Patents

Literature

88 results about "Dodecyl methacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dodecyl methacrylate; lauryl methacrylate; from MeSH. Depositor-Supplied Synonyms. Chemical names and identifiers provided by individual data contributors and associated to PubChem Substance records. Synonyms of Substances corresponding to a PubChem Compound record are combined.

Self-repairing conductive double network structure hydrogel and preparation method thereof

InactiveCN108440772AImprove reinforcementHigh strengthTissue regenerationProsthesisCarbon nanotubeFlexible electronics

The invention provides a preparation method of a self-repairing conductive double network structure hydrogel. The hydrogel is a carbon nanotube / chitosan double network structure hydrogel, a first network is formed by electrostatic interaction of carboxylated carbon nanotubes and chitosan, and a second network is a hydrophobic association network hydrogel obtained by free radical polymerization ofmain monomer acrylamide or N-isopropyl acrylamide and hydrophobic monomer octyl methacrylate, dodecyl methacrylate, hexadecyl methacrylate or long-chain aliphatic acrylate. The introduction of the carbon nanotubes provides excellent conductivity for the hydrogel, and the hydrophobic monomer can stably form a hydrophobic association center in an emulsifier, and has an obvious reinforcing effect onthe hydrogel, and the obtained hydrogel ahs significantly-improved strength. In addition, the presence of ionic and hydrophobic association effects provides a rapid self-healing property for the hydrogel, and the hydrogel is useful in bionic biology, flexible electronics, biosensors and other fields.

Owner:CHANGCHUN UNIV OF TECH

Surface modification glass fiber and preparation method and application thereof

The invention relates to a surface modification glass fiber and a preparation method and an application thereof, and belongs to the fields of surface modification fibers and preparation thereof. The preparation method is characterized in that the copolymer solution is adopted to be coated on the surface of the pre-processed glass fiber, wherein the copolymer used in the method comprises dodecyl methacrylate, styrene, and maleic anhydride; and the glass fiber is pre-processed by a coupling agent KH550. The surface modification glass fiber, provided by the invention, has the advantages that the preparation process is simple; the cost is low; the industrialization is facilitated; the dispersing performance and the heat stability of the modification glass fiber are good after the preparation method; and the surface modification glass fiber can be well bonded with thermoplastic resin.

Owner:DALIAN UNIV

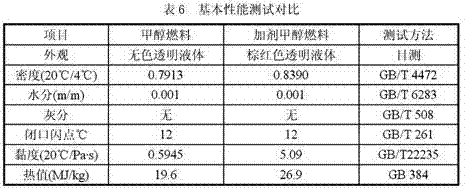

Methanol diesel fuel complex additive and preparation method thereof

ActiveCN101709234AGood compatibility stabilityStable in natureLiquid carbonaceous fuelsCyclohexanoneN-Butylamine

The invention discloses a methanol diesel fuel complex additive and a preparation method thereof. The complex additive is prepared from the following raw materials in parts by volume: 1-4 parts of diethyl phthalate, 1-8 parts of n-butylamine, 1-9 parts of isooctanol, 1-6 parts of cyclohexanone, 13-42 parts of lauryl methacrylate, 7-30 parts of mixed fatty glyceride, 1-5 parts of phenyl propargyl ether, 1-8 parts of dihexadecyl dimethyl ammonium chloride, 2-12 parts of ethyl formate, 2-14 parts of isooctyl nitrate and 1-6 parts of polyoxyethylene hexadeeylalkyl ether selies. The methanol diesel fuel complex additive can enable methanol diesel fuel to be evenly mixed and to be stably stored for more than 6 months, which effectively improves the fire behaviour of the methanol diesel fuel and inhibits the volatilization when the methanol content is higher; moreover, the production process is simple and the use is convenient, thereby being beneficial to the popularization and application of the methanol diesel fuel.

Owner:临沂星火知识产权服务有限公司

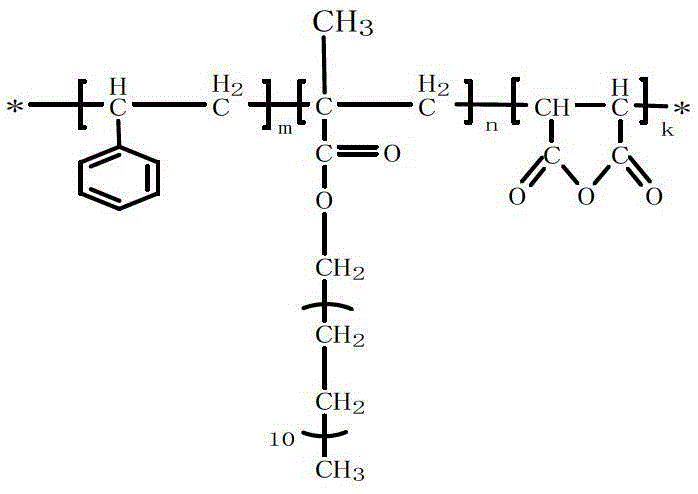

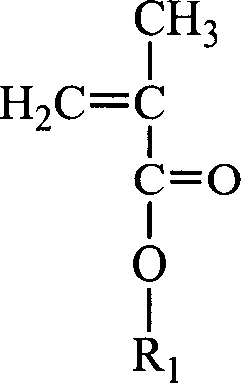

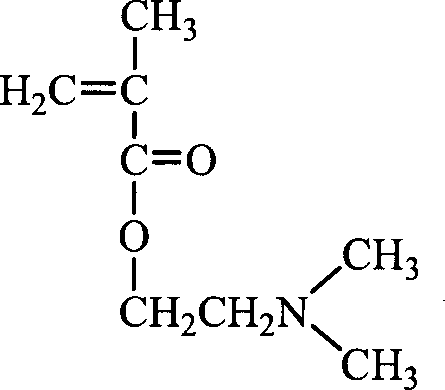

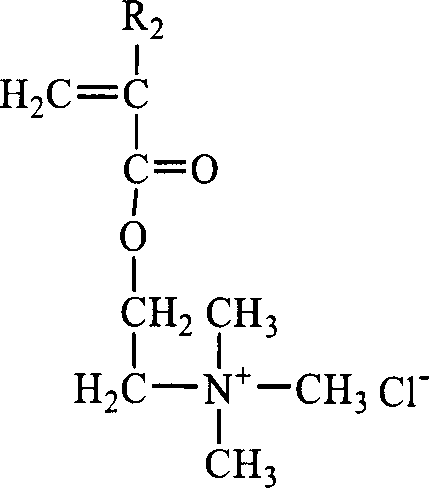

Random and copolymer cation macromolecular emulsion and its preparation

InactiveCN1896112AReduce manufacturing costLow costTransportation and packagingMixingHydrophilic monomerPolymer science

A random copolymerized cationic macromolecular emulsifier and its production are disclosed. The emulsifier consists of hydrophobic monomer and hydrophilic monomer. The hydrophobic monomer is selected from methyl-propenoic acid lauryl ester or methyl-propenoic acid octadecyl ester; The hydrophilic monomer is selected from methyl-propenoic-2-(dimethy)carbethoxy, acryloyl-oxyethylated trimethyl-ammonia chloride or methyl-acryloy-oxyethylated trimethyl-ammonia chloride in proportion of 1:9-4:6mol. The process is carried out by selecting oil-soluble azo initiating agent or oil-soluble peroxide initiating agent by normal free-radical polymerization and reacting at 60-80degree. It is fast, simple and has high conversion rate. It can be used for paper additive, binder, anti-static agent, textile finishing auxiliary and sewage water treatment.

