A kind of hydrophobic lignin/cellulose airgel oil-water separation material and its preparation method and application

An aerogel oil and separation material technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as environmental pollution, lack of use of lignin value, etc., achieve environmental friendliness, promote development and application, improve The effect of oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

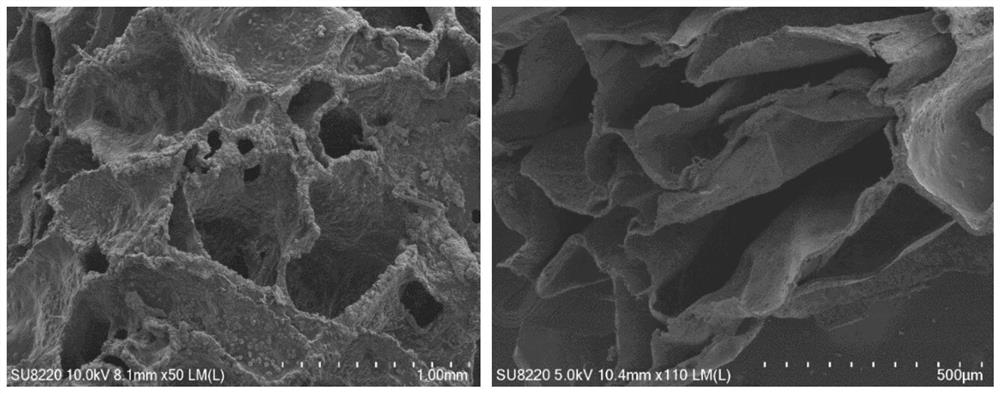

Image

Examples

Embodiment 1

[0035] 5 to 10% by weight of the NaOH solution was prepared from 10 to 20 parts of solvent, and 2 hydroxyethylcellulose were added, 1 hydroxyethyl cellulose, 1 part of the base, and stirred at room temperature to obtain a homogeneous lignin / cellulose composite solution. 1 part of epoxy chloropropane was added at room temperature for cross-linking reaction, and the mixture was placed in a mold at room temperature for 24 h to form lignin / cellulose composite hydrogel. The hydrogel was then placed in anhydrous ethanol solution for 24 h, and then placed in a solvent in deionized water for 2 days, freeze-dried 36 h to obtain a lignin / cellulose composite gas gel at -40 ° C. The preparative lignin / cellulose composite gas gel is cut into 3 cm × 3 cm × 3 cm block, and the airgel and 1 ml of open vials with methyltrimethoxysilane are placed in a closed container at 70 ° C oven. 12h to obtain hydrophobic modified lignin / cellulose composite gas gel oil absorbing materials.

[0036] 0...

Embodiment 2

[0038] 5 ~ 10% by weight of the NaOH solution was prepared from 10 to 20 parts of solvent, 2 parts of hydroxyethyl cellulose, 3 parts of alkalin, and stirred at room temperature for 5 hours to obtain a uniform lignin / cellulose composite solution. 1 part of epoxy chloropropane was added at room temperature for cross-linking reaction, and the mixture was placed in a mold at room temperature for 24 h to form lignin / cellulose composite hydrogel. The hydrogel was then placed in anhydrous ethanol solution for 24 h, and then placed in a solvent in deionized water for 2 days, freeze-dried 36 h to obtain a lignin / cellulose composite gas gel at -40 ° C. The prepared lignin / cellulose composite gas gel is cut into 3 cm × 3 cm × 3 cm block, and the airgel and 1 ml of methyltrimethoxysilane are placed in a closed container at 70 ° C oven at 70 ° C. To obtain hydrophobic modified lignin / cellulose composite gas gel oil absorbing materials.

[0039] The prepared gas gel oil was placed in...

Embodiment 3

[0041]5 to 10% by weight of the NaOH solution was prepared from 10 to 20 parts of solvent, and 2 hydroxyethylcellulose were added, 10 parts of alkali lignin, and stirred at room temperature for 5 h to obtain a uniform lignin / cellulose composite solution. 1 part of epoxy chloropropane was added at room temperature for cross-linking reaction, and the mixture was placed in a mold at room temperature for 24 h to form lignin / cellulose composite hydrogel. The hydrogel was then placed in anhydrous ethanol solution for 24 h, and then placed in a solvent in deionized water for 2 days, freeze-dried 36 h to obtain a lignin / cellulose composite gas gel at -40 ° C. The prepared lignin / cellulose composite gas gel is cut into 3 cm × 3 cm × 3 cm block, and the airgel and 1 ml of methyltrimethoxysilane are placed in a closed container at 70 ° C oven at 70 ° C. To obtain hydrophobic modified lignin / cellulose composite gas gel oil absorbing materials.

[0042] 0.5 g of the prepared gas gel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com