Patents

Literature

66results about How to "Easy steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

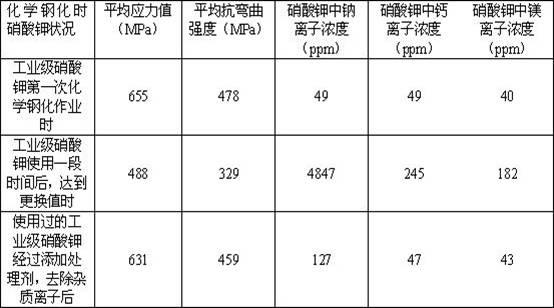

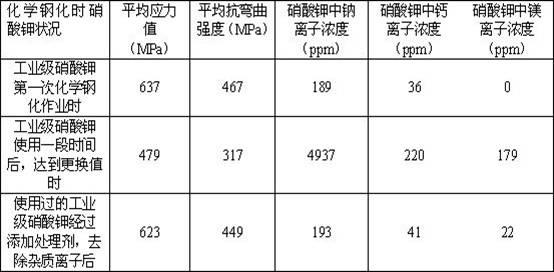

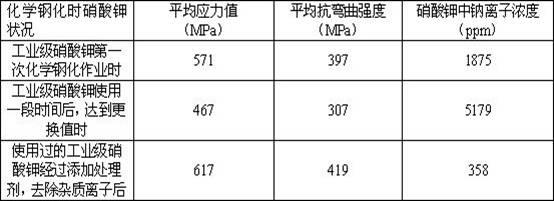

Method for removing potassium nitrate impurity ions on line in chemical tempering production

ActiveCN102515491AEasy stepsSimple processGlass tempering apparatusGlass productionImpurity ionsPotassium nitrate

The invention relates to a method for removing potassium nitrate impurity ions on line in chemical tempering production. The method implements the invention through the following steps in the mass chemical tempering operation: (1) the concentration of sodium, calcium and magnesium ions in molten potassium nitrate in a chemical tempering furnace is detected; when the glass stress and strength are lower than set values after a certain amount of chemical tempering, the tempering is stopped, and the concentration of the sodium, calcium and magnesium ions in the molten potassium nitrate in the furnace is recorded; (2) an appropriate amount of treated reagent (potassium pyroantimonate) is added in the potassium nitrate of which the tempering is stopped and simultaneously is stirred, so that the reaction is uniform and full; (3) the molten potassium nitrate obtained in the step (2) stands at constant temperature, so that the molten potassium nitrate reacts, is deposited and clarified thoroughly; and (4) after the molten potassium nitrate obtained in step (3) is fully clarified, the chemical tempering is re-started. The method can reduce the replacing frequency of the chemically tempered potassium nitrate, reduces the cost, improves the production efficiency, is simple in process and is convenient to implement.

Owner:GUANGDONG AVIC SPECIAL GLASS TECH

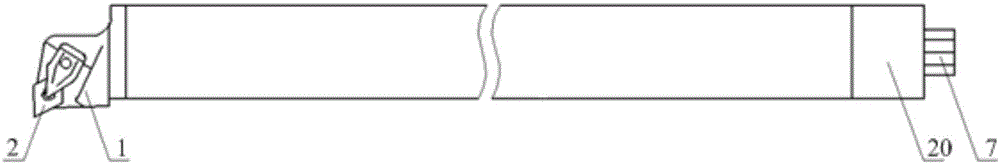

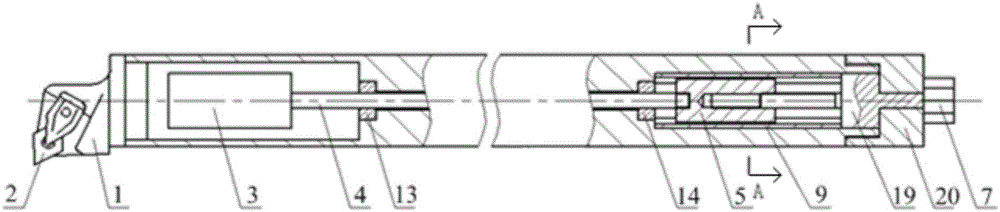

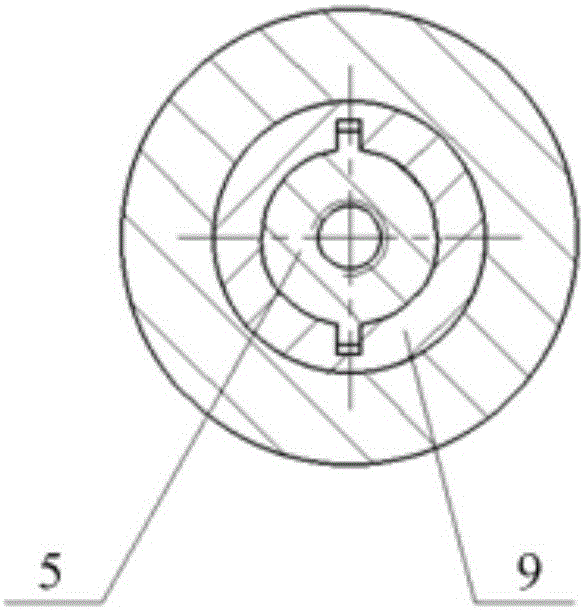

Passive type vibration absorption boring bar and optimal vibration absorption performance adjustment method thereof

ActiveCN106270590ASimple structureEasy stepsMeasurement/indication equipmentsBoring barsCantilevered beamDeep hole

Owner:HARBIN UNIV OF SCI & TECH

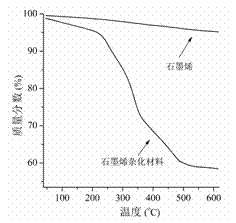

Preparation method of environmental response type graphene hybrid material

The invention discloses a preparation method of an environmental response type graphene hybrid material. The preparation method comprises the following steps of: (1) anchoring an RAFT (Reversible Addition Fragmentation Chain Transfer) agent on the surface of graphene; and (2) triggering a functional monomer to polymerize by utilizing the RAFT agent on the surface of the graphene to obtain an environmental response type polymer grafted graphene hybrid material. The preparation method disclosed by the invention is simple, mild in polymerization condition and suitable for large-scale production; and the prepared functional graphene has controllability for the thickness of a polymer on the surface, favorable response to the simulation for the external environment and long-term dispersibility in a solvent.

Owner:ANKANG UNIV

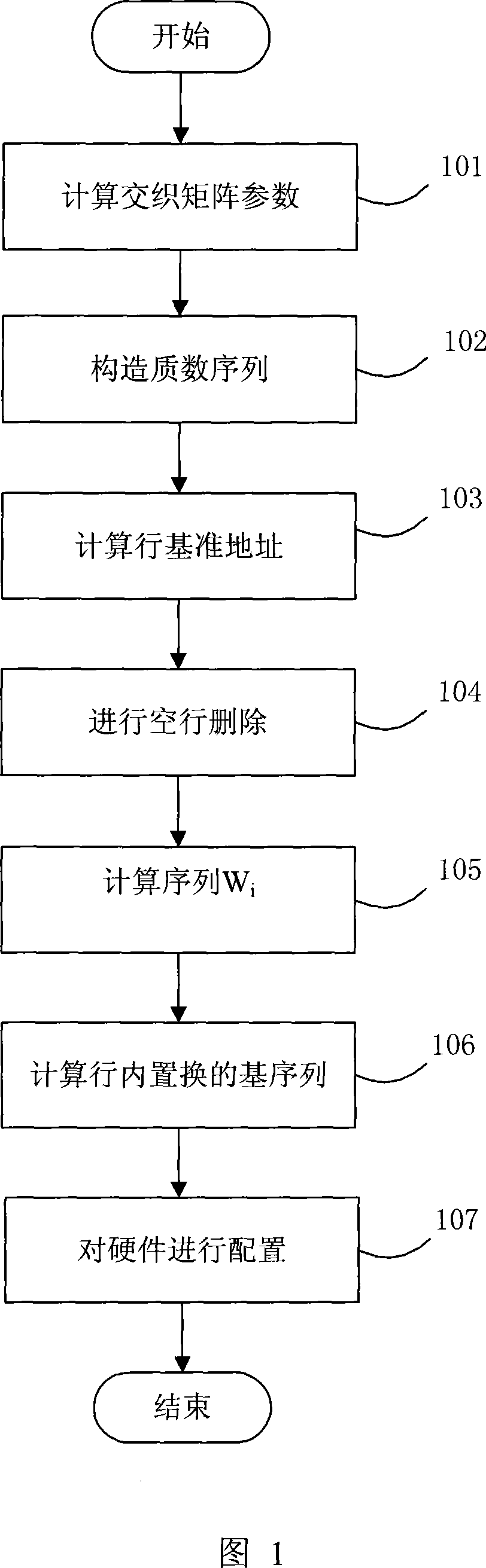

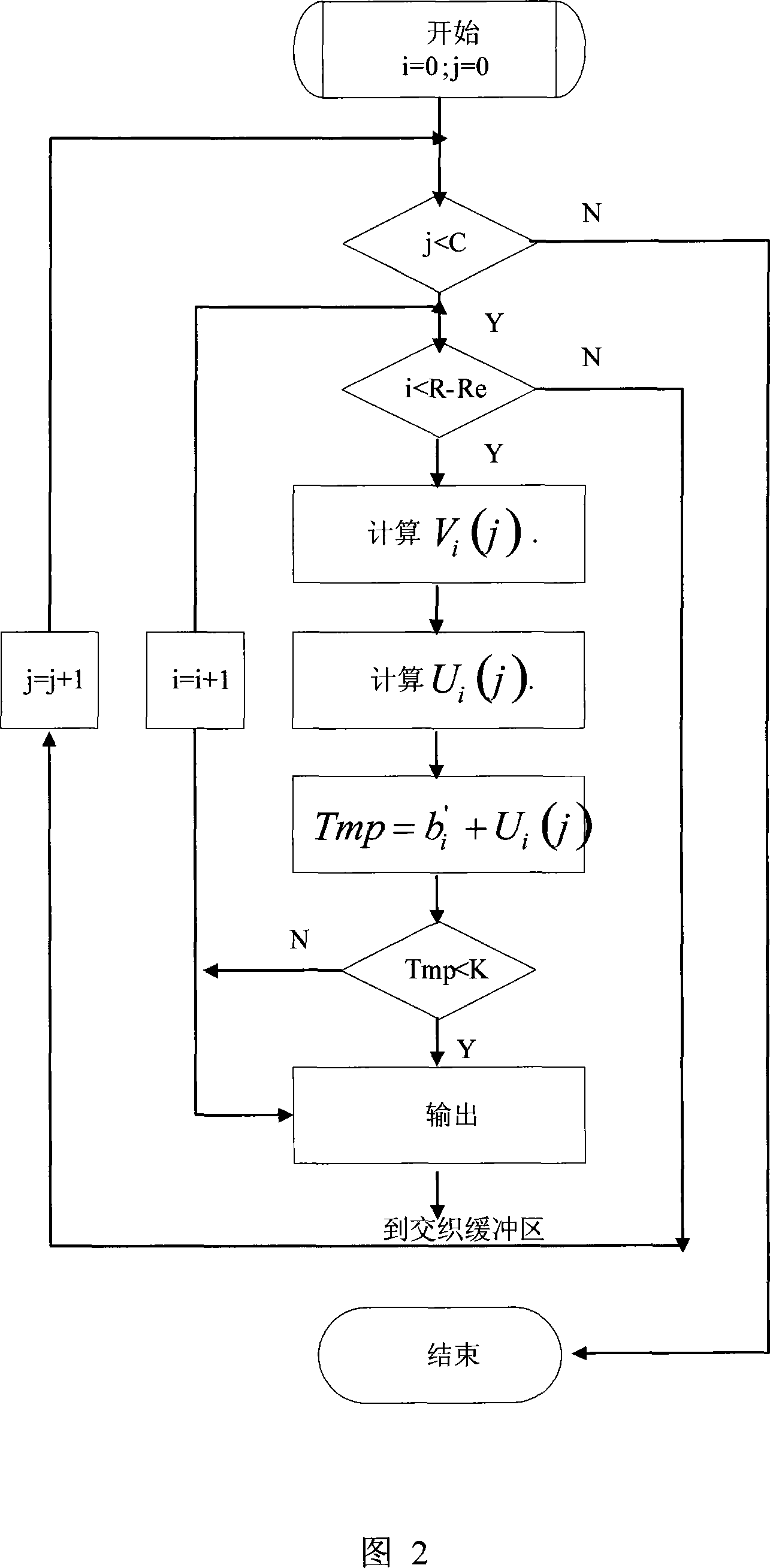

Implementation method for in-Turbo code interweaver

InactiveCN101034951AEasy stepsSave storage resourcesError preventionCode division multiplexHardware implementationsTurbo coded

Owner:ZTE CORP

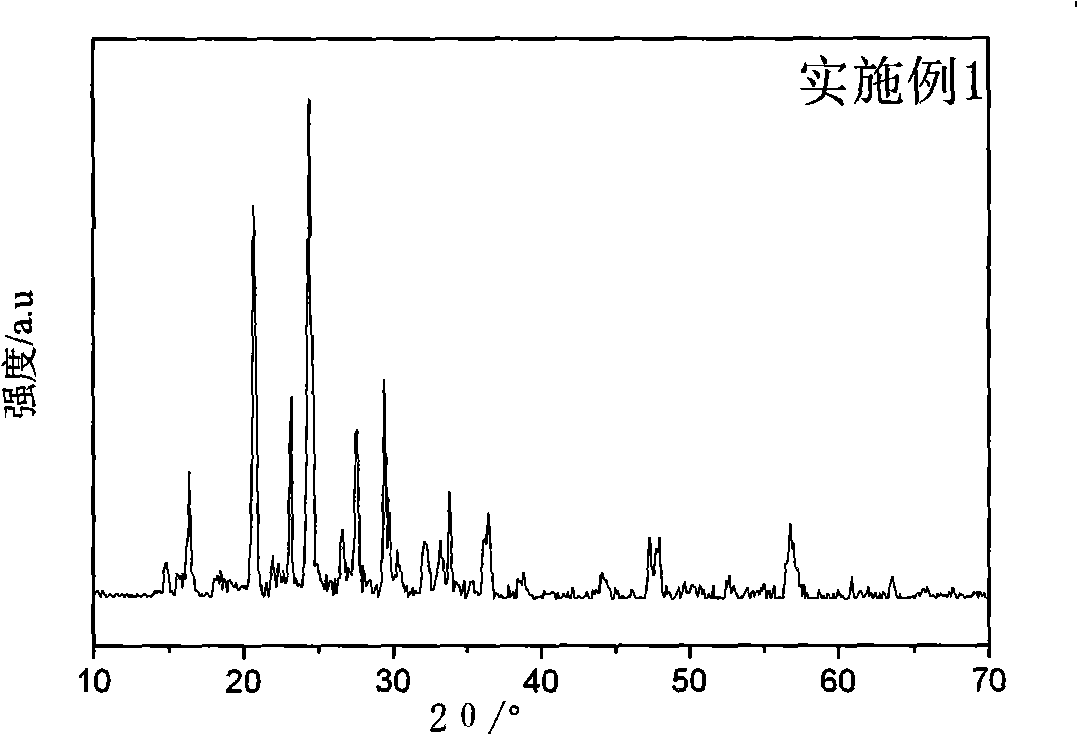

Method for preparing Li3V2(PO4)3/C composite anode material and anode material made by the same

InactiveCN101304084ASimple reaction conditionsEasy stepsElectrode manufacturing processesSolid phasesPre treatment

The invention discloses a preparation method of a Li3V2 (PO4)3 / C composite anode material and a prepared anode material. The preparation method is as follows: a. Li source, V source, organic carbon source and NH4H2PO4 are ball-milled together and evenly mixed; b. the product obtained in step a is pretreated at a temperature of 300 DEG C to 450 DEG C; c. the pretreated product is roasted at a temperature of 500 DEG C to 700 DEG C in the protective atmosphere of inert gas. By adopting low-temperature solid-phase method to synthesize the anode material of the lithium ion battery, the preparation method has simple reaction conditions and convenient steps, and is extremely suitable for mass production; organic matter is used as the indirect carbon source which is fully ball-milled and mixed to form carbon after pretreatment, thus the agglomeration of material grains can be effectively organized and the conductivity of the materials can be improved.

