Magnesium alloy protective coating and preparation method thereof

A protective coating, magnesium alloy technology, applied in metal material coating process, coating, vacuum evaporation plating and other directions, can solve the problems of magnesium alloy matrix lack of protection, poor wear performance, low hardness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

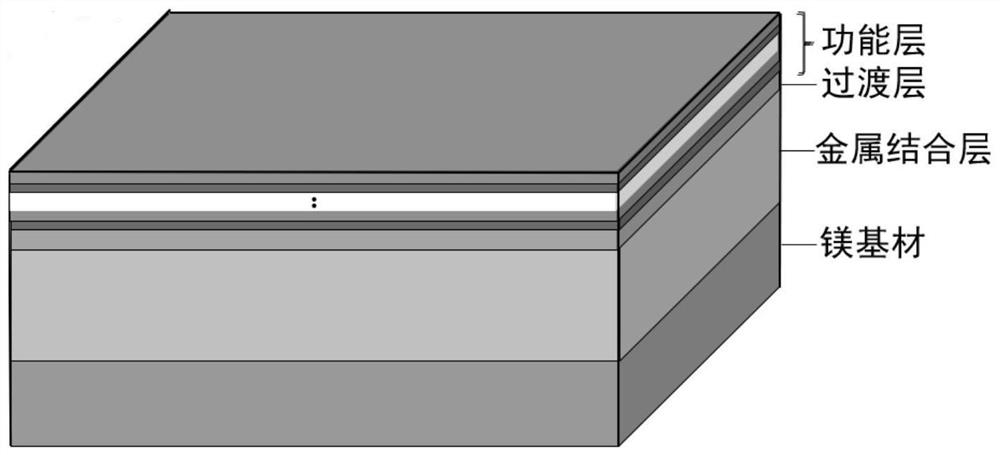

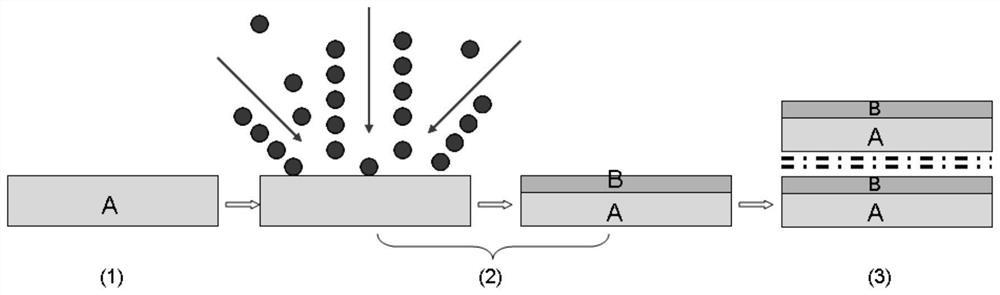

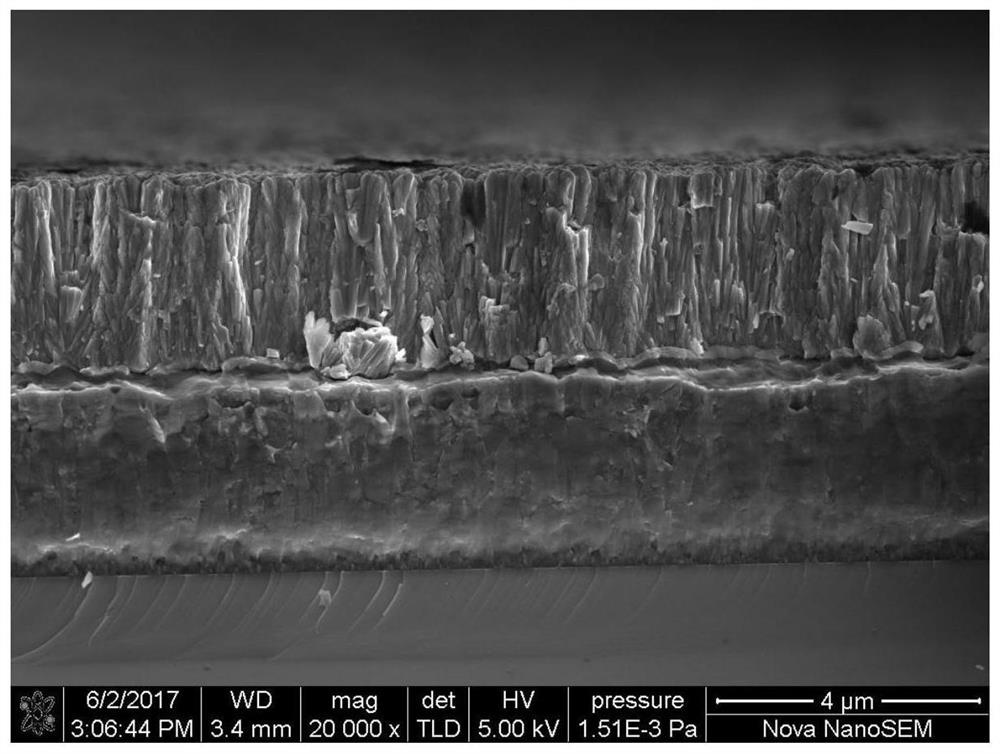

[0031] The present application also provides a preparation method of a magnesium alloy protective coating, which includes the following steps:

[0032] A) carrying out surface pretreatment to the magnesium alloy substrate;

[0033] B) Depositing a metal bonding layer on the surface of the magnesium alloy substrate obtained in step A) by magnetron sputtering or filtered cathodic arc method;

[0034] C) Depositing a transition metal layer on the surface of the magnesium alloy substrate obtained in step B) by magnetron sputtering;

[0035] D) The magnetron sputtering method is used to deposit a functional layer on the surface of the magnesium alloy substrate obtained in step C) one or more times; the metal ionization rate or gas ionization rate is increased during the process of the magnetron sputtering method.

[0036] In the process of preparing the magnesium alloy protective coating, the present application first carries out surface pretreatment on the magnesium alloy substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com