Ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method

A technology of melt-blown polypropylene and non-woven fabrics, which is applied in the field of ultraviolet compounded melt-blown polypropylene oil-absorbing non-woven fabrics and its preparation, which can solve the problems of narrow application range and achieve complete oil absorption performance, large pores, and low UV energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

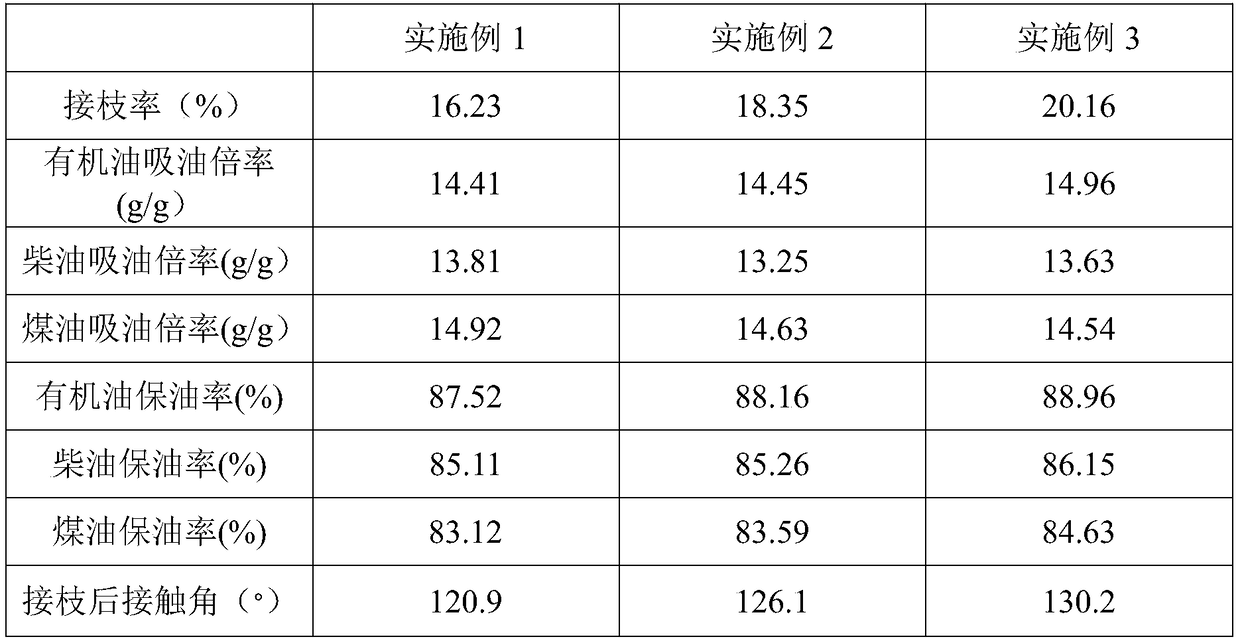

Embodiment 1

[0025] (1) Preparation of melt-blown polypropylene non-woven fabric: After the polypropylene chips or masterbatches are extruded and heated by a screw extruder to form a molten state, they are then metered into the spinneret by a gear metering pump, and the melt is under the action of its own gravity It is sprayed out by the melt-blown nozzle, and at the same time, it is refined into polypropylene microfibers under the action of high-speed hot air. After being cooled by the outside air, it solidifies into a network, and finally forms a melt-blown polypropylene non-woven fabric, abbreviated as MBPP.

[0026] (2) Boil the melt-blown polypropylene non-woven fabric in deionized water for 90 minutes, soak it in absolute ethanol for 2 hours, and then wash it to remove surface impurities, then dry it at 65-75°C, and weigh it.

[0027] (3) Under the pressure of 30Pa and the power of 40W, the non-woven fabric was first pretreated in a low-temperature plasma device for 5 minutes, so tha...

Embodiment 2

[0032] (1) Preparation of melt-blown polypropylene non-woven fabric: After the polypropylene chips or masterbatches are extruded and heated by a screw extruder to form a molten state, they are then metered into the spinneret by a gear metering pump, and the melt is under the action of its own gravity It is sprayed out by the melt-blown nozzle, and at the same time, it is refined into polypropylene microfibers under the action of high-speed hot air. After being cooled by the outside air, it solidifies into a network, and finally forms a melt-blown polypropylene non-woven fabric, abbreviated as MBPP.

[0033] (2) Boil the melt-blown polypropylene non-woven fabric in deionized water for 115 minutes, soak it in absolute ethanol for 2.5 hours, wash it to remove surface impurities, then dry it at 65-75°C and weigh it.

[0034] (3) Under the pressure of 30Pa and the power of 40W, the non-woven fabric was first pretreated in a low-temperature plasma device for 8 minutes, so that the s...

Embodiment 3

[0039](1) Preparation of melt-blown polypropylene non-woven fabric: After the polypropylene chips or masterbatches are extruded and heated by a screw extruder to form a molten state, they are then metered into the spinneret by a gear metering pump, and the melt is under the action of its own gravity It is sprayed out by the melt-blown nozzle, and at the same time, it is refined into polypropylene microfibers under the action of high-speed hot air. After being cooled by the outside air, it solidifies into a network, and finally forms a melt-blown polypropylene non-woven fabric, abbreviated as MBPP.

[0040] (2) Boil the melt-blown polypropylene non-woven fabric in deionized water for 120 minutes, soak it in absolute ethanol for 3 hours, wash it to remove surface impurities, then dry it at 65-75°C, and weigh it.

[0041] (3) Under the pressure of 30Pa and the power of 40W, the non-woven fabric is first pretreated in a low-temperature plasma device for 5-10 minutes, so that the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com