Owner:SHENZHEN BAK BATTERY CO LTD

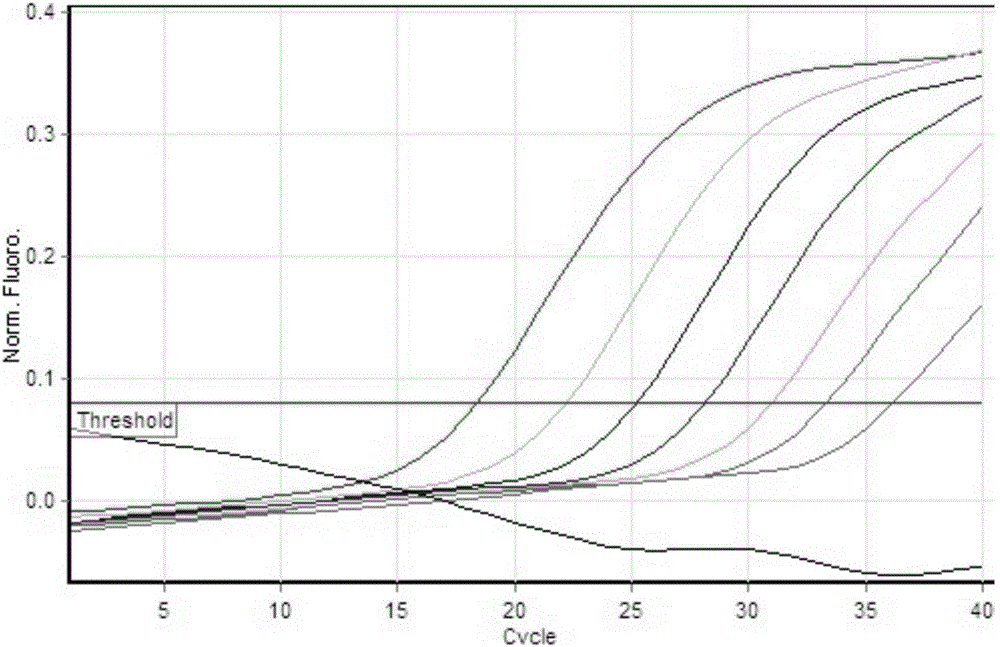

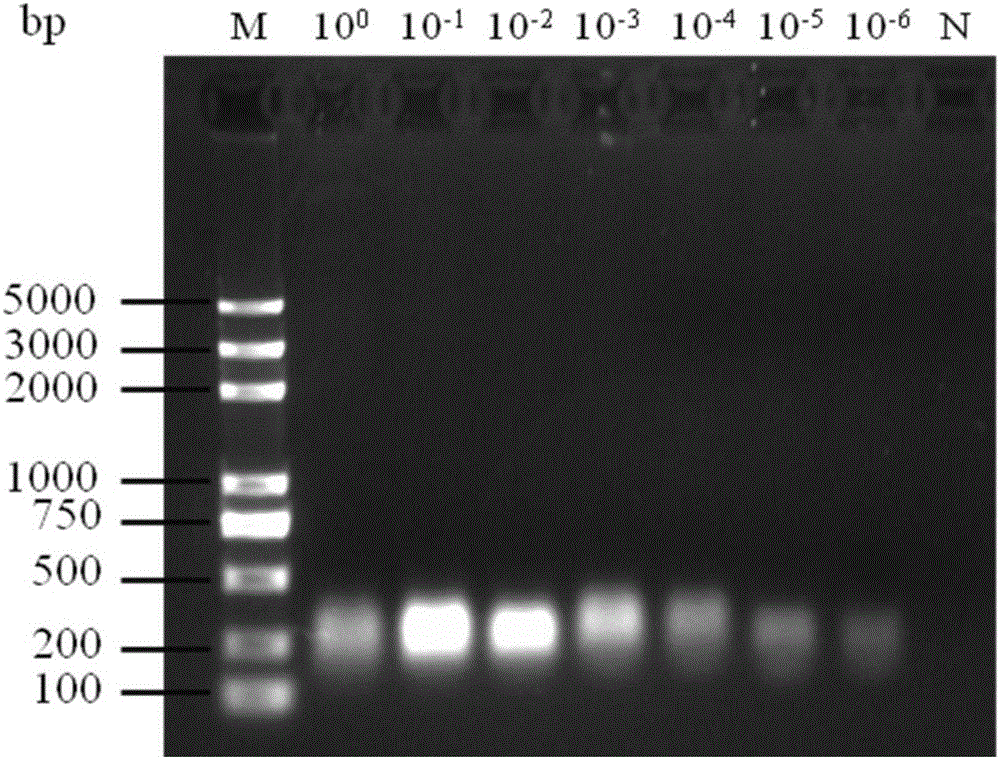

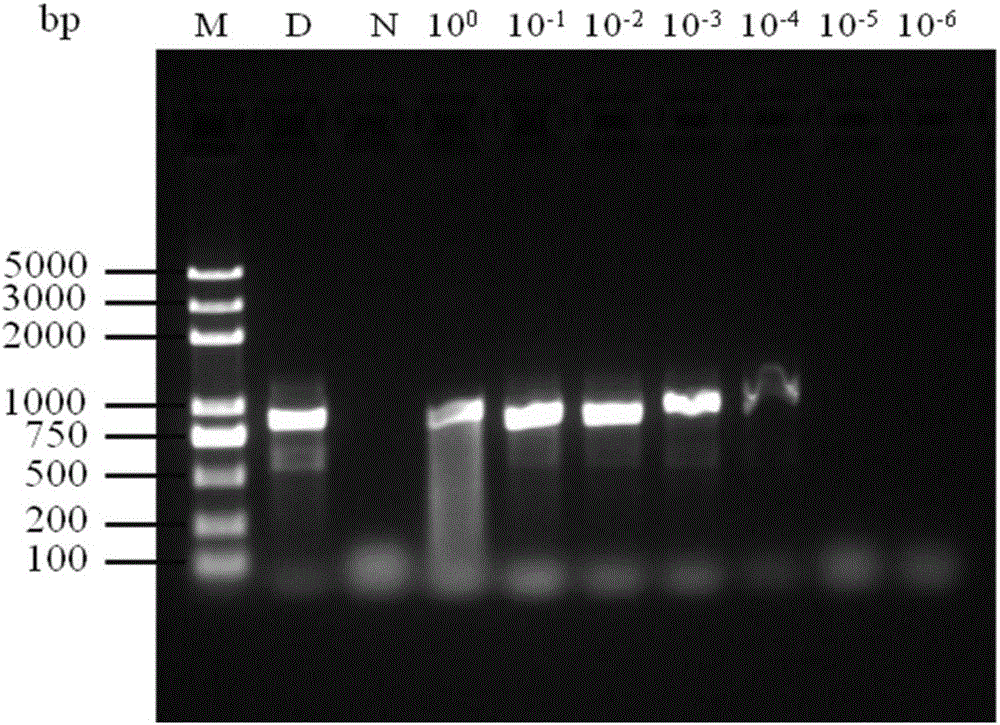

Primer, probe and kit for detecting canine parvovirus and detection method

InactiveCN105803112AGood specificityEasy stepsMicrobiological testing/measurementDNA/RNA fragmentationCanine parvovirusNucleotide sequencing

The invention relates to a primer, probe and kit for detecting canine parvovirus and a detection method.According to the fluorogenic quantitative PCR primer for detecting canine parvovirus, an upstream detection primer CPV-F has the nucleotide sequence as shown in the SEQ ID NO.1, and a downstream detection primer CPV-R has the nucleotide sequence as shown in the SEQ ID NO.2.The probe has the nucleotide sequence as shown in the SEQ ID NO.3.The kit comprises the primer and the probe.The fluorogenic quantitative PCR primer, probe and kit for detecting canine parvovirus have the advantages that operation is easy, cost is low, sensitivity is high and specificity is high, and can guarantee clinical detection.

Owner:中国人民解放军成都军区疾病预防控制中心

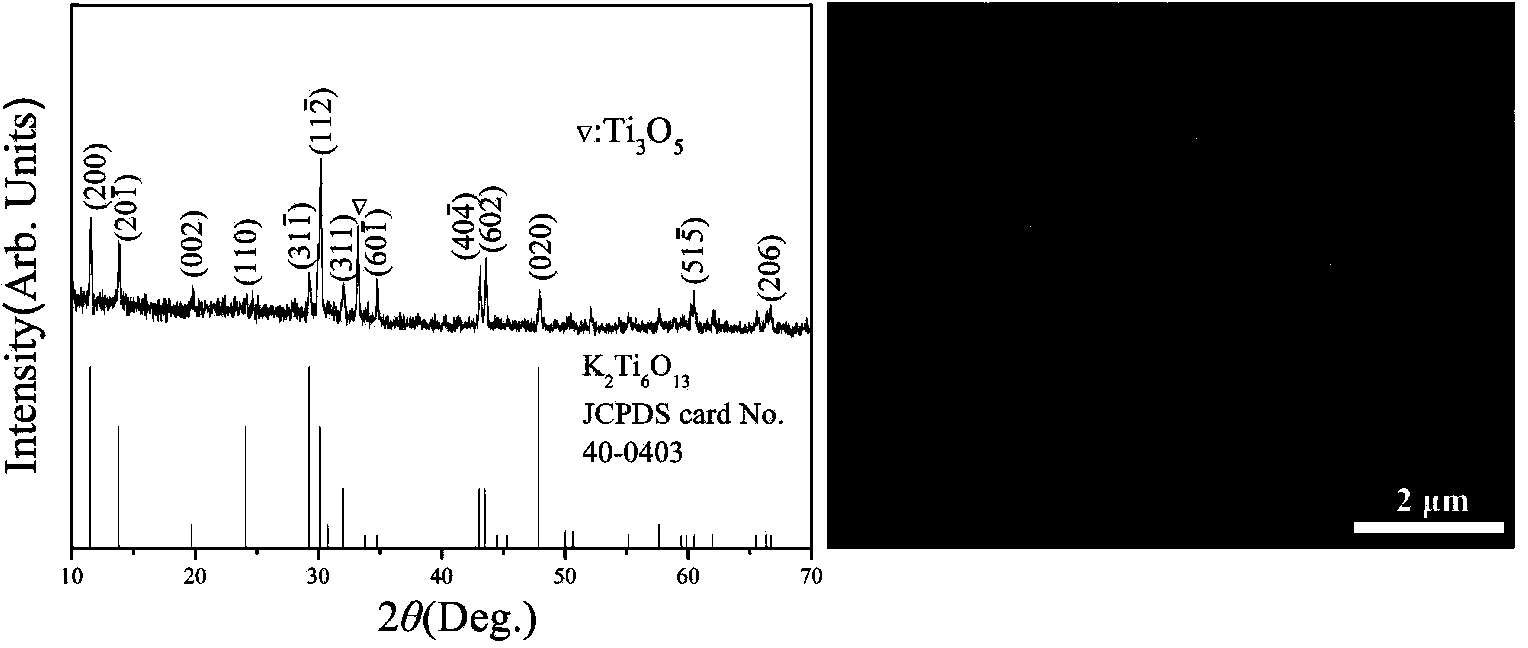

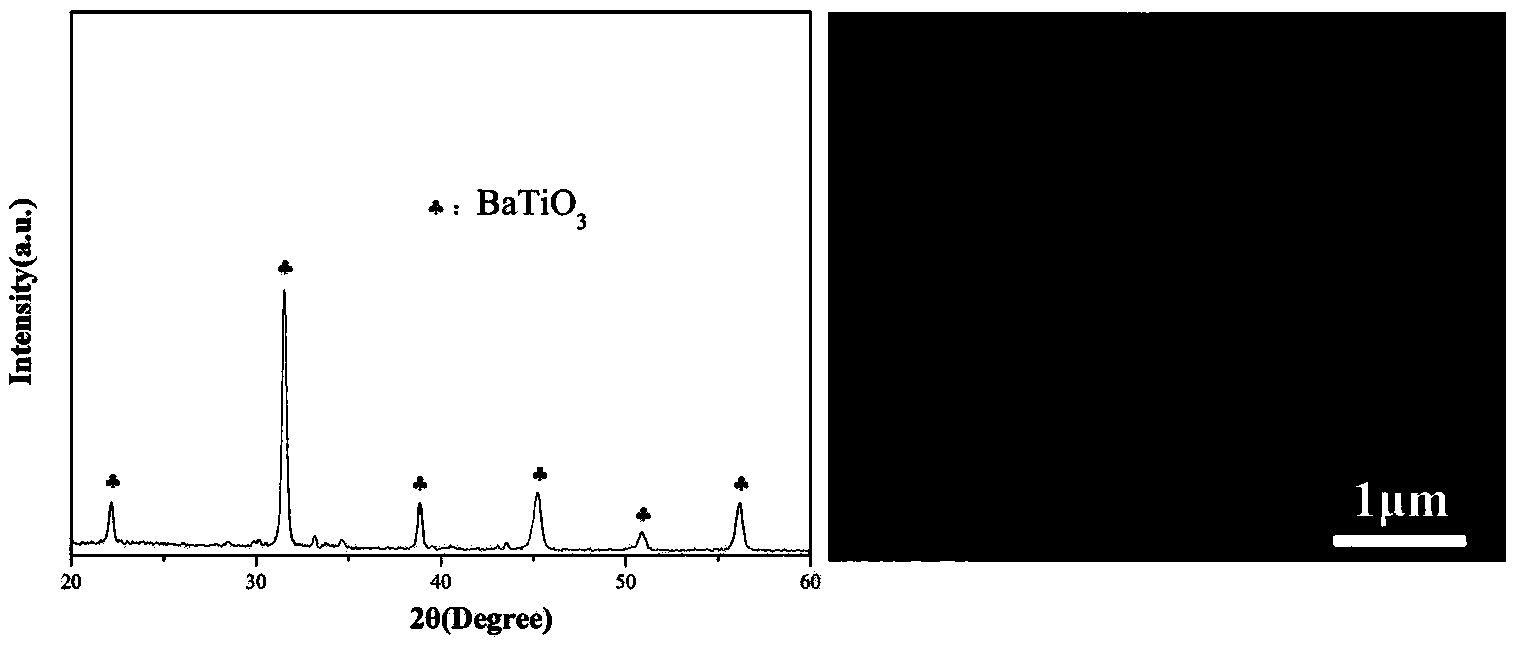

Method using ion exchange solvothermal method for preparation of titanate nano powder

ActiveCN103818949AEasy stepsEasy to implementTitanium compoundsBulk chemical productionIon exchangeCalcium titanate

The invention discloses a method using an ion exchange solvothermalmethod for preparation of titanate nano powde, the method comprises raw material weighing, mixing and drying, heating, boiling water extraction, precursor preparation and solvothermal reaction steps. The method of the invention is the ion exchange solvothermal method, the synthesized nano powder is in fact the nano titanate powder, when temperature and pressure are over supercritical points of an organic solvent liquid, the liquid is in a supercritical state, the solubility of compounds in the liquid as a solvent is increased, the viscosity is decreased, and the ion activity is enhanced. By the method, nano strontium titanate, calcium titanate, barium titanate and the like can be synthesized in more temperate conditions, the method has the advantages of being simple in operation step, easy to implement, mild in reaction condition, and convenient in industrial production.

