Patents

Literature

43results about How to "Good lipophilic and hydrophobic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extraction separation of vanadium and chromium from vanadium-chromium slag pickle liquor

InactiveCN107312942AImprove extraction abilityGood lipophilic and hydrophobicProcess efficiency improvementSolubilitySlag

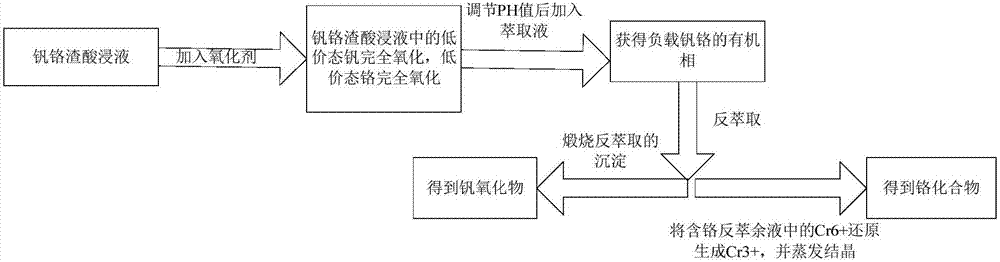

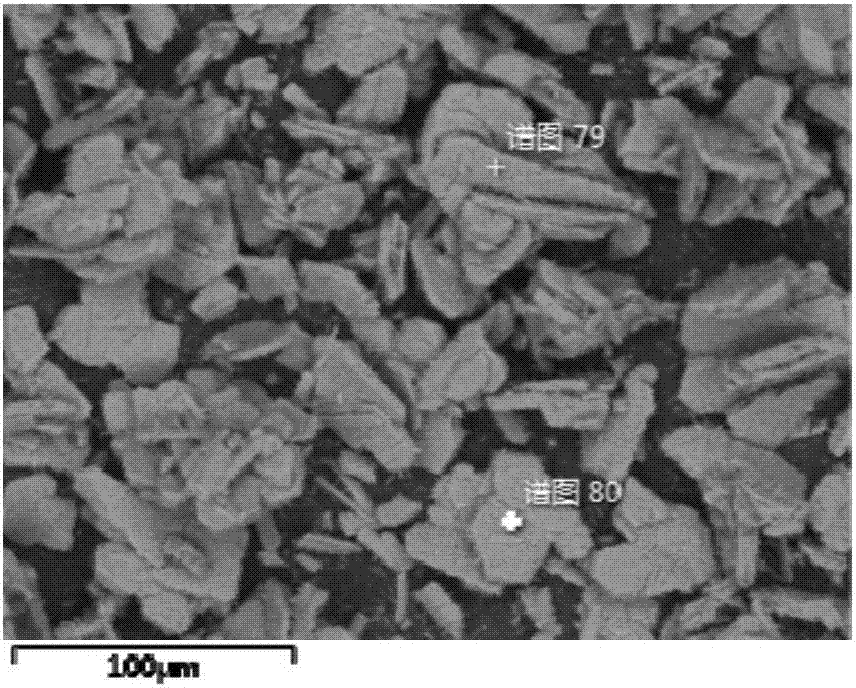

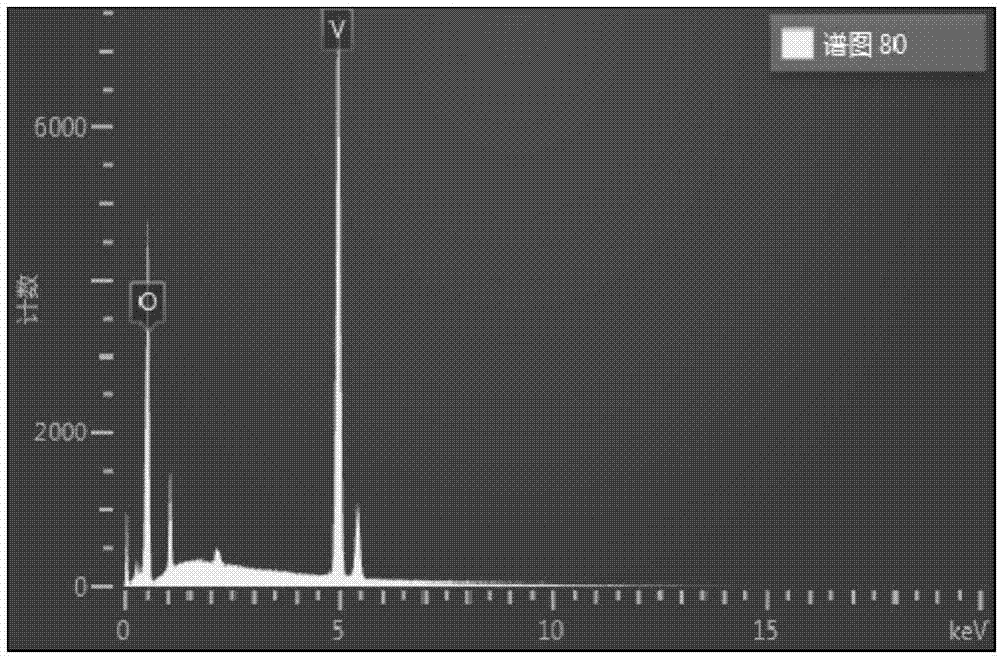

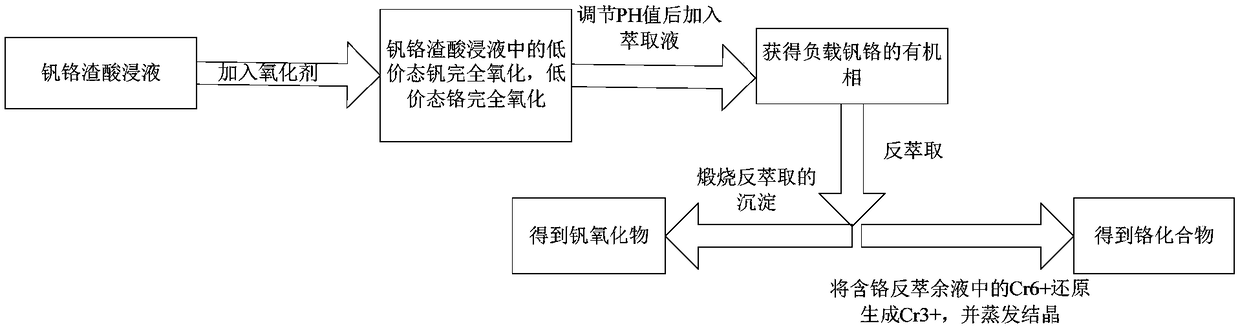

The invention provides a method for extraction separation of vanadium and chromium from vanadium-chromium slag pickle liquor. The method comprises the steps that S1, pentavalent vanadium and hexavalent chromium in the vanadium-chromium slag pickle liquor are extracted into organic phases through extract liquor and then separated from aqueous phases, and vanadium-chromium-loaded organic phases are obtained; S2, the vanadium-chromium-loaded organic phases obtained in the S1 are subjected to reverse extraction through a stripping agent, and after reverse extraction is completed, chromium-containing raffinate, ammonium metavanadate or ammonium polyvanadate precipitation and regenerative ionic liquid are obtained; S3, the ammonium metavanadate or ammonium polyvanadate precipitation obtained in the S2 is roasted at 550-600 DEG C, and vanadium oxides are obtained; and S4, Cr6+ in the reverse raffinate obtained in the S2 is reduced into Cr3+, after the pH of chromium is adjusted, chromium is precipitated in a precipitation form, and Cr2O3 is obtained through roasting. The method is high in extraction efficiency, layering is rapid after extraction, emulsion is avoided, ionic liquid has good lipophilic-hydrophobic property, has good solubleness in long-chain alcohol and is not mutually soluble with water, and thus organic phase losses caused by aqueous phase inclusion or dissolution can be reduced.

Owner:NORTHEASTERN UNIV

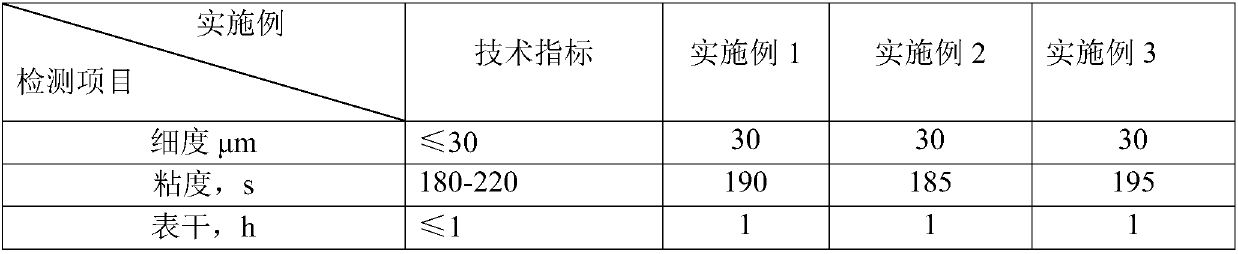

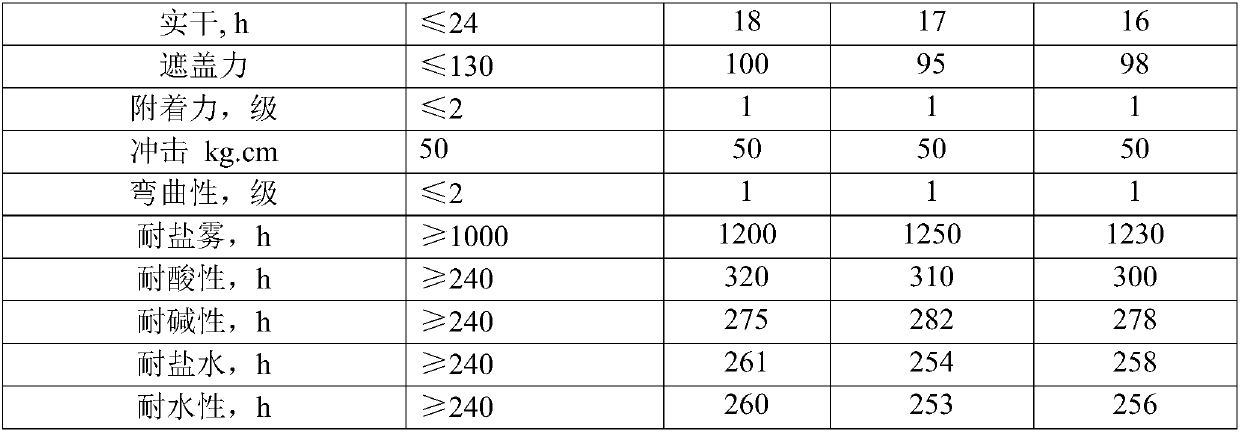

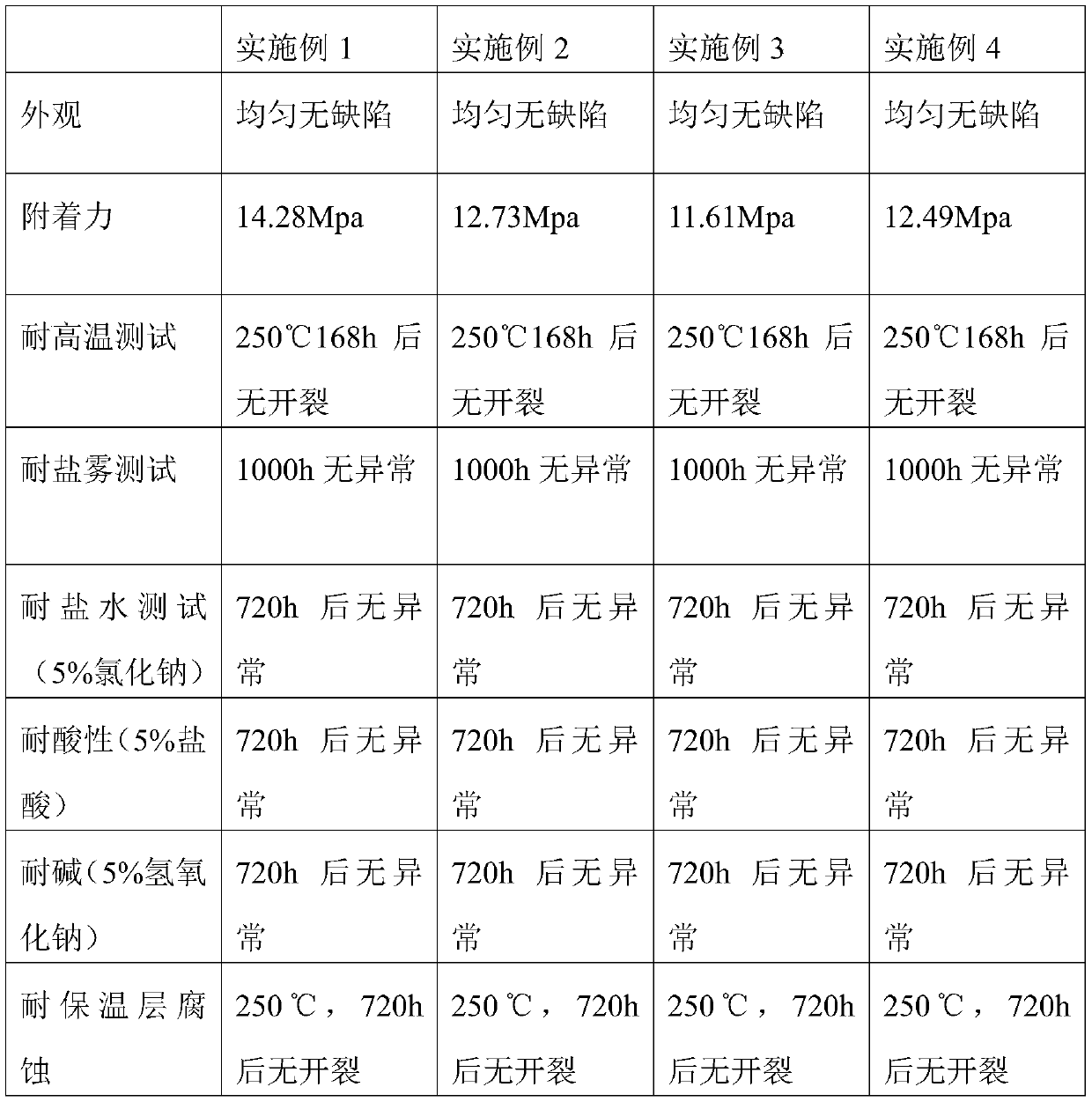

Graphene modified steel structure water-based anti-corrosive paint and preparation method thereof

InactiveCN107793865AImprove thermal stabilityGood chemical stabilityAnti-corrosive paintsWater basedEmulsion

The invention discloses a graphene modified steel structure water-based anti-corrosive paint and a preparation method thereof. The anti-corrosive paint is prepared from the components in percentage byweight: 10 to 20 percent of deionized water, 5 to 10 percent of graphene dispersion liquid, 30 to 40 percent of anionic acrylic emulsion, 5 to 13 percent of pigment, 20 to 30 percent of filler, 0.1 to 0.8 percent of wetting dispersant, 0.1 to 0.5 percent of defoaming agent, 0.2 to 0.5 percent of pH modifier, 0.3 to 0.6 percent of thickening agent, 0.2 to 0.5 percent of SiO2 hollow microspheres, 0.1 to 0.4 percent of RS preservative, and 2 to 5 percent of coalescing agents. The sum of the weight percent contents of the components in the graphene modified steel structure water-based anti-corrosive paint is 100 percent. Due to the interaction and the space effect among the graphene, the SiO2 hollow microspheres, the pigment and the filler, the defects of poor water fastness, weather fastnessand easiness of flash rust of a traditional water-based acrylic anti-corrosive paint are overcome, the hardness of a film is ensured on the basis of flexibility, and the paint has excellent storage and anti-corrosive performances.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Bentonite surface modification and intercalation technique

ActiveCN101890330AWide range of usesNo toxic side effectsOther chemical processesMycotoxinSodium Bentonite

The invention relates to a bentonite surface modification and intercalation technique. In the technique, natural bentonite serving as a base is subjected to surface modification and intercalation, wherein the ion exchange capacity of the natural bentonite is 50 to 150 mmol / 100g; and the bentonite is sodium-based bentonite, calcium-based bentonite or sodium-calcium-based bentonite. The bentonite subjected to the surface modification and the intercalation has the advantages of high adsorption property, high oleophylic and hydrophobic property, capacity of effectively adsorbing harmful substances such as all kinds of mycotoxin and the like in feed, wide application and suitability for the fields of feed production or environmental protection, coating, papermaking, lubricants and the like.

