Method for preparing Li3V2(PO4)3/C composite anode material and anode material made by the same

A composite positive electrode material, NH4H2PO4 technology, applied in the direction of electrode manufacturing, battery electrodes, electrical components, etc., can solve the problems of small purity particle size, cumbersome steps, danger, etc., achieve good electrical conductivity, simple reaction conditions, and improve electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

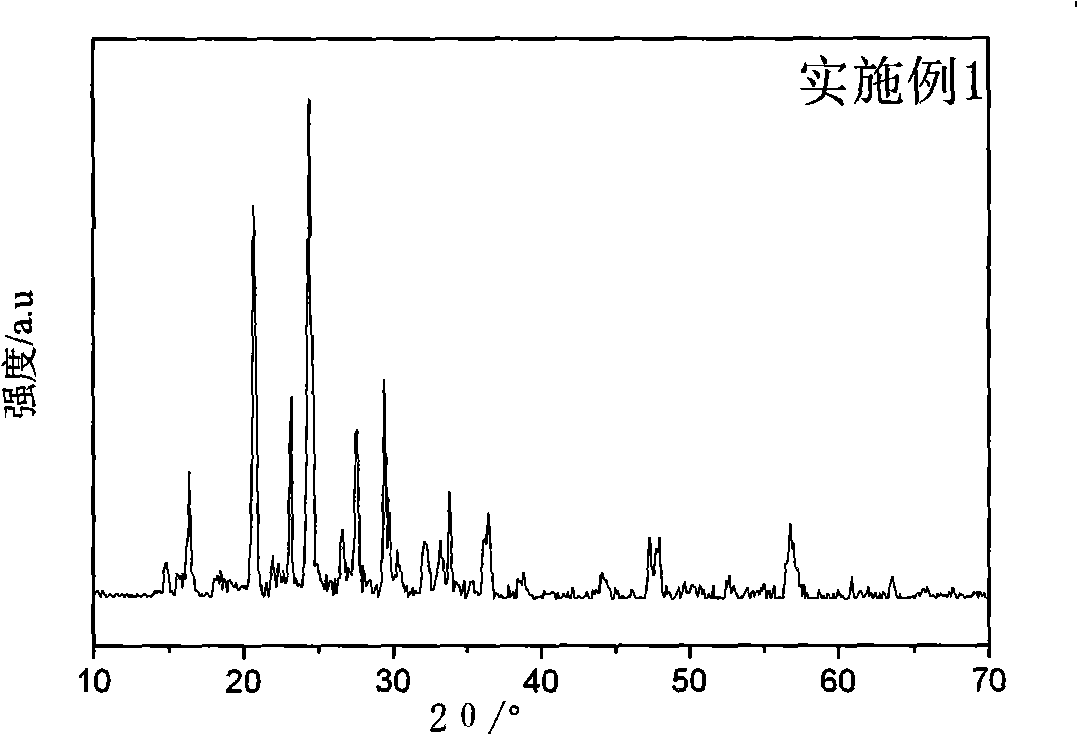

Embodiment 1

[0037] Weigh LiOH·H with the molar ratio of Li:V:P:citric acid=3:2:3:2 2 O, V 2 o 5 , NH4 h 2 PO 4 and citric acid, put it in a 500ml ball mill jar, use acetone as a dispersant, the ball mill speed is 400 rpm, and the ball mill time is 8h. After the completion, the mixture is sent into the muffle furnace for pretreatment at 300°C for 2 hours. Decompose the residual organic matter, cool naturally with the furnace, take out the sample and put it back into the ball mill jar for ball milling, the ball milling speed is 200 rpm, and the ball milling time is 5h. Then the sample was sent to a closed-type Ar protection atmosphere muffle furnace and roasted at 500 ° C for 6 hours, and cooled to room temperature with the furnace temperature to obtain Li 3 V 2 (PO 4 ) 3 / C composite cathode material.