Owner:SUZHOU UNIV

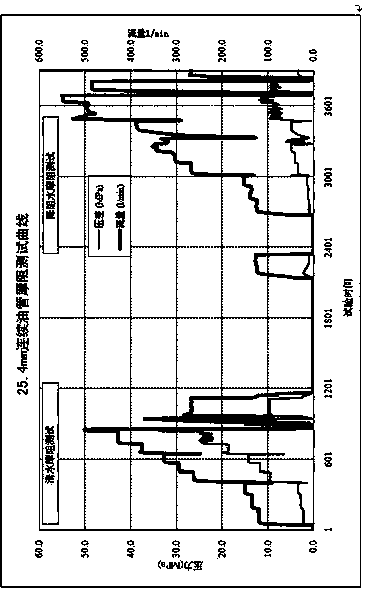

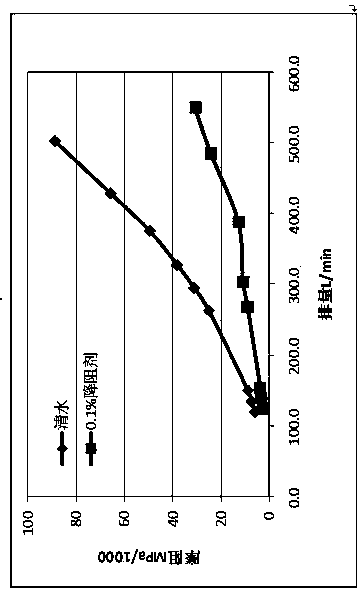

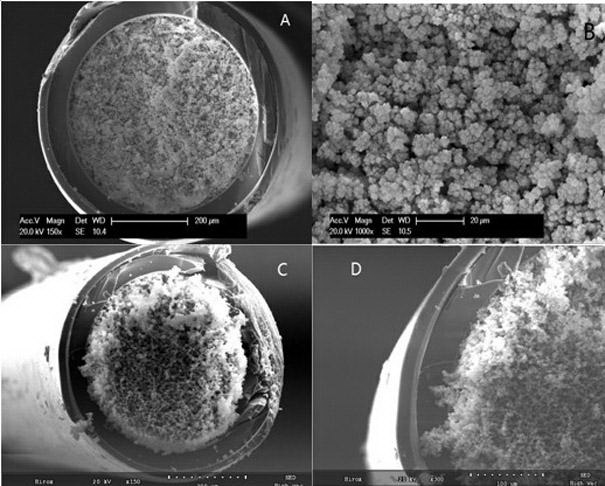

Inverse emulsion drag reduction agent for fracturing shale gas by using quick water and preparation method thereof

ActiveCN103881693AImprove structural stabilityGood drag reduction effectDrilling compositionFracturing fluidSodium hydrogen sulphite

The invention discloses an inverse emulsion drag reduction agent for fracturing a shale gas by using quick water and a preparation method thereof, and relates to the technical field of petroleum engineering. The inverse emulsion drag reduction agent is a macromolecular water soluble polymer which is prepared from acrylamide, sodium acrylate and dodecyl methacrylate copolymerized in an inverse emulsion, and azo diisobutyl hydrochloride and sodium hydrogen sulfite as complex initiation systems. A long-chain hydrophobic monomer is introduced into the drag reduction agent, so that the shear resistance of the drag reduction agent in a high displacement pump injection process is improved, meanwhile, the drag reduction agent is prepared from the inverse emulsion in a polymerization manner, the product is a liquor and instant, the liquor demands of a continuous mixed construction technology for fracturing the shale gas are met, the dosage for field use is 0.06-0.8% of mass of clean water, and the drag reduction rate can be up to 73%.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Waterproof paint

The invention discloses a waterproof paint. The waterproof paint comprises the following components in parts by weight: 75-125 parts of methyl acrylic acid-2-hydroxy ethyl acrylate, 20-40 parts of methyl acrylic acid, 100-150 parts of methyl methacrylate, 80-100 parts of dodecyl methacrylate, 200-300 parts of styrene, 150-200 parts of butyl methacrylate and 20-40 parts of styrene. The waterproof paint disclosed by the invention is simple to prepare, is prepared from nontoxic production raw materials, is good in using effect, is environment-friendly, is capable of forming a firm and tenacious coating, and has long-lasting waterproofness and antistatic property.

Owner:刘骏

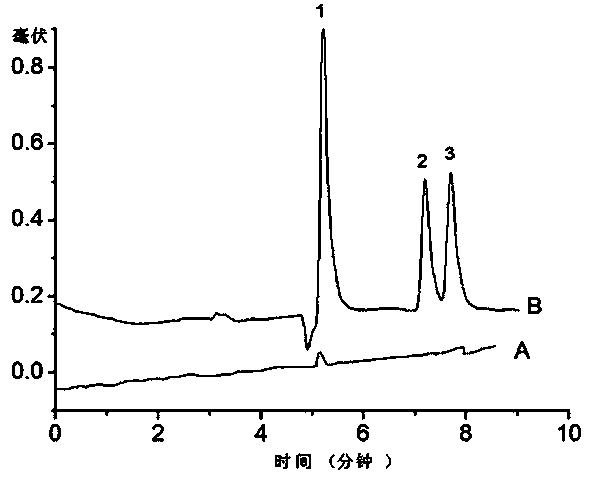

Micro-extraction monolithic column of ionic liquid polymer capillary tube and preparation method thereof

ActiveCN103833885AEnhanced mass transferHigh enrichment efficiencyOther chemical processesSolid sorbent liquid separationFunctional monomerEthyleneglycol dimethacrylate

The invention discloses a micro-extraction monolithic column of an ionic liquid polymer capillary tube and a preparation method thereof. The method comprises the following steps: by adopting imidazolium ionic liquids and dodecyl methacrylate as functional monomers, taking ethylene glycol dimethyl acrylic ester as a cross-linking agent, taking normal propyl alcohol and butanediol as pore-foaming agents and taking azodiisobutyronitrile as an initiator, evenly mixing the raw materials at room temperature in an oscillating manner, and injecting into a vinyl-modified quartz capillary tube; sealing, and carrying out thermal initiation one-step polymerization, so as to obtain the micro-extraction monolithic column of the ionic liquid polymer capillary tube in manners of cleaning and drying. The micro-extraction monolithic column is simple and convenient in synthetic process, controllable in reaction, and low in cost. The prepared micro-extraction column for the capillary tube has good permeability, porosity, and chemical and mechanical stability; a plurality of interaction sites such as an imidazole ring with positive electricity and different lengths of carbon chains and the like are formed on the surface; the micro-extraction monolithic column has good extraction ability on the substances such as phenolic environmental hormone and the like, and is quick to extract, and easy to build an analysis method with high sensitivity by combining with capillary electrochromatography.

Owner:FUZHOU UNIV

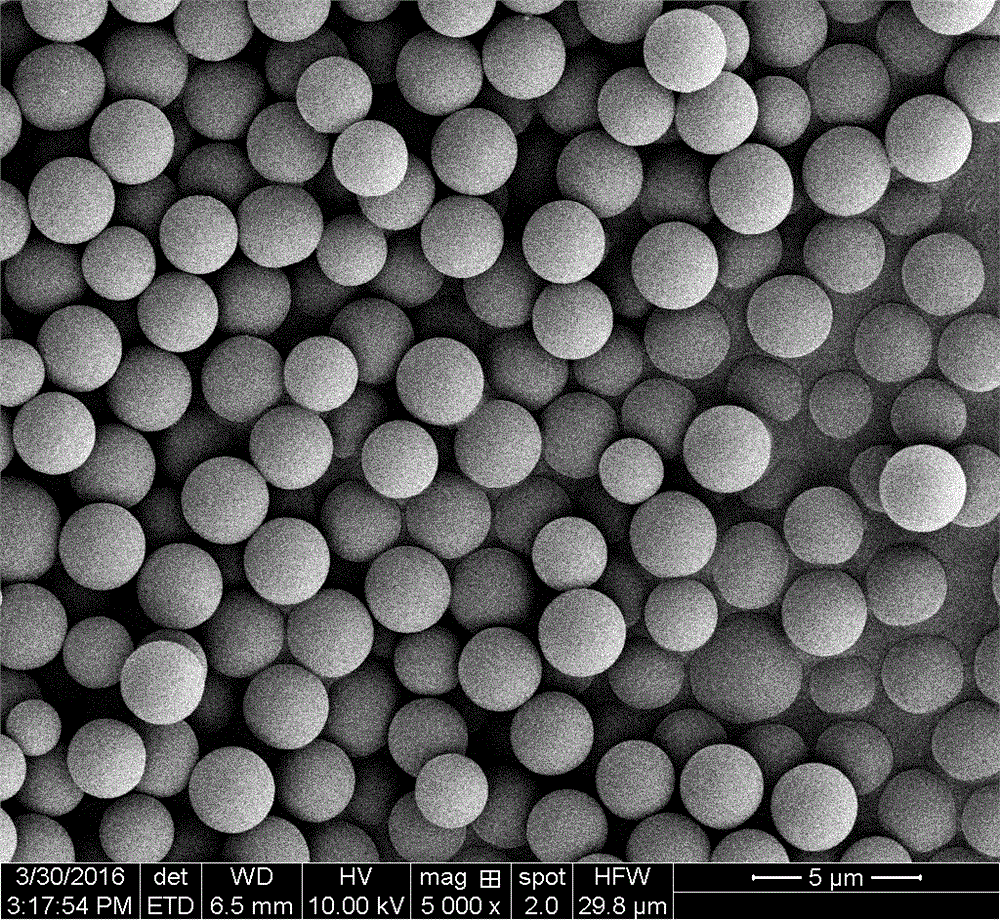

Ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method

InactiveCN109137466ALight in massLarge poresOther chemical processesUltrasonic/sonic fibre treatmentUltravioletNonwoven fabric