Owner:江苏奥迈生物科技有限公司

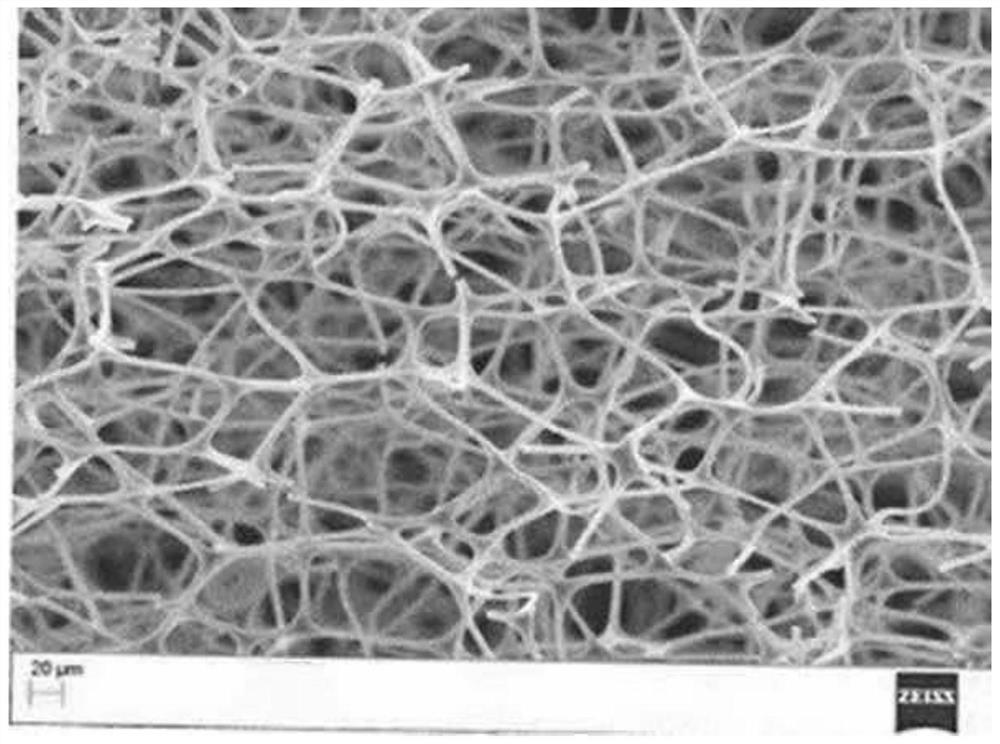

Ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method

InactiveCN109137466ALight in massLarge poresOther chemical processesUltrasonic/sonic fibre treatmentUltravioletNonwoven fabric

The invention discloses an ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method. According to the preparation method, a photosensitizer, compound monomers, solvents and melt-blowing polypropylene non-woven fabric are involved, wherein the photosensitizer relates to benzophenone, the compound monomers refer to optional two of butyl methacrylate,dodecyl methacrylate, methyl acrylate and butyl acrylate, and the solvents refer to isopropyl alcohol and deionized water. The non-woven fabric can adsorb oil substances in different type, has good oleophylic hydrophobicity, can absorb oil but water, can be reused, can also adsorb some heavy-metallic ion. Besides, as the optimum processing condition good for achieving the optimum oil absorption capacity is reached as researched, the fabric has more thorough oil absorption performance and better oil holding capacity.

Owner:JIXI YUANDAO AGRI IND TECH

Teflon film filter paper impregnation sintering and technique of preparing the same

InactiveCN101138690AHydrophobicImprove performanceDomestic articlesFiltration separationFiberPolymer science

The present invention discloses a technique to immerse, agglomerate and manufacture a polytetrafluoro ethylene film filter paper. A traditional filter paper is used as a base material and is immersed, rolled, pressed and agglomerated with polytetrafluoro ethylene latex to form the filter paper, the fiber surface of which is enveloped with a polytetrafluoro ethylene film. The present invention is characterized in that the polytetrafluoro ethylene film is 10 to 25 nanometers thick; agglomeration is conducted in three temperature zones; a first temperature zone is 75 to 85 centigrade degrees, a second temperature zone is 115 to 125 centigrade degrees, and a third temperature zone is 145 to 155 centigrade degrees; the total time of agglomeration is five minutes. The present invention basically keeps filtration functions of the original filter paper, and the filtration precision, the ventilation property and other technical indexes are not changed greatly. However, the water resistance, the temperature resistance, the acid, alkali and corrosion resistance, the abrasion resistance, the intensity, and the deformation resistance are greatly promoted. The present invention can be blown reversely to remove the dust, and can be cleaned and used repeatedly. Moreover, a function of water resistance and oil proximity is added for the present invention, so the present invention can be used for water and oil segregation.

