Method using ion exchange solvothermal method for preparation of titanate nano powder

A technology of nano-powder and solvothermal method, which is applied in the production of chemical instruments and methods, titanium compounds, and bulk chemicals. Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

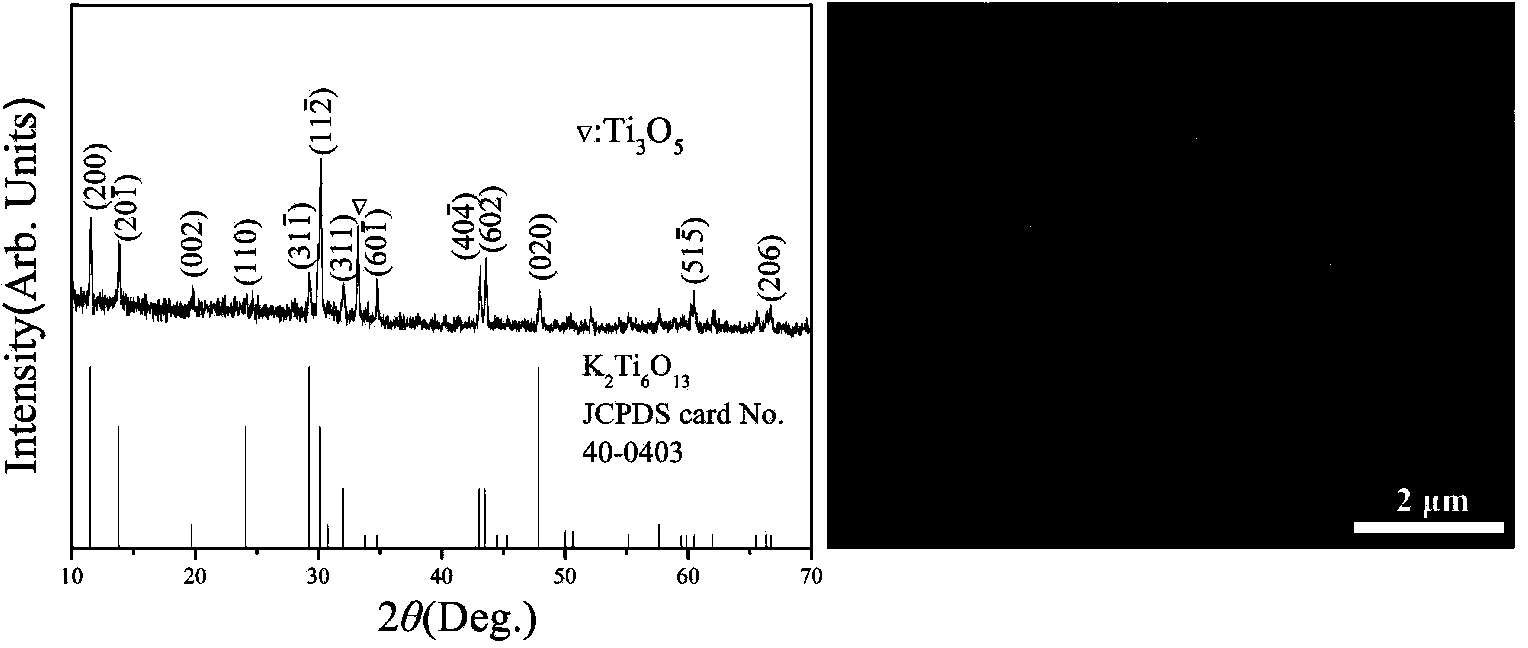

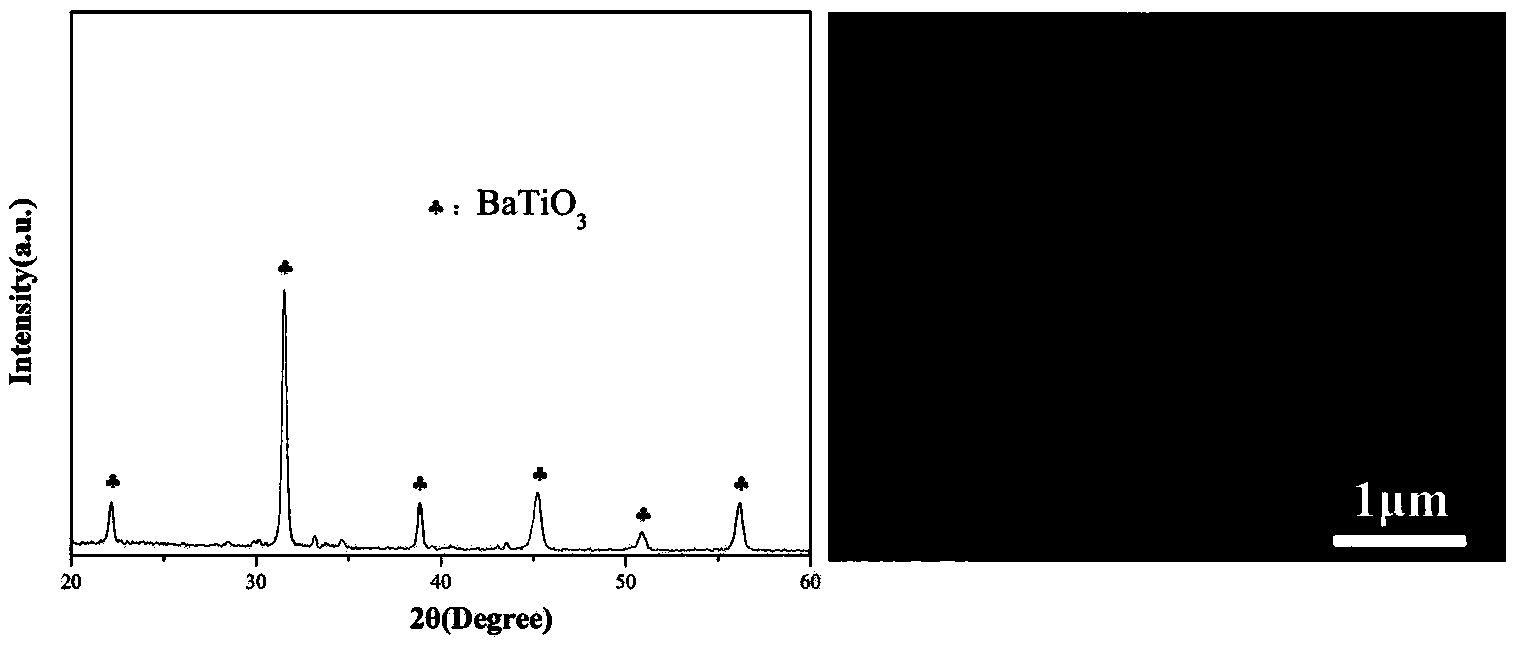

[0025] This embodiment provides a kind of nano functional material, the precursor of synthesis is K 2 Ti 6 o 13 Nano whiskers, the resulting final product has the molecular formula BaTiO 3 , the preparation method comprises the following steps:

[0026] Step 1: According to TiO 2 / K 2 Weigh K in proportion to O=3 2 CO 3 and TiO 2 , carry out ball milling or add alcohol magnetic stirring for a period of time, and then dry; place the dried mixture in a muffle furnace, rapidly raise the temperature to 1150°C at a heating rate of 10°C / min, keep it warm for 1h for calcination, and quickly from Take it out of the muffle furnace for rapid cooling;

[0027] Step 2: Extract the product obtained in Step 1 in boiling water for 2 hours to remove residual K 2 O and other residues, the obtained powder was dried at 60°C for 24 hours to obtain K 2 Ti 6 o 13 nano whiskers;

[0028] Step 3: Configure 0.2M Ba(OH) 2 solution, and the K obtained in step two 2 Ti 6 o 13 Precursors ...

Embodiment 2

[0031] Step 1: According to TiO 2 / K 2 Weigh K in proportion to O=3 2 CO 3 and TiO 2 , carry out ball milling or add alcohol magnetic stirring for a period of time, and then dry; place the dried mixture in a muffle furnace, rapidly raise the temperature to 860°C at a heating rate of 10°C / min, keep it warm for 1h for calcination, and reach the holding time Later, quickly removed from the muffle furnace and rapidly cooled;