The invention discloses an ultraviolet compound melt-blowing polypropylene oil-absorbing non-woven fabric and its preparation method. According to the preparation method, a photosensitizer, compound monomers, solvents and melt-blowing polypropylene non-woven fabric are involved, wherein the photosensitizer relates to benzophenone, the compound monomers refer to optional two of butyl methacrylate,dodecyl methacrylate, methyl acrylate and butyl acrylate, and the solvents refer to isopropyl alcohol and deionized water. The non-woven fabric can adsorb oil substances in different type, has good oleophylic hydrophobicity, can absorb oil but water, can be reused, can also adsorb some heavy-metallic ion. Besides, as the optimum processing condition good for achieving the optimum oil absorption capacity is reached as researched, the fabric has more thorough oil absorption performance and better oil holding capacity.

Owner:JIXI YUANDAO AGRI IND TECH

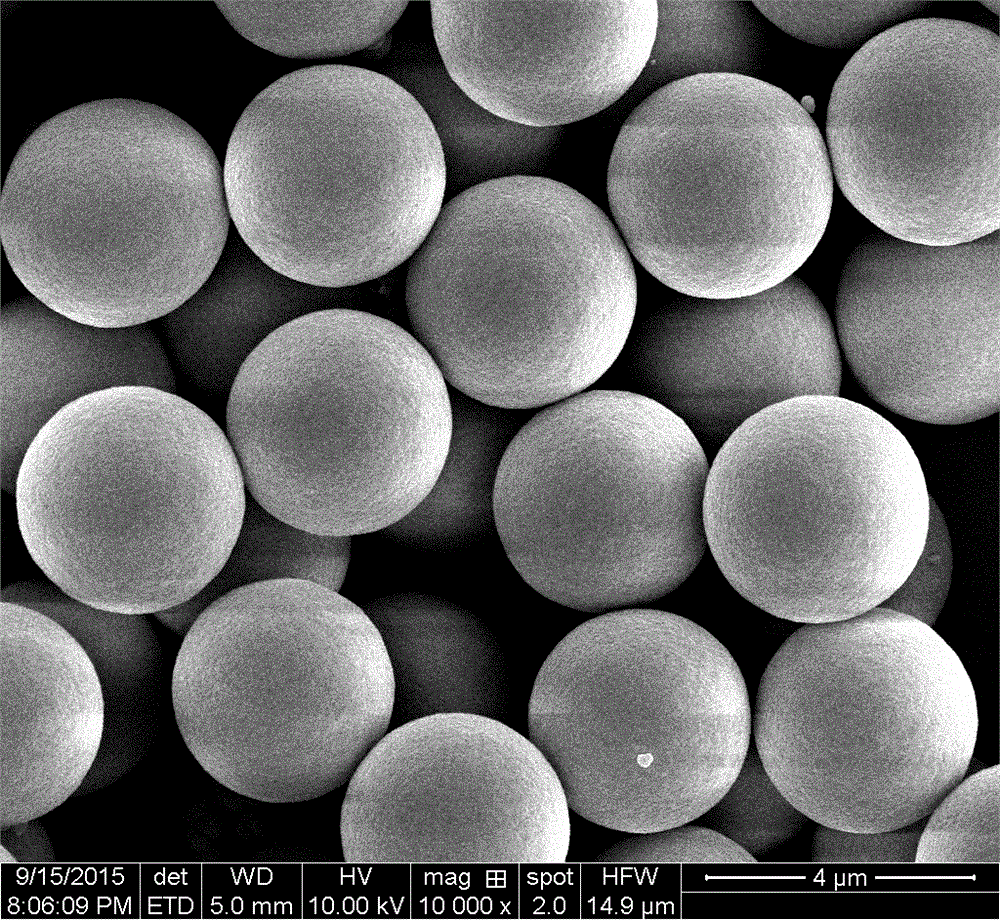

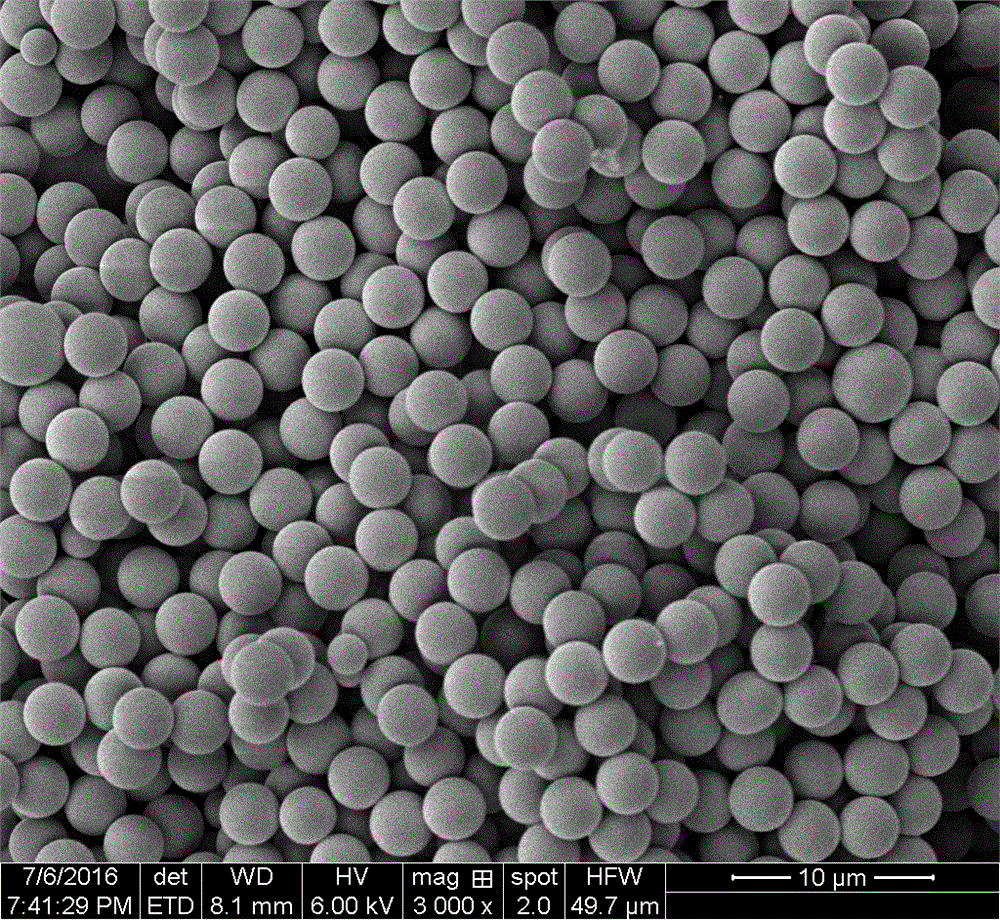

Super-hydrophobic monodisperse polymer microspheres and preparation method thereof

The invention relates to super-hydrophobic monodisperse polymer microspheres and a preparation method thereof. The method comprises the following steps: by adopting precipitation polymerization, adding lauryl metbacrylate, divinyl benzene and an initiator to a solvent, mixing evenly, putting the mixture into a stainless steel reaction kettle and sealing; controlling a reaction temperature to be 82-200 DEG C and the reaction time to be 1-12h; and carrying out washing and centrifugal precipitation on the obtained product by using a solvent, and drying to obtain the super-hydrophobic monodisperse polymer microspheres. The microspheres are simple in preparation process and short in elapsed time; the monomer input amount reaches 20%; the yield of the microspheres is higher than 90%; the raw materials are fluoride-free monomers; the microspheres are friendly to environment and low in price; and industrial production is easy to implement.