Owner:新乡市胜达过滤净化技术有限公司

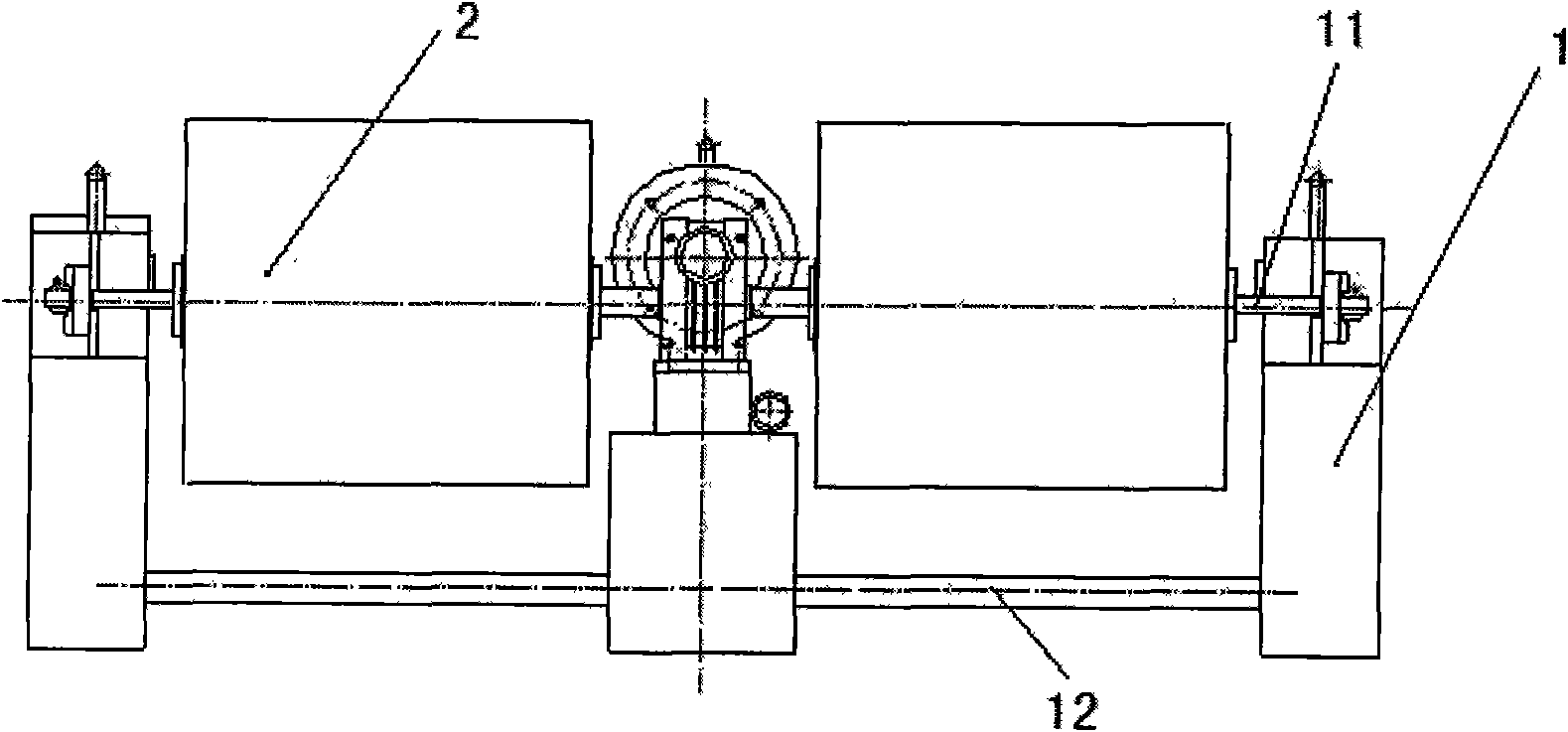

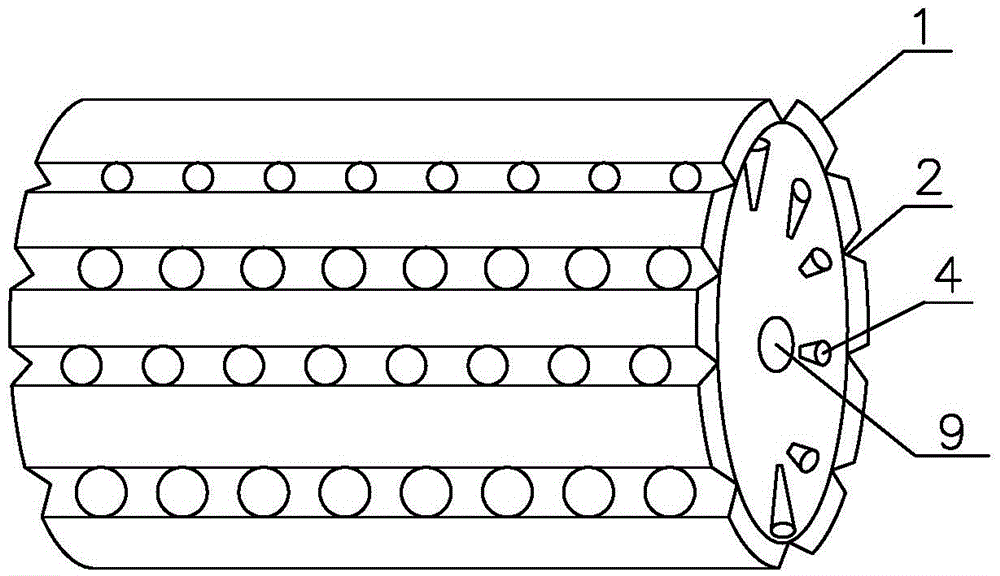

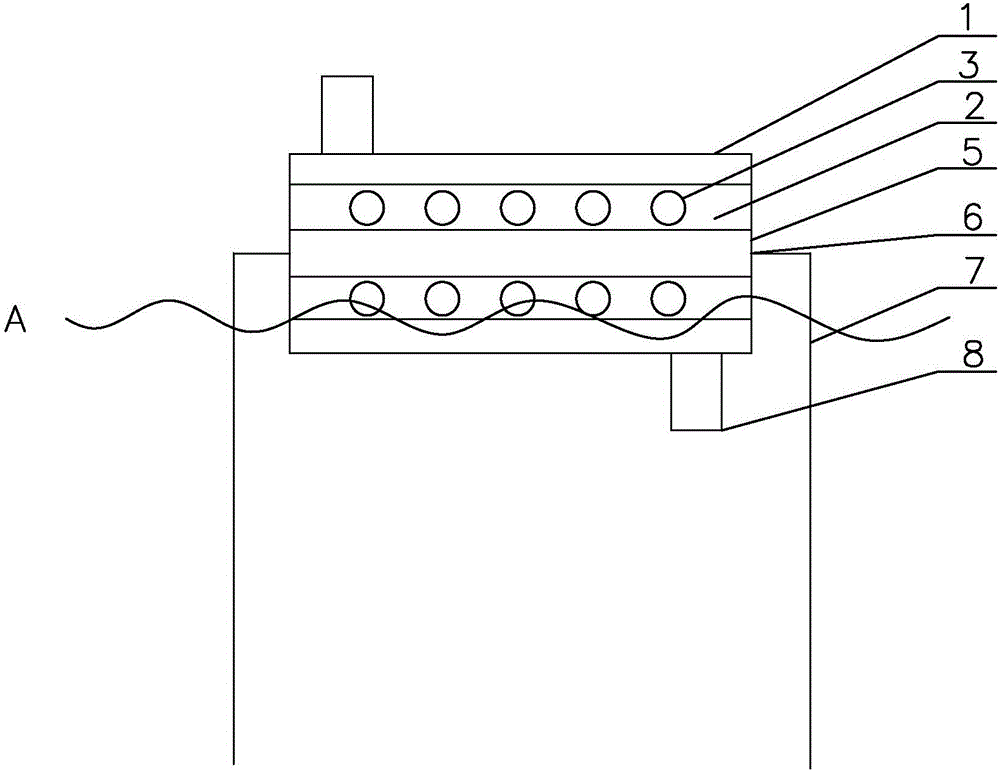

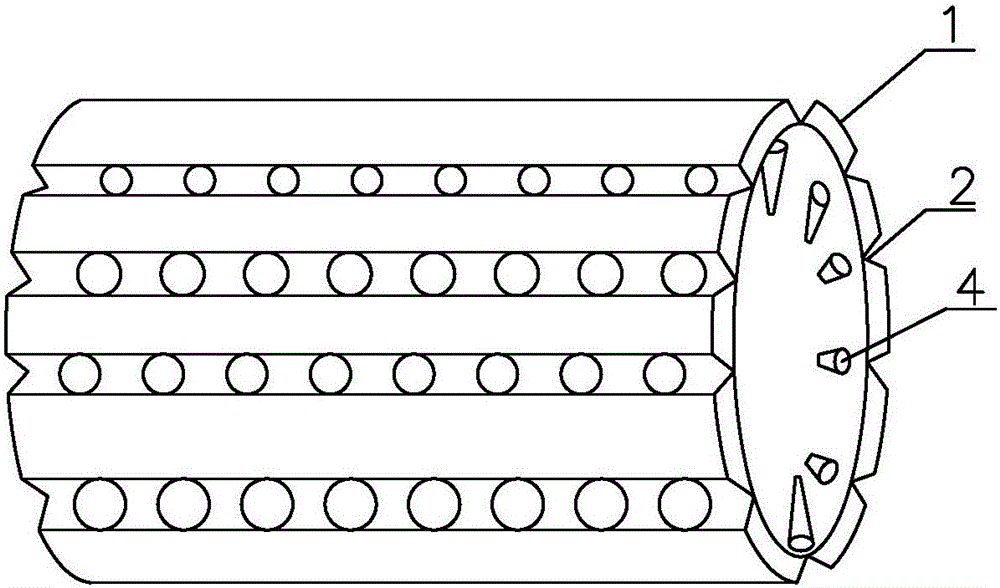

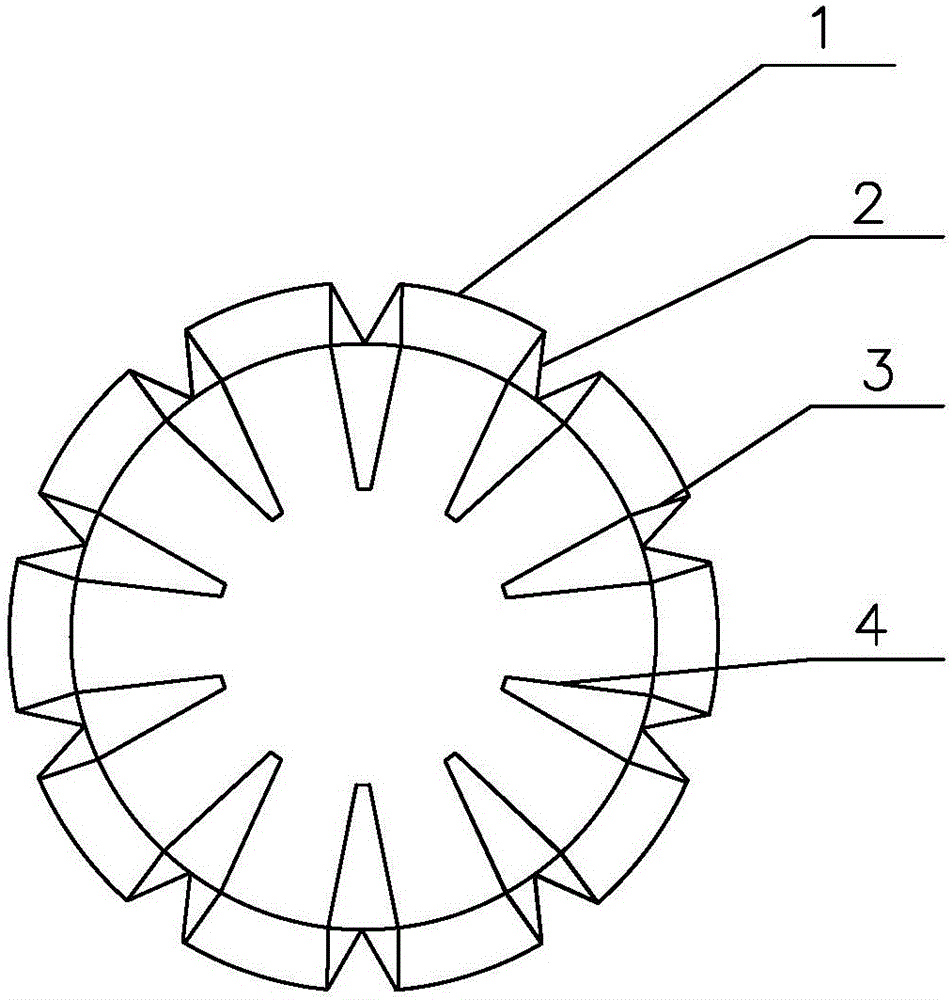

Nano rotor drum oil-collecting device

ActiveCN101613140AImprove oil recovery efficiencyGood lipophilic and hydrophobicFatty/oily/floating substances removal devicesLiquid separationMechanical engineeringHigh polymer

The invention provides a nano rotor drum oil-collecting device, which can effectively make up the defect of current floating oil-collecting device, comprising a frame and a plurality of rotor drums, wherein, the surface of the rotor drum is coated with a nano layer with good hydrophilic and oleophylic performance which is prepared by nano high polymer materials; the rotor drum shaft is arranged on the frame and a rotor drum driving device is used for driving the rotor drum to revolve along the shaft; the frame is also provided with an oil-collecting tank; the edge of the rotor drum is provided with an oil scraper plate and the bottom end thereof is arranged in the oil-collecting tank which is used for collecting the oil on the rotor drum into the oil-collecting tank; the bottom part of the oil-collecting tank is arranged with an oil discharge pipeline which is used for discharging the waste oil collected by the oil-collecting tank. The nano rotor drum oil-collecting device can stick the waste oil which floats on the liquid level onto the nano layer of the rotor drum; with the rotation of the rotor drum, the oil scraper plate can scrape the waste oil on the nano layer of the rotor drum into the oil-collecting tank; the waste oil in the oil-collecting tank can be discharged via the oil discharging pipeline through pumping to finish oil removal.

Owner:MAIWANG INT BUSINESS SHANGHAI

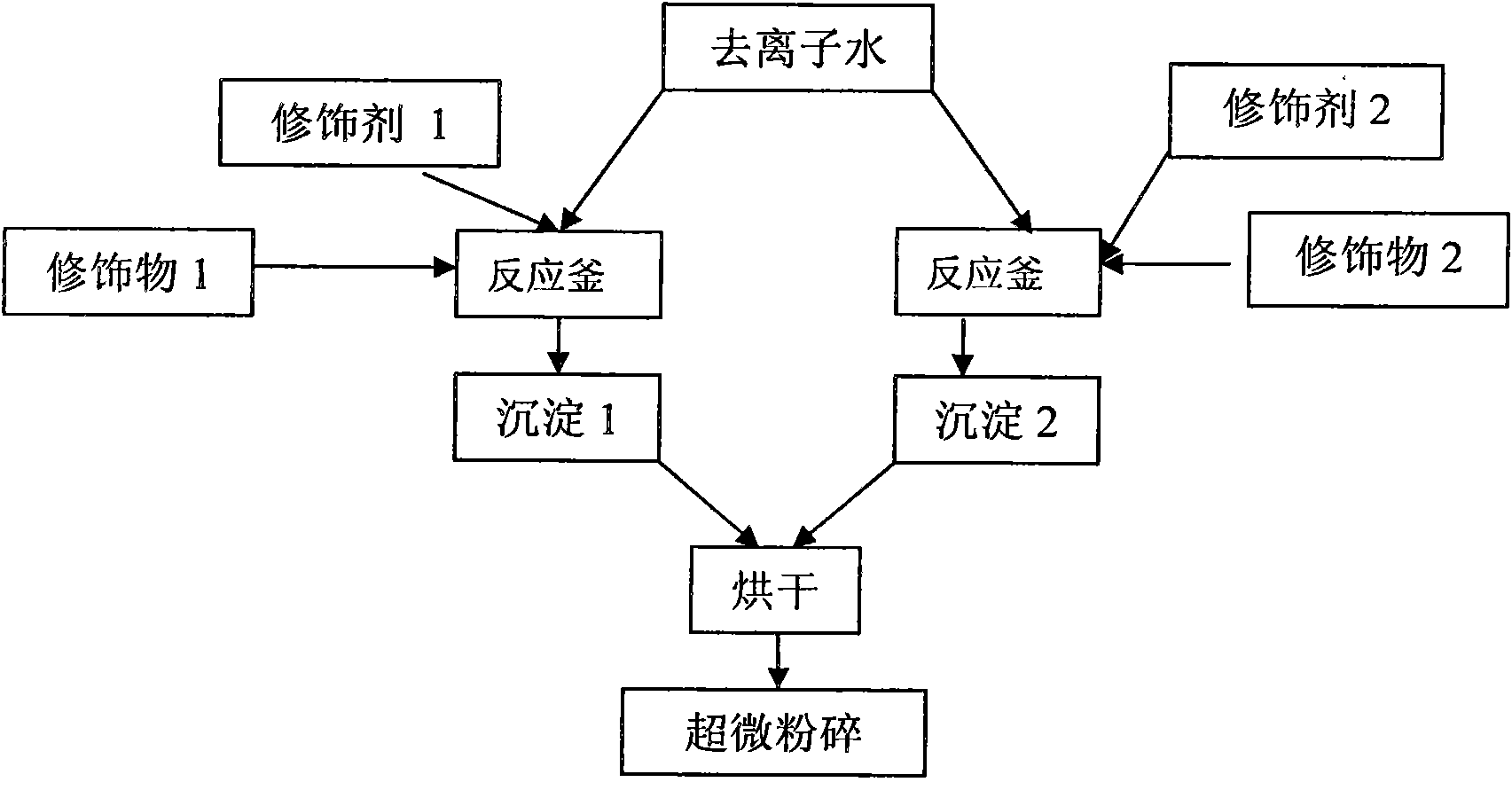

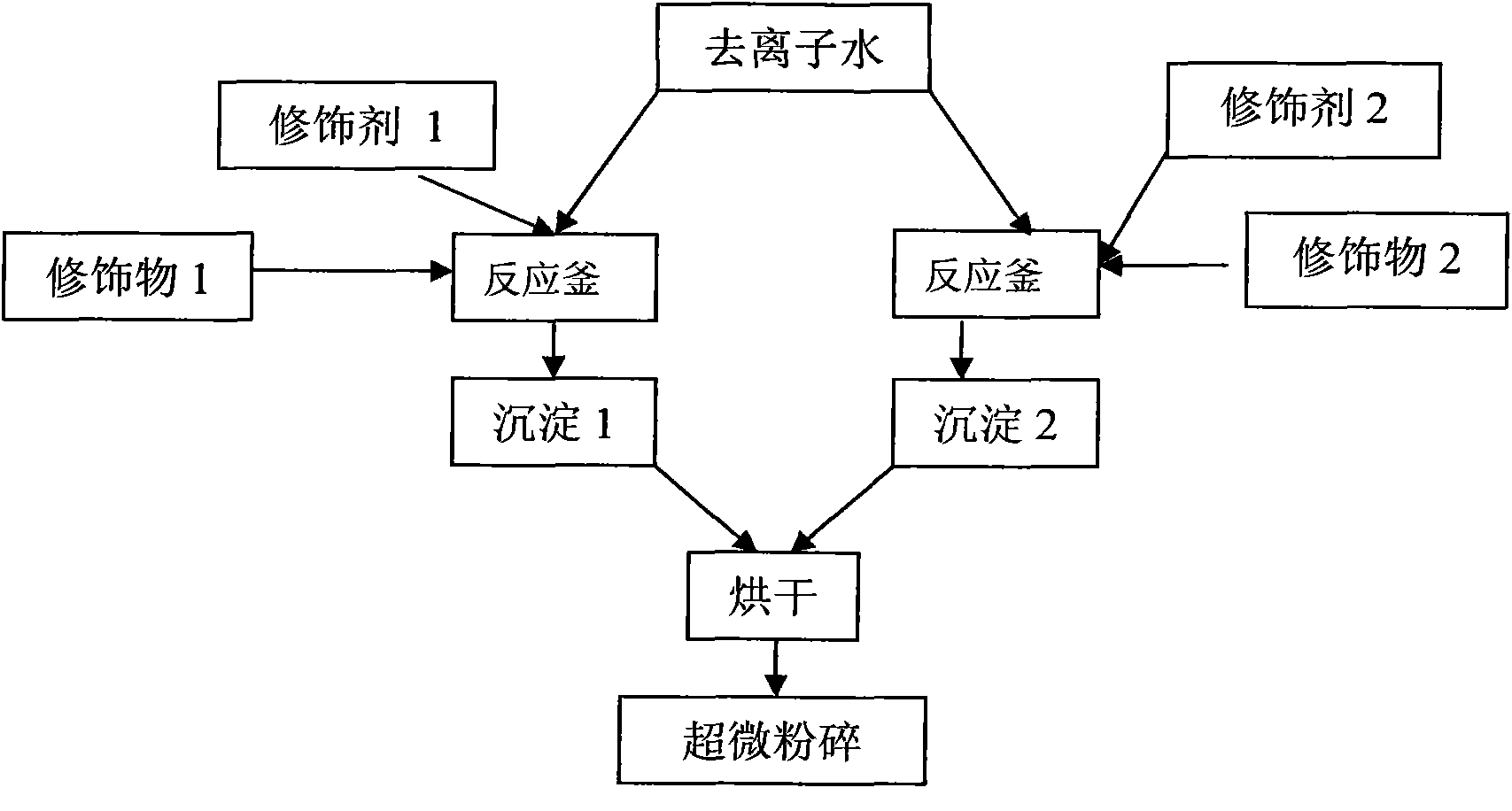

Method for preparing high-dispersion barite

ActiveCN110451549AGood lipophilic and hydrophobicGood dispersionMaterial nanotechnologyCalcium/strontium/barium sulfatesDispersityEthylene diamine

The invention discloses a method for preparing high-dispersion barite. The method comprises the following steps: roughly crushing barite, adding the barite into a grinding machine, and performing grinding so as to obtain barite powder; putting water and a dispersant into the barite powder, performing grinding continuously in a ball mill till the particle size is 20-200nm, and performing filteringand drying so as to obtain nano barite; putting the nano barite into a reaction kettle, adding water till the solid-liquid ratio is 1:(2-3), further adding a mixed acid, and performing stirring, filtering and water washing, wherein the mixed acid consists of citric acid, ethylene diamine tetraacetic acid andhydroxy ethylidene biphosphonic acid; and conveying the nano barite obtained after treatment into a surface modifier, adding a surface treatment agent consisting of alkyl naphthalene sulfonate and octakis(trimethylsiloxy)silsesquioxane, and performing stirring, drying and dispersion, so asto obtain high-dispersion barite powder. By adopting the high-dispersion barite powder prepared by using the method, not only is the dispersity improved, but also the compatibility of the powder withan organic base material is improved, processing properties can be improved, the whiteness of the product can be up to 95%, and application of the barite powder can be widened.

Owner:平利县篮泰重晶石工贸有限公司

Detergent for military electronic device and preparation method of detergent

InactiveCN108251227AEasy to cleanNo pollution in the processInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPyrollidone 2Linear alkylbenzene

The invention discloses detergent for a military electronic device and a preparation method of the detergent. The detergent is prepared from the following components in parts by weight: 6 to 10 partsof fatty alcohol-polyoxyethylene ether, 4 to 8 parts of sodium n-alkyl benzene sulfonate, 3 to 7 parts of polyoxyethylene octylphenol ether, 2 to 5 parts of N-methyl-pyrrolidone, 3 to 7 parts of sodium silicate, 0.1 to 0.5 part of benzotriazole, 0.5 to 1 part of silicone oil, 0.1 to 2 parts of pH adjusting agent and 60 to 80 parts of water, and the pH adjusting agent comprises quaternary ammoniumbase and triethanolamine. The detergent of the scheme has a good cleaning effect, and is free from residue, free from corrosion, applicable to various water and pollution-free to the environment.