Owner:临沂创实新型材料有限公司

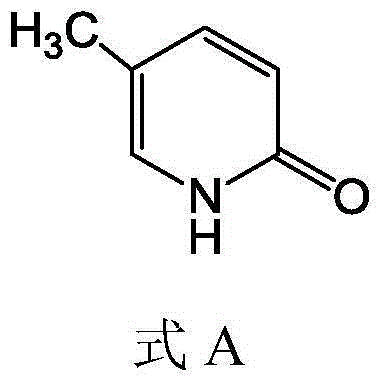

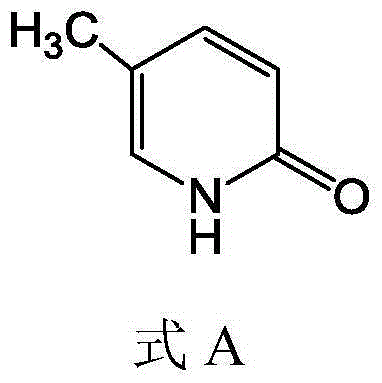

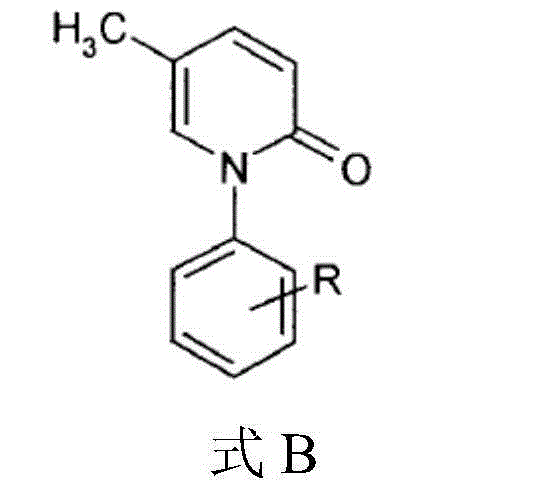

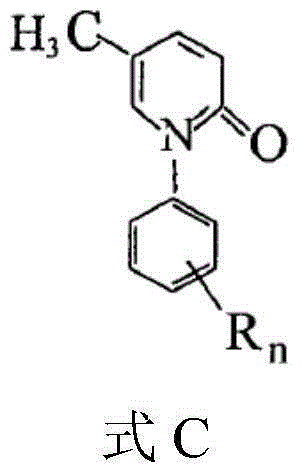

5-methyl-2(1H)pyridone derivatives, and preparation method and application thereof

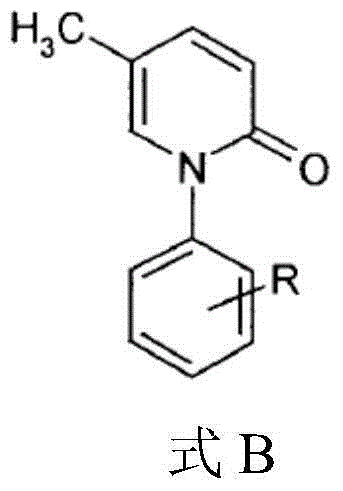

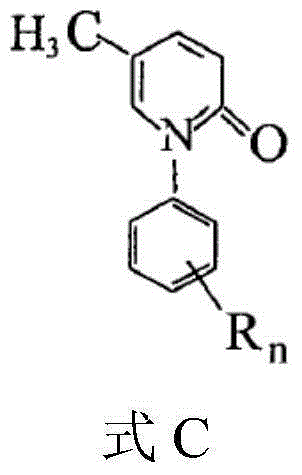

InactiveCN105085383AReduce processEasy stepsOrganic active ingredientsOrganic chemistryDiseaseMethyl group

The invention discloses 5-methyl-2(1H)pyridone derivatives disclosed as Formula I, or crystal forms, pharmaceutically acceptable salts, hydrates, solvates or pro-drugs thereof. In the formula I, R is selected from hydroxy group, mercapto group, amino group or imino group. The invention provides the new 5-methyl-2(1H)pyridone derivatives; and the new 5-methyl-2(1H)pyridone derivatives have obvious inhibiting effects on fibroblast proliferation and fibroblast secretory fiber binding protein (Fn), and can be used for preparing drugs for treating or preventing fibrosis diseases, tumors and the like. The preparation method of the compounds disclosed as Formula I has the advantages of fewer procedures, simple steps, mild reaction conditions, low energy consumption, high efficiency, low cost, environment friendliness and the like, and is very suitable for application in industry.

Owner:SICHUAN UNIV

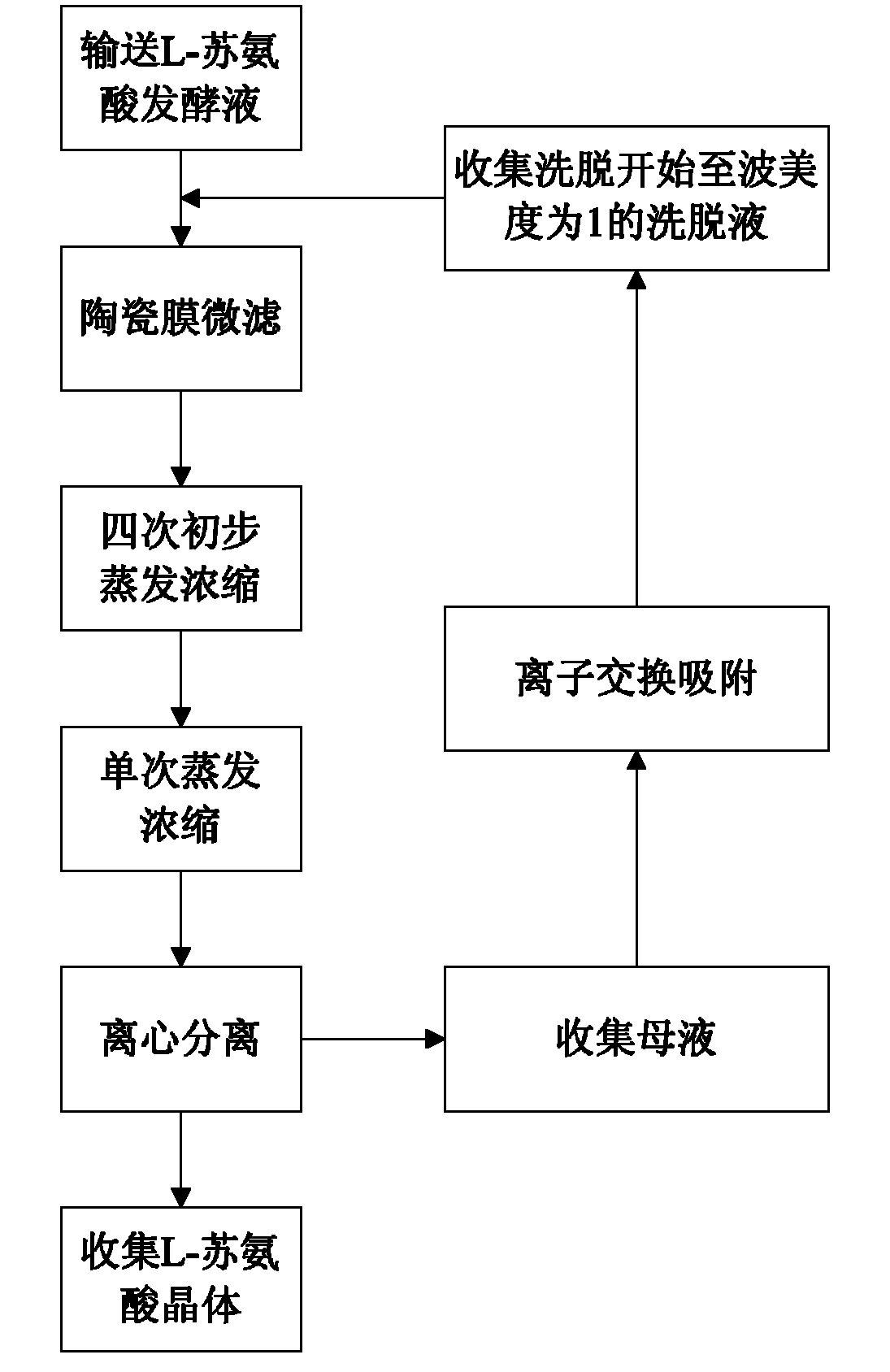

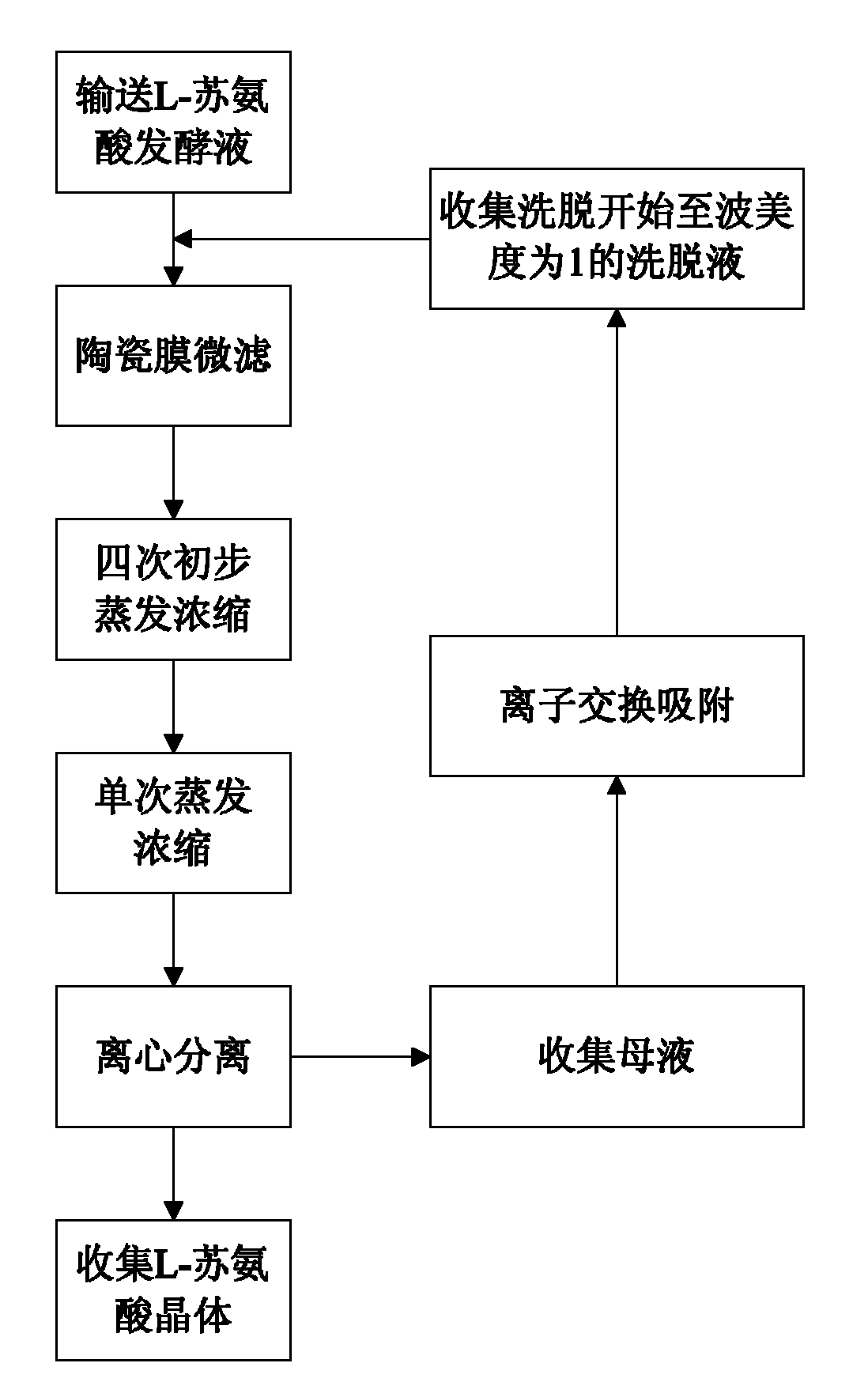

Method for extracting L-threonine

ActiveCN102001957AEasy stepsHigh purityOrganic compound preparationAmino-carboxyl compound preparationChemistryMother liquor

The invention relates to the field of biochemical engineering, in particular to a method for extracting L-threonine. The method comprises the following steps of: (1) micro-filtrating L-threonine fermentation liquor, concentrating a filtrate to a solid-to-liquid ratio of 0.45-0.75 to 1 and centrifugating to obtain L-threonine crystals and mother liquor; (2) carrying out cross-adsorption on the mother liquor, then, eluting with ammonia with a pH value of 10-14 and collecting eluant from the start of elution to the Baume degree of 1; and (3) adding the L-threonine fermentation liquor to the eluant in the step (2), carrying out micro-filtration, concentrating the filtrate to the solid-to-liquid ratio of 0.45-0.75 to 1, centrifugating to obtain L-threonine crystals and mother liquor and repeating the step (2) to the mother liquor. The method of the invention is simple and convenient for operation without bleaching and can obtain high-quality L-threonine through separation by controlling the concentration times, and the crystallized mother liquor after the cross-adsorption is mixed and cycled with the L-threonine fermentation liquor to improve the purity of the subsequently extracted L-threonine.

