Preparation method of environmental response type graphene hybrid material

A technology of graphene and graphite, which is applied in the field of environment-responsive graphene hybrid materials and its preparation, can solve the problems of limited application, difficulty in dissolving or dispersing, and achieve simple steps, stable structure, good solubility and dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Specifically, the preparation method of graphene hybrid material of the present invention comprises the following steps:

[0029] (1) Under nitrogen protection, graphene and RAFT chain transfer agent 2-(dodecyl trithiocarbonate group)-2-methyl propionic acid-3-azidopropyl ester in o-dichlorobenzene Ultrasonic disperse for 30~60 minutes, heat up to 120~160 o C, react for 40 to 60 hours, cool to room temperature, filter and wash with ethanol for 4 to 6 times, and dry to obtain the graphene anchoring the RAFT chain transfer agent on the surface;

[0030] (2) Ultrasonic disperse the above-mentioned graphene with RAFT chain transfer agent anchored on the surface in an organic solvent for 30-60 minutes, add monomer and initiator azobisisobutyronitrile, and 50-80 minutes under nitrogen protection o C reacted for 2 to 48 hours, filtered, washed with chloroform and methanol for 5 to 8 times, and dried to obtain the environment-responsive polymer-grafted graphene hybrid materia...

Embodiment 1

[0034] Dissolve 200 mg graphene oxide and 10 mg 2-(dodecyltrithiocarbonate)-2-methylpropanoic acid-3-azidopropyl ester in 25 mL o-dichlorobenzene and ultrasonically disperse for 30 minutes, under nitrogen protection, 120 o C was reacted for 50 hours. Cool to room temperature, filter and wash with ethanol for 4 times, and dry to obtain graphene oxide with RAFT chain transfer agent anchored on the surface.

[0035] Graphene oxide functionalized with 100 mg of the above RAFT chain transfer agent was ultrasonically dispersed in 100 mL of 1,4-dioxane for 30 min, and 5 g of N-isopropylacrylamide and 11.6 mg of azobisisobutyronitrile were added, 70 under the protection of nitrogen o C was reacted for 12 hours. Filter, wash with chloroform and methanol three times respectively, and dry to obtain a temperature-sensitive poly-N-isopropylacrylamide grafted graphene oxide hybrid material.

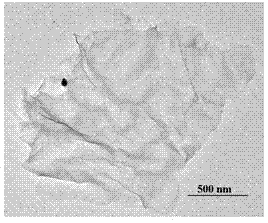

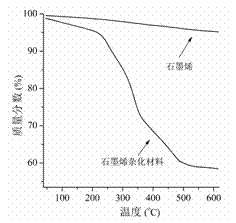

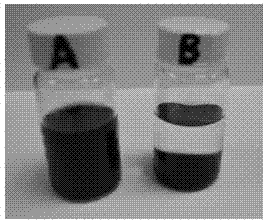

[0036] figure 1 For the transmission electron microscope photo of the hybrid material, changin...

Embodiment 2

[0038] Dissolve 300 mg graphene oxide and 10 mg 2-(dodecyltrithiocarbonate)-2-methylpropanoic acid-3-azidopropyl ester in 25 mL o-dichlorobenzene and ultrasonically disperse for 30 minutes, under nitrogen protection, 120 o C was reacted for 50 hours. Cool to room temperature, filter and wash with ethanol for 4 times, and dry to obtain graphene oxide with RAFT chain transfer agent anchored on the surface.

[0039] Graphene oxide functionalized with 100 mg of the above RAFT chain transfer agent was ultrasonically dispersed in 100 mL of 1,4-dioxane for 30 min, and 4 g of diethylaminoethyl methacrylate and 6.9 mg of azobisiso Nitrile, under nitrogen protection 70 o C was reacted for 12 hours. Filter, wash with chloroform and methanol three times respectively, and dry to obtain a pH-sensitive polydiethylaminoethyl methacrylate grafted graphene oxide hybrid material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com