Owner:UNIV OF JINAN

Nano-clay added foaming polypropylene and high-molecular absorbent composite material and preparation method thereof

InactiveCN104987588AHigh hole densityLarge specific surface areaOther chemical processesLow-density polyethylenePolyvinyl alcohol

The invention discloses a nano-clay added foaming polypropylene and high-molecular absorbent composite material. The nano-clay added foaming polypropylene and high-molecular absorbent composite material is characterized by being prepared by, by weight, 95-98 parts of high-melt-strength polypropylene, 2-3 parts of low-density polyethylene, 5-7 parts of nano clay, 1-2 parts of polyvinyl akohol, 2-3 parts of calcium carbonate, 4-6 parts of ammonium bicarbonate, 0.1-0.2 part of cetyltrimethylammonium chloride, an appropriate amount of deionized water, 4-5 parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-9 parts of dodecyl methacrylate, 0.08-0.1 part of N,N,-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and 2-3 parts of di-cotyl phosphoric acid. The composite foaming material is relatively compact in appearance, small in particles and good in lustrousness, meets the environmental protection requirement, can be prepared by adopting a simple injection molding process, the preparation process of a micro-foaming material is simplified, and comprehensive performance is excellent.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Deodorant

InactiveCN105816898ASimple compositionGood deodorizing effectDeodrantsOdor sourcePolyethylene glycol

The invention discloses a deodorant, which comprises the following raw materials in parts by weight: 15-20 parts of citronella extract, 15-20 parts of ethanol, 10-15 parts of polyethylene glycol, 7-10 parts of eucalyptus oil, mandala 5-10 parts of Luo extract, 5-10 parts of citric acid, 1-2 parts of lauryl methacrylate, 0.5-1 part of chitosan, 0.2-0.5 part of dodecyltrimethylammonium bromide. The deodorant of the present invention has the advantages of simple composition, good deodorizing performance and long-term deodorizing technical effect, uses pure natural vegetable oil to extract essential oil to purify air, decomposes and removes odor, and can be used in public toilets, garbage stations and farms , Sewage treatment plants and other large-area odor sources deodorization.

Owner:陈卫康

Multifunctional gasoline addictive

The present invention pertains to the field of chemical industry, wherein a multifunctional gasoline additive is disclosed, which comprises methyl teriarybutyl ether, dimethylbenzene, isopropyl alcohol, silicon oil and methacrylic acid dodecyl ester. The invention also discloses the method for preparing the gasoline additive.

Owner:SHANGHAI ZHONGYOU ENTERPRISE GRP CO LTD

Electron beam curing ink-jet ink as well as preparation method and application thereof

The invention discloses electron beam curing ink-jet ink as well as a preparation method and application thereof. The electron beam curing ink-jet ink comprises the following raw materials in parts byweight: 15-35 parts of polyurethane acrylate, 20-35 parts of isobornyl acrylate, 5-10 parts of an organic pigment toner, 0.5-1 part of fumed silica, 5-10 parts of dodecyl methacrylate, 5-20 parts oftri(2-hydroxyethyl)isocyanurate triacrylate, 5-10 parts of tristyrylphenol polyoxyethylene ether methacrylate, 1-5 parts of a dispersing agent and 3-5 parts of an auxiliary agent. According to the invention, 99.99% of high-purity nitrogen is required to fill a reaction container; and then electron beam scanning is adopted to cure ink-jet ink, so that the ink-jet ink forms a color ink layer with high hardness, good film forming toughness, boiling resistance, solvent corrosion resistance, scratch resistance and the like on liquid crystal glass, colorful patterns are formed on the surface of theglass through color combination, and the product attractiveness is improved.

Owner:黄山四原色电子科技材料有限公司

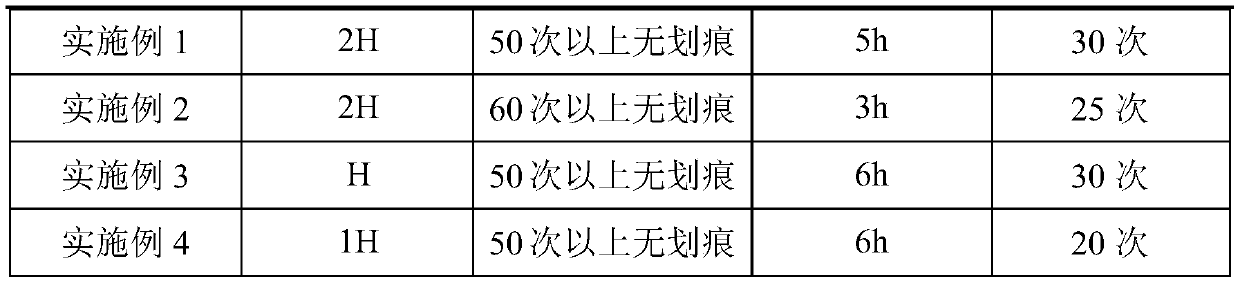

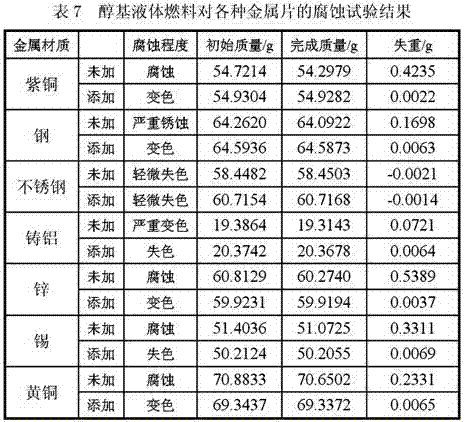

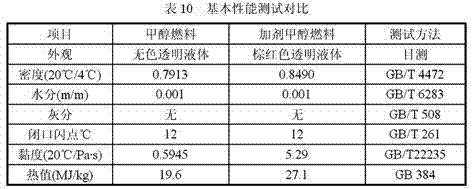

Additive for alcohol base liquid fuel

ActiveCN106957701AChange the viscosityChange lubricityLiquid carbonaceous fuelsFuel additivesCorrosionDodecyl methacrylate

The invention relates to an additive for an alcohol base liquid fuel. The additive is prepared from 4-20 parts of polymethyl methacrylate isooctyl, 6-21 parts of 2,4-dimethyl-6-tert-butyl phenol, 2-5 parts of N,N'-disalicylal-1,2-propanediamine, 6-26 parts of lauryl metbacrylate, 3-21 parts of diethylene glycol monomethyl ether, 10-40 parts of methyl palmitoleate, 3-12 parts of diethylaminoethyl methacrylate, 2-9 parts of zinc dibutyl dithiocarbamate, 5-11 parts of 2-n-octyl-4-isothiazolin-3-one, 8-23 parts of dioctyl phthalate, 7-17 parts of N-phenyl-N-sec-butyl phenylenediamine and 0-7 parts of isopropyl benzoate. The additive is added into methanol in a mass ratio of 7-10% to prepare the alcohol base liquid fuel. On the basis of increasing the heat value of the alcohol base liquid fuel, corrosion on a metal part caused by the fuel can be effectively alleviated, the lubricating property and viscosity of the fuel are increased, and the fuel color and combustion flame color are changed.