Owner:JINAN JIAXING TECH

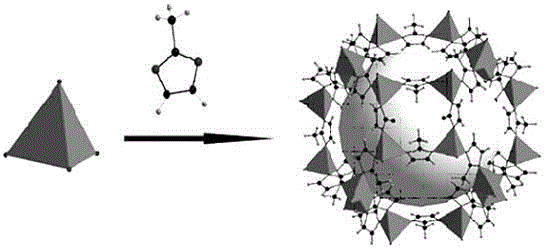

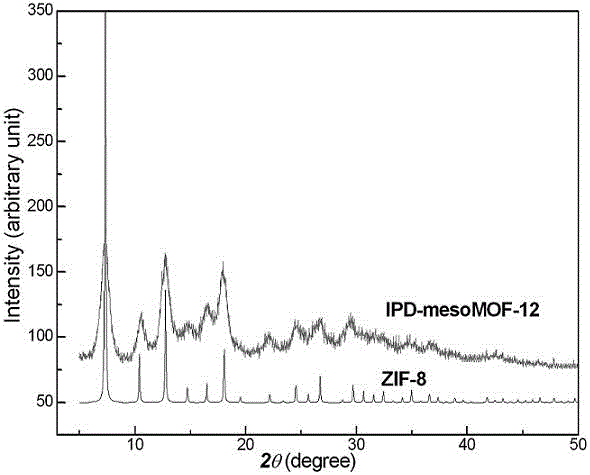

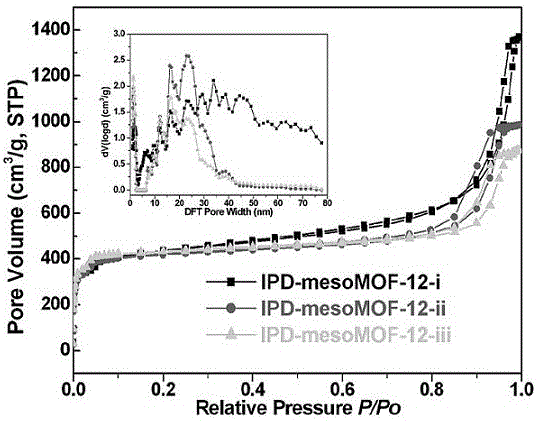

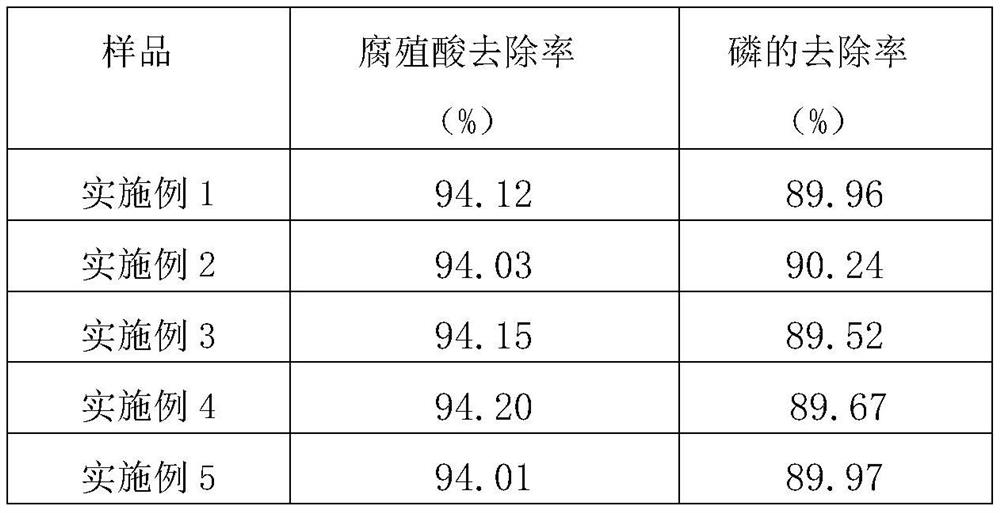

MOF type hierarchical porous material IPD-mesonMOF-12

ActiveCN105664860ALarge mesopore volumeImprove thermal stabilityOther chemical processesDispersed particle separationOrganic solventAdhesive

The invention relates to an MOF type hierarchical porous material.The diameter of mesoporous ranges from 2 nm to 50 nm, the size of micropores is smaller than 2 nm, the BET specific surface ranges from 1300 M<2> / g to 1850 M<2> / g, the total pore volume ranges from 1.20 cm<3> / g to 2.80 cm<3> / g, and the pore volume of the mesoporous ranges from 0.5 cm<3> / g to 1.90 cm<3> / g.The preparation method comprises the following steps that 1, metal zinc salt, 2-methylimidazole, alkali and an organic solvent are stirred to be uniform and transferred into a reaction kettle to be subjected to a reaction for 2-12 h at the constant temperature of 80-130 DEG C; 2, the reaction is completed, cooling is performed to reach the room temperature, obtained gel materials are dried under the temperature of 20-50 DEG C to form a dry adhesive, and then extraction and washing are performed for 6 h or longer; 3, finally, heating is performed for 12 h or longer under the vacuum condition at the temperature of 130-150 DEG C, and then the hierarchical porous material is obtained.The micropores are from the ZIF-8 structure, the mesoporous is frame holes between particles, and the hierarchical porous material can be used for adsorbing and purifying organic pollutants.

Owner:BEIJING SIDAAN NEW MATERIAL TECH

Quartz sand filter material with excellent oleophylic and hydrophobic properties and preparation method thereof

InactiveCN112807847AHas the ability to removeGood lipophilic and hydrophobicFatty/oily/floating substances removal devicesOther chemical processesLipophilicityHydroxymethyl

The invention relates to a quartz sand filter material with excellent oleophylic and hydrophobic properties and a preparation method thereof. The quartz sand filter material is obtained by performing surface modification on quartz sand through a surface modification liquid, then performing self-assembly of a molecular film through a self-assembly liquid, and finally performing composite modification through an iron-copper modification liquid. The surface modification liquid is mainly prepared from the following components by mass: 390-400 parts of anhydrous ethanol, 25-28 parts of tris(hydroxymethyl)aminomethane, 1.5-1.6 parts of nano zinc oxide and 0.002-0.003 part of dopamine hydrochloride; the self-assembly liquid is mainly prepared from the following components by mass: 5-20 parts of a coupling agent and 80-100 parts of a solvent. According to the quartz sand filter material with excellent oleophylic and hydrophobic properties and the preparation method thereof, the formula is reasonable, the quartz sand filter material which is high in surface roughness, has a super-hydrophobic surface, is excellent in lipophilicity and high in oil removal efficiency and has the capacity of removing micro-pollutants in water is prepared, the preparation process is simple, large-scale production is easy, and the application prospect is wide.

Owner:徐州康纳高新材料科技有限公司

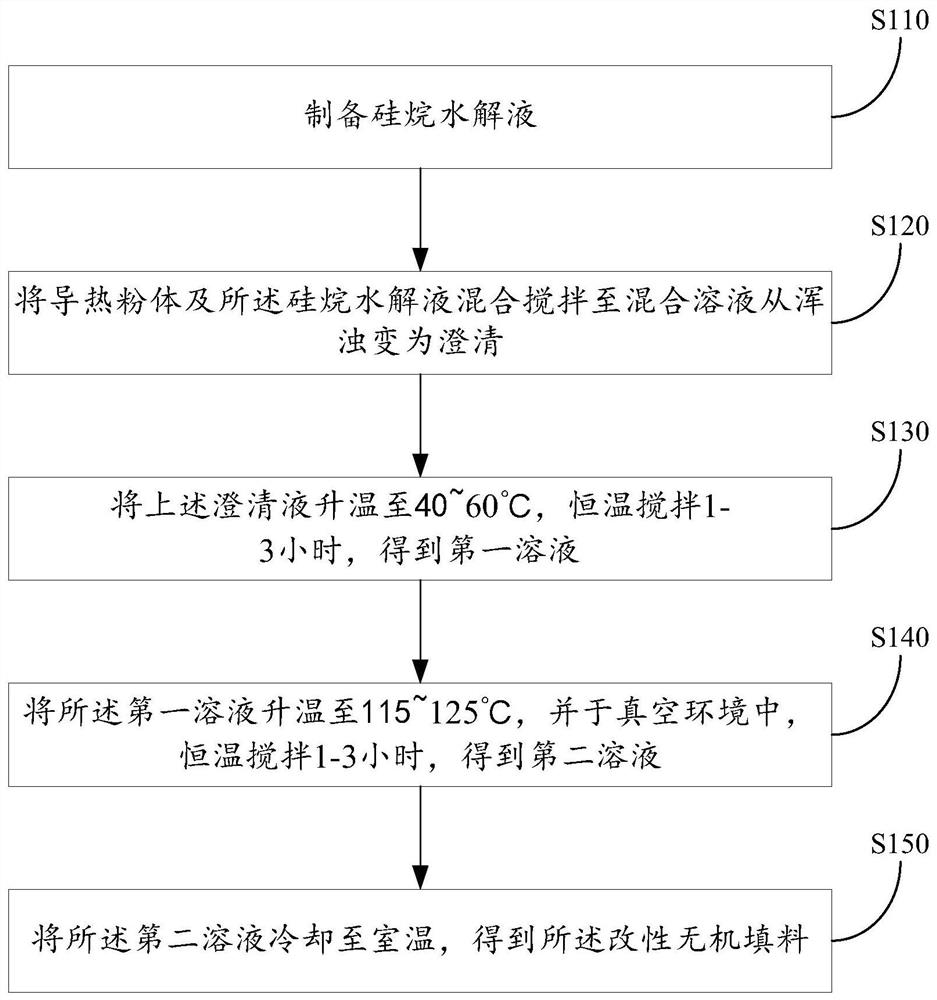

Preparation method of modified inorganic filler, modified inorganic filler and heat-conducting gel

PendingCN113667325AGood flexibilityGood lipophilic and hydrophobicHeat-exchange elementsPigment treatment with organosilicon compoundsHydrolysateResin matrix

The invention provides a preparation method of a modified inorganic filler, which comprises the steps of mixing and stirring heat-conducting powder and the silane hydrolysate until a mixed solution becomes clear from turbid, heating the clear solution to 40-60 DEG C, stirring for 1-3 hours at a constant temperature to obtain a first solution, heating the first solution to 115-125 DEG C, stirring for 1-3 hours at a constant temperature in a vacuum environment, obtaining a second solution, cooling the second solution to the room temperature, and obtaining the modified inorganic filler. According to the preparation method of the modified inorganic filler, through modification of special silane, long-chain functional groups with good compatibility are grafted to the surface of the heat-conducting powder, the modified inorganic filler has more excellent oleophylic and hydrophobic performance and is more tightly combined with a resin matrix, and the flexibility of the material is improved. In addition, the invention also provides a modified inorganic filler and heat-conducting gel.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

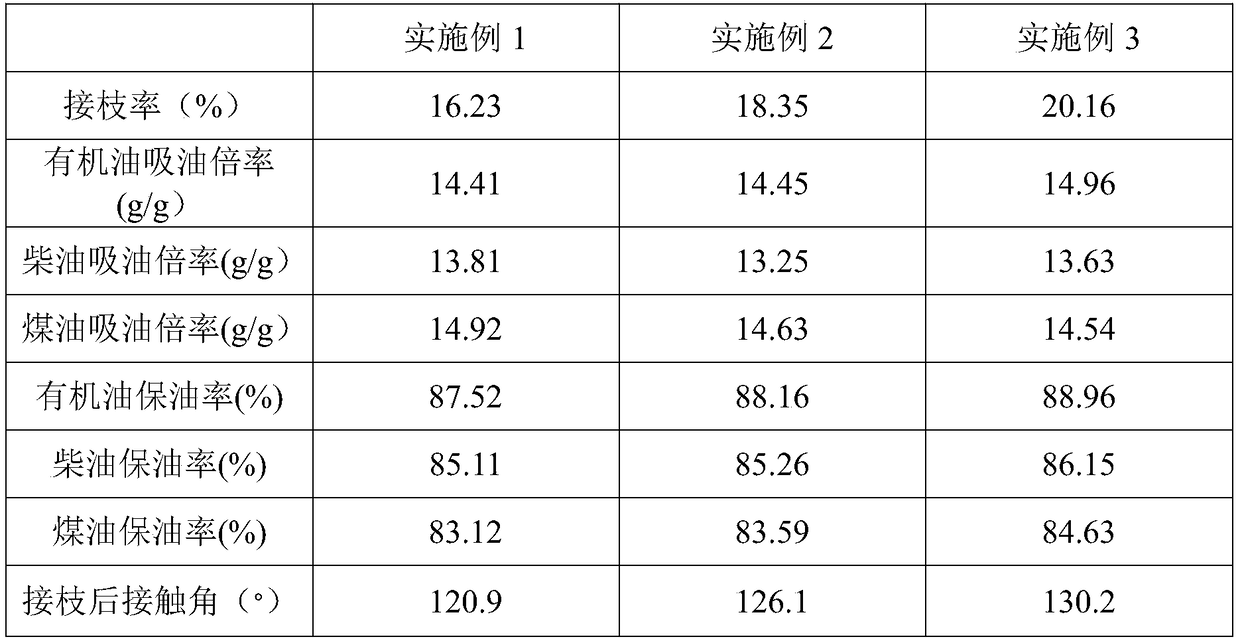

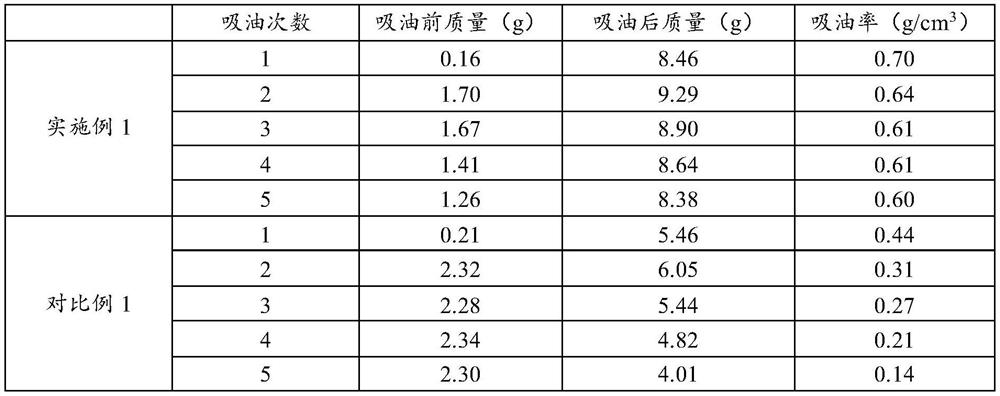

Preparation method of high efficient oil storage type oil absorbent felt material

InactiveCN110124621AEasy to manufactureImprove oil storage capacityOther chemical processesNon-miscible liquid separationOysterResin-Based Composite

The invention discloses a preparation method of a high efficient oil storage type oil absorbent felt material, and belongs to the field of oil pollution treatment. Oyster mushroom bran is processed byplasma to increase the content of polar groups on the surface so as to improve the lipophilic property and oil adsorption performance; methyl methacrylate and butyl acrylate are used to prepare composite resin, which can increase the oil absorption amount and has good mechanical stability and lipophilic-hydrophobic properties; processed chitosan is added to enhance the oil absorbing performance of the oil absorbent felt material, moreover, chitosan has excellent thermal stability and a good solid-solid phase change performance; when the oil absorbent felt material is used in an environment with a large temperature difference, during the solid-solid phase change process, the chitosan can maintain a relatively stable volume in the oil absorbent felt material, and thus other components can well exert their functions. The problem that the oil absorbing performance and oil storage performance of a conventional oil absorbent felt are not good is solved.