Owner:梅花生物科技集团股份有限公司

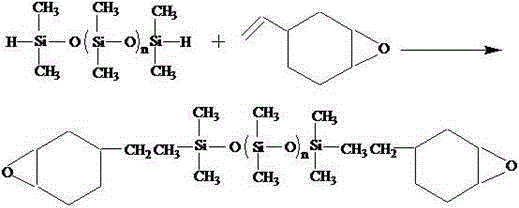

Purely cationic photosensitive resin for 3D printing stereolithographic rapid prototyping, and preparation method and application thereof

ActiveCN105384913AEasy stepsGood photosensitivityAdditive manufacturing apparatusLight exposureChemistry

The invention provides a purely cationic photosensitive resin for 3D printing stereolithographic rapid prototyping, and a preparation method and application thereof. The purely cationic photosensitive resin comprises the following raw materials by mass: 15 to 95% of alicyclic epoxy resin containing siloxane, 1 to 30% of an oxetane compound, 1 to 50% of an alicyclic epoxy compound, 1 to 25% of an aliphatic epoxy compound and 1 to 12% of a cationic initiator. The preparation method comprises the following steps: mixing the above-mentioned raw materials according to the mass percentages; and then carrying out heating at 20 to 80 DEG C and stirring for 5 to 120 min so as to obtain transparent light-yellow uniform liquid. The photosensitive resin prepared in the invention is small in irritation, has few volatile matters and can be conveniently prepared; the photosensitive resin has good photosensitivity and critical light exposure Ec of less than 19.0 mJ / cm2; and a molded part has high precision, a warping factor CF(6) of the molded part is in a range of + / - 0.01 and a warping factor CF(11) of the molded part is in a range of + / - 0.03. A part printed from the photosensitive resin prepared in the invention has higher shaping precision compared with a part printed from conventional photosensitive resin.

Owner:NANCHANG UNIV

Preparation method of freshly ground soybean milk raw material

InactiveCN103798403AThe processing technology is simpleEasy stepsMilk substitutesFood scienceElectric heatingRaw material

The invention discloses a preparation method of a freshly ground soybean milk raw material. The preparation method comprises the following steps: 1. selecting beans, and removing moldy beans, moth-eaten beans and hard beans; 2. cleaning and peeling the selected beans; 3. soaking the cleaned beans for 4-8 hours; 4. cleaning the soaked beans once again; 5. steaming the beans cleaned once again in a steam jacket kettle, wherein the beans are boiled through strong fire and are kept slightly boiled for 1-4 hours with slow fire; and 6. draining off the steamed beans, pouring the beans to a stirring pan when the beans are still hot, adding white sugar to the beans in the ratio of (0.5-0.8): 1, completely and uniformly stirring through the stirring pan, and roasting in an electric heating oven for 1min-5min to obtain the sugar beans. The processing method disclosed by the invention is simple and convenient; with the help of the product disclosed by the invention, soybean milk can be directly produced through a soybean milk making machine within 2min, thus greatly facilitating processing of soybean milk.

Owner:李立平

5-methyl-2(1H)pyridone derivatives, preparation method and applications thereof

The invention discloses 5-methyl-2(1H)pyridone derivatives represented by the formula (I), crystal form, pharmaceutically-acceptable salts, hydrates, solvates, or prodrugs thereof. In the formula (I), the R1 represents a hydrogen atom, a halogen element, a C1-C6 alkyl group, a C1-C6 alkyloxy group, a C2-C6 amido group, a C2-C6 aminoacyl group, and a C3-C6 heterocyclic group. The provided derivatives have a prominent inhibiting effect on the proliferation and fibronectin (FN) secretion of fibroblast, so the derivatives can be used to prepare drugs for preventing or treating fibrotic diseases and tumors. The provided preparation method has the advantages of few and simple steps, mild reaction conditions, low energy consumption, high efficiency, low cost, and environment-friendliness, and is suitable for industry.

Owner:SICHUAN UNIV

Regenerated plant in-vitro culture method for Sirindhorn michelia figo

InactiveCN103718969AHigh induction rate and survival rateEasy stepsPlant tissue cultureHorticulture methodsEcology

The invention discloses a regenerated plant in-vitro culture method for Sirindhorn michelia figo. The regenerated plant in-vitro culture method comprises the following six steps: (1) adopting explants and treating materials; (2) establishing a sterile propagule; (3) carrying out multiplication culture; (4) carrying out rooting culture; (5) transplanting; and (6) culturing seedlings. According to the regenerated plant in-vitro culture method for the Sirindhorn michelia figo, the inductivity and the survival rate are high; the steps are simple, convenient and feasible; the regenerated plant in-vitro culture method has very urgent and important meanings on preserving and rescuing world valuable and rare endangered michelia figo varieties and breeding extremely-endangered trees; the regenerated plant in-vitro culture method is used for carrying out tissue culture on big tree twigs of michelia figo plants; the problems of a tissue culture propagation technology that the pollution rate is low, the browning is serious, the inductivity is low, the transplanting survival rate is low and the like are overcome and the method has the very valuable academic research value.

Owner:SOUTH CHINA AGRI UNIV +1

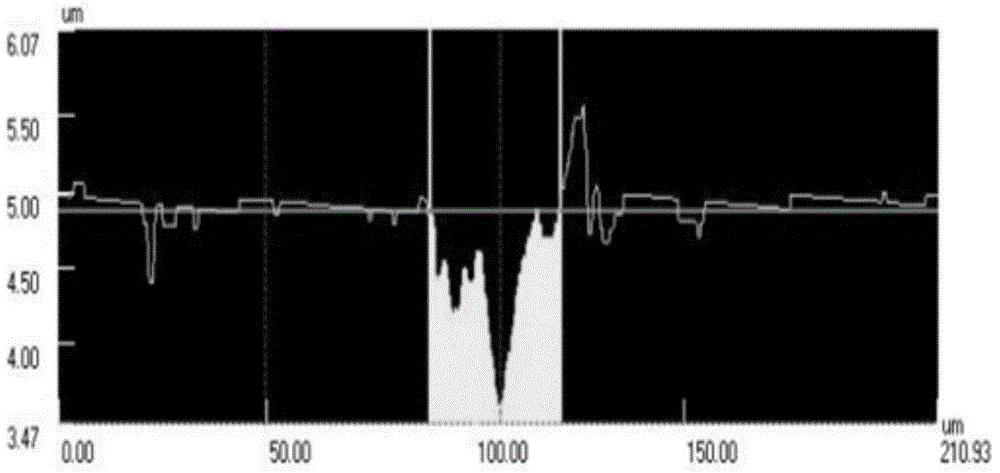

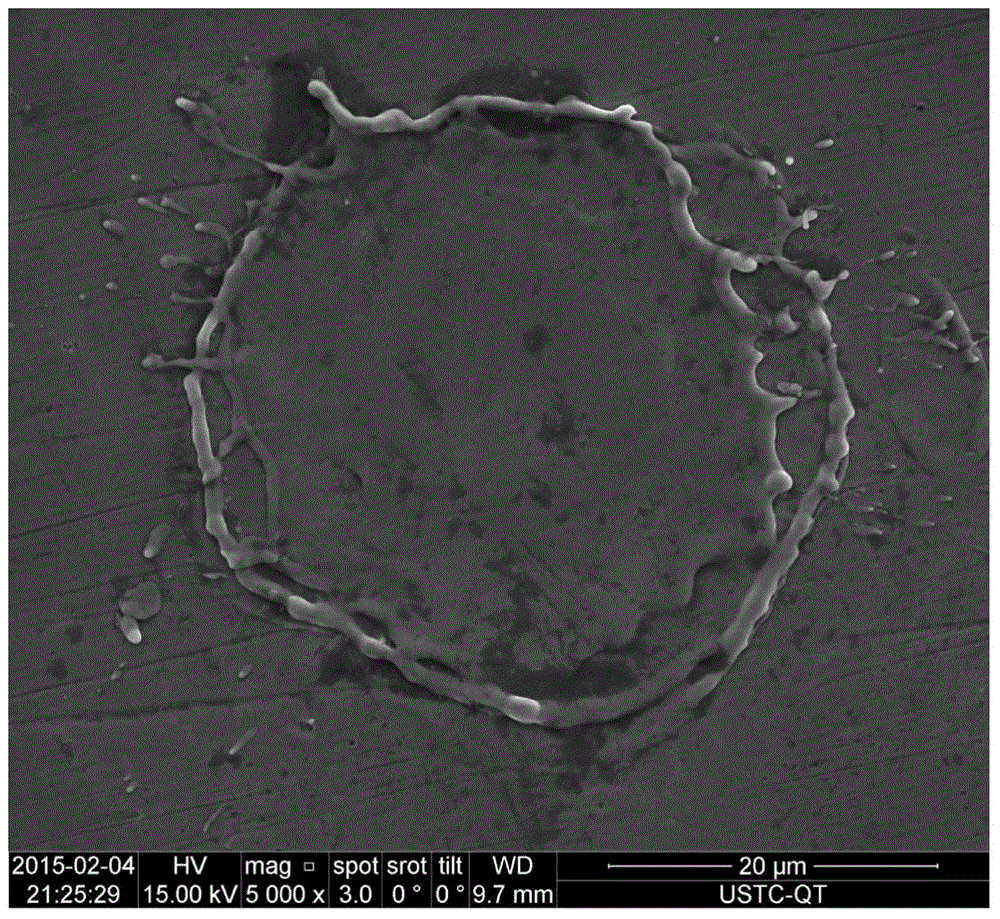

Mew method for increasing laser boring depth of stainless steel

The invention provides a new method for increasing laser boring depth of stainless steel. The new method comprises the steps that 1 pretreatment is conducted on the stainless steel; 2 gold nanoparticle solution is prepared; 3 self-assembly of gold nanoparticles on the surface of the stainless steel is conducted: the APTMS is prepared into APTMS-methanol solution, the processed stainless steel is socked into the APTMS-methanol solution, the stainless steel is taken out and is washed with deionized water, the stainless steel is soaked into the gold nanoparticle solution, and then the stainless steel is taken out and dried for use later; 4 laser boring is conducted: laser boring is conducted on the surface of the self-assembly stainless steel, and the wave length of the laser is same to that of the absorbing wave length of the gold nanoparticles; 5 aftertreatment on the stainless steel is conducted. According to the new method for increasing laser boring depth of stainless steel, a gold nanoparticle layer is self assembled on the surface of the stainless steel, then laser treatment is conducted, and the temperature of a boring position is increased rapidly, so that the boring depth is increased. The new method for increasing laser boring depth of the stainless steel has the advantages that the operating procedures are simple, the energy consumption is little, the processing efficiency is high, and the repeating performance is high.

Owner:JIANGSU UNIV

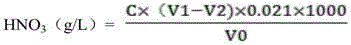

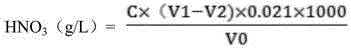

Method for accurate measurement on nitric acid content of chemical corrosion solution for titanium alloy

InactiveCN103823017ARapid responseEasy stepsChemical analysis using titrationCarbon dioxidePotassium permanganate

The invention provides a method for accurate measurement on nitric acid content of a chemical corrosion solution for titanium alloy. With the presence of high concentration sulfuric acid, NO<3-> is reduced into NO through ferrous sulfate, and the excessive ferrous sulfate is titrated through potassium permanganate standard solution; a Gaikeli funnel is used during the experiment, carbon dioxide produced by sodium bicarbonate ensures complete exhausting of air from an erlenmeyer flask, and carbon dioxide constantly produced during the reaction protects the solution and prevents the entry of external air, so as to ensure sufficient reduction of the solution while preventing the interference from oxygen in the air. The above points show that the experiment method saves time, and can eliminate the influence of metal impurities and other weak-acid or weak-base salt solutions; the end point mutation is obvious during solution titration, so as to measure more accurate nitric acid content.

Owner:AECC AVIATION POWER CO LTD

Construction method of human retinal pigment epithelial cell bank

InactiveCN106801039AEasy stepsHigh purityCell dissociation methodsMicrobiological testing/measurementRetinal pigment epithelial cellCell preparation

The invention relates to a construction method of a human retinal pigment epithelial cell bank. The method comprises the steps of collecting eyeballs of a donor; separating and obtaining human retinal pigment epithelial cells; carrying out serial subcultivation; carrying out quality detection of the human retinal pigment epithelial cells; carrying out cryopreservation; and constructing the bank. The cryopreserved human retinal pigment epithelial cells revive for clinical injection in use. The method is simple in step and operation; the obtained, cultured and cryopreserved human retinal pigment epithelial cells are high in purity, high in multiplication capacity and high in recovery efficiency; construction of the cell bank is based on HLA matching; the cells subjected to quality detection and HLA matching can be directly applied to clinical injection after reviving; the problems of production, storage and transportation of a cell preparation are solved; and when a patient needs to adopt the human retinal pigment epithelial cells for transporting, the clinically applicable human retinal pigment epithelial cells subjected to HLA matching can be directly provided.