Owner:山西甲纯新能源科技有限公司

Hydrophobic enhanced foamed polypropylene and polymer absorbent composite material and preparation method thereof

InactiveCN104987592ALower decomposition temperatureUniform cellsOther chemical processesLow-density polyethylenePolymer science

The invention discloses a hydrophobic enhanced foamed polypropylene and polymer absorbent composite material. The hydrophobic enhanced foamed polypropylene and polymer absorbent composite material is characterized by being compared, by weight, by the following raw materials of 95-98 parts of high-melt-strength polypropylene, 2-3 parts of low-density polyethylene, 2-3 parts of calcium carbonate, 2-3 parts of ammonium bicarbonate, 3-4 parts of sisal fibers, 0.5-0.6 part of vinyltriethoxysilane, appropriate deionized water, 4-5 parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-9 parts of dodecyl methacrylate, 0.08-0.1 part of N,N-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and 2-3 parts of bis(2-ethylhexyl) phosphate. According to the hydrophobic enhanced foamed polypropylene and polymer absorbent composite material and a preparation method thereof, the composite material is prepared by adopting a novel technology, the two advantages that resin is strong in oil-keeping performance and foamed polypropylene is high in oil-absorption times are merged together, the whole prepared product is better in oil absorbency, the preparation method is simple, the hydrophobic property is excellent, and the strength of the product is high.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

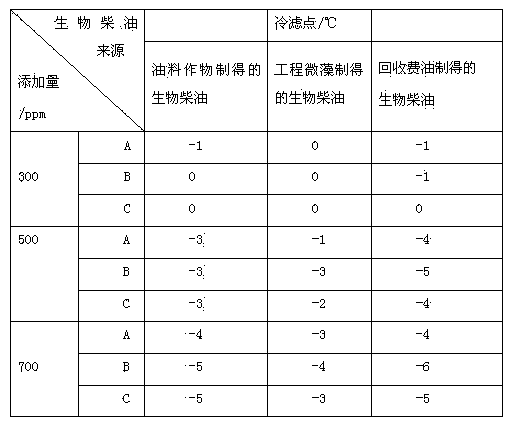

Preparation method of biodiesel composite additive

ActiveCN103642543ALower freezing temperatureGood fluidity at low temperatureLiquid carbonaceous fuelsBiodieselOil additive

The invention belongs to the field of fuel oil additives and in particular relates to a preparation method of a biodiesel composite additive. The preparation method of the biodiesel composite additive comprises the following steps: adding dodecyl methacrylate, steary methacrylate, isooctyl nitrate and dicthyl ortho-phthalate into a raw material mixing tank and stirring evenly; adding maleic anhydride and isooctanol and stirring evenly; and then adding tert-butylamine and double hexadecyl dimethyl ammonium chloride and stirring for 30-35 minutes; adding polyoxyethylene hexadecy phenolic ether and phenyl propargyl ether into a solution, heating to 45-50 DEG C, stirring for 20-30 minutes at 0.5-1.0MP, standing for 24 hours and filtering to remove sediment. The biodiesel composite additive prepared by the preparation method is good in cold filtering point reducing effect; and meanwhile, the problem of reversion of the cold filtering point can be avoided; the effects of other diesel additives are not influenced; and the biodiesel composite additive is efficient and stable in dispersion capability and good in oil solubility.

Owner:临沂星火知识产权服务有限公司

Foamed polypropylene and polymer absorbent composite material with high flame-retardant effect and preparation method thereof

InactiveCN104987591ALower decomposition temperatureStable structureLow-density polyethylenePolymer science

The invention discloses a foamed polypropylene and polymer absorbent composite material with a high flame-retardant effect. The foamed polypropylene and polymer absorbent composite material is characterized by being prepared from, by weight, 95-98 parts of high-melt-strength polypropylene, two to three parts of low-density polyethylene, two to three parts of diisopropyl azodicarboxylate, 0.6-0.8 part of polydimethylsiloxane, three to four parts of antimonous oxide, one to two parts of red phosphorus, a proper amount of deionized water, four to five parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-nine parts of dodecyl methacrylate, 0.08-0.1 part of N,N,-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and two to three parts of bis phosphate. The foamed polypropylene and polymer absorbent composite material is excellent in flame retardant property, spontaneous combustion, caused by oil absorption, of products is avoided, and potential safety hazards are reduced. The foamed polypropylene and polymer absorbent composite material is widely applied to petroleum leakage, water pollution control, oil-water separation, dangerous chemical protection, emergency treatment and other fields.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Deodorizing agent for toilet

InactiveCN105194707APlay a bactericidal effectImprove the bactericidal effectBiocideDisinfectantsCalcium biphosphateMedicine

The invention discloses a deodorizing agent for a toilet. The deodorizing agent is characterized by comprising the following components by weight percent: 30 to 32 percent of polyethylene glycol, 5 to 6 percent of camphor, 8 to 10 percent of silica gel, 15 to 20 percent of calcium hydrophosphate, 8 to 10 percent of dodecyl methacrylate, 18 to 22 percent of paradichlorobenzene, 2 to 4 percent of methoxyl acrylamide and 3 to 4 percent of spice. A preparation method comprises the following steps: first adding the polyethylene glycol into a stirring paddle, stirring the polyethylene glycol, heating to 60 to 70 DEG C, adding the calcium hydrophosphate, the dodecyl methacrylate, the paradichlorobenzene and the methoxyl acrylamide, heating to 70 to 80 DEG C, and stirring for 30 minutes by virtue of a motor with the highest rotation speed of 500; cooling to 50 DEG C, adding the spice, and stirring for 10 minutes at the highest rotation speed 500; casting a mold, and cooling. The deodorizing agent has the beneficial effects that the calcium hydrophosphate is used for disintegrating peculiar smell, the dodecyl methacrylate is used for sterilization, and the dodecyl methacrylate is compounded with the polyethylene glycol, the camphor, the silica gel and the paradichlorobenzene and the like to produce a better sterilization effect.

Owner:铜陵翔宇商贸有限公司

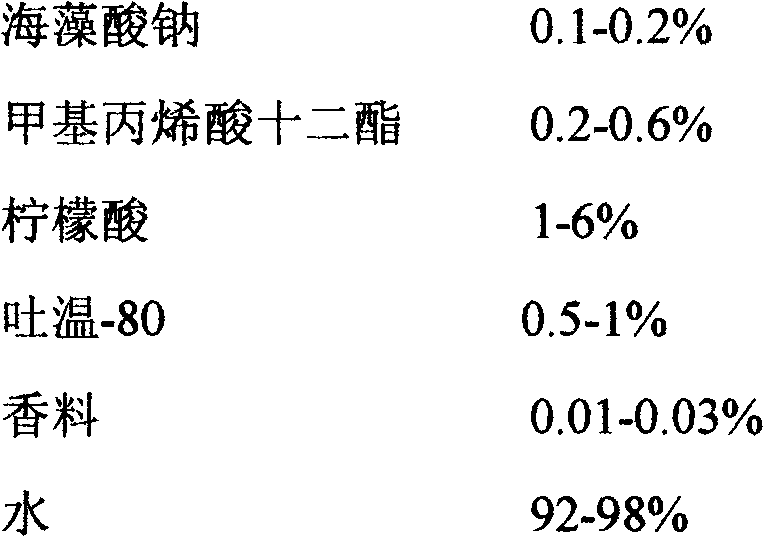

Novel high-efficiency biochemical deodorant

The invention discloses a novel high-efficiency biochemical deodorant. The novel high-efficiency biochemical deodorant disclosed by the invention contains 0.1-0.2% of sodium alga acid, 0.2-0.6% of dodecyl methacrylate, 1-6% of citric acid, 0.5-1% of Tween-80, 0.01-0.03% of spice and 92-98% of water. The novel high-efficiency biochemical deodorant is diluted by water in proportion, and after the diluted high-efficiency biochemical deodorant is sprayed on a foul smell source, foul gas can be rapidly adsorbed, eliminated and covered, and the breeding of mosquito and fly is reduced. The novel high-efficiency biochemical deodorant is widely applied to large-area foul smell source occasions such as public toilets, garbage stations, livestock farms and sewage treatment plants.