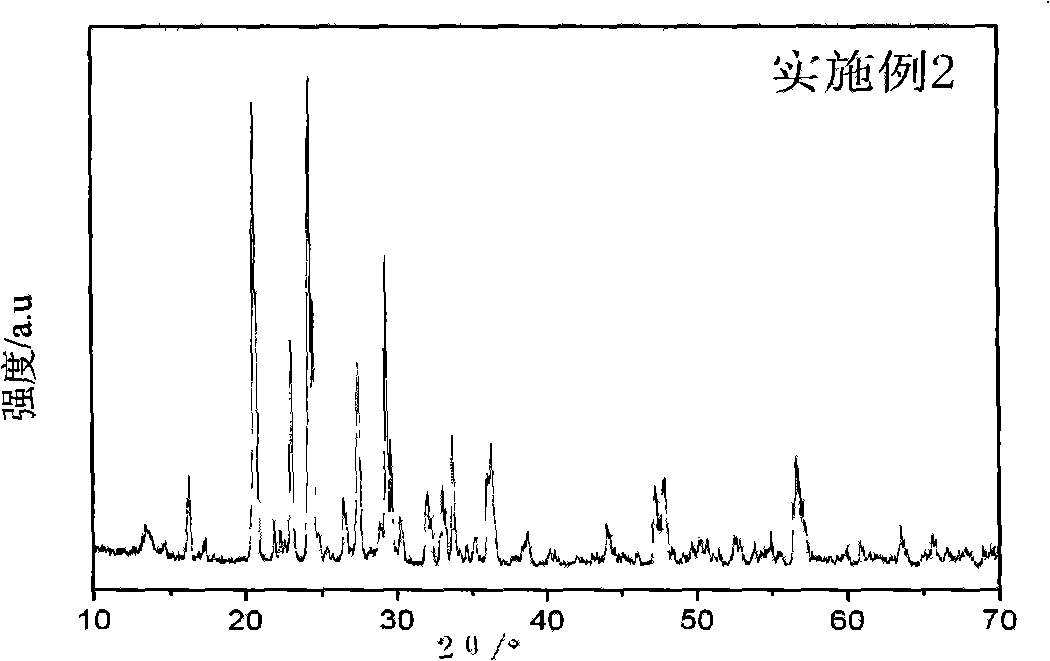

Embodiment 2

[0039] Weigh LiOH·H with the molar ratio of Li:V:P:citric acid=3:2:3:2 2 O, V 2 o 5 , NH 4 h 2 PO 4 and citric acid, put it in a 500ml ball mill jar, use ethanol as a dispersant, the ball mill speed is 600 rpm, and the ball mill time is 6h. After the completion, the mixture is sent into the muffle furnace for pretreatment at 300°C for 4 hours. Decompose the remaining organic matter, cool naturally with the furnace, take out the sample and put it back into the ball mill jar for low-speed ball milling, the ball milling speed is 300 rpm, and the ball milling time is 4h. Then the sample was sent to a closed-type Ar protection atmosphere muffle furnace for 10 hours at 700 ° C, and cooled to room temperature with the furnace temperature to obtain Li 3 V 2 (PO 4 ) 3 / C composite cathode material.

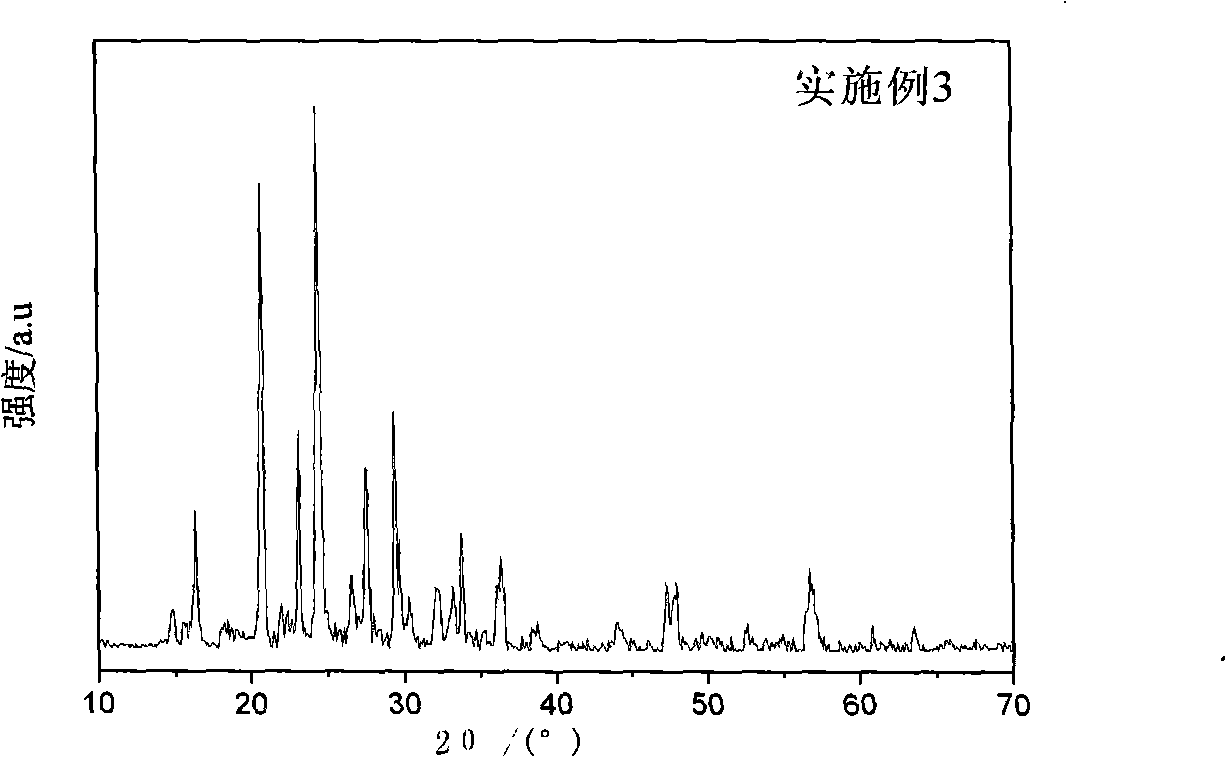

Embodiment 3

[0041] Weigh LiOH·H with the molar ratio of Li:V:P:citric acid=3:2:3:2 2 O, V 2 o 5 , NH 4 h 2 PO 4 and citric acid, put it in a 500ml ball mill jar, use acetone as a dispersant, the ball mill speed is 500 rpm, and the ball mill time is 7h. After the completion, the mixture is sent into the muffle furnace for pretreatment at 450°C for 2 hours. Decompose the remaining organic matter, cool naturally with the furnace, take out the sample and put it back into the ball mill jar for low-speed ball milling, the ball milling speed is 400 rpm, and the ball milling time is 2h. Then the sample was sent to a closed-type Ar protection atmosphere muffle furnace and roasted at 670 ° C for 8 hours, and cooled to room temperature with the furnace temperature to obtain Li 3 V 2 (PO 4 ) 3 / C composite cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com