Owner:JIANGSU PROVINCE HOSPITAL +1

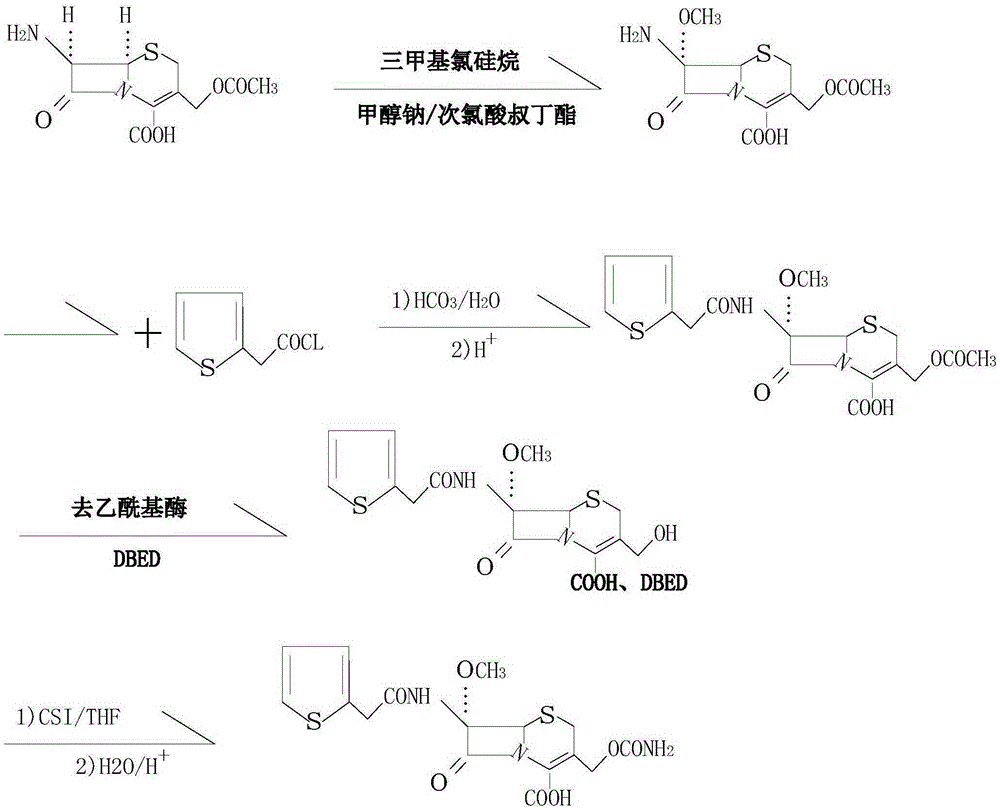

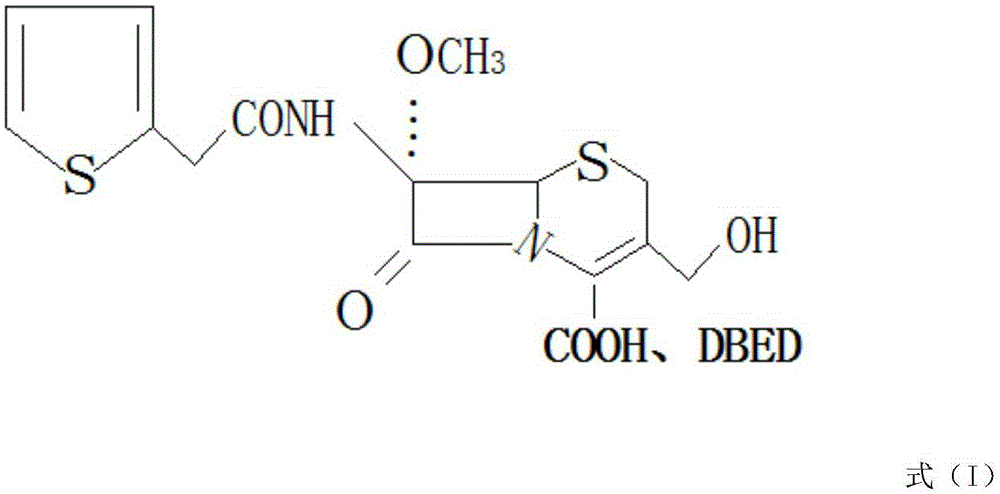

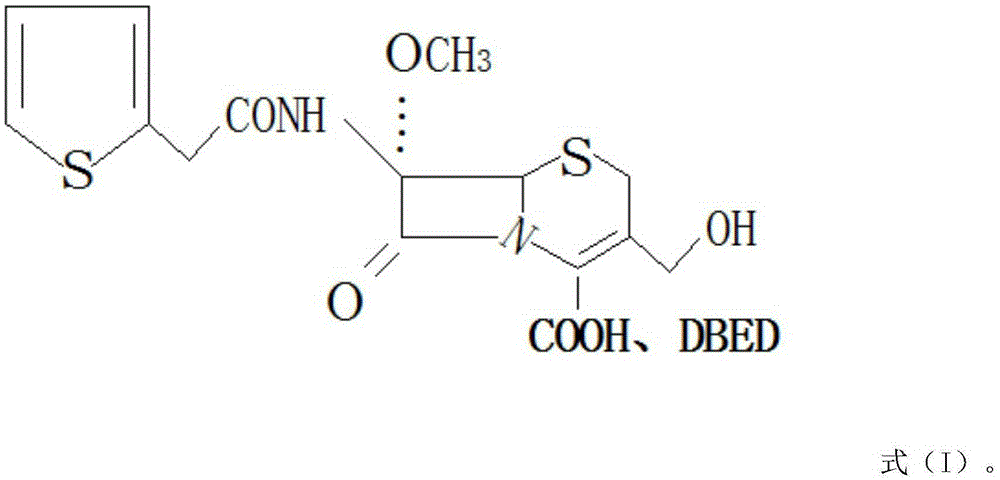

Method for synthesizing cefoxitin acid

InactiveCN105385746AThe synthesis process is simpleEasy stepsOrganic chemistryFermentationMethoxideAcylation

The invention discloses a method for synthesizing cefoxitin acid. 7-aminocephalosporanic acid is adopted as a raw material and reacts with sodium methylate under protection of a protection agent, methoxy is introduced into the seventh bit of 7-aminocephalosporanic acid, and methoxide complex is obtained; after the reaction is finished, 2-thiophene acetyl chemical reagent is dropwise added for reacting, then solidifying enzyme is added to obtained wet feed in an alkaline solution for hydrolysis, and after hydrolysis is completed, solidifying enzyme is filtered out; after the reaction is finished, a benzathine diacetate water solution is dropwise added to reaction liquid, crystals are separated out, and a compound I is obtained; the compound I and an ammonia methoxyl acylation reagent act, a carbamyl methoxyl group is introduced to the third bit of the compound I, and cefoxitin acid is obtained. The synthesis process is simple, the steps are easy and convenient, implementation is easy, the yield is effectively increased, production cost is reduced, the production steps are reduced, the obtained product is high in purity, the impurity content is low, the color gradation is good, product quality is effectively improved, drug use safety is improved, and the method is suitable for mass production.

Owner:四川清山绿水医药化工股份有限公司

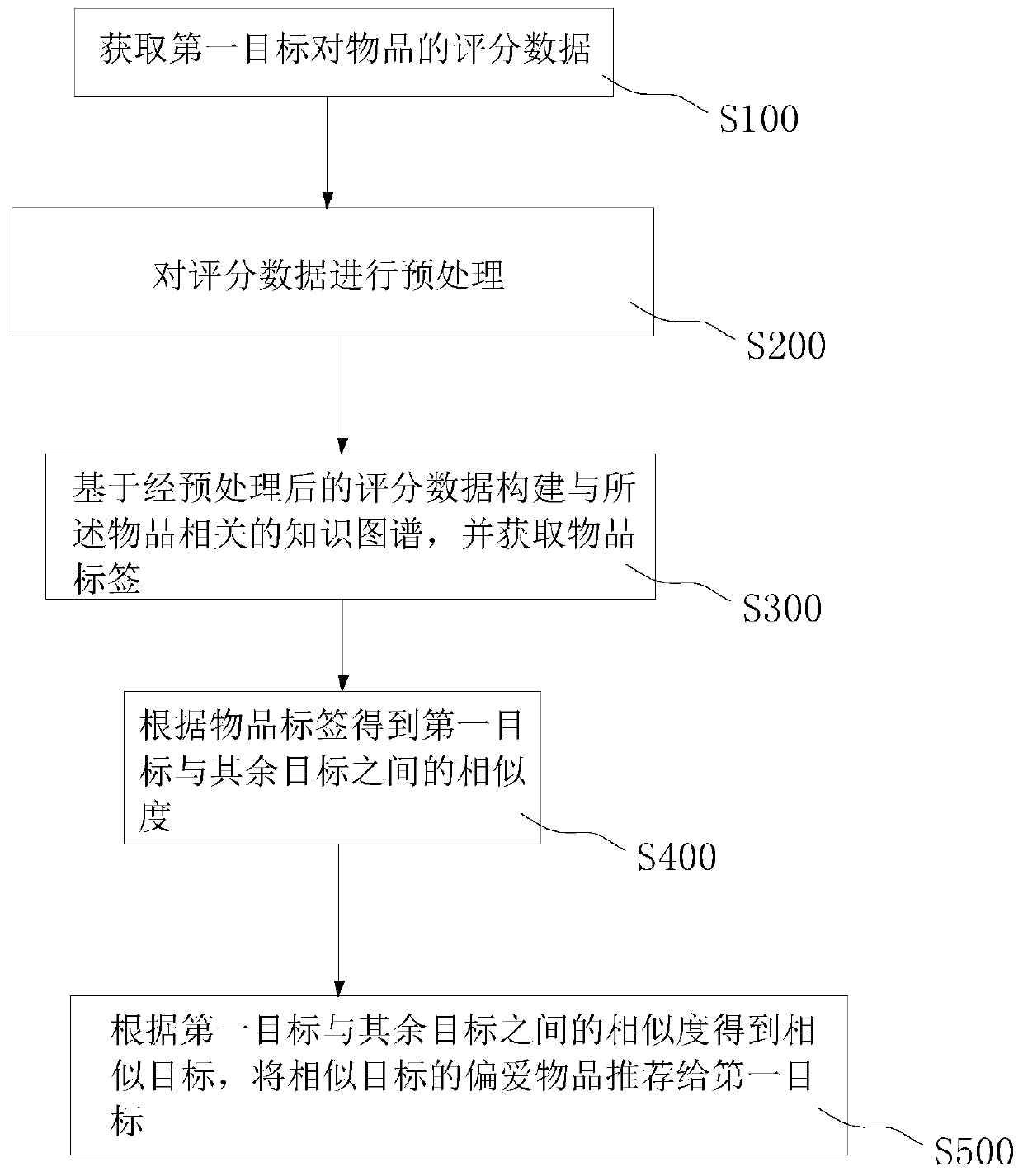

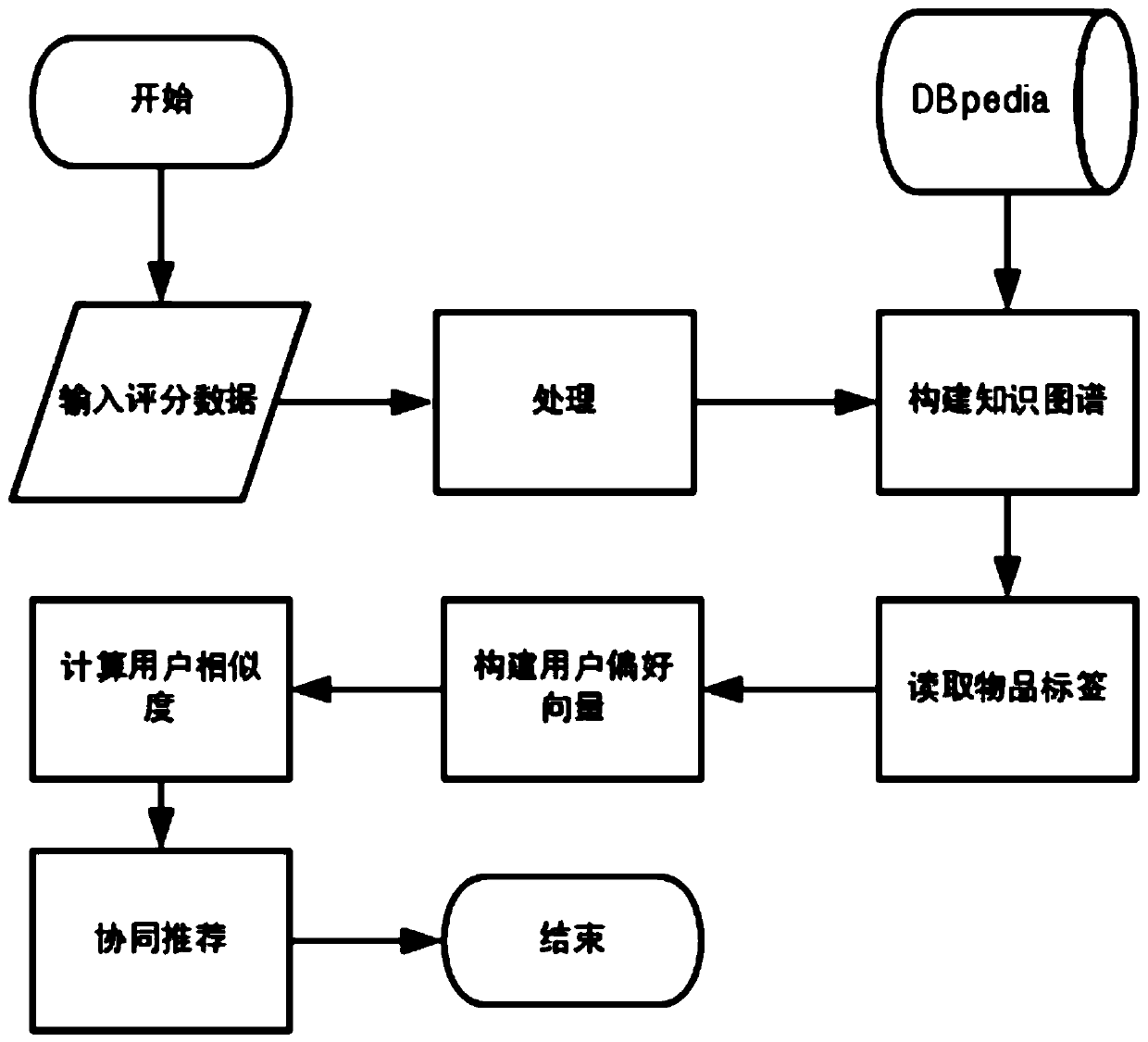

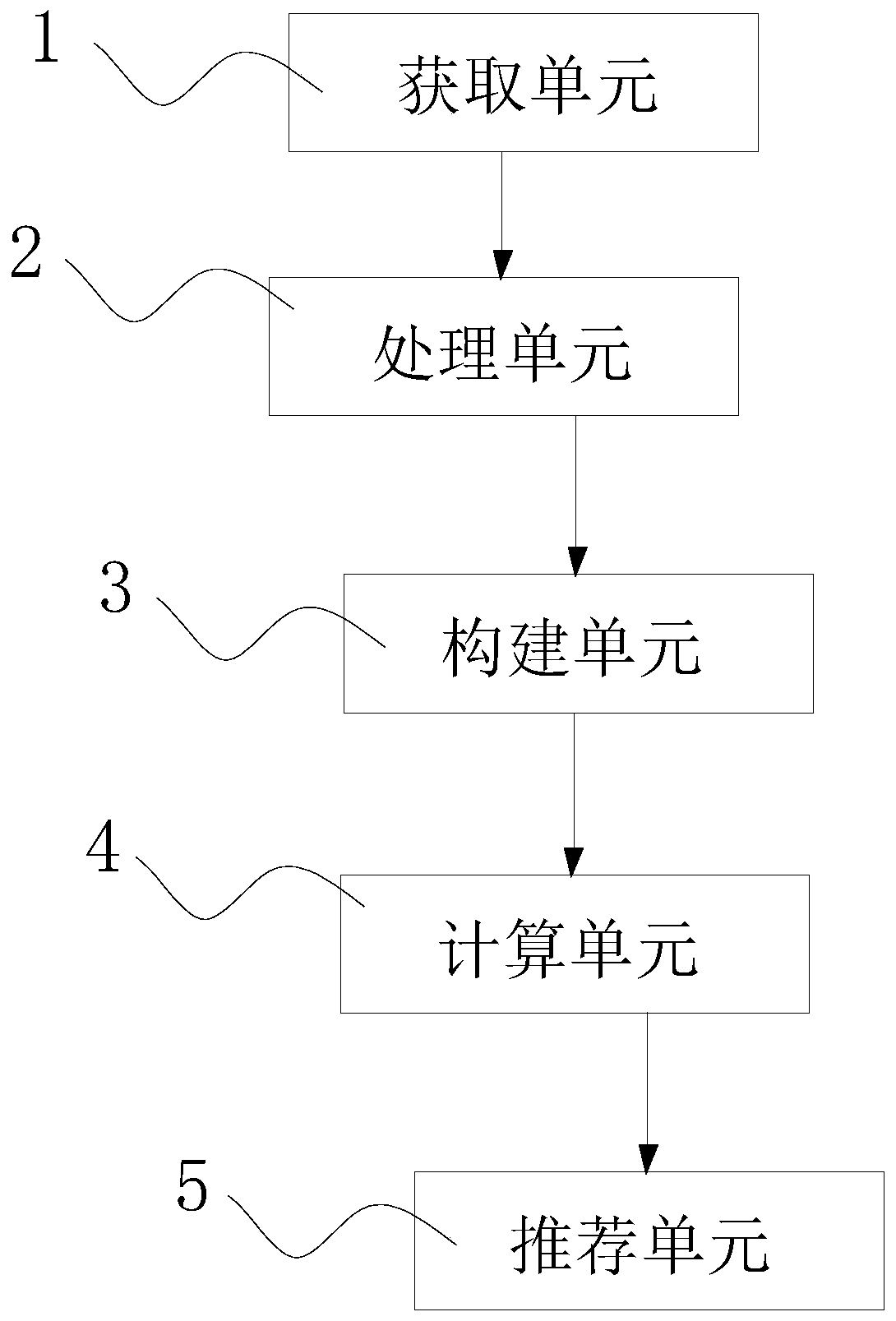

Knowledge graph-based collaborative recommendation method, apparatus and device, and storage medium

PendingCN110472155AEasy stepsReasonable designDigital data information retrievalBuying/selling/leasing transactionsAnnotationData mining

The invention discloses a knowledge graph-based collaborative recommendation method, apparatus and device, and a storage medium, and the method comprises the following steps: obtaining score data of afirst target for an article; preprocessing the scoring data; constructing a knowledge graph related to the article based on the preprocessed scoring data, and obtaining an article label; obtaining the similarity between the first target and other targets according to the article label; and obtaining a similar target according to the similarity between the first target and other targets, and recommending preferred articles of the similar target to the first target. Compared with the prior art, the invention has the advantages that the steps are simple and convenient, the design is reasonable,expert annotation is not needed while the cold start problem is solved, the labor and time cost is greatly reduced, and favorite articles can be recommended to users according to the interests of theusers.