Owner:陈文涛

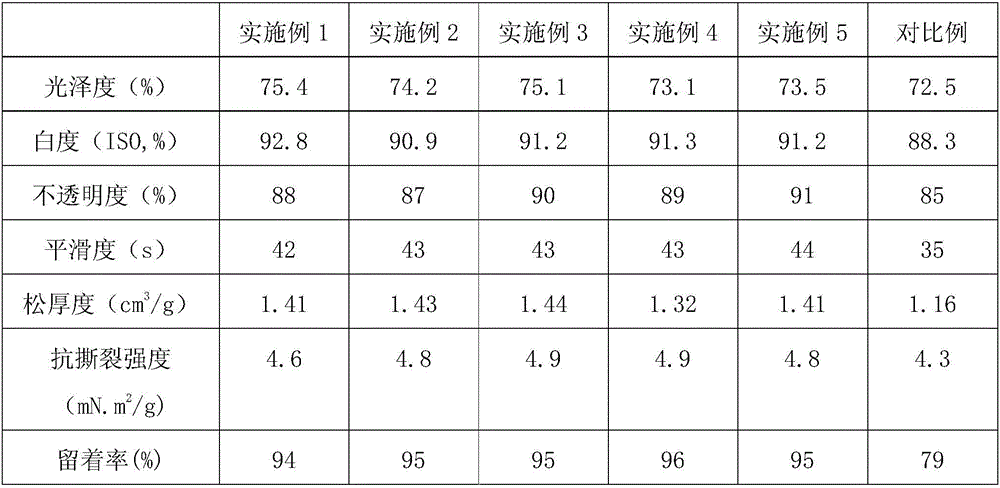

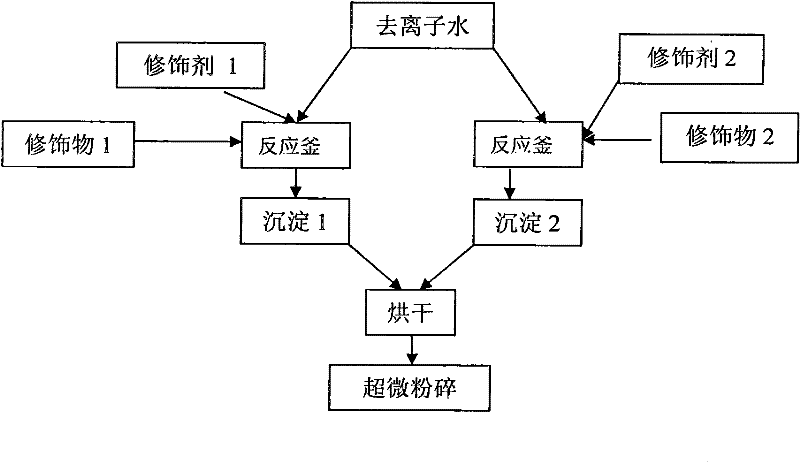

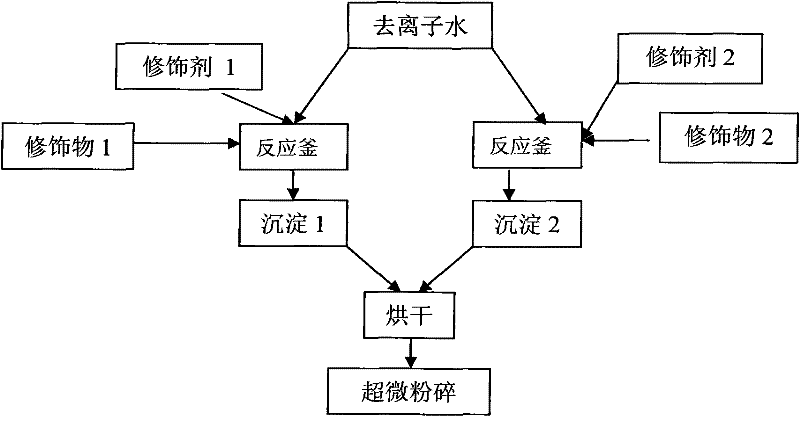

Paper preparation method using modified calcium carbonate as filler

InactiveCN107524032AHigh burst resistanceShort reaction timeInorganic compound additionRaw material divisionStarch solutionChemistry

The invention belongs to the field of paper preparation, and relates to a paper preparation method using modified calcium carbonate as filler. The method includes the following steps that 1, after paper pulp raw materials are placed in water of 90-95 DEG C for soaking for 1.5-3 hours, and a coupling agent is added for beating; 2, light calcium carbonate is prepared into calcium carbonate suspension with the concentration of 40-55%; 3, cationic starch is prepared into starch suspension with the concentration of 50-65%, and then gelatinization is conducted for 20-30 min; 4, the pH value of the gelatinized starch solution is regulated to 8-10, a sodium stearate solution with the concentration of 10-15% is added, and a composite is formed; 5, the composite is added in the calcium carbonate suspension, a dispersant is added, precipitates are obtained, and the precipitates are mixed and stirred for 40-50 min at 75-85 DEG C and 250-300 r / min. By means of the method, the strength of paper can be improved, the smoothness of paper is increased, and the printing performance of paper is improved.

Owner:广西华洋矿源材料有限公司

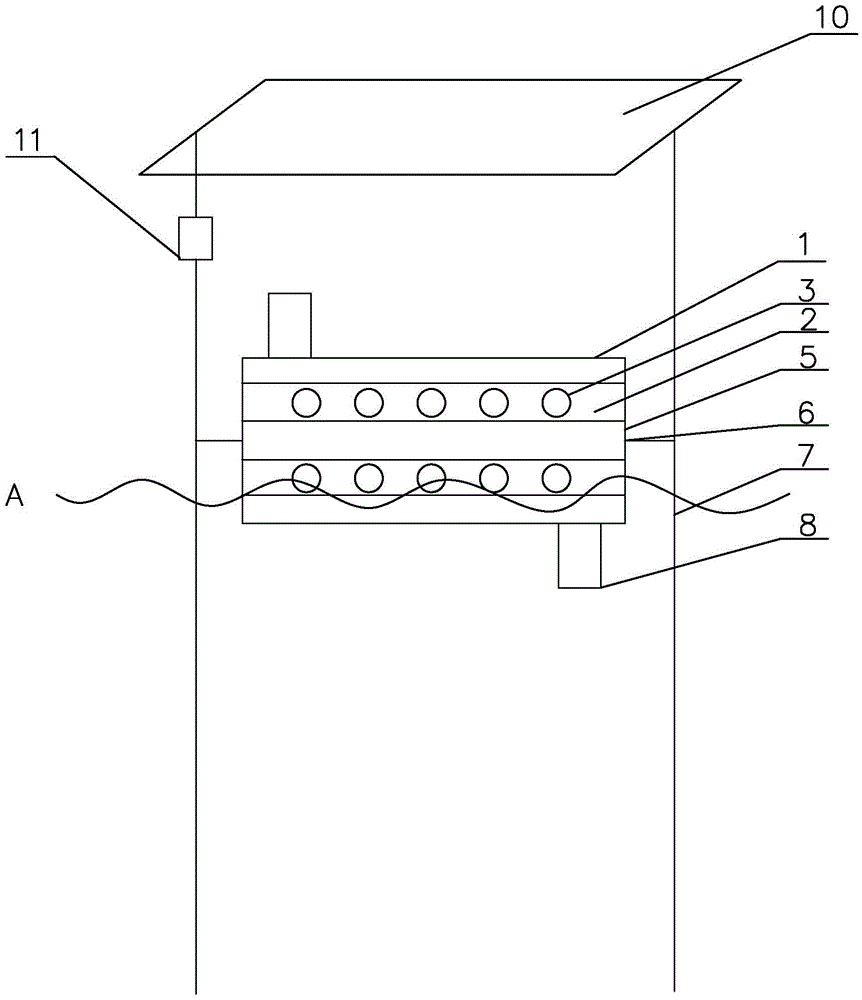

Device for removing riverway floating oil through solar energy photolysis

ActiveCN105621528ALow running costEasy maintenanceWater cleaningFatty/oily/floating substances removal devicesElectricityEngineering

The invention discloses a device for removing riverway floating oil through solar energy photolysis. The device comprises a support, a body, a solar cell panel and a storage battery. The body is erected on the support and movably connected with the support, the solar cell panel is arranged above the body, and the storage battery is electrically connected with the solar cell panel. The body comprises a hollow barrel, a sealing cover and multiple blades. Ultraviolet tubes electrically connected with a positive electrode and a negative electrode of the solar cell panel and a positive electrode and a negative electrode of the storage battery are arranged in the hollow barrel. The outer surface, covered with an oleophilic layer, of the hollow barrel is provided with axial grooves with through holes formed in the bottoms, the through holes stretch inwards in the radial direction to form hollow conical barrels with holes formed in the tops, the bottoms of the hollow conical barrels are arranged on the inner wall of the hollow barrel and provided with open holes right opposite to the corresponding through holes, and the side wall faces, irradiated by the ultraviolet tubes, of the hollow conical barrels are covered with photocatalytic materials. At least one openable sealing cover covers the two ends of the hollow barrel. The blades protrude outwards in the radial direction from the outer surface of the hollow barrel. No power device is needed, and the device is high in oil removal efficiency, simple in structure, low in price, convenient to use and low in maintenance cost.

Owner:NINGBO DAHONGYING UNIV

Method for modifying nano silica

InactiveCN108559311AGood dispersionImprove stabilityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsSucroseWeather resistance

The invention discloses a method for modifying nano silica, which comprises the following steps of: adding nano silica into water, and stirring and uniformly mixing to obtain a nano silica slurry; delivering the nano silica to a surface treatment machine, heating to and then adding a first surface treatment agent, the first surface treatment agent described is composed of saturated fatty acid andfatty alcohol polyoxyethylene ether sodium sulfate, stirring to complete the first surface modification of the nano silica; the modified nano silica through dehydration, drying, pulverization and classification to obtain the nano silica powder; then delivering the nano silica to a high-speed mixer, controlling the temperature of the material , adding a second surface treatment agent which is composed of the alkylphenol polyoxyethylene ether sodium sulfate and the acrylic rosin polyoxyethylene sucrose ester , high-speed stirring uniformly, carrying out the discharging and drying , and obtainingthe modified nano silica . The nano silica modified by the method not only has good dispersibility, good stability, but also has excellent weather resistance, oxidation resistance, storage stabilityand processing flow property.

Owner:广西高企科技有限公司

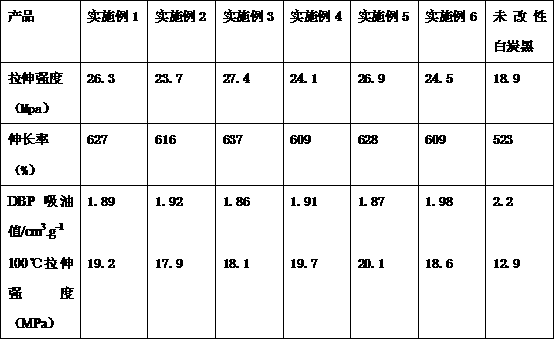

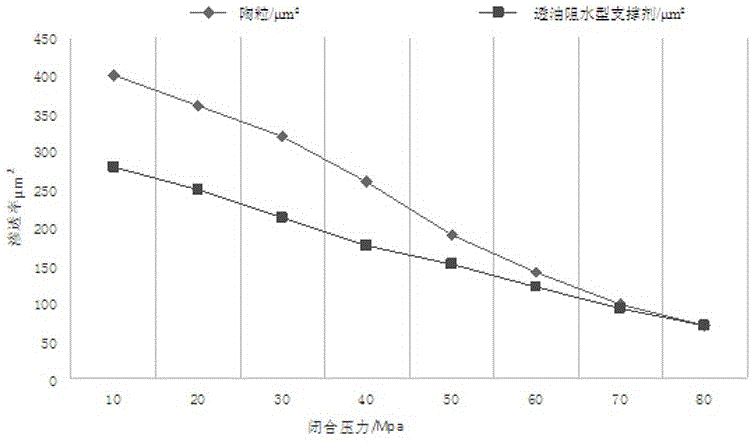

Oil-permeable water-blocking type propping agent and preparation method thereof

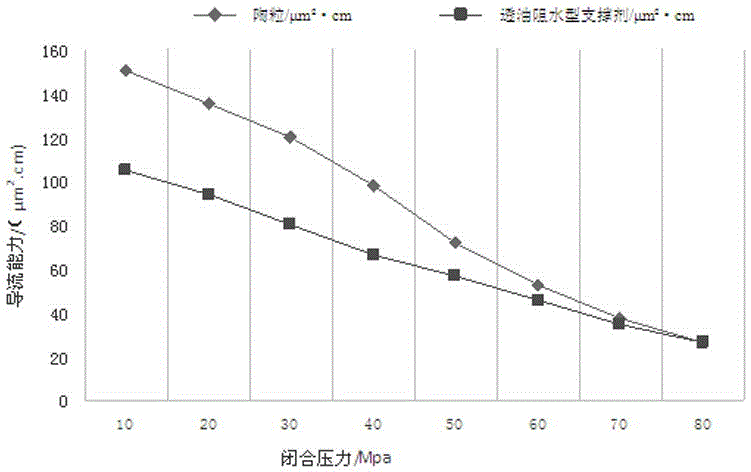

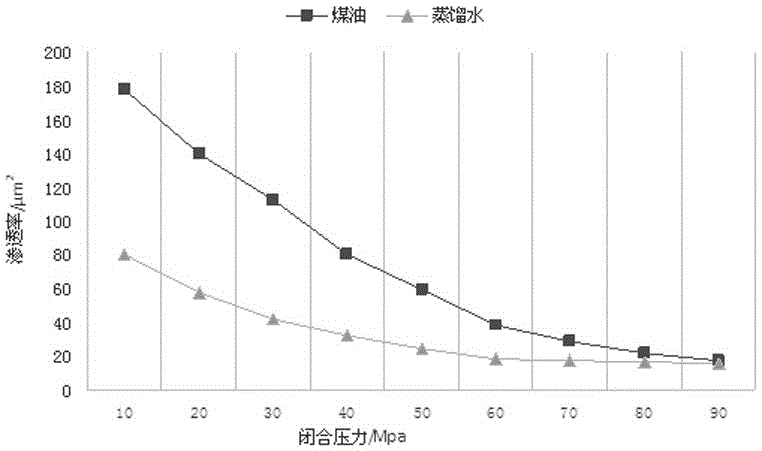

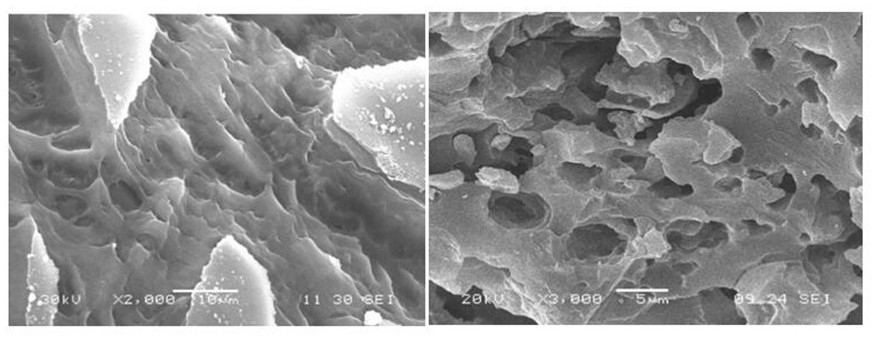

InactiveCN106190091AIncrease oil outputImprove diversion capacityFluid removalDrilling compositionPlasticizerThermal insulation

The invention discloses an oil-permeable water-blocking type propping agent and a preparation method thereof. Firstly, a polyurethane curing agent and nano-particles are added into the polyurethane solution, the mixture is subjected to ultrasonic dispersion for 20-40 minutes to obtain a suspension solution with dispersed nano-particles; a silane coupling agent, a thermoplastic resin, a plasticizer, a coloring agent and an amine curing agent are added into the aggregate in turn under the conditions of 110-200 DEG C thermal insulation and stirring, the mixture is stirred for 5-10 min and then a dispersing agent is added, the mixture is continuously stirred until the dispersing agent is uniformly dispersed, discharging, cooling and sieving are performed to obtain a coated propping agent; the coated propping agent is arranged in the suspension solution with dispersed nano-particles, soaked for 30 min, then filtered and dried to obtain the oil-permeable water-blocking type propping agent. The propping agent has good lipophilicity and hydrophobicity, the oil yield of crude oil is increased, the flow guiding capacity of the crude oil is greatly improved, the oil exploitation is facilitated, and the propping agent is very important for improving the yield and grade of crude oil in China.