Owner:烟台荣和环保能源股份有限公司

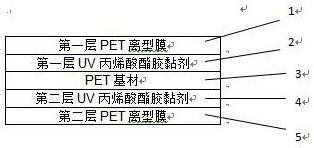

UV type acrylate pressure-sensitive adhesive for low-surface-energy material and processing technology of UV type acrylate pressure-sensitive adhesive

InactiveCN111777967ASolving Adhesion ProblemsReduce pollutionOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesIsooctyl acrylatePolymer science

Owner:NANJING HUIXIN PHOTOELECTRIC MATERIAL

Foamed polypropylene-high molecular absorbent composite anti-aging filtering material, and preparation method thereof

InactiveCN105032377ALower decomposition temperatureDecomposition is smooth and fastOther chemical processesWater/sewage treatment by sorptionLow-density polyethyleneKetone

The invention discloses a foamed polypropylene-high molecular absorbent composite anti-aging filtering material. The foamed polypropylene-high molecular absorbent composite anti-aging filtering material is prepared from, by weight, 95 to 98 parts of high melt strength polypropylene, 2 to 3 parts of liquid paraffin, 5 to 7 parts of azodicarbonamide, 2 to 3 parts of low density polyethylene, 4 to 5.5 parts of nano-montmorillonite, 1 to 2 parts of anti-oxidant 1010, an appropriate amount of deionized water, 4 to 5 parts of methyl cellulose, 13 to 15 parts of butyl acrylate, 7.5 to 9 parts of dodecyl methacrylate, 0.08 to 0.1 part of N,N-methylene bisacrylamide, 0.5 to 0.6 part of azodiisobutyronitrile, 11 to 12.5 parts of ethyl acetate, and 2 to 3 parts of di-cotyl phosphoric acid. The foamed polypropylene-high molecular absorbent composite anti-aging filtering material is capable of absorbing almost all kinds of liquid organic chemicals including fuel such as gasoline, diesel oil, aircraft fuel, and crude oil, aromatic solvents such as benzene and xylene, and chlorinated solvents and polar compounds such as perchloroethylene and methyl ethyl ketone.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

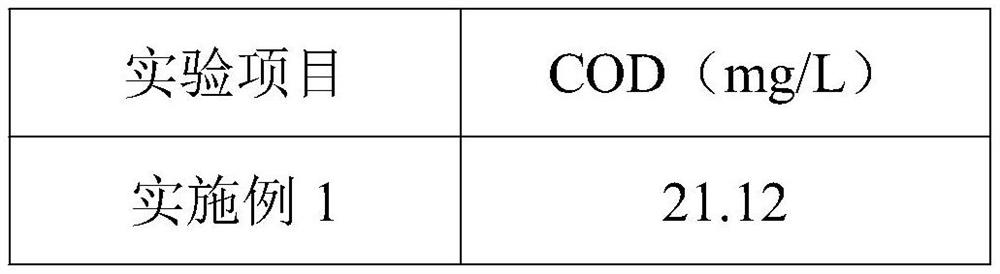

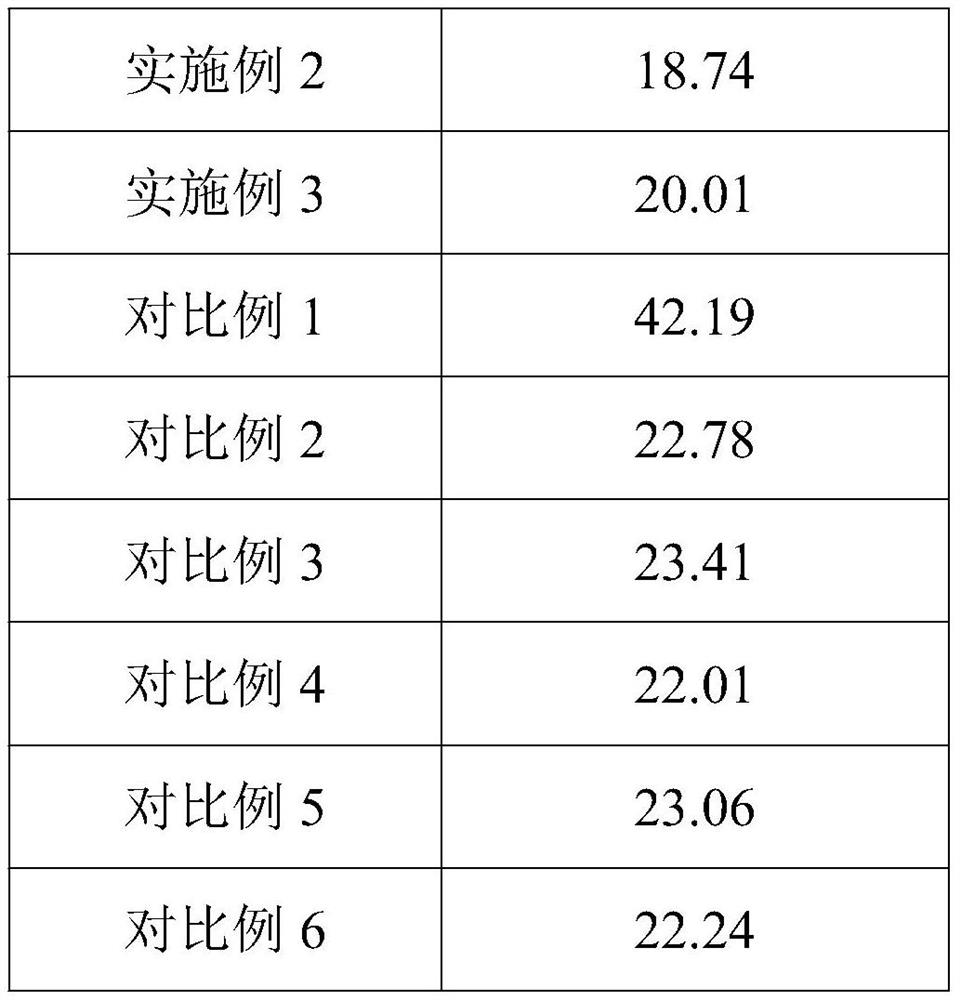

Novel efficient chemical and preparation process thereof, and application of novel efficient chemical in aquaculture wastewater treatment

ActiveCN113443722AReduce chemical oxygen demand CODImprove adsorption capacityWater contaminantsWater aerationBiotechnologyAstaxanthin

The invention discloses a novel efficient chemical. The novel efficient chemical is prepared from the following raw materials in parts by weight: 72 to 100 parts of modified coconut shell powder, 42 to 46 parts of decomposed soybean meal, 9 to 10 parts of complex microbial inoculants, 3.2 to 4 parts of astaxanthin, 5 to 9 parts of kieselguhr, 4 to 6 parts of sodium humate, 0.6 to 1 part of sodium lignin sulfonate, 0.3 to 0.5 part of soybean oligopeptide powder and 0.5 to 0.8 part of dodecyl methacrylate. The novel efficient chemical is prepared through the steps of raw material mixing, crushing, drying and the like. The novel efficient chemical has the advantages of no toxicity, safety, environmental protection and the like, is applied to treatment of aquaculture wastewater, has a COD removal rate of 94.9% or above, and can be vigorously popularized and applied.

Owner:中国科技开发院广西分院 +2

Reinforced and toughened even-bubble foamed-polypropylene and macromolecule-absorbent composite material and preparing method thereof

InactiveCN104987589ALower decomposition temperatureLarge specific surface areaOther chemical processesLow-density polyethyleneSodium bicarbonate

The invention discloses a reinforced and toughened even-bubble foamed-polypropylene and macromolecule-absorbent composite material. The composite material is characterized by comprising, by weight, 95 parts to 98 parts of high-melt-strength polypropylene, 2 parts to 3 parts of low-density polyethylene, 3 parts to 4 parts of glass fibers, 1 part to 2 parts of simethicone, 4 parts to 6 parts of sodium bicarbonate, 2 parts to 3 parts of POE, a proper amount of deionized water, 4 parts to 5 parts of methylcellulose, 13 parts to 15 parts of butyl acrylate, 7.5 parts to 9 parts of dodecyl methacrylate, 0.08 part to 0.1 part of N,N-methylenebis acrylamide, 0.5 part to 0.6 part of azodiisobutyronitrile, 11 parts to 12.5 parts of ethyl acetate and 2 parts to 3 parts of Di-cotyl phosphoric acid. According to the prepared product, the advantage of high oil holding performance of resin and the advantage of many oil-absorption times of foamed polypropylene are combined, bubbles are even and fine, and foaming is even; in addition, the preparing technology brings convenience to industrial control, the production process is environmentally friendly and low in carbon, and the overall oil absorption performance and the overall oil holding performance are good.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