Owner:WUYI UNIV

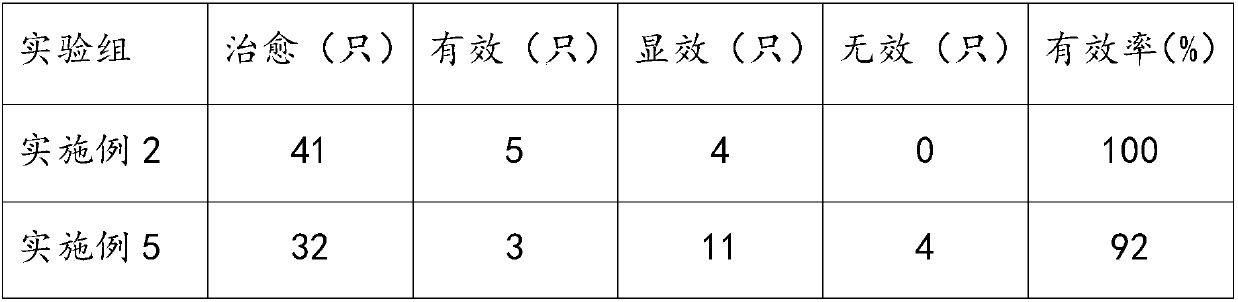

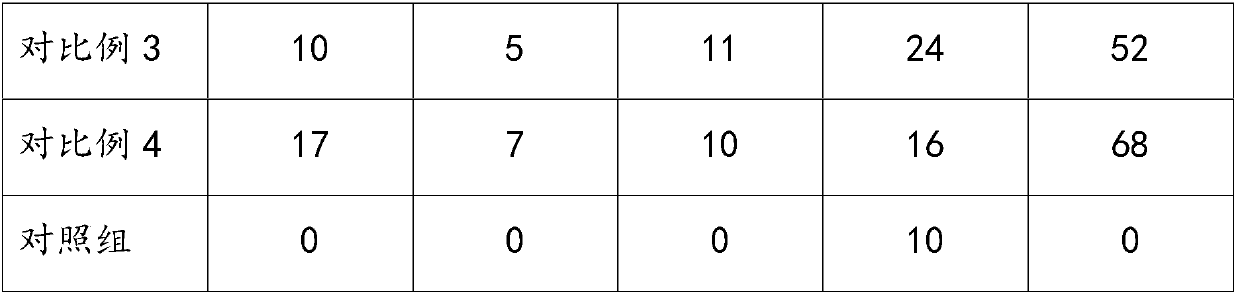

Externally-used ointment for treating skin diseases of pets and preparation method thereof

InactiveCN107648308AEffective treatmentHigh bactericidal activityOrganic active ingredientsAntimycoticsDiseaseMedicine

The invention provides an externally-used ointment for treating skin diseases of pets and a preparation method thereof. The externally-used ointment for treating the skin diseases of the pets comprises ketoconazole, metronidazole, peppermint oil, Solidago decurrens extract and auxiliary materials as raw material components, and through the compounding action among the components, a good pet skin disease treatment effect can be achieved. Meanwhile, the preparation method has the advantages of simple process steps and simple operation and is suitable for industrialized scale production.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

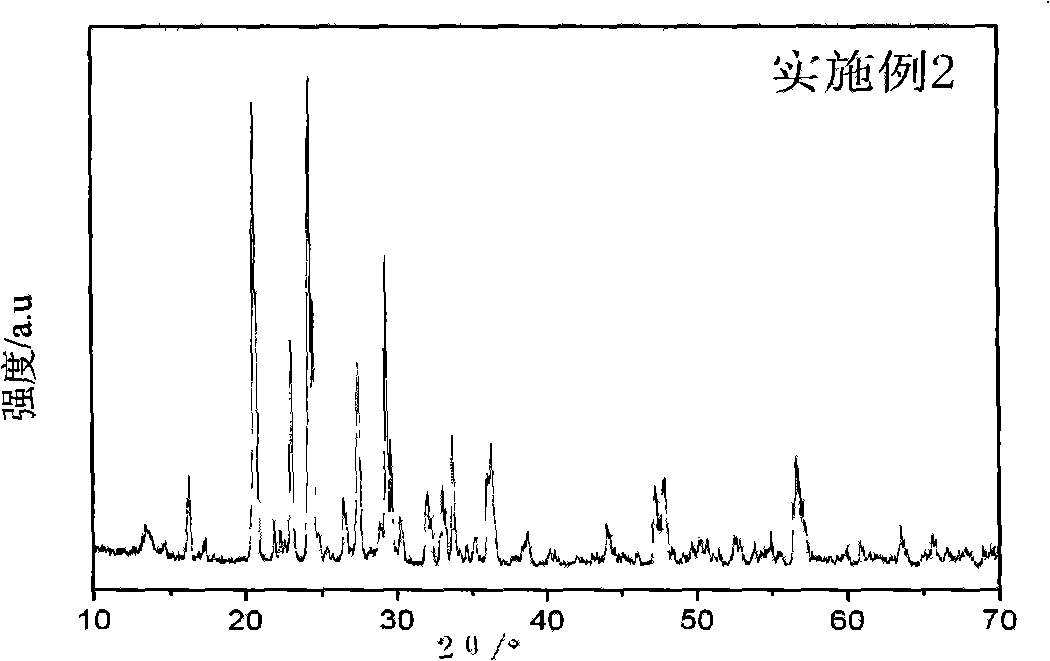

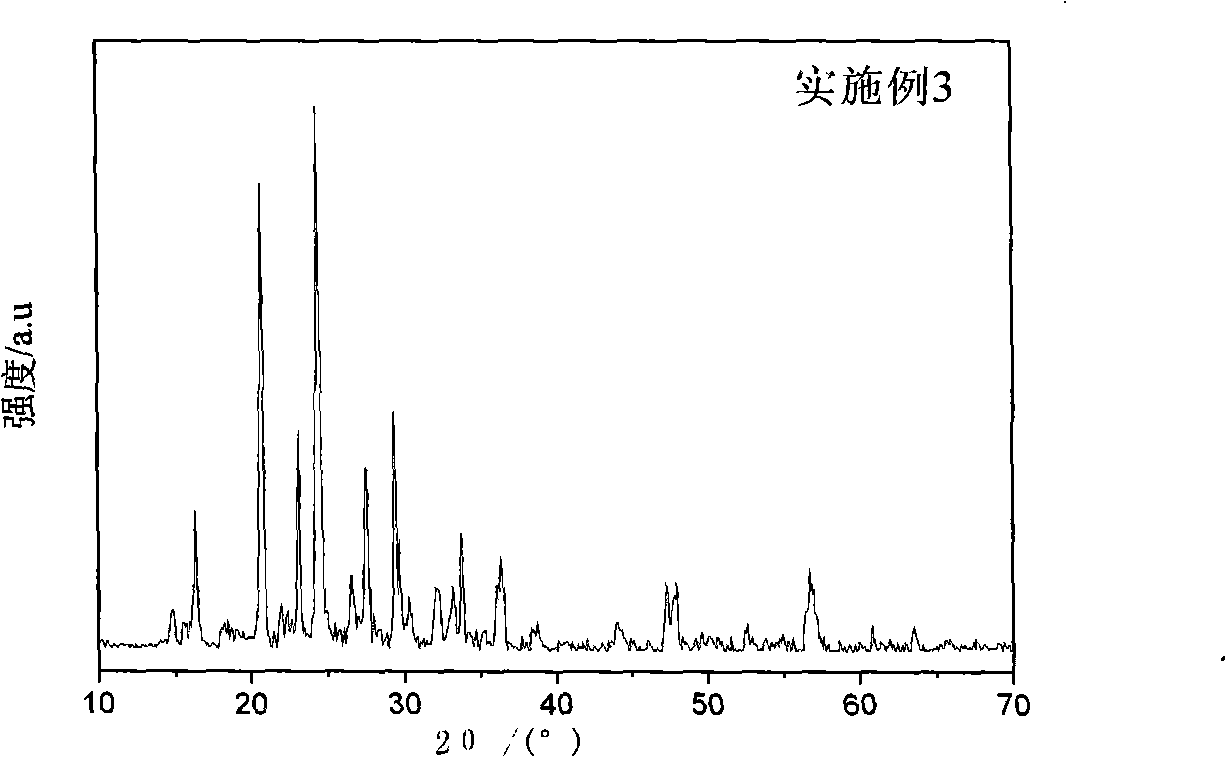

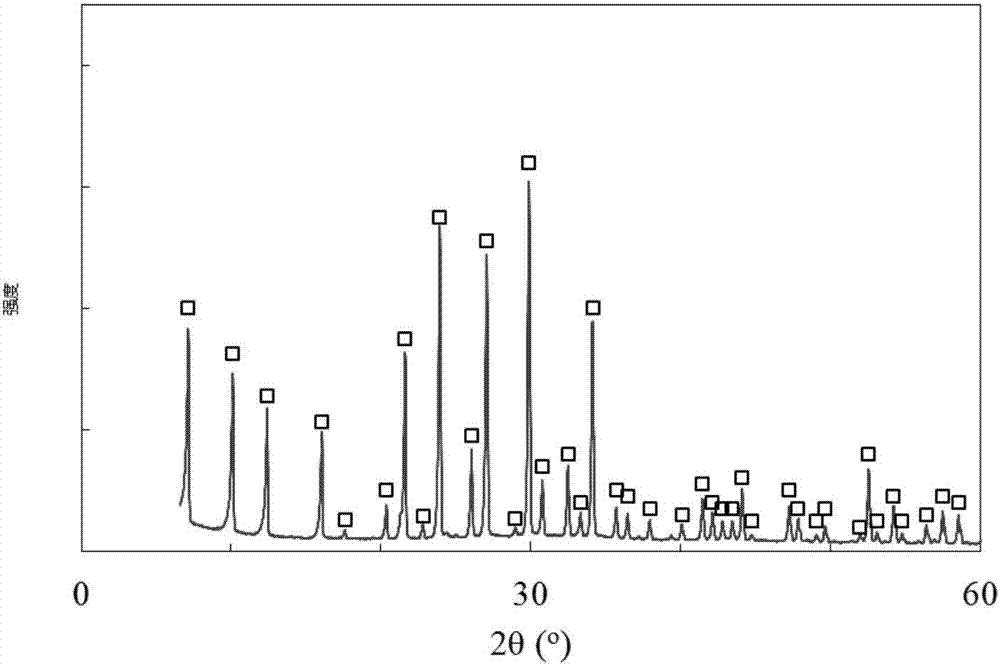

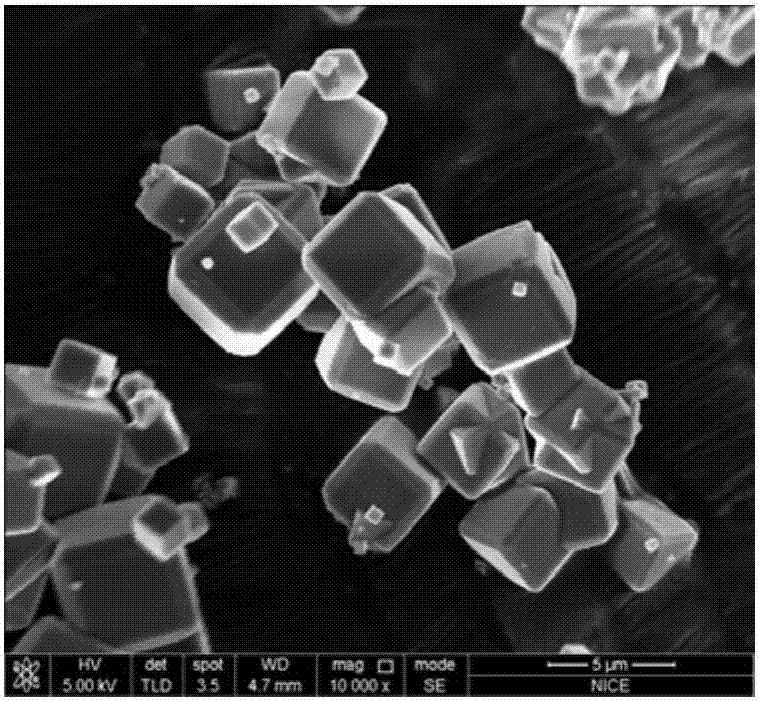

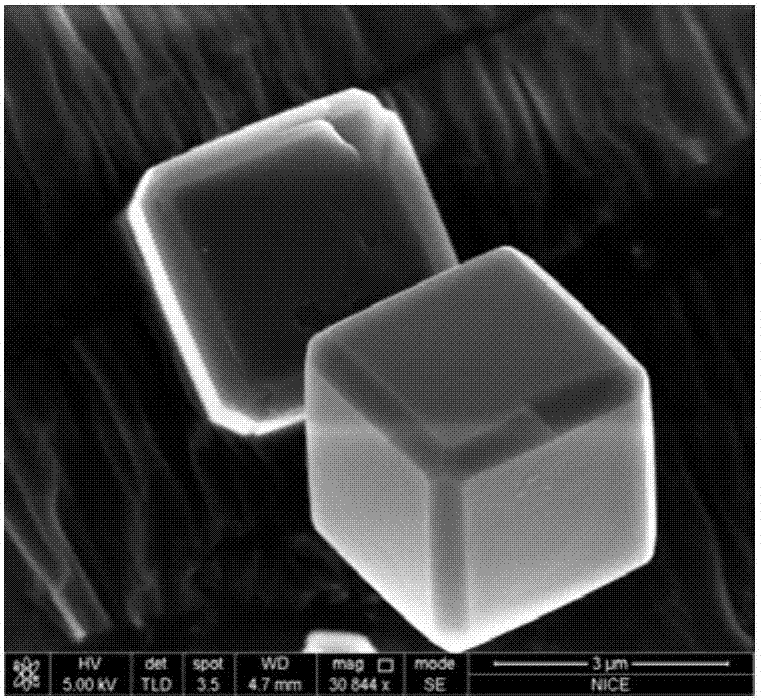

4A type molecular sieve and preparation method thereof

The invention relates to the field of coal resource utilization and discloses a 4A type molecular sieve and a preparation method thereof. The method comprises the following steps: (1) performing reaction on coal ash under the acidic condition to obtain a mixture; (2) filtering the mixture to obtain filter residue and AlCl3 mother liquid separately; (3) performing reaction on the filter residue under the alkaline condition to obtain Na2SiO3 mother liquid; and (4) performing mixing reaction and crystallization on the AlCl3 mother liquid and the Na2SiO3 mother liquid sequentially. By the method provided by the invention, the 4A type molecular sieve with high purity and crystallization degree can be prepared by treating the coal ash with high price and huge yield by an acid dissolution method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