Owner:XINMI WANLI IND DEV

Packing bag coating and preparation method thereof

InactiveCN105315798AAntiseptic and insecticidalHas anti-corrosion effectAntifouling/underwater paintsRosin coatingsFiberCellulose

The invention discloses a packing bag coating and a preparation method thereof. The packing bag coating comprises the following raw materials by weight: 1 to 2 parts of tung oil, 1 to 2 part of tung oil anhydride, 0.3 to 0.5 part of a silane coupling agent, 20 to 40 parts of calcium carbonate, 15 to 25 parts of polypropylene, 10 to 20 parts of permethrin, 5 to 10 parts of cellulose base fiber, 5 to 10 parts of alanine, 3 to 7 parts of talcum powder, 2 to 5 parts of nano titanium dioxide, 1 to 2 parts of isobutyl methacrylate, and 5 to 7 parts of rosin resin. The preparation method comprises the steps of grinding, modifying, stirring and drying. After being treated with the packing bag coating, the surface of a material is excellent in lipophilic-hydrophobic property; moreover, rosin resin has a forming and enveloping function, and permethrin has corrosion-resistant and insect-killing functions, so that the coating is resistant to corrosion.

Owner:桐城市人和包装有限公司

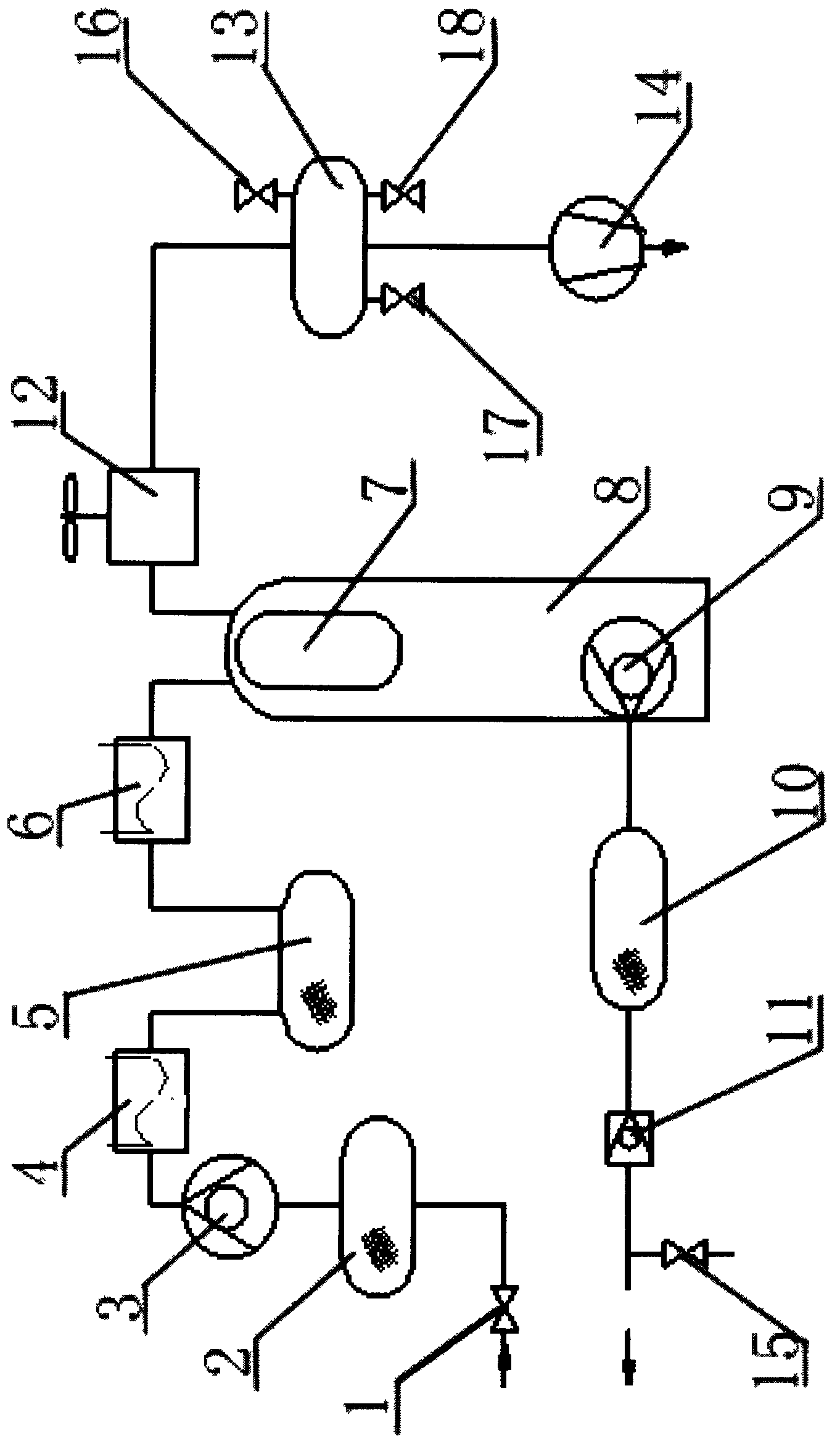

TLY turbine oil vacuum purification device

InactiveCN103566654AImprove cleanlinessGood lipophilic and hydrophobicDewatering/demulsification with mechanical meansFiltration circuitsInlet valveTurbine

The invention discloses a TLY turbine oil vacuum purification device. The TLY turbine oil vacuum purification device comprises an oil inlet valve, a primary filter, an oil absorption pump, a heater, a separation device and an oil drain pump, wherein the oil inlet valve is communicated with the primary filter, the oil absorption pump, the heater and the separation device in sequence; the lower part of the separation device is provided with the oil drain pump; the separation device comprises a vacuum cylinder; a coalescing separator is arranged in the vacuum cylinder; the oil drain pump is communicated with the bottom of a vacuum pump; the heater is communicated with the coalescing separator in the vacuum cylinder; the top of the vacuum cylinder is communicated with a defoaming and cooling device through an air cooling condenser. A coalescing and vacuum dewatering technology is used for separating quickly, heating in a circulation manner and demulsifying; due to the combination of air cooling and water cooling condensers, the water is removed completely; a precise filtering cartridge is used for filtering layer by layer in four stages, so that the service life of the filtering cartridge is prolonged, and the requirement of filtering precision is ensured; the device is capable of operating synchronously with steam turbine generator sets and purifying the stored turbine oil.

Owner:江苏能建机电实业集团有限公司

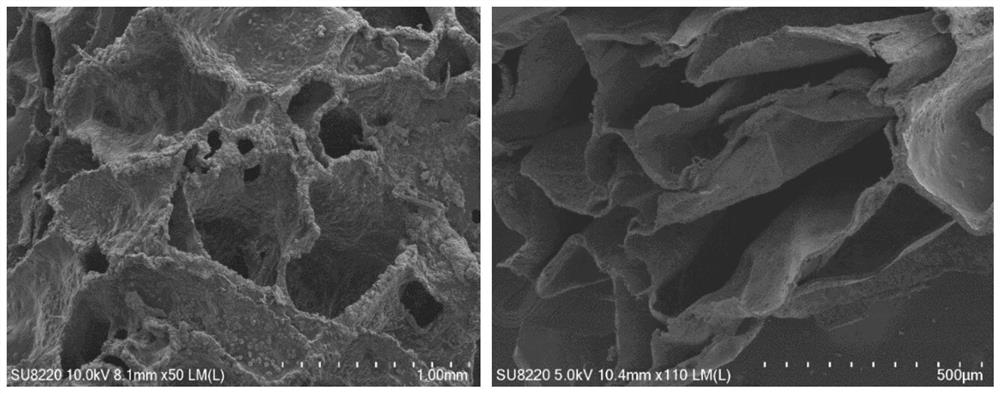

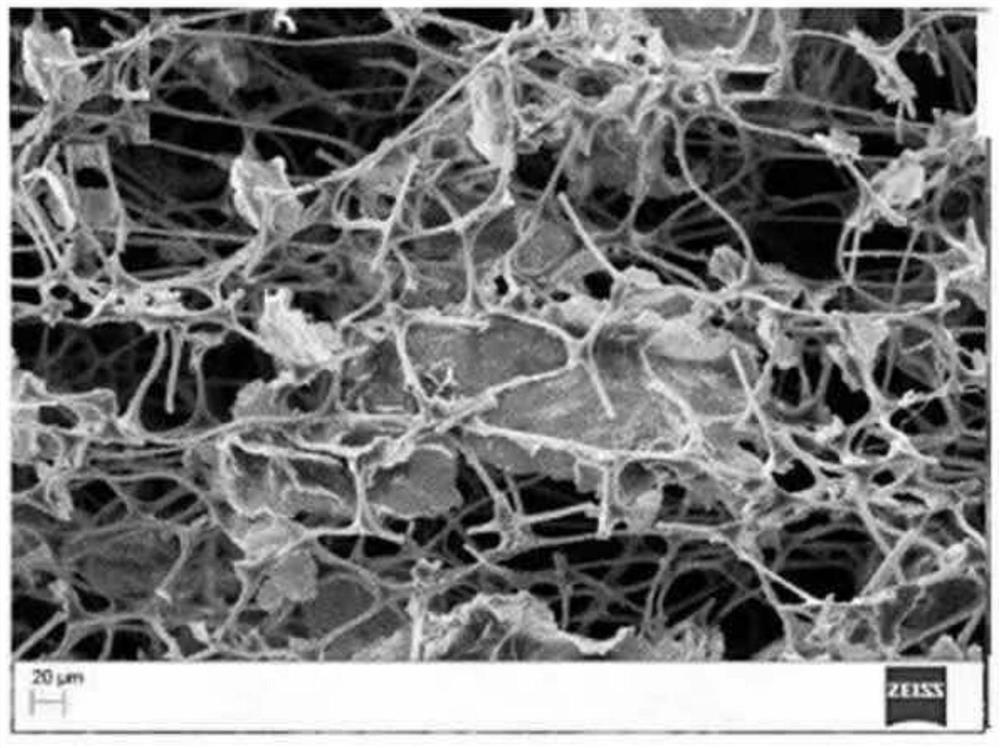

A kind of hydrophobic lignin/cellulose airgel oil-water separation material and its preparation method and application

ActiveCN112480464BWide variety of sourcesImprove oil absorption capacityLiquid separationCelluloseCross linker

The invention belongs to the technical field of environmental protection materials, and specifically discloses a hydrophobic lignin / cellulose airgel oil-water separation material and a preparation method and application thereof. The preparation method comprises the following steps: adding lignin and cellulose to an alkaline solution to obtain a lignin / cellulose mixed solution; adding a crosslinking agent to obtain a lignin / cellulose composite hydrogel; solvent exchange and drying The elastic airgel is obtained, and then the elastic airgel is hydrophobically modified by a chemical vapor deposition method using a silane coupling agent to obtain a hydrophobic lignin / cellulose airgel. The lignin / cellulose airgel oil-absorbing material prepared before and after hydrophobic modification has a highly porous network structure, and the prepared oil-absorbing material is placed in an oil-water mixture, and the absorption rate is as high as 10 to 25 times its own weight. After the oil is absorbed, the oil can be extruded by extrusion, and the oil-absorbing material can be regenerated, and the recycling still has a high oil-absorbing efficiency.

Owner:图们市华威友邦化工有限公司

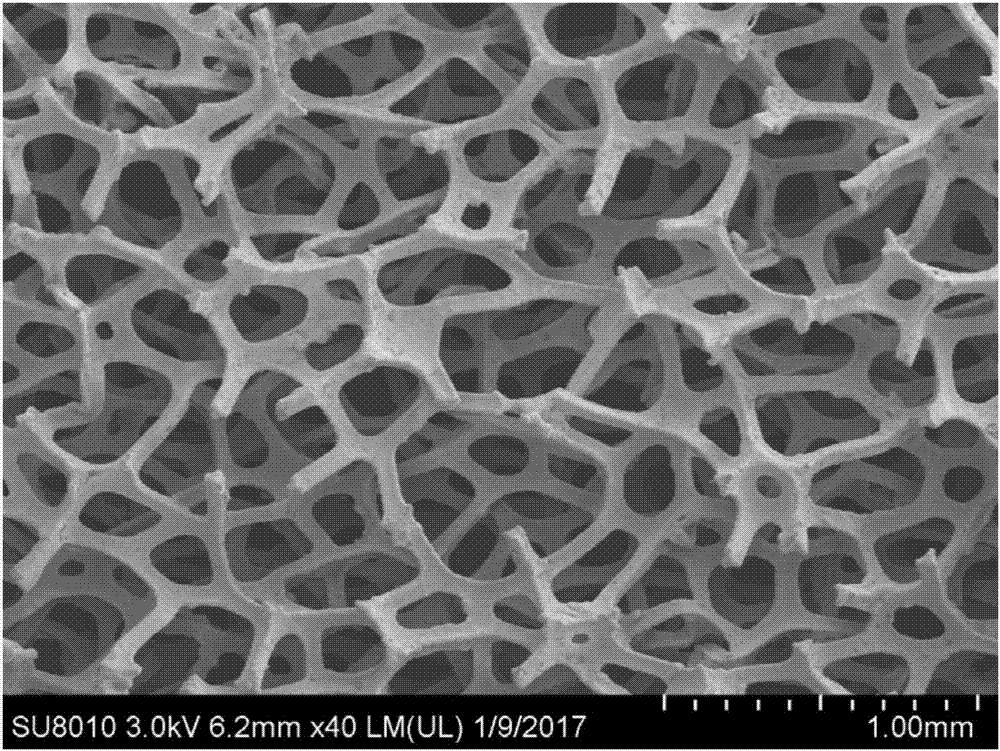

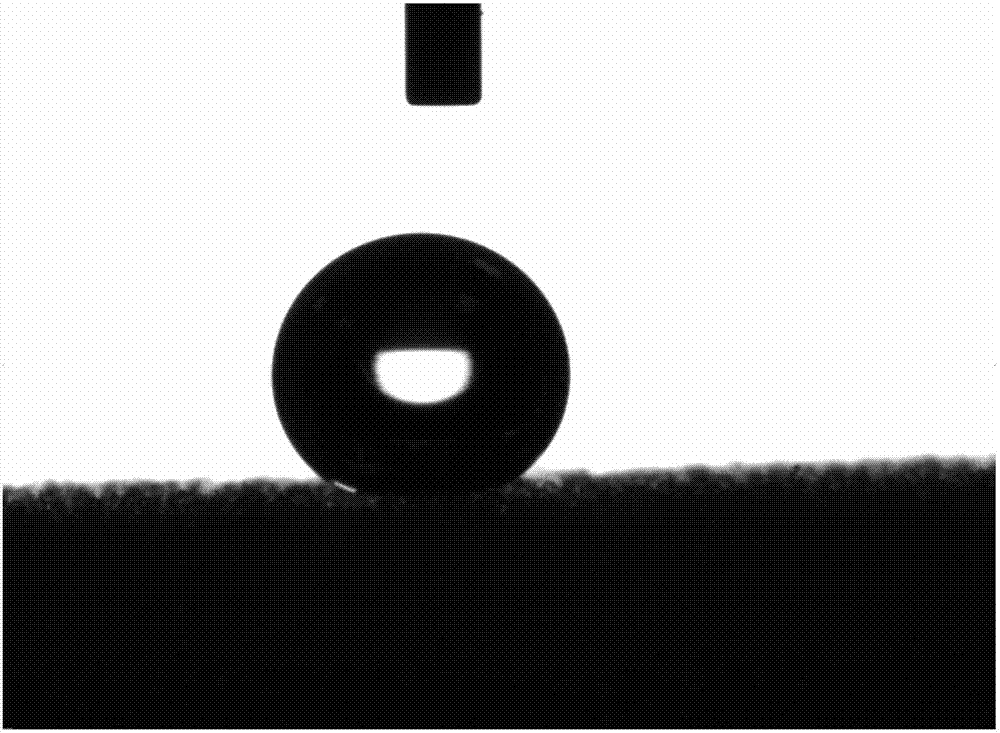

Porous metal material having lipophilicity and hydrophobicity and preparation method of same

InactiveCN107159090AOleophilic and hydrophobicGood lipophilic and hydrophobicOther chemical processesWater contaminantsSolventLipophilicity

The invention belongs to the field of surface functional modification of materials and particularly relates to a porous metal material having lipophilicity and hydrophobicity and a preparation method of same. The preparation method includes the steps of: soaking a porous metal base material into a mixture liquid prepared from silicon oil, silicon rubber and a solvent, and drying the base material to cure the mixture liquid to prepare the porous metal material having lipophilicity and hydrophobicity, wherein the porous metal base material is a metal fabric material or a metal foam material. The porous metal material has good lipophilicity and hydrophobicity and long service life, has certain strength when being compared with sponge and is higher in permeability than sponge. The preparation method is simple, has short production period, is easy to achieve in industrial production and is prepared from existing industrial products. The porous metal material has stable technology and low cost.

