Purely cationic photosensitive resin for 3D printing stereolithographic rapid prototyping, and preparation method and application thereof

A cationic, stereolithography technology, applied in the direction of additive processing, etc., can solve the problems of photosensitivity gap and other problems, and achieve the effect of simple steps, good photosensitivity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

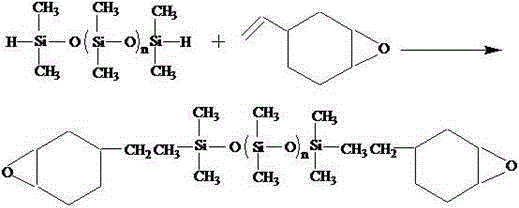

Method used

Image

Examples

Embodiment 1

[0036] (1) In a special 5000ml glass three-necked flask equipped with a stirrer and a condenser, add 1100 grams of siloxane-containing cycloaliphatic epoxy resin, add 3,4-epoxycyclohexylcarboxylic acid-3 , ,4 , - Epoxycyclohexyl methyl ester 800 g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 500 g, 1,4-butanediol diglycidyl ether 470 gram, 130 grams of triarylsulfonium hexafluoroantimonate.

[0037] (2) Heat to 50°C and stir for 30 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 18.5mJ / cm 2 .

[0038] (3) The cantilever beam test pieces were fabricated by using the SLA-3500 UV laser curing rapid prototyping equipment manufactured by 3DSystems, and then these test pieces were post-cured for 90 minutes in a UV box with a power of 500 mW. Their warpage factors CF(6)=0.01, CF(11)=0.02 were measured.

[0039] (4) Using the SLA-3500 UV laser curing rapid prototyping equipment manufactu...

Embodiment 2

[0041] (1) In a special 5000ml glass three-necked flask equipped with a stirrer and a condenser, add 1500 grams of siloxane-containing cycloaliphatic epoxy resin, add 3,4-epoxycyclohexylcarboxylic acid-3 , ,4 , - Epoxycyclohexyl methyl ester 700g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 300g, 1,4-cyclohexanedimethanol diglycidol 370 grams of ether, 130 grams of triarylsulfonium hexafluoroantimonate.

[0042] (2) Heat to 40°C and stir for 30 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 17.9mJ / cm 2 .

[0043] (3) Some test pieces were made by using SLA-3500 UV laser curing rapid prototyping equipment, and then post-cured for 90 minutes in a UV box with a power of 500 mW. Their warpage factors CF(6)=-0.01, CF(11)=-0.02 were measured.

[0044] (4) Using SLA-3500 UV laser curing rapid prototyping equipment, some test pieces were made according to ASTMD638 and ASTMD256 standards...

Embodiment 3

[0046](1) In a special 5000ml glass three-necked flask equipped with a stirrer and a condenser, add 1600 grams of siloxane-containing cycloaliphatic epoxy resin, add bis(3,4-epoxycyclohexylcarboxylate)-hexyl Diacid ester 600g, 3,3-[oxybismethylene]-bis[3-ethyl]oxetane 500g, polypropylene glycol diglycidyl ether 250g, triarylsulfonium hexafluoroantimony Salt 140 grams.

[0047] (2) Heat to 50°C and stir for 20 minutes to make it into a transparent light yellow uniform liquid, which is a prepared photosensitive resin. Measure its critical exposure E c 16.9mJ / cm 2 .

[0048] (3) Some test pieces were made by using SLA-3500 UV laser curing rapid prototyping equipment, and then post-cured for 90 minutes in a UV box with a power of 500 mW. Their warpage factors CF(6)=-0.01, CF(11)=-0.03 were measured.

[0049] (4) Using SLA-3500 UV laser curing rapid prototyping equipment, some test pieces were made according to ASTMD638 and ASTMD256 standards, and then post-cured for 90 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com