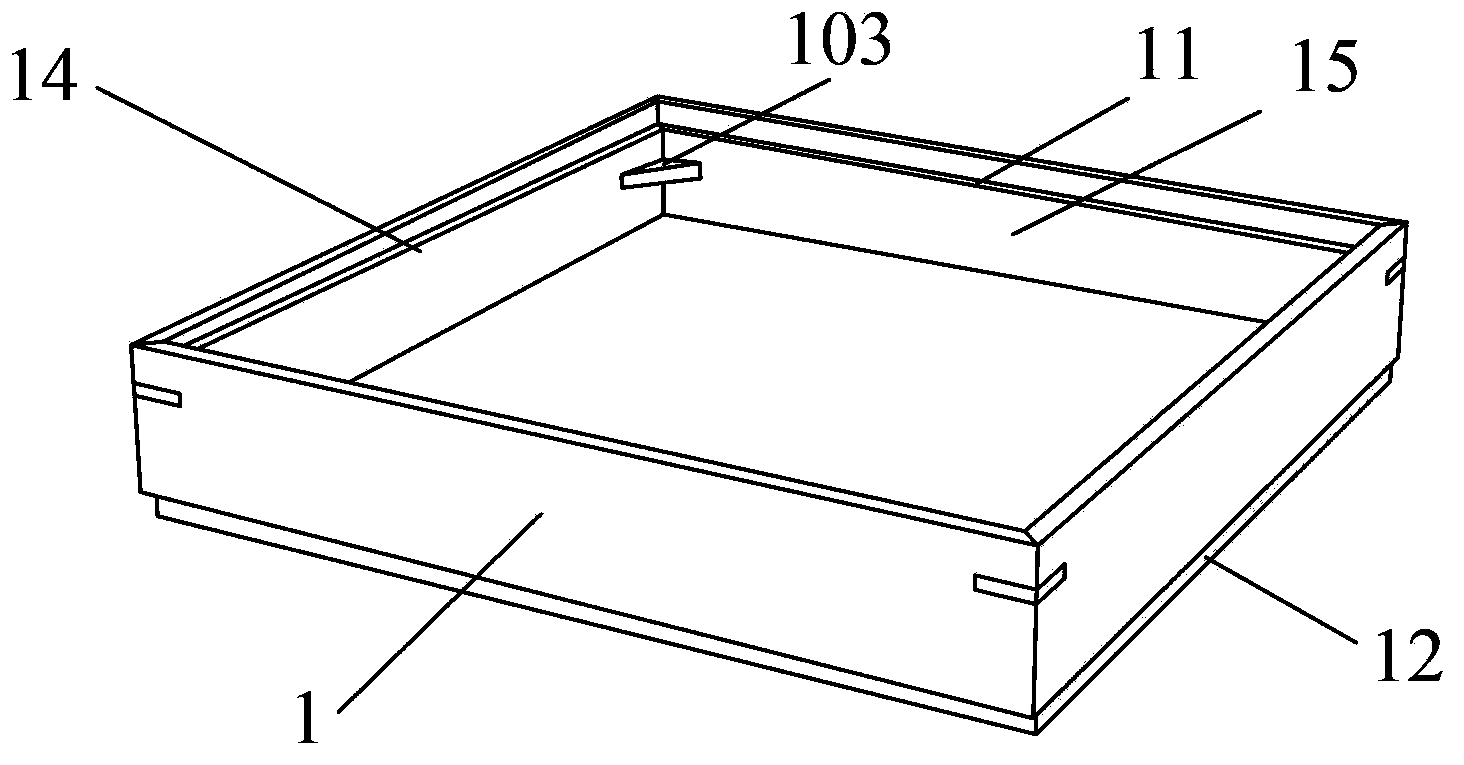

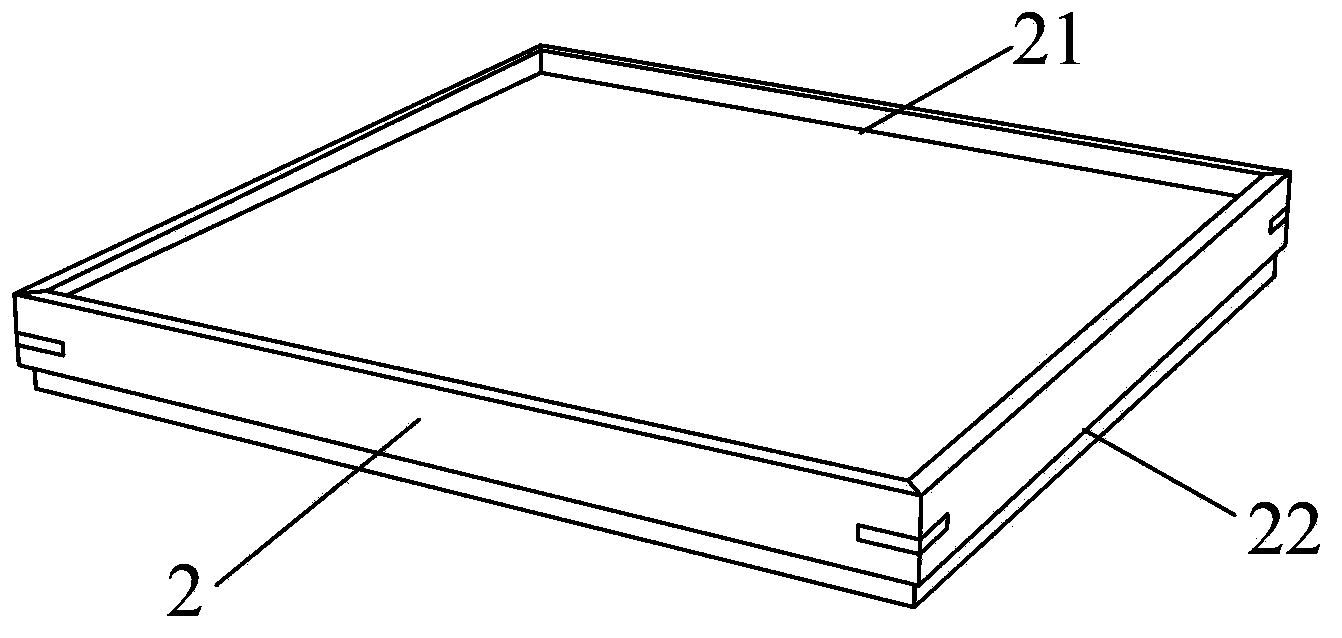

Square storage box

InactiveCN103662263ABig spaceEasy stepsRigid containersInternal fittingsEngineeringStructural engineering

The invention discloses a square storage box. The square storage box comprises a square box body (1) which is provided with a bottom and free of a top and a square storage box cover (2) which is provided with a top and free of a bottom; a square-annular-shaped inner opening I (11) are formed at the top of the peripheral lateral wall; a square-annular-shaped projection portion II (22) is arranged on the outer surface at the bottom of the square storage box cover (2); the square-annular-shaped projection portion II (22) is clamped into the square-annular-shaped inner opening I (11).

Owner:HANGZHOU PUSHINE & TT COTTAGE CULTURE & ART

Crab culture method

InactiveCN107821261ASimple stepsEasy stepsClimate change adaptationPisciculture and aquariaDiseaseWater quality

The invention relates to a crab culture method, comprising the following steps: step S1, fertilizing pond water quality; step S2, enhancing aquatic plant management; step S3, scientifically feeding food; step S4, intensifying disease prevention and control, in afternoon, splashing vitamin C in a whole pond. Beneficial effects are that the invention provides the crab culture method, the steps of the method is simple and practicable, diseases and insect pests of crabs are few, and the method can effectively improve survival rate of crabs, and meat quality of adult crabs is improved.

Owner:桂林市安琪玫瑰农业发展有限公司

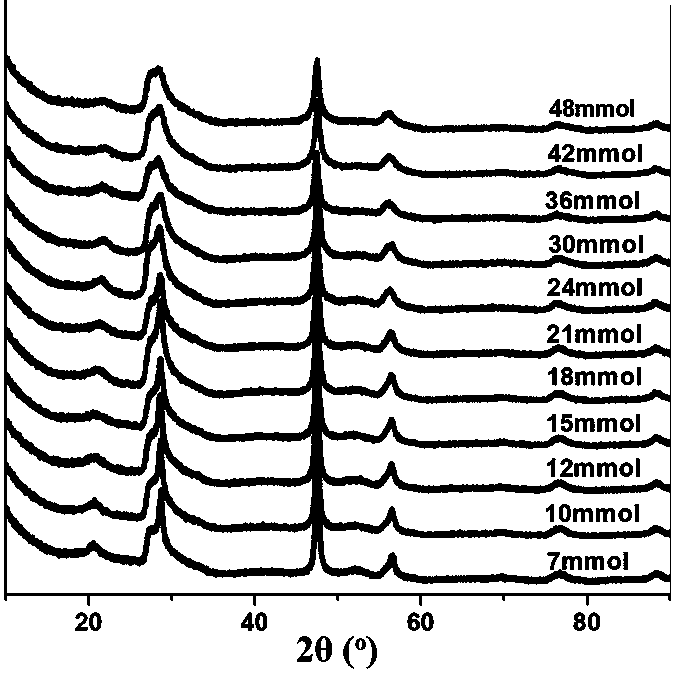

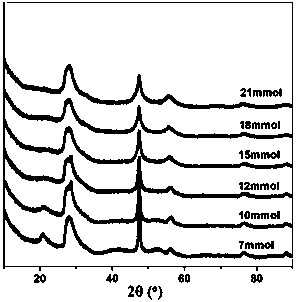

Preparation method of MoP-Zn3In2S6 composite nano material

ActiveCN109821562AEasy stepsMild reaction conditionsHydrogenPhysical/chemical process catalystsNon noble metalElectron hole

The invention discloses a preparation method of a MoP-Zn3In2S6 composite nano material. The method comprises the following steps of: synthesizing a monomer Zn3In2S6 with high activity by optimizing preparation conditions of Zn3In2S6, and then constructing a non-noble metal visible light response nano composite material MoP-Zn3In2S6 to further improve the photo-induced electron-hole separation efficiency, wherein the non-noble metal visible light response nano composite material MoP-Zn3In2S6 is constructed by uniformly loading noncrystalline amorphous MoP on the surface of a three-dimensional spherical Zn3In2S6 hierarchical structure assembled by two-dimensional nano sheets.The preparation method has the advantages of simple and convenient steps, mild reaction conditions and high yield; thepreparation conditions of the Zn3In2S6 are optimized, and the stability and the photo-induced electron-hole separation efficiency of the Zn3In2S6 are improved by uniformly loading a non-noble metal MoPcocatalyst. The high stability of noncrystallineMoP not only can effectively protect aprimary catalyst Zn3In2S6, but also can realize the effective photo-induced electron-hole separation of Zn3In2S6,and obviously improves the photocatalytic performance of the Zn3In2S6.

Owner:江西新节氢能源科技有限公司

Preparation method of titanium boride powder

The invention belongs to the field of titanium material preparation, and particularly relates to a preparation method of titanium boride powder. The technical problem to be solved are complicated steps, low production efficiency and high cost of a titanium boride powder preparation method in the prior art. The technical scheme of the invention is to provide a method for preparing the titanium boride powder, comprising the following steps: by using TiCl4 and BCl3 as raw materials, magnesium metal as a reducing agent, and magnesium chloride as a reaction medium, introducing a gaseous mixture ofTiCl4 and BCl3 into molten salt formed by heating a mixture of magnesium metal and magnesium chloride, and performing one-step synthesis by a magnesium thermal reduction method to prepare the TiB2 powder. The method has the advantages of simple steps, low equipment requirements, no use of high-cost raw materials such as titanium powder and boron powder, and capability of significantly reduing theproduction cost. Moreover, a product obtained by the method is high in purity, less in impurity residual and proper in particle size, and has good application prospect.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

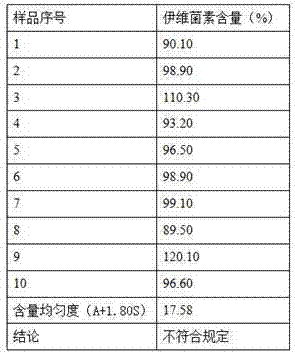

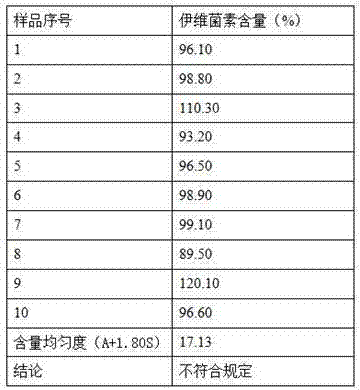

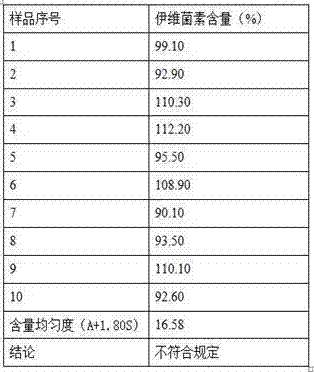

Albendazole and ivermectin premixing agent and preparation method thereof

ActiveCN107349212ALittle side effectsEasy stepsPowder deliveryOrganic active ingredientsChemistrySide effect

The invention discloses an albendazole and ivermectin premixing agent and a preparation method thereof. The premixing agent comprises the following components, by mass, of 5.5-6.5% of albendazole, 0.22-0.26% of ivermectin, 10-15% of medicinal carbon, 5-10% of corncob powder, 4.5-5.5% of yasumiya and tocolytic plant extracting essence and the balance starch. In preparation, the yasumiya and tocolytic plant extracting essence is added in a formula so that the side effect of the albendazole can be reduced. An equidensity and equivalent progressively-increasing mixing method is adopted for preparation so that effective guarantee can be provided for safe using of the premixing agent. The prepared albendazole and ivermectin premixing agent is small in effective component content deviation, small in side effect and capable of being used for pregnant domestic animals; the preparation step is simple and convenient and easy to operate; and the measured A+1.80S average value of the content uniformity of the ivermectin is smaller than 10.0 (according to the national standard, the A+1.80S average value is smaller than 15.0).