Owner:淄博高新技术产业开发区精细化工和高分子材料研究院 +1

Bentonite surface modification and intercalation technique

ActiveCN101890330BIncrease spacingImprove adsorption capacityOther chemical processesMycotoxinSodium Bentonite

The invention relates to a bentonite surface modification and intercalation technique. In the technique, natural bentonite serving as a base is subjected to surface modification and intercalation, wherein the ion exchange capacity of the natural bentonite is 50 to 150 mmol / 100g; and the bentonite is sodium-based bentonite, calcium-based bentonite or sodium-calcium-based bentonite. The bentonite subjected to the surface modification and the intercalation has the advantages of high adsorption property, high oleophylic and hydrophobic property, capacity of effectively adsorbing harmful substances such as all kinds of mycotoxin and the like in feed, wide application and suitability for the fields of feed production or environmental protection, coating, papermaking, lubricants and the like.

Owner:江苏奥迈生物科技有限公司

Method for extracting and separating vanadium and chromium from vanadium-chromium slag acid leaching solution

InactiveCN107312942BImprove extraction abilityGood lipophilic and hydrophobicProcess efficiency improvementSolubilitySlag

The invention provides a method for extracting and separating vanadium and chromium from the vanadium-chromium slag acid leaching solution, comprising: S1, using the extraction solution to extract the pentavalent vanadium and hexavalent chromium in the vanadium-chromium slag acid leaching solution to the organic phase and then combine with The aqueous phase is separated to obtain an organic phase loaded with vanadium chromium; S2, using a stripping agent to carry out back extraction of the organic phase loaded with vanadium chromium in step S1, after the stripping ends, obtain chromium-containing back raffinate, ammonium metavanadate or ammonium polyvanadate precipitation and regenerated ionic liquid; S3, calcining the ammonium metavanadate or ammonium polyvanadate precipitation obtained in step S2 at 550°C-600°C to obtain vanadium oxide; S4, stripping step S2 The Cr6+ in the remaining liquid is reduced to form Cr3+, and the chromium is precipitated in the form of precipitation after adjusting the pH of the chromium, which is calcined to obtain Cr2O3. The method of the present invention has high extraction efficiency, rapid stratification after extraction, no emulsification phenomenon, and the ionic liquid has good lipophilic and hydrophobic properties, has good solubility in long-chain alcohols, and is basically immiscible with water, which can reduce the Loss of organic phase due to entrainment or dissolution of the aqueous phase.

Owner:NORTHEASTERN UNIV LIAONING

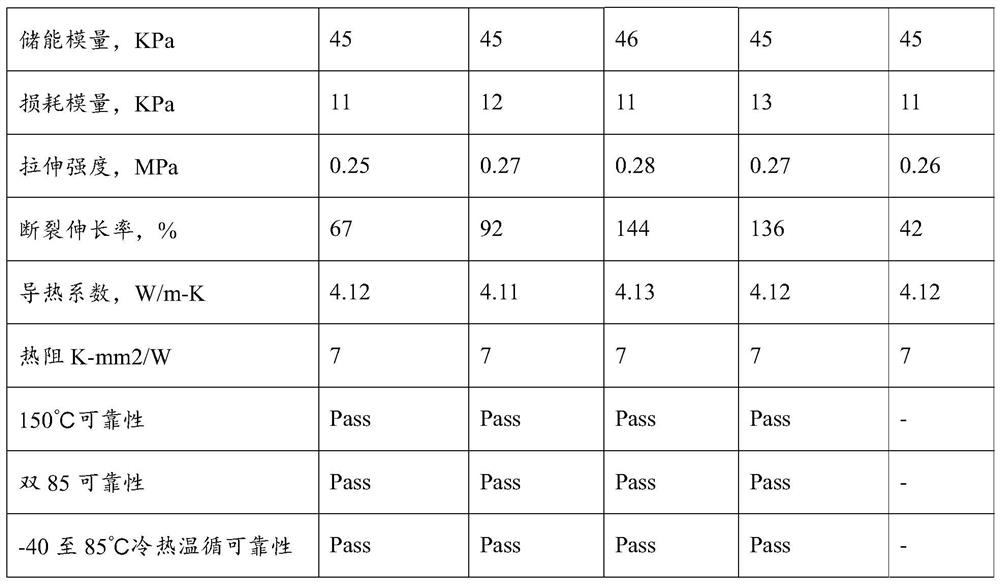

Single-component thermal interface material and preparation method thereof

The invention discloses a single-component thermal interface material and a preparation method thereof. The single-component thermal interface material is prepared from the following raw material components in percentage by mass: 1 to 10 percent of vinyl-terminated polysiloxane, 0.1 to 3.6 percent of terminated hydrogen-containing polysiloxane, 0.1 to 3.4 percent of side hydrogen-containing polysiloxane, 0.01 percent of catalyst, 0.003 percent of inhibitor and 85 to 95 percent of modified filler. The modified filler is silane coupling agent modified heat-conducting powder. The single-component thermal interface material provided by the invention has high thermal conductivity, high elongation, low modulus, low adhesive layer thickness and low thermal resistance, has excellent infiltration performance, can meet the strict requirements of chip packaging process flow and technology, has high application reliability, can provide a proper, stable and healthy working temperature environment for chips, and has wide application prospect. And the service life and efficiency of the chip are improved.