[0032] Step 2: Extract the product obtained in Step 1 in boiling water for 2 hours to remove residual K 2 O and other residues. Dry the obtained powder at 60°C for 24 hours to obtain K 2 Ti 4 o 9 nano whiskers;

[0033] Step 3: Configure 0.8M Ba(OH) 2 solution, and the K obtained in step two 2 Ti 4 o 9 Precursors and configured Ba(OH) 2 Solution, stir evenly, and add a certain amount of organic solvents such as isopropanol, continue stirring for a period of time, and transfer to the polytetrafluoroethylene lining. The reaction temperature is 2...

Embodiment 3

[0036] Step 1: According to TiO 2 / K 2 Weigh K in proportion to O=3 2 CO 3 and TiO 2 , carry out ball milling or add alcohol magnetic stirring for a period of time, and then dry; place the dried mixture in a muffle furnace, rapidly raise the temperature to 860°C at a heating rate of 15°C / min, keep it warm for 1h and carry out calcination to reach the holding time Later, quickly removed from the muffle furnace and rapidly cooled;

[0037] Step 2: Extract the product obtained in Step 1 in boiling water for 2 hours to remove residual K 2 O and other residues. Dry the obtained powder at 60°C for 24 hours to obtain K 2 Ti 4 o 9 nano whiskers;

[0038] Step 3: Configure 0.8M Sr(OH) 2 solution, and the K obtained in step two 2 Ti 4 o 9 Precursors and configured Sr(OH) 2 Solution, stir evenly, and add a certain amount of organic solvents such as isopropanol, continue stirring for a period of time, and transfer to the polytetrafluoroethylene lining. The reaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com