Owner:GUANGDONG WENS DAHUANONG BIOTECH

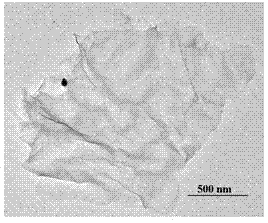

Graphene concentrated solution and preparation method therefor

The invention relates to a graphene concentrated solution and a preparation method therefor. Firstly, water-soluble titanate is dissolved in water; then, graphene is added, a graphene dispersion solution is subjected to ultrasonic treatment in a magnetic field, and thus water-soluble titanate can be used for carrying out full surface modification on graphene in the water so as to achieve the effect of full dispersion for graphene; and finally, the graphene dispersion solution is subjected to distillation or reduced-pressure distillation in an externally-applied magnetic field, thereby preparing the graphene concentrated solution. The graphene concentrated solution is low in moisture content and high in graphene content, so that performance degradation caused by the fact that excess moisture is introduced during use is avoided; the number of active groups of the surface of graphene is increased due to modification by water-soluble titanate, so that the bonding force of graphene to other materials is increased; and modified graphene are not subjected to an agglomeration phenomenon, so that fully-stripped graphene can better exert the properties such as high strength, electrical conductivity, thermal conductivity and the like of graphene. By the method disclosed by the invention, the dispersity of graphene and the performance of products can be further improved.

Owner:ZHEJIANG TAISUO TECH

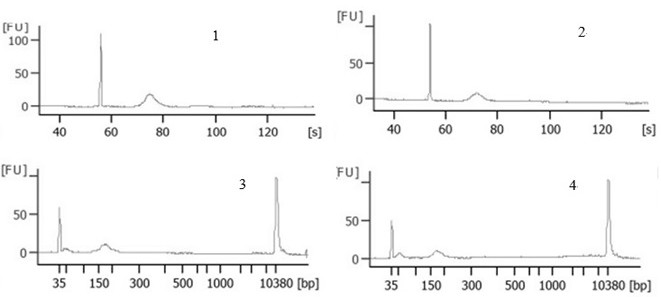

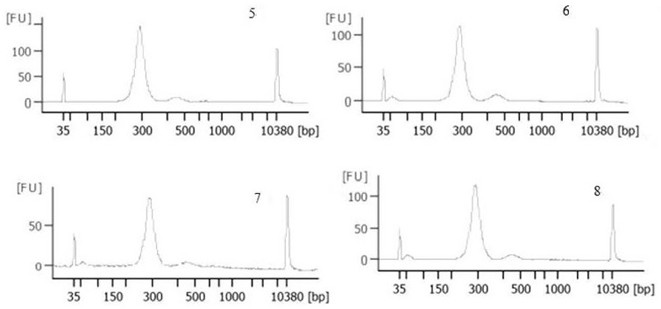

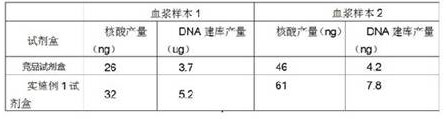

Kit for rapidly extracting free nucleic acid in plasma based on paramagnetic particle method

ActiveCN114058616AEasy to operateEasy stepsMicrobiological testing/measurementDNA preparationActive agentEthylenediaminetetraacetic acid

The invention discloses a kit for rapidly extracting free nucleic acid from plasma based on a paramagnetic particle method. The kit comprises a lysate, a deproteinization rinsing solution, a desalting rinsing solution, an eluent and magnetic beads, wherein the lysate contains a chaotropic agent with a concentration of 2 to 6 M, 0.05 to 10% of lauryl sodium sulfate, ethylenediamine tetraacetic acid with a concentration of 50 to 200 mM, trihydroxymethyl aminomethane with a concentration of 10 to 200 mM, sodium chloride with a concentration of 50 to 500 mM, 0.1 to 5% of sodium dodecyl benzene sulfonate, 1 to 5% of sodium laureth sulfate and 5 to 15% of a nonionic surfactant. According to the method, unique lysate components and the magnetic beads are adopted, protease K does not need to be added, nucleic acid yield can be effectively increased, and therefore, the yield of downstream NGS library building is increased.

Owner:GENFINE BIOTECH BEIJING CO LTD

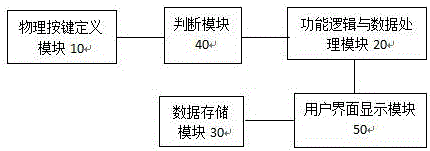

Method and device for simulating touch screen to start application function through physical key

InactiveCN105867770ASimple stepsEasy stepsInput/output processes for data processingUser needsData processing

The present invention provides an electronic device for activating application functions by simulating a touch screen with a physical button, which includes a physical button definition module, a function logic and data processing module, and a data storage module. Initiate, the physical button definition module responds, and at the same time, the function logic and data processing module needs to confirm the customization by the user again long press after completing the matching of the physical button and the specific application function, thereby completing the physical button function customization. Thus, the user can conveniently and quickly match commonly used applications to the physical buttons according to their own needs, so that when the user needs to start the application, he only needs to press the physical button to quickly open the matched application function , to provide users with a better experience.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

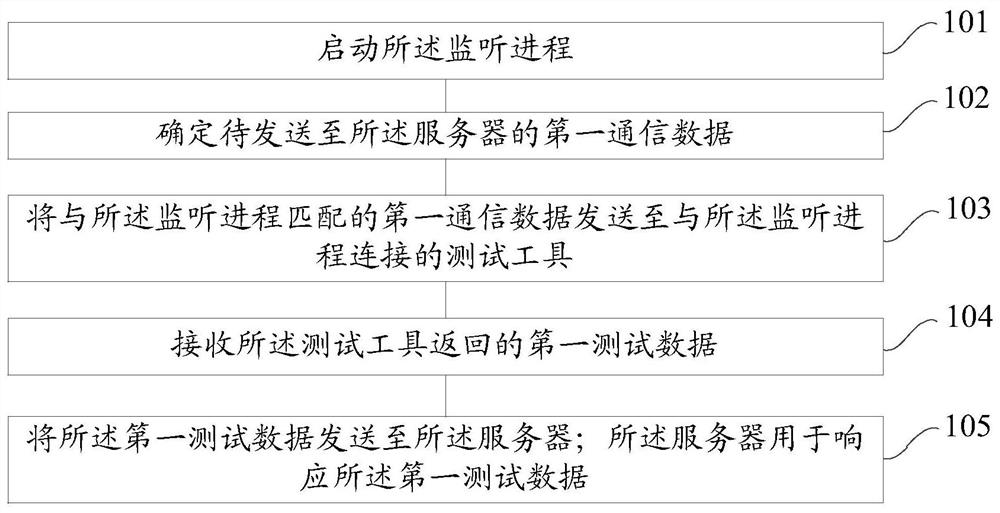

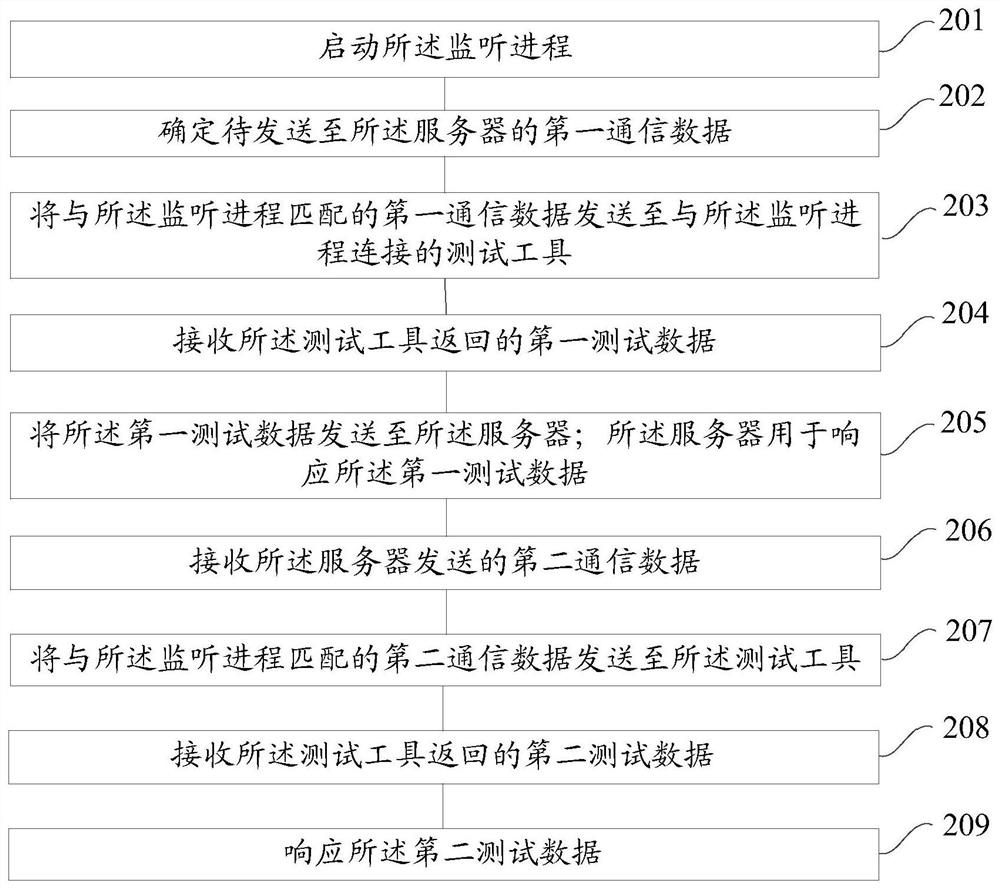

A test method, device, electronic equipment and storage medium

The embodiment of the present invention provides a test method, device, electronic equipment and storage medium, the method is applied to a client, the client is provided with a monitoring process, and the client is connected to a preset server; the method Including: starting the monitoring process; determining the first communication data to be sent to the server; sending the first communication data matching the monitoring process to a test tool connected to the monitoring process; receiving the testing tool return the first test data; send the first test data to the server; the server is used to respond to the first test data. The embodiment of the present invention can test the function and stability of the server, effectively prevent the hidden danger of communication data being leaked and tampered with due to the leakage of the test tool, and increase the stability of the software system composed of the client and the server and security.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

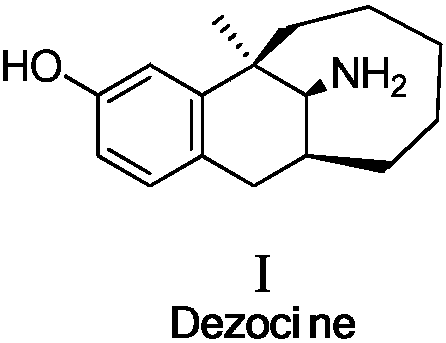

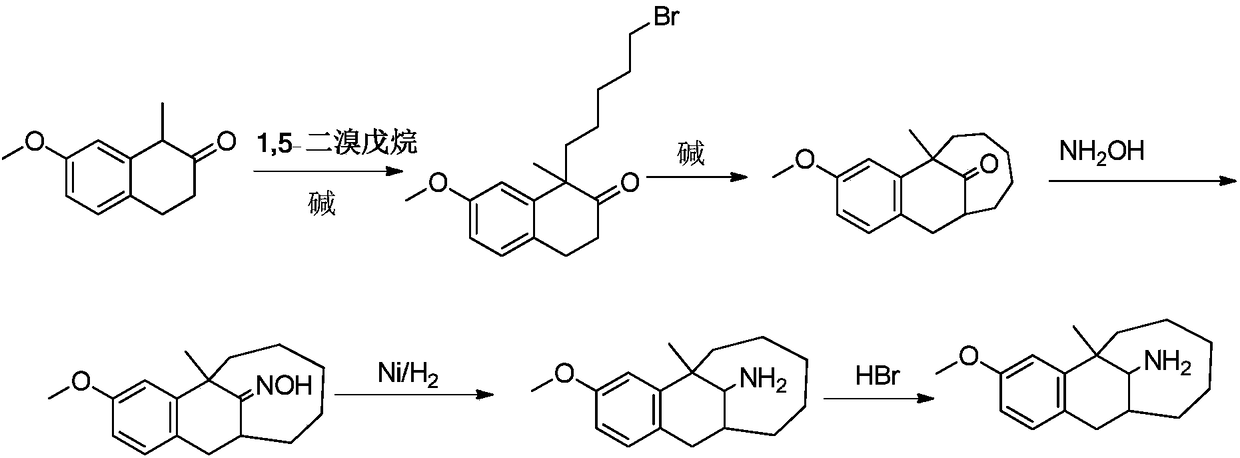

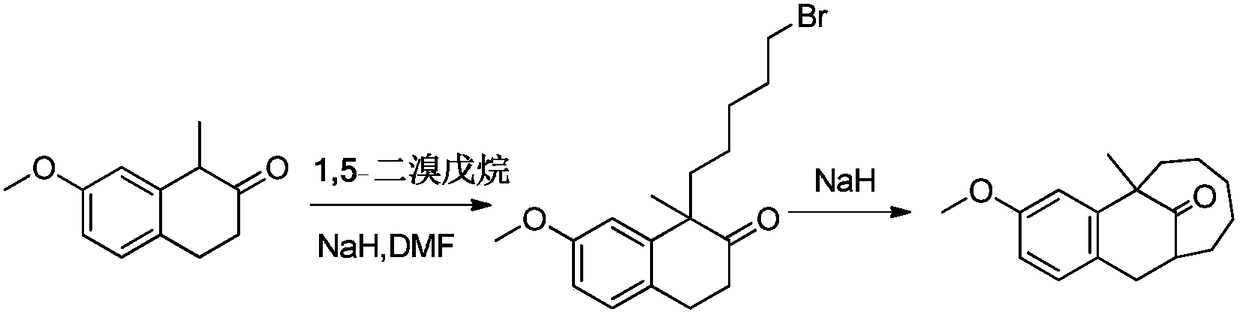

Asymmetric synthesis method of dezocine key intermediate

ActiveCN108299173AEasy stepsHigh yieldOrganic compound preparationCarbonyl compound preparationAlkyl transferEnantioselective synthesis

The invention discloses an asymmetric synthesis method of a dezocine key intermediate, namely, (5R,11S)-5,6,7,8,9,10,11,12-octahydro-3-methoxy-5-methyl-5,11-methylenebenzocyclodecene-13-one. The synthesis method comprises the steps as follows: 7-methoxy-1-methyl-2-tetralone is adopted as a raw material, and an alkylation reaction intermediate, namely, (1R)-1-(5-bormopentyl)-7-methoxy-1-methyl-tetralone, is synthesized in a stereoselective manner under the catalysis of a cinchonidine derivative; ring formation under the alkaline action is performed, and (5R,11S)-5,6,7,8,9,10,11,12-octahydro-3-methoxy-5-methyl-5,11-methylenebenzocycldecene-13-one with high chiral purity is obtained through recrystallization. The method is high in reaction yield, low in cost, mild in condition and suitable for efficient synthesis of dezocine on a large scale.

Owner:YANGTZE RIVER PHARM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com