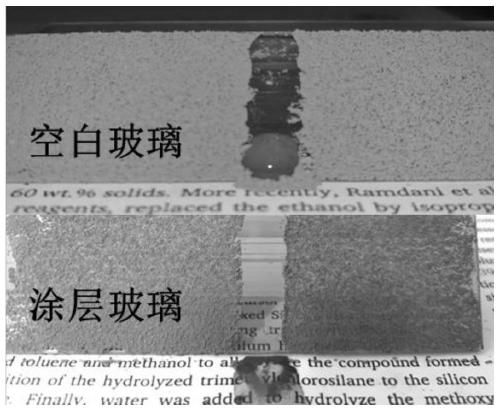

[0026] At 70°C, add 0.4mol methyltriethoxysilane, 0.8mol butanol, 8mmol acetone, 0.9mol silica sol and 0.1mol ethyl acetate into a three-necked flask, mix well and stir for 25 minutes. The pH of the deionized water was adjusted to 2.7 with glacial acetic acid, and 1.2 mol of acetic acid aqueous solution was weighed and added dropwise into the mixed solution. The above mixed solution was stirred at 70° C. for 4 hours, and a mixed hydrolyzate was obtained through a hydrolysis-condensation reaction. The above mixed hydrolyzate was raised to 130°C at a gradient rate of 3°C / min, and distilled under normal pressure to obtain nano-SiO with a high degree of crosslinking. 2 Hybrid self-cleaning silicone resin. nano-SiO 2 The hybrid self-cleaning silicone resin is diluted with butanol and evenly coated on the glass sheet. Its visible light transmittance is 98%, water contact angle is 125°, GB / T6739-2006 pencil hardness is 5H grade, ISO-2409 attached The strength is grade 1, and the m...

example 2

[0031] At 60°C, 0.2mol methyltrimethoxysilane, 0.2mol methyltriethoxysilane, 0.1mol dimethyldimethoxysilane, 1mol methanol, 0.7mmol cyclohexanone, 1.25mol silica sol and 0.1 mol ethyl propionate was added into the three-necked flask, mixed evenly and then stirred for 30 minutes. The pH of the deionized water was adjusted to 1.7 with dilute hydrochloric acid, and 0.3 mol aqueous hydrochloric acid solution was weighed and added dropwise into the mixed solution. The above mixed solution was stirred at 60° C. for 5 hours, and a mixed hydrolyzate was obtained through hydrolysis-condensation reaction. The above mixed hydrolyzate was raised to 180°C at a gradient rate of 10°C / min, and distilled under normal pressure to obtain nano-SiO with a high degree of crosslinking. 2 Hybrid self-cleaning silicone resin. nano-SiO 2 The hybrid self-cleaning silicone resin is diluted with butanol and evenly coated on the glass sheet. Its visible light transmittance is 94%, water contact angle is...

example 3

[0033] At 40°C, add 0.1mol trimethylmethoxysilane, 0.3mol methyltriethoxysilane, 1.0mol ethanol, 0.4mmol methyl butanone, 1.0mol silica sol and 0.2mol ethyl acetate into a three-necked flask , and stir for 45 minutes after mixing well. Ascorbic acid was used to adjust the pH of the deionized water to 3.3, and 1.0 mol of ascorbic acid aqueous solution was weighed and added dropwise to the mixed solution. The above mixed solution was stirred at 40° C. for 7 hours, and a mixed hydrolyzate was obtained through a hydrolysis-condensation reaction. The above mixed hydrolyzate was raised to 120°C at a gradient rate of 5°C / min, and distilled under normal pressure to obtain nano-SiO with a high degree of crosslinking. 2 Hybrid self-cleaning silicone resin. nano-SiO 2The hybrid self-cleaning silicone resin is diluted with butanol and evenly coated on the glass sheet. Its visible light transmittance is 98%, water contact angle is 121°, GB / T6739-2006 pencil hardness is 3H, ISO-2409 atta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Maximum temperature | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com