Matte degree controllable core-shell emulsion as well as preparation method and application thereof

A core-shell emulsion and core-shell technology, applied in the direction of coating, can solve the problems of affecting the leveling and viscosity stability of matte varnish, easy to produce streaks in printed products, and short storage time, etc., to achieve operability. The effect of stability, strong printing adaptability and long storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

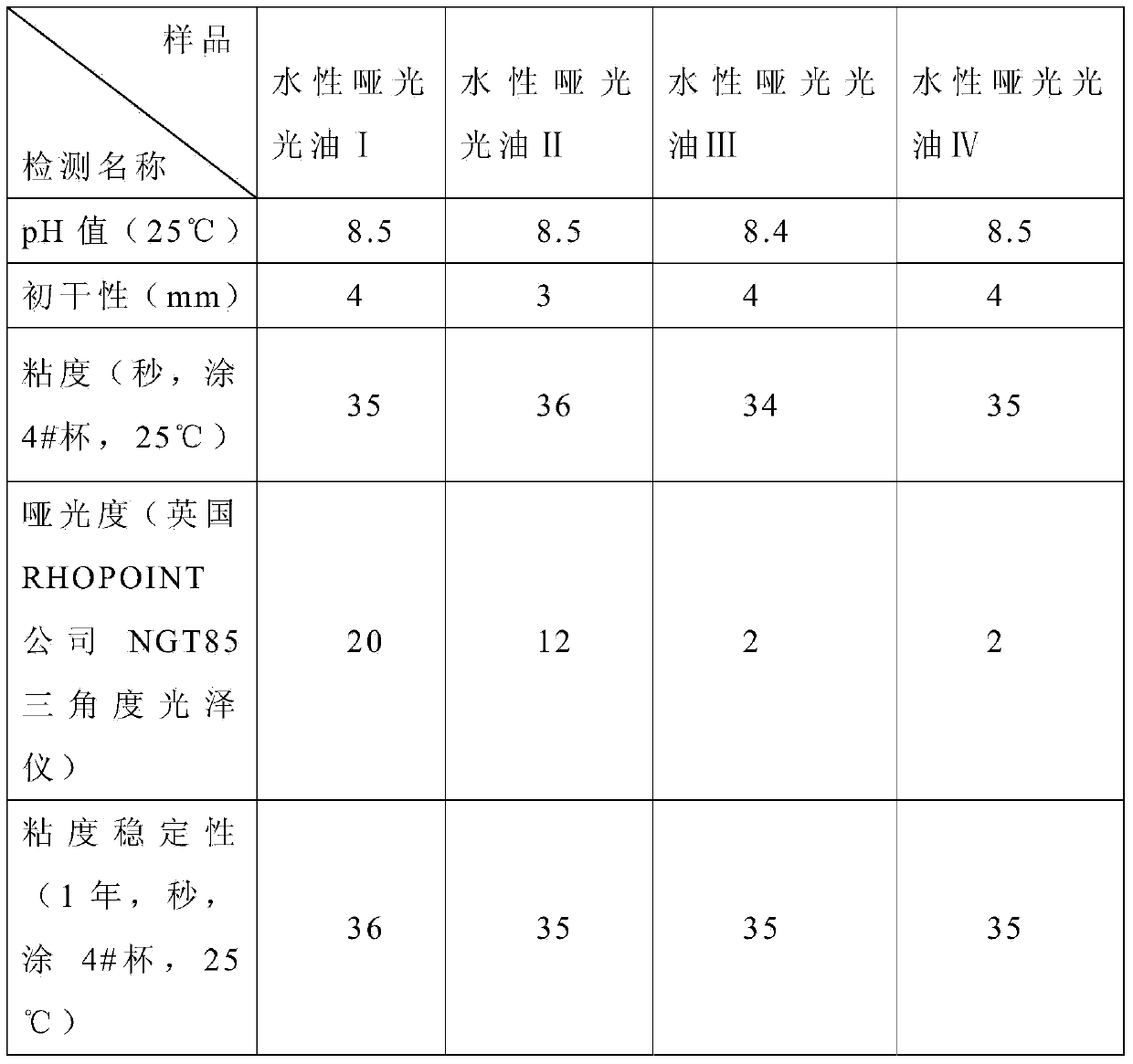

Examples

Embodiment 1

[0037] Add 1458 grams of deionized water and 6 grams of water-soluble initiator ammonium persulfate into a four-neck flask equipped with a thermometer, a reflux condenser, a dropping device, and stirring, and raise the temperature to 83°C. Add 500 grams of deionized water, 6 grams of reactive emulsifier sodium acrylamido isopropyl sulfonate, 150 grams of acrylamide, 170 grams of N-methylol acrylamide, 40 grams of methacrylic acid, methacrylic acid 50 grams of methyl ester, 50 grams of styrene, and 20 grams of molecular weight regulator 3-mercaptopropanol were pre-emulsified. Add the pre-emulsified mixed monomers dropwise into the flask by "starvation method" within the temperature range of 80°C to 85°C, and the dropwise addition time is 90 minutes. After the dropwise addition, 38 grams of ammonia water was added to adjust the pH value of the emulsion to 8.5, and the emulsion was kept for 30 minutes to prepare the shell emulsion.

[0038]Dissolve 12 grams of ammonium persulfat...

Embodiment 2

[0040] Add 1146 grams of deionized water and 8 grams of water-soluble initiator ammonium persulfate into a four-neck flask equipped with a thermometer, a reflux condenser, a dropping device, and stirring, and raise the temperature to 83°C. Add 500 grams of deionized water, 10 grams of reactive emulsifier containing allyl-containing special alcohol ether sulfate, 248 grams of acrylamide, and 72 grams of N-methylol acrylamide (the effective content accounts for 7.5%), 40 grams of methacrylic acid, 50 grams of methyl methacrylate, 50 grams of styrene, and 20 grams of molecular weight modifier tertiary dodecyl mercaptan for pre-emulsification. Add the pre-emulsified mixed monomers dropwise into the flask by "starvation method" within the temperature range of 80°C to 85°C, and the dropwise addition time is 90 minutes. After the dropwise addition, 50 g of monoethanolamine was added to adjust the pH of the emulsion to 8.5, and the emulsion was kept for 30 minutes to prepare the shell...

Embodiment 3

[0043] Add 1171 grams of deionized water and 8 grams of water-soluble initiator ammonium persulfate into a four-neck flask equipped with a thermometer, a reflux condenser, a dropping device, and stirring, and raise the temperature to 83°C. Add 500 grams of deionized water, 10 grams of reactive emulsifier sodium salt of alcohol ether sulfosuccinate containing double bonds, 176 grams of acrylamide, and 144 grams of N-methylol acrylamide (the effective content accounts for 15% of the total amount), 40 grams of methacrylic acid, 50 grams of methyl methacrylate, 50 grams of styrene, and 20 grams of n-dodecyl mercaptan acetate as a molecular weight modifier for pre-emulsification. Add the pre-emulsified mixed monomers dropwise into the flask by "starvation method" within the temperature range of 80°C to 85°C, and the dropwise addition time is 90 minutes. After the dropwise addition, 25 grams of diethanolamine was added to adjust the pH of the emulsion to 8.5, and the emulsion was ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com