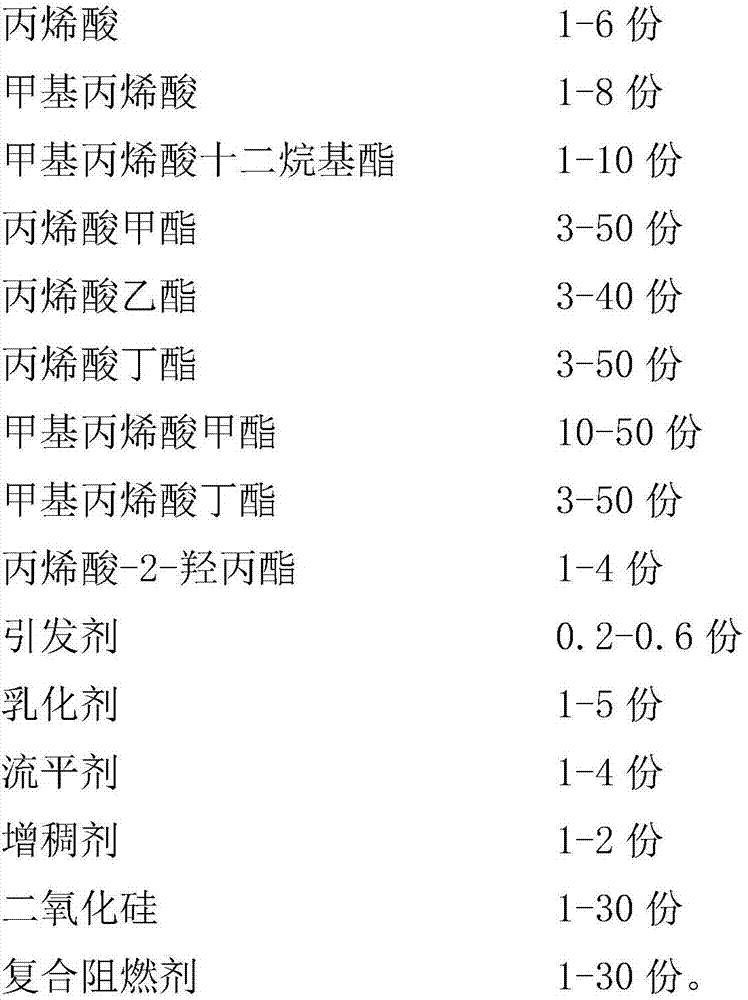

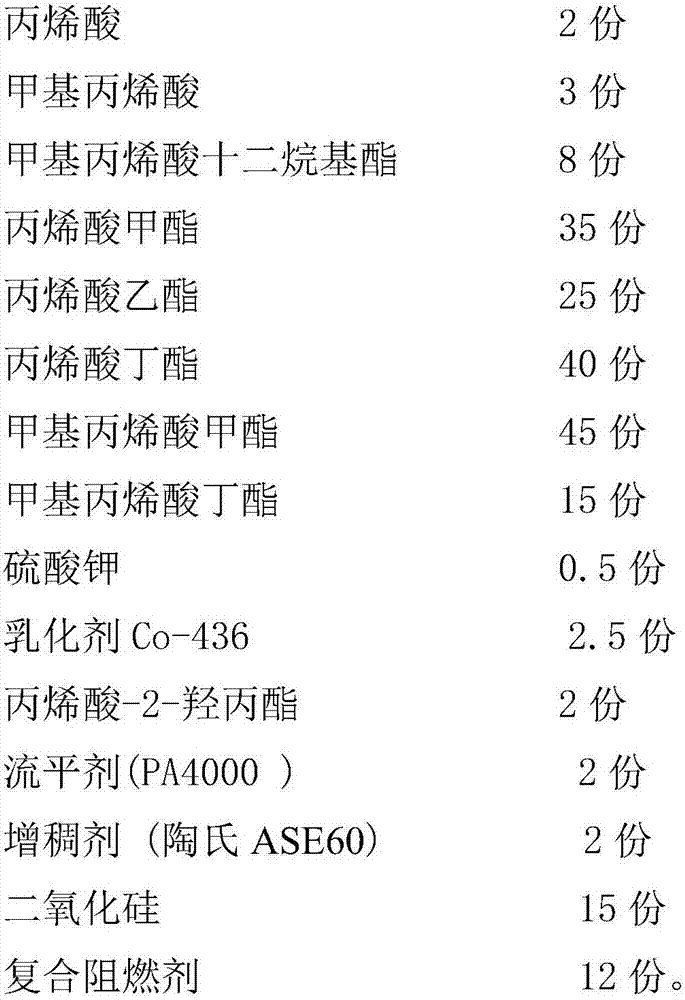

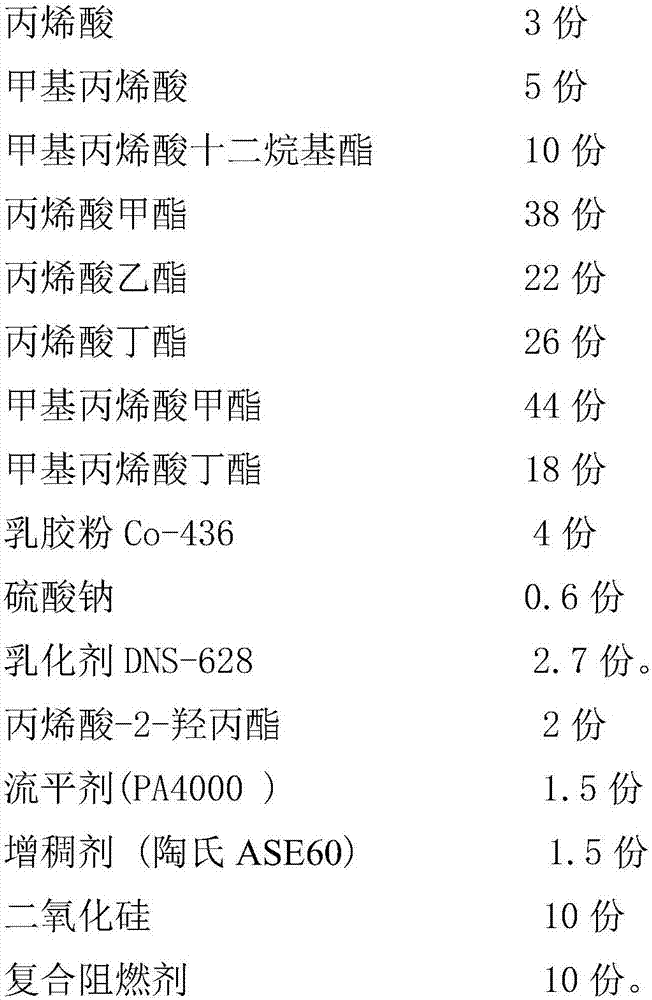

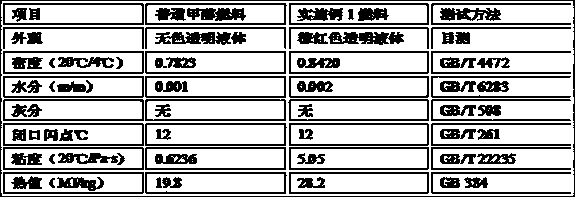

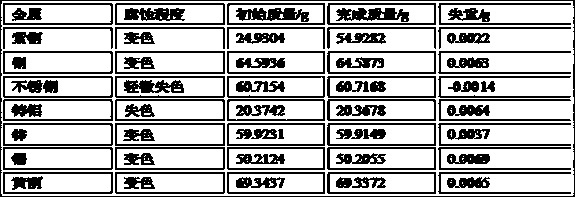

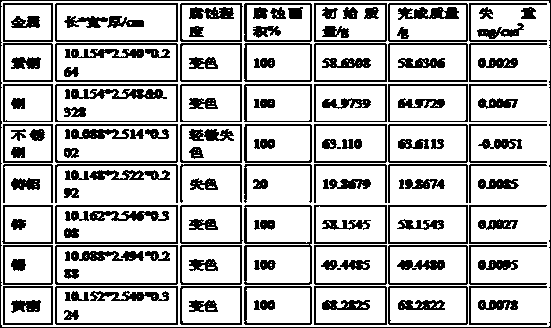

Weak solvent ink absorption flame retardant coating and preparation method thereof

InactiveCN107573796AGood ink absorptionImprove flame retardant performanceFireproof paintsSolventAbsorption rate