Owner:SHENZHEN INST OF ADVANCED ELECTRONICS MATERIALS

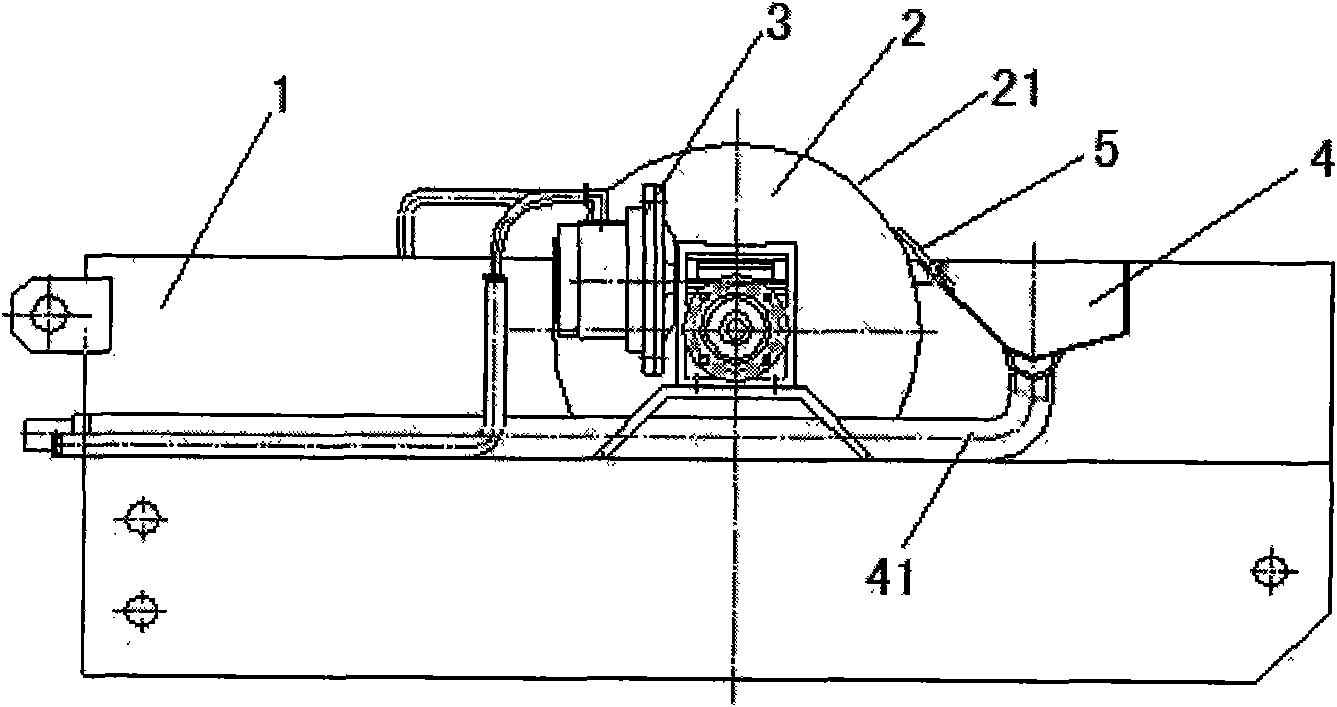

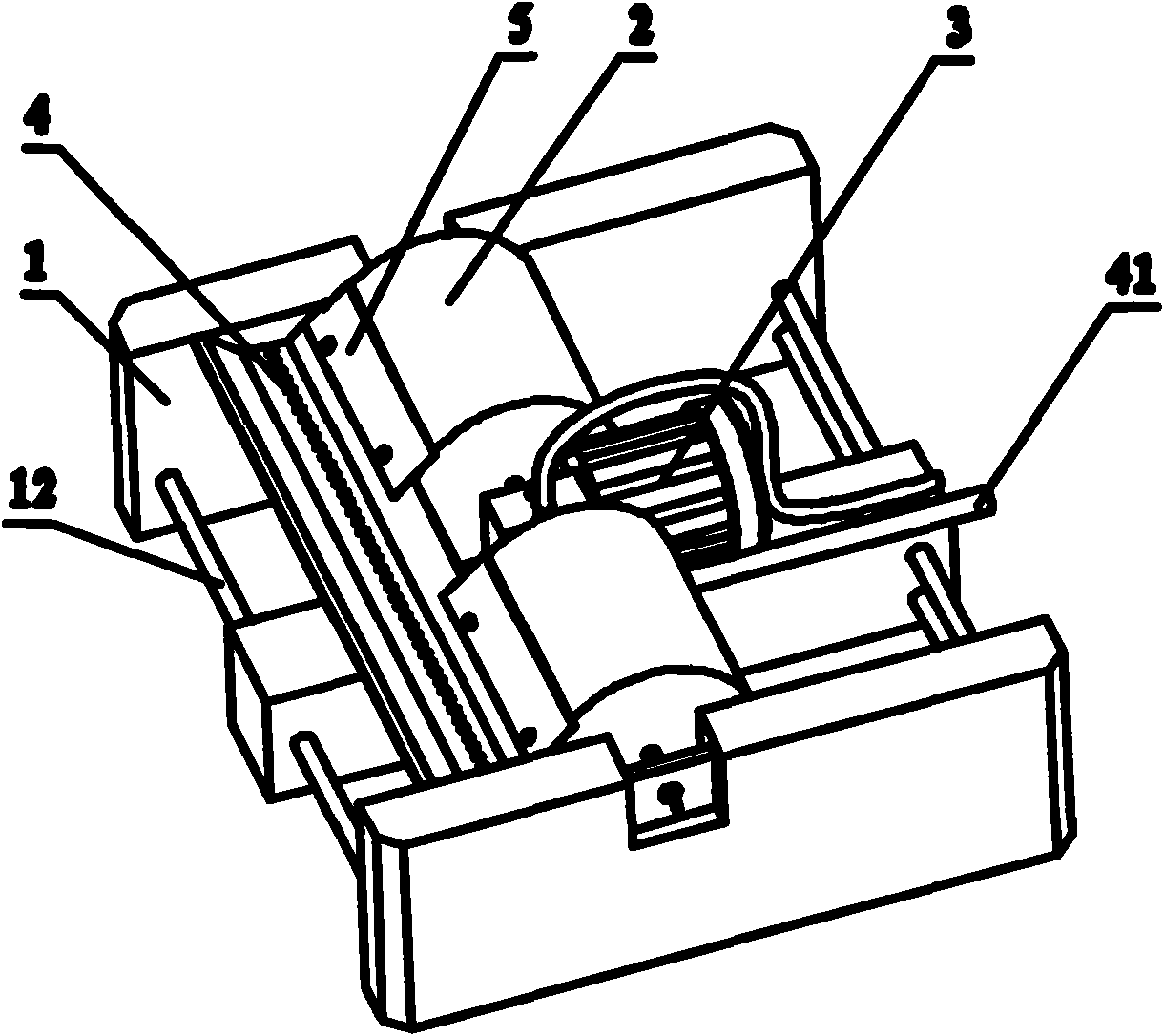

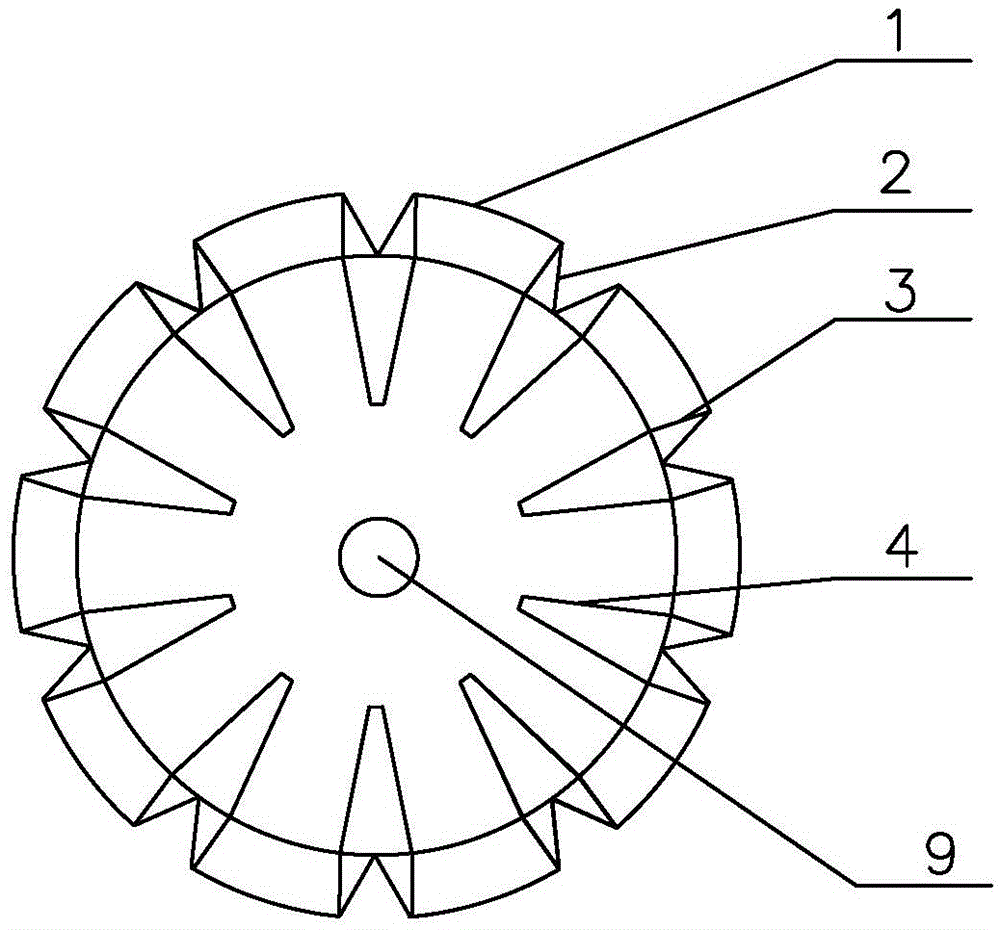

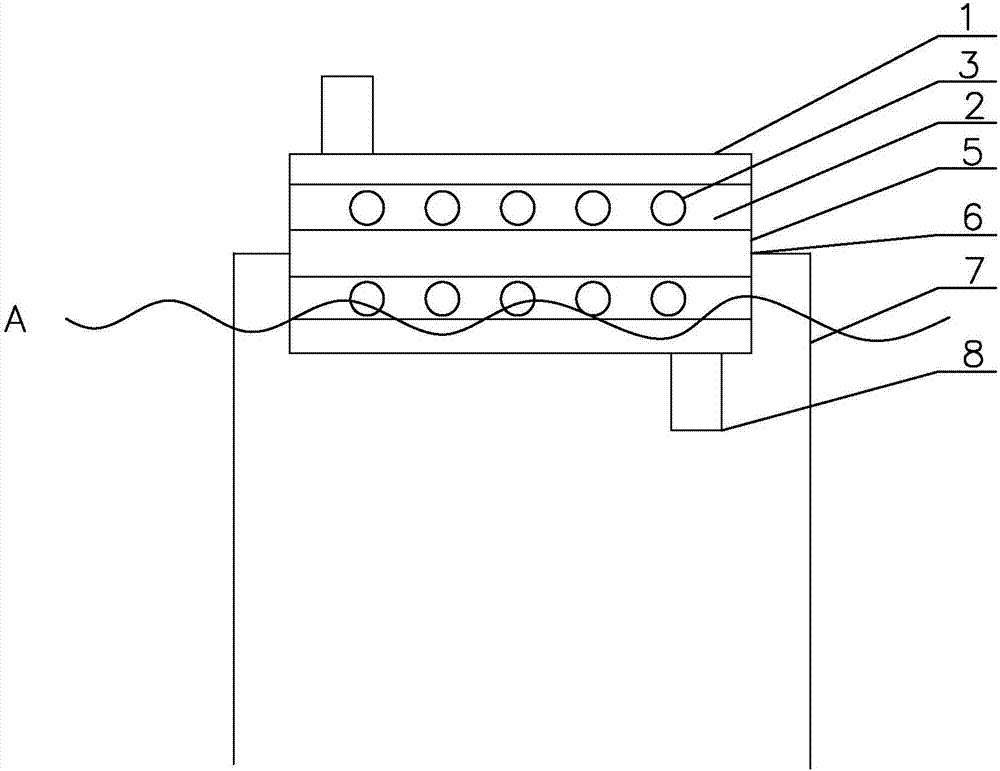

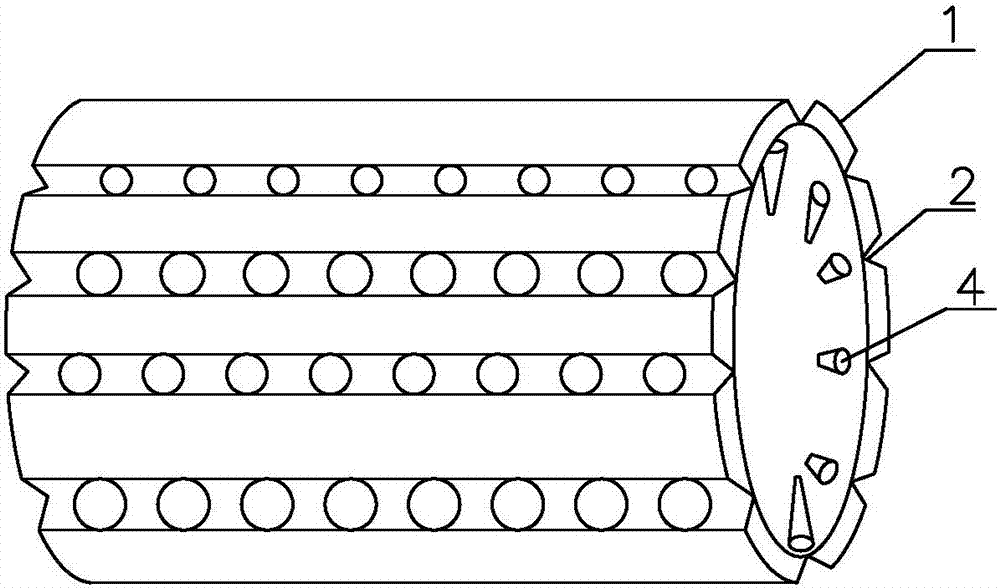

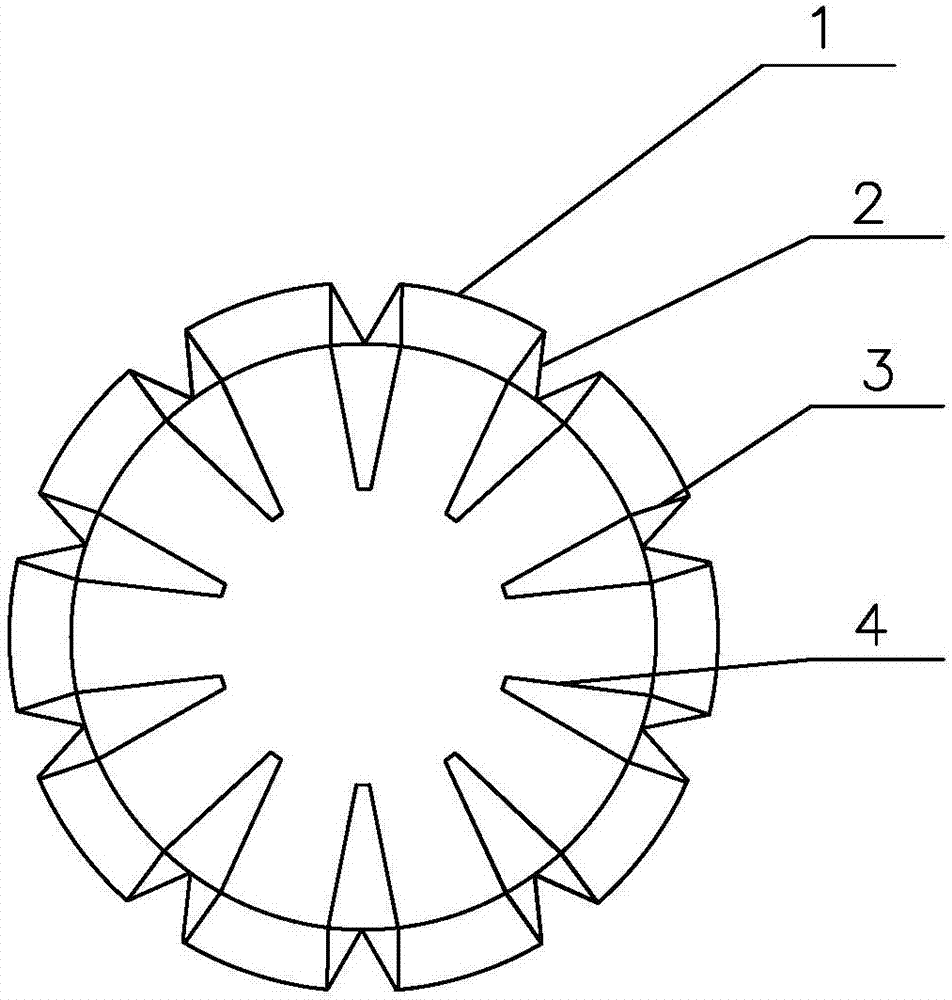

Riverway floating oil removing device

ActiveCN105756023APrevent throwingNo power requiredWater cleaningGeneral water supply conservationEngineeringHollow cylinder

The invention discloses a riverway floating oil removing device which comprises a bracket and a main body, wherein the main body is arranged on the bracket and moveably connected with the bracket and comprises a hollow cylinder, a sealing cover and a plurality of blades; grooves are formed in the axial direction in the outer surface of the hollow cylinder; through holes are formed in the bottoms of the grooves; the outer surface of the hollow cylinder and the surfaces of the grooves are all covered by oleophilic layers; one hollow conical cylinder extends inwards in the radial direction of each through hole in the inner wall of the hollow cylinder; the bottom of each hollow conical cylinder is arranged on the inner wall of the hollow cylinder; holes are formed in the bottom and the top of the hollow conical cylinder and are right aligned to the corresponding through holes; the sizes of the holes are not smaller than those of the corresponding through holes; sealing covers are arranged at two ends of the hollow cylinder; at least one of the sealing covers can be opened; blades protrude outwards in the radial direction on the outer surface of the hollow cylinder. The riverway floating oil removing device needs no power device, and is high in oil removing efficiency, simple in structure, low in price, moveable, convenient to use and low in maintenance cost.

Owner:NINGBO DAHONGYING UNIV

Graphene-based sponge as well as preparation method and application thereof

InactiveCN113736133AGood lipophilic and hydrophobicEasy to operateFatty/oily/floating substances removal devicesLiquid separationPolymer scienceOrganosolv

The invention relates to the technical field of environment-friendly materials, in particular to graphene-based sponge and a preparation method and application thereof. The preparation method of the graphene-based sponge comprises the following steps: performing ultrasonic treatment on a mixture of dispersion liquid of graphene oxide and polyurethane sponge to obtain the polyurethane sponge loaded with the graphene oxide; and then carrying out heating treatment on the polyurethane sponge loaded with the graphene oxide; wherein the temperature of the heating treatment is 140-220 DEG C, and the time of the heating treatment is 5-20 hours. The preparation method of the graphene-based sponge is green, non-toxic, environment-friendly and simple to operate, and the obtained graphene-based polyurethane sponge material has excellent oleophylic and hydrophobic properties, can be repeatedly used after being regenerated, and has a very good treatment effect on sewage containing oily substances and / or organic solvents.

Owner:北京美斯顿科技开发有限公司

A self-suspending proppant for clear water fracturing system

ActiveCN106147746BGood suspensionIncrease oil outputDrilling compositionStarch gelatinizationGuar gum

The application belongs to the technical field of oil and gas exploitation, and in particular relates to a proppant with relatively high self-suspension ability applied to a clear water fracturing system. The self-suspending proppant is prepared through multiple steps of starch gelatinization, hydrogel preparation, mixing resin preparation, proppant preparation and the like. Compared with the existing proppant products, the present invention gets rid of the restriction that the traditional proppant must rely on the use of guar gum and drag-reducing agent. When the proppant provided by the present invention is used, the proppant can be directly transported to the corresponding formation by natural water. The proppant product provided by the present invention can not only reduce the cost of fracturing in the process of oil and gas exploitation, but also reduce the damage to the formation environment in the process of oil and gas exploitation due to the good environmental performance of the material, and it has a certain improvement The advantages of oil and gas production, so it has good promotion and application value.

Owner:XINMI WANLI IND DEV

Preparation method for high-friction oil strain-accommodating wiping material

InactiveCN109181005AImprove surface friction performanceImprove friction performanceCarpet cleanersOther chemical processesPorosityMaterials preparation

The invention discloses a preparation method for a high-friction oil strain-accommodating wiping material and belongs to the technical field of wiping material preparation. According to the preparation method, after purified algal cellulose is added into a precursor sol, the purified algal cellulose can slowly absorb water and swell; mullite whiskers can grow in the swelling purified algal cellulose during an ageing process; under high temperature, the instantaneous temperature on a friction surface is higher, and meanwhile, a softer material is generated and transferred to the friction surface of a harder material, so as to form a transferring film on the friction surface; yeast fermentation modification is adopted by the preparation method, and the blind holes and inner channels of the fiber sponge can be simultaneously opened by oily substances, such as a dimethyl silicone polymer, under the microbial action; the algal cellulose aerogel according to the invention has moderate pore size and high porosity; the wiping material provided by the invention comprises the main components as follows: plant cellulose, mountain flour sol and common nontoxic organic matters; a large amount of wastewater and slags are avoided in the production process; the preparation method has a wide application prospect.

Owner:赵建平

Processing method of perlite oil absorbent for absorbing oil on water surface

ActiveCN107262022BGood lipophilic and hydrophobicNo damage reductionOther chemical processesAlkali metal oxides/hydroxidesPhysical chemistryManganese oxide

The invention discloses a method for processing perlite oil absorbent used for absorbing oil dirt on water surface. The method comprises the following steps: 1) selecting the components according to the mass percentage of 72-75% of silica, 15-18% of alumina, 0.5-1% of iron oxide, 2.9-3.5% of sodium oxide, 0.5-2% of calcium oxide, 2.5-3% of potassium oxide, 0.1-0.4% of manganese oxide, and 4-6% of moisture, screening the perlite ore sands with appropriate granularity of 0.2-0.5 mm as a raw material; 2) placing the perlite ore sand in a preheating furnace for preheating; 3) placing the preheated perlite ore sand in an expansion furnace for high-temperature roasting to reach instant expansion; and S4) performing film-coating modification on the particles surface for the expanded perlite ore sand to prepare the perlite oil absorbent used for absorbing oil dirt on water surface. The perlite oil absorbent particles have the advantages of light weight and high porosity, can suspend on the water surface for long time, and have high floating oil rate on the adsorbed water surface, and the adsorbed floating oil can be effectively recovered and used.

Owner:广东盛达穗南环保科技有限公司

A kind of preparation method of lipophilic hydrophobic membrane-covered proppant

InactiveCN104277821BIncrease oil outputIncrease productionFluid removalDrilling compositionProduction ratePlasticizer

The invention discloses a preparation method of an oleophilic hydrophobic coated proppant. The method comprises the following steps: 1) mixing a thermoplastic resin and petroleum asphalt, heating to 70-100 DEG C, melting, stirring and compounding to obtain a compounded resin; and weighing 20-40-mesh quartz sand and haydite aggregate, adding into a resin sand mill, heating to 140-230 DEG C, sequentially adding a silane coupling agent, the compounded resin, a plasticizer and an amine curing agent while stirring, adding a dispersing agent when a dispersion evidence occurs, discharging, cooling, and screening to obtain the oleophilic hydrophobic coated proppant. After adding the asphalt, the coated proppant product has favorable oleophilicity and hydrophobicity, has higher flow conductivity in crude oil than the traditional coated proppant, is beneficial to petroleum exploitation, enhances the oil output of the crude oil, and has crucial importance for enhancing crude oil production rate and grade of China.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A river oil slick removal device

ActiveCN105756023BLow running costEasy maintenanceWater cleaningGeneral water supply conservationEngineeringPower unit

The invention discloses a device for removing slick oil in a river course, comprising: a bracket, and a main body erected on the bracket and movably connected with the bracket, the main body includes a hollow cylinder, a sealing cover and several blades, wherein the outer surface of the hollow cylinder is along the A groove is opened in the axial direction, and a through hole is opened at the bottom of the groove. The outer surface of the hollow cylinder and the surface of the groove are covered with an oleophilic layer; A hollow cone is extended inside, the bottom of the hollow cone is set on the inner wall of the hollow cylinder, the bottom and top of the hollow cone are provided with openings, and the bottom openings are facing the corresponding through holes, the size of which is not less than The size of the corresponding through hole; the sealing cover is arranged at both ends of the hollow cylinder, and at least one of them can be opened; the vane protrudes outward from the outer surface of the hollow cylinder in a radial direction. The device does not need to be equipped with a power device, and has high oil removal efficiency, simple structure, low price, movable, convenient use and low maintenance cost.

Owner:NINGBO DAHONGYING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com