Method for accurate measurement on nitric acid content of chemical corrosion solution for titanium alloy

A technology for chemical corrosion and nitric acid content, applied in the field of chemical analysis, can solve problems such as low nitric acid content determination accuracy, and achieve the effects of obvious changes in the titration end point, high method accuracy, and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

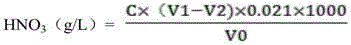

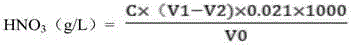

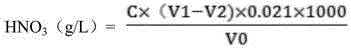

Image

Examples

Embodiment 1

[0030] In this embodiment, taking the titanium milling groove liquid as an example, the method for measuring nitric acid content therein adopts the following steps:

[0031] Step 1: Accurately draw 5.00mL of titanium alloy chemical corrosion solution with a polytetrafluoroethylene pipette, place it in a 500mL polytetrafluoroethylene volumetric flask pre-added with 400ml of distilled water, add distilled water to dilute to the mark, and shake the solution evenly . A uniformly mixed dilution of the titanium alloy chemical corrosion solution is obtained.

[0032] Step 2, use a polytetrafluoroethylene pipette to accurately draw 5.00mL of the above dilution, and place it in a 500mL Erlenmeyer flask. The dilution of the titanium alloy chemical etching solution divided into 500mL Erlenmeyer flasks was obtained.

[0033] Step 3, accurately add 25.00mL0.1mol / L ferrous sulfate standard solution to the 500mL Erlenmeyer flask from which the diluent of titanium alloy chemical corrosion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com