The invention belongs to the technical field of materials, and particularly relates to a weak solvent ink absorption flame retardant coating and a preparation method thereof. The coating is prepared from the following raw materials in parts by weight: 1 to 7 parts of acrylic acid, 1 to 8 parts of methacrylic acid, 3 to 20 parts of dodecyl methacrylate, 3 to 50 parts of methyl acrylate, 3 to 40 parts of ethyl acrylate, 3 to 50 parts of butyl acrylate, 10 to 70 parts of methyl methacrylate, 3 to 50 parts of butyl methacrylate, 0.2 to 0.6 part of an initiator, 1 to 5 parts of an emulsifier, 1 to4 parts of a leveling agent, 1 to 2 parts of a thickener, 1 to 30 parts of silicon dioxide and 1 to 30 parts of a composite flame retardant. The surface of the coating prepared according to the preparation method is flat, bubble-free, crack-free, good in water resisting effect, high in printing quality, high in flame retardancy, and particularly extremely excellent in ink absorption rate.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

High-cleanness alcohol-based liquid fuel

PendingCN110923022AImprove the lubrication effectHigh viscosityLiquid carbonaceous fuelsLiquid fuelBenzioc acid

The invention provides a high-cleanness alcohol-based liquid fuel, and belongs to the technical field of alcohol-based liquid fuels. The high-cleanness alcohol-based liquid fuel is prepared from methanol, ethanol gasoline and an additive; and the additive is prepared from polyisooctyl methacrylate, 2,4-dimethyl-6-tert-butyl phenol, N,N'-disalicylidene-1,2-propanediamine, dodecyl methacrylate, diethylene glycol monomethyl ether, methyl palmitate, diethylaminoethyl methacrylate, zinc dibutyl dithiocarbamate, 2-n-octyl-4-isothiazolin-3-one, dioctyl phthalate, N-phenyl-N'-sec-butylphenylenediamineand isopropyl benzoate. The alcohol-based liquid fuel has the advantages of small corrosivity to metal parts, good lubricity, high viscosity and high heat value, has reddish brown color, achieves a blue-green combustion fire, does not generate residual liquid, smoke dust, carbon deposition, sulfur dioxide or other harmful gases in the combustion process, and meets environmental protection requirements.

Owner:中油新能源有限公司

Novel foamed polypropylene and acrylic resin composite material and preparation method thereof

InactiveCN104987593ALower decomposition temperatureLarge specific surface areaOther chemical processesLow-density polyethyleneSodium bicarbonate

The invention discloses a novel foamed polypropylene and acrylic resin composite material. The novel foamed polypropylene and acrylic resin composite material is characterized by being prepared from the following raw materials of, by weight, 95-98 parts of high-melt strength polypropylene, 2-3 parts of low-density polyethylene, 6-8 parts of sodium bicarbonate, 4-6 parts of talcum powder, 1.5-2.5 parts of glycerin monostearate, 0.6-0.8 part of polydimethylsiloxane, an appropriate amount of deionized water, 4-5 parts of methylcellulose, 13-15 parts of butyl arcylate, 7.5-9 parts of dodecyl methacrylate, 0.08-0.1 part of N,N-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and 2-3 parts of di (isooctyl) phosphate. A preparation method combines the two advantages of the strong oil-holding performance of polyacrylate resin and the good oil-absorption rate of foamed polypropylene, the whole oil absorbency and the oil-holding capacity are good, the preparation method is simple, and the novel foamed polypropylene and acrylic resin composite material and the preparation method thereof have great application prospect in the aspect of recovery processing of water surface floating oil.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Environment-friendly recyclable foamed polypropylene and macromolecule absorbent composite material and preparation method thereof

InactiveCN104987590ALower decomposition temperatureLarge specific surface areaLow-density polyethylenePhosphate

The invention discloses an environment-friendly recyclable foamed polypropylene and macromolecule absorbent composite material is characterized by being prepared, by weight, by 95-98 parts of high-melt-strength polypropylene, 4-6 parts of carbon nano tube powder, 3-4 parts of talcum powder, 1-2 parts of glycerin monostearate, 3-4 parts of RA foaming agents, 2-3 parts of low-density polyethylene, 1-2 parts of ethylene-vinyl acetate copolymer, 1-1.5 part of antioxygen 168, an appropriate amount of deionized water, 4-5 parts of methylcellulose, 13-15 parts of butyl acrylate, 7.5-9 parts of dodecyl methacrylate, 0.08-0.1 part of N,N-methylene bisacrylamide, 0.5-0.6 part of azodiisobutyronitrile, 11-12.5 parts of ethyl acetate and 2-3 parts of di phosphate. According to the composite material produced through the preparation method, the specific surface area is effectively increased, a good adsorption filtering effect is achieved, and the composite material is safe, environmentally friendly and recycled.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

High-alcohol-resistance water-soluble acrylic resin and preparation method thereof

The invention discloses high-alcohol-resistance water-soluble acrylic resin and a preparation method thereof. The high-alcohol-resistance water-soluble acrylic resin comprises the following components in parts by weight: 3-5 parts of a special monomer, 8-12 parts of methyl methacrylate, 4-8 parts of butyl acrylate, 17-20 parts of styrene, 3-7 parts of acrylonitrile, 5-8 parts of methacrylic acid, 8-15 parts of butyl methacrylate, 1-2 parts of an initiator, 25-30 parts of propylene glycol monomethyl ether and 10-15 parts of industrial ethanol. The preparation method comprises the following steps: (1) adding propylene glycol monomethyl ether into a reaction kettle under the protection of inert gas, and then heating; (2) mixing methyl methacrylate, butyl acrylate, styrene, dodecyl methacrylate, acrylonitrile, butyl methacrylate, methacrylic acid and part of the initiator to obtain a mixed solution; and (3) dropwise adding the mixed solution into a reaction kettle, adding the residual initiator after reaction, cooling, and adding industrial ethanol to obtain the high-alcohol-resistance water-soluble acrylic resin. After the high-alcohol-resistance water-soluble acrylic resin is dried to form a film, the alcohol resistance is greatly improved, and the high-alcohol-resistance water-soluble acrylic resin can resist over 200 times of alcohol wiping.

Owner:JIANGSU HUALUN CHEM +1

Amphiphilic comb-shaped superplasticizer

InactiveCN108084356AGood initial dispersion performanceIncreasing the thicknessHydrodynamic radiusSide chain

An amphiphilic comb-shaped superplasticizer is disclosed. In order to study the effect of hydrophobic long side chains on the dispersibility of comb superplasticizers, an amphiphilic comb-shaped poly(dodecyl methacrylate)-isoprenol polyoxyethylene ether-maleic anhydride terpolymer (APC) is prepared by an aqueous solution free radical copolymerization by use of ammonium persulfate as an initiator.Comb type. Three monomers are well copolymerized. The weight average relative molecular mass and the number average relative molecular mass of a sample are 50625 and 10173, respectively. The relativemolecular mass distribution index is 4.97. Through introduction of a hydrophobic alkyl ester long side chain, the comb copolymer is self-assembled in a cement pore solution to form micelles with a diameter of more than 100 nm. A TEM (transmission electron microscope) observes the micelles to find that the micelles are spherical and cemented together to form agglomerates, the hydrodynamic radius and the solvation layer thickness of the copolymer can be increased, and the dispersion properties of a water reducer can be reduced.

Owner:韩会义

Waterborne over-rust corrosion protective coating for steel and preparation method thereof

InactiveCN105925098AThe appearance of the coating film is uniform and brightWidely producedAnti-corrosive paintsMeth-Potassium ferricyanide

The invention discloses a waterborne over-rust corrosion protective coating for steel and a preparation method thereof. The preparation method comprises the following steps: weighing butyl methacrylate, potassium hexacyanoferrate, polyhydric alcohol phosplonate, methyl acrylate, acrylonitrile, N-methylol acrylamide, toluene-2,4-diisocyanate, talcum powder, zinc oxide, barium sulfate, dodecyl methacrylate, sodium dodecyl sulfonate, acrylic acid and aluminum triphosphate; stirring the raw materials and grinding, wherein the appearance of a costing film is uniform and bright; carrying out surface drying for 30min to 50min and carrying out complete drying for 18h to 22h, wherein the viscosity is 30s to 50s, the flexibility is 0.4mm to 0.8mm and the adhesive force is grade 1 to grade 2; immersing into water at 30 DEG C to 40 DEG C for 7d to 11d, wherein the coating film has no bubbles and is not released and the impact resistance is 60cm to 100cm, the coating is used for protecting the surface of metal steel, the solid content is 50 percent to 55 percent and the hardness is 0.4 to 0.6. The waterborne over-rust corrosion protective coating can be widely produced and can continuously replace existing materials.

Owner:WUXI EPIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com