Manufacturing method for epoxy resin filling type pre-stress steel strand

A technology of prestressed steel strand and epoxy resin, applied in epoxy resin coating, auxiliary device for rope making, coating, etc., can solve the problem of poor corrosion resistance of prestressed steel strand, increase corrosion resistance, The effect of good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

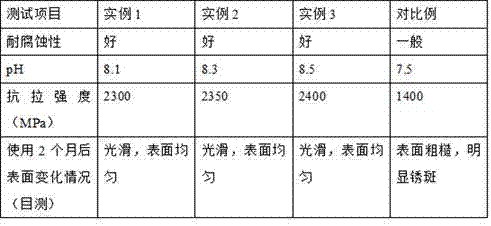

Examples

example 1

[0027]In parts by weight, add 70 parts of deionized water and 8 parts of sodium lauryl sulfate into a three-necked flask with a stirrer and a dropping funnel, start the stirrer, stir for 45min at a speed of 300r / min, and obtain the prepared Emulsion, after adding 40 parts of aniline to the pre-emulsion, add 20 parts of ammonium persulfate solution with a mass fraction of 5% to the three-necked flask dropwise with a dropping funnel at a rate of 3 mL / min. React for 6 hours and discharge to obtain a polyaniline emulsion; add 50mL acetone to 200mL polyaniline emulsion, break the emulsion for 2 hours to obtain a polyaniline suspoemulsion, place the polyaniline suspoemulsion in a high-speed centrifuge at a speed of 4000r / min After centrifugation for 10 minutes, filter with suction, remove the filtrate to obtain a filter cake, wash the filter cake with deionized water 3 times, place the product after suction filtration and washing in a vacuum drying oven with a set temperature of 40°C...

example 2

[0029] In parts by weight, add 75 parts of deionized water and 9 parts of sodium lauryl sulfate into a three-necked flask with a stirrer and a dropping funnel, start the stirrer, and stir for 47min at a speed of 310r / min to obtain the prepared mixture. Emulsion, after adding 45 parts of aniline to the pre-emulsion, add 22 parts of ammonium persulfate solution with a mass fraction of 5% to the three-necked flask dropwise with a dropping funnel at a dropping rate of 4mL / min. React for 6.5 hours and discharge to obtain polyaniline emulsion; add 55mL acetone to 210mL polyaniline emulsion, break the emulsion for 2.5h to obtain polyaniline suspoemulsion, place polyaniline suspoemulsion in a high-speed centrifuge, and spin at 4200r / min After centrifugation at a speed of 11 minutes, filter with suction, remove the filtrate to obtain a filter cake, wash the filter cake with deionized water 4 times, and place the product after suction filtration and washing in a vacuum drying oven with a...

example 3

[0031] In parts by weight, add 80 parts of deionized water and 10 parts of sodium lauryl sulfate into a three-necked flask with a stirrer and a dropping funnel, start the stirrer, and stir for 50 min at a speed of 330 r / min to obtain the prepared Emulsion, after adding 50 parts of aniline to the pre-emulsion, add 25 parts of ammonium persulfate solution with a mass fraction of 5% to the three-necked flask dropwise with a dropping funnel at a rate of 5 mL / min. React for 7 hours and discharge to obtain polyaniline emulsion; add 60mL acetone to 220mL polyaniline emulsion, and break the emulsion for 3 hours to obtain polyaniline suspoemulsion. After centrifugation for 12 minutes, filter with suction, remove the filtrate to obtain a filter cake, wash the filter cake with deionized water 5 times, place the product after suction filtration and washing in a vacuum drying oven with a set temperature of 45°C, and dry it for 14 hours. Grind and pass through a 100-mesh sieve